A downhole-started self-locking casing centralizer

a centralizer and self-locking technology, applied in the field of centralizers, can solve the problems of large running force during use, affecting cementing quality, wide edges and narrow edges, etc., and achieves the effects of large supporting force, high reliability and practicality, and effective reducing pressure per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The invention is described in detail in combination with the following drawings and preferred embodiments for clear understanding.

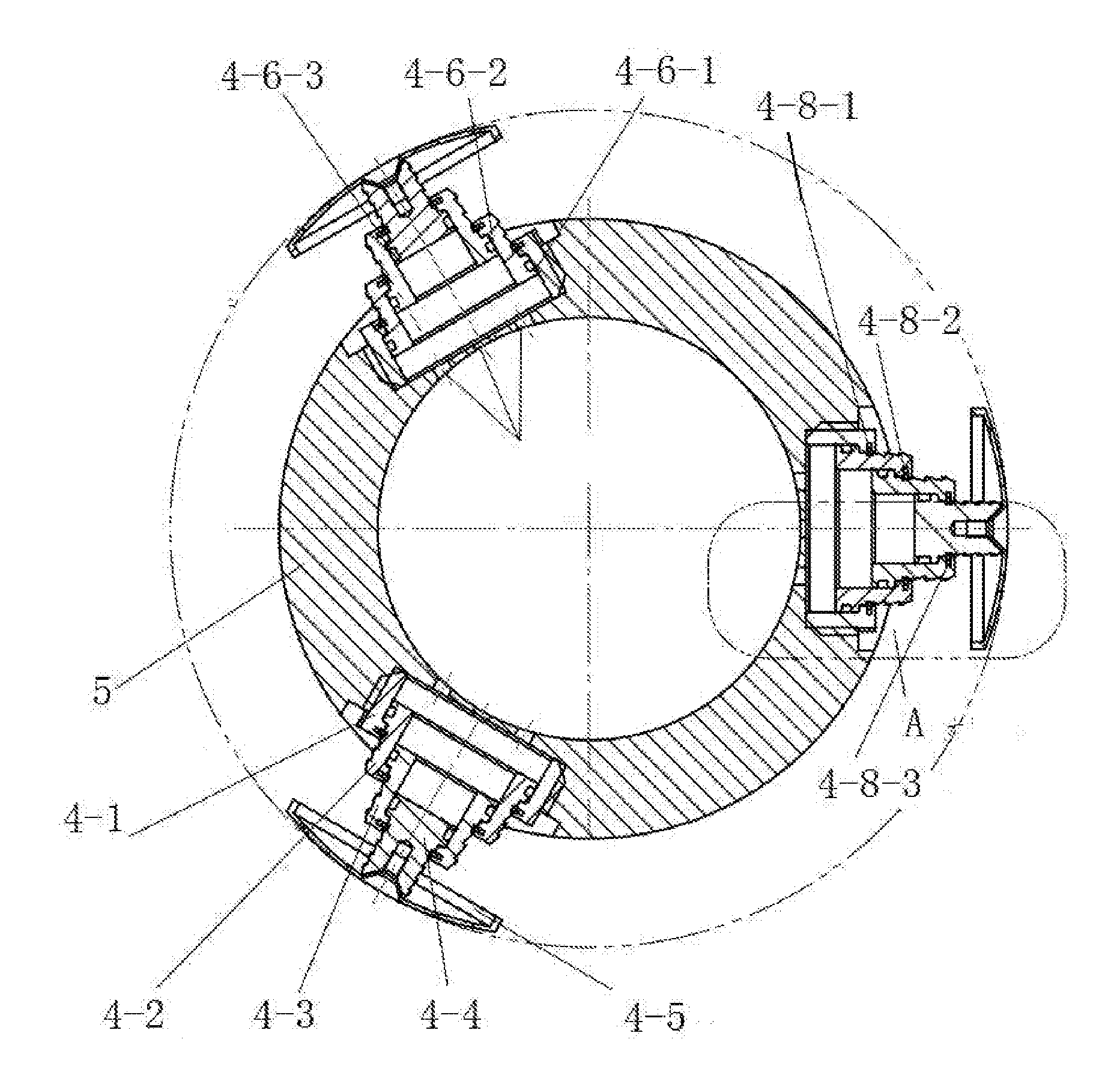

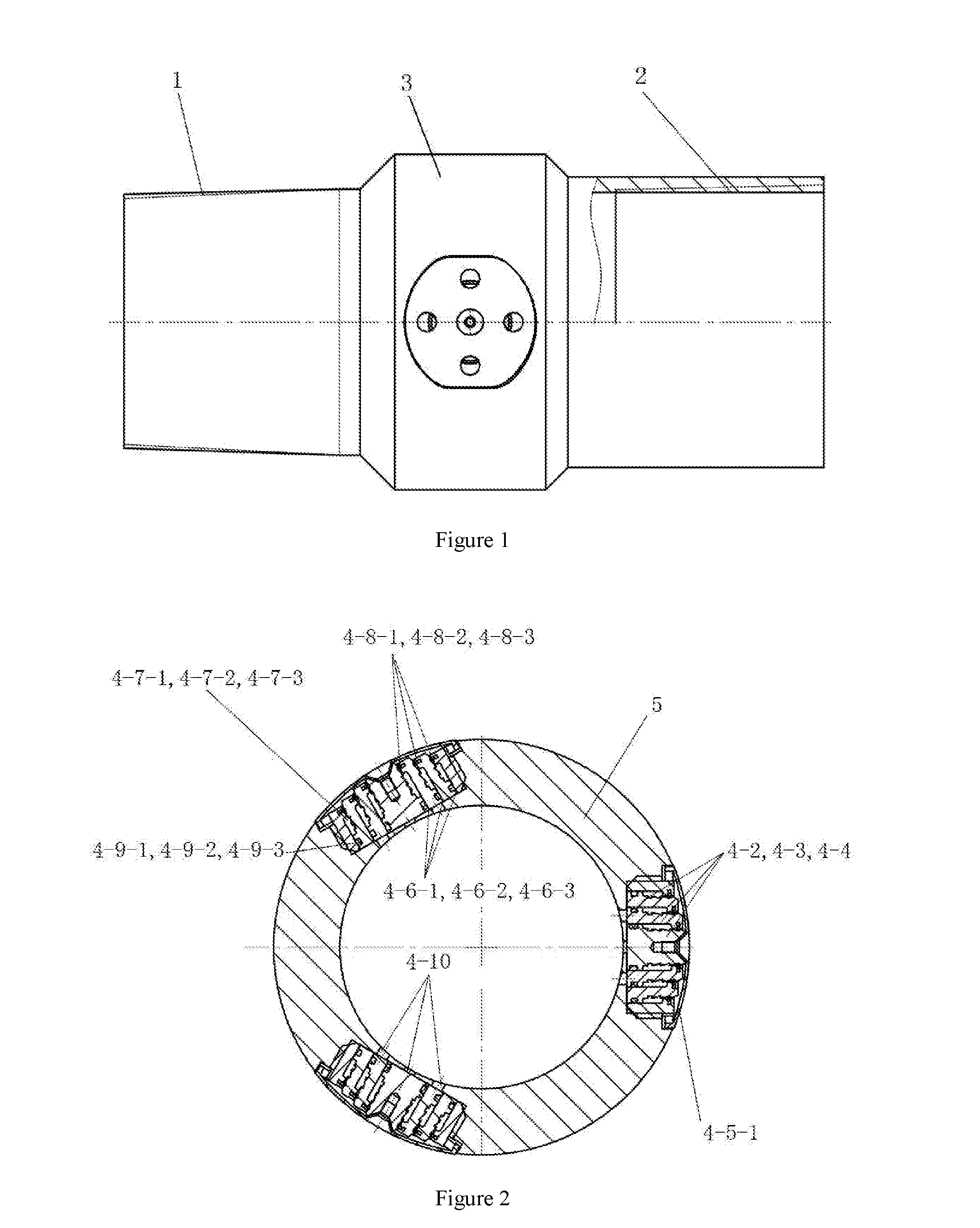

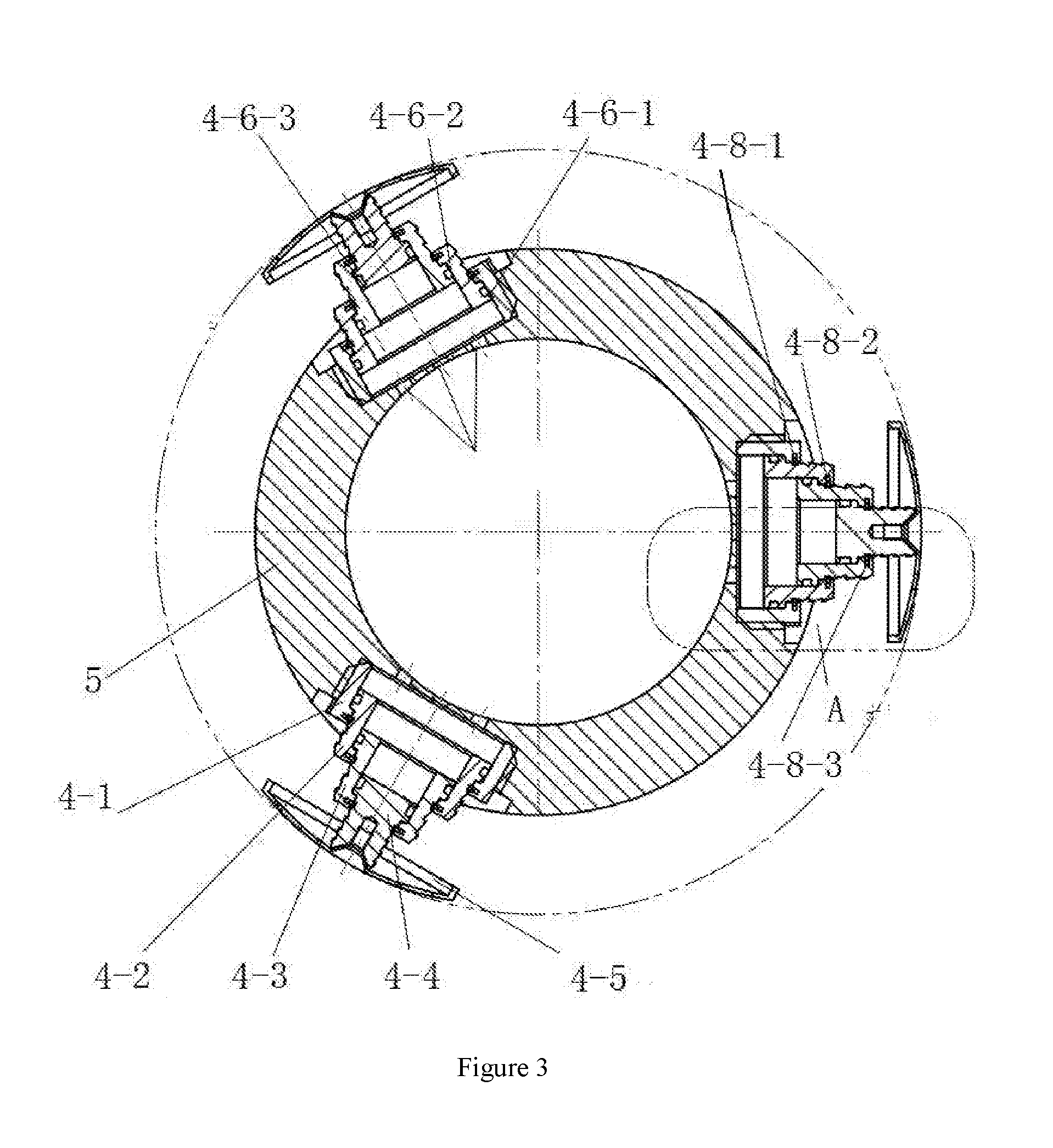

[0031]As shown in FIG. 1, a downhole-started self-locking casing centralizer provided by the invention comprises a connecting part (1) and a connecting part (2) on both ends, a central supporting part (3) is arranged between the connecting part (1) and the connecting part (2), the connecting part (1) and the connecting part (2) are of casing-connected thread structures, the connecting part (1) uses LTC PIN thread, and the connecting part (2) uses LTC BOX thread.

[0032]The downhole-started self-locking casing centralizer of the invention is in threaded connection with a casing, replacing couplings and exerting connection function, thus avoiding the problem that an elastic centralizer cannot control the downhole location as the elastic centralizer is sheathed outside a pipe string, and also avoiding the problem of difficulty in casing running as a rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com