Compound bow

a bow and compound technology, applied in bows/crossbows, white arms/cold weapons, weapons, etc., can solve the problems of insufficient strength of bows and drop of arrow accuracy, and achieve the effect of minimizing twisting of bows, inherent strength of bows, and enhancing accuracy of arrows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0040]Hereinbelow, a compound bow according to the present invention will be described in more detail with reference to the accompanying drawings.

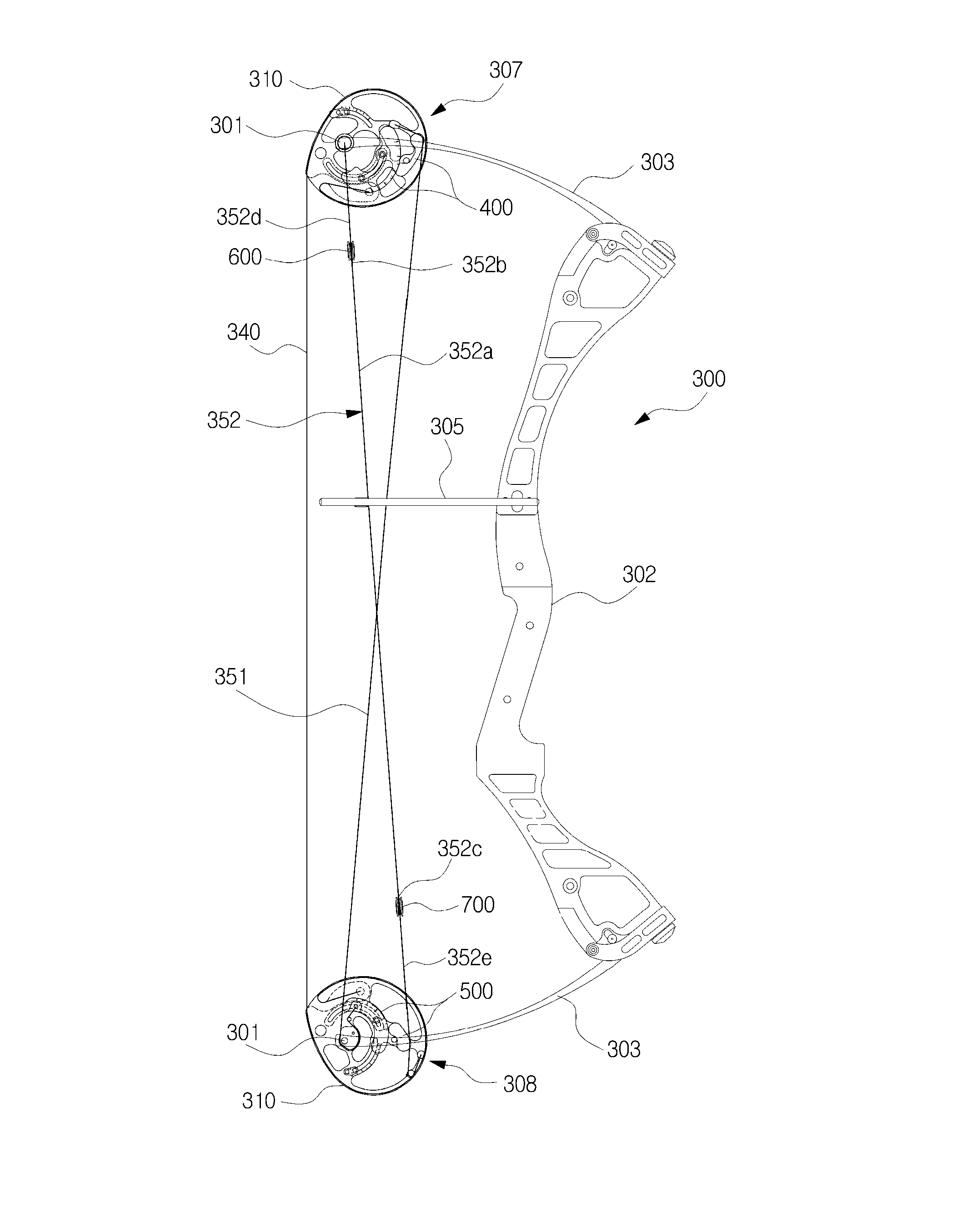

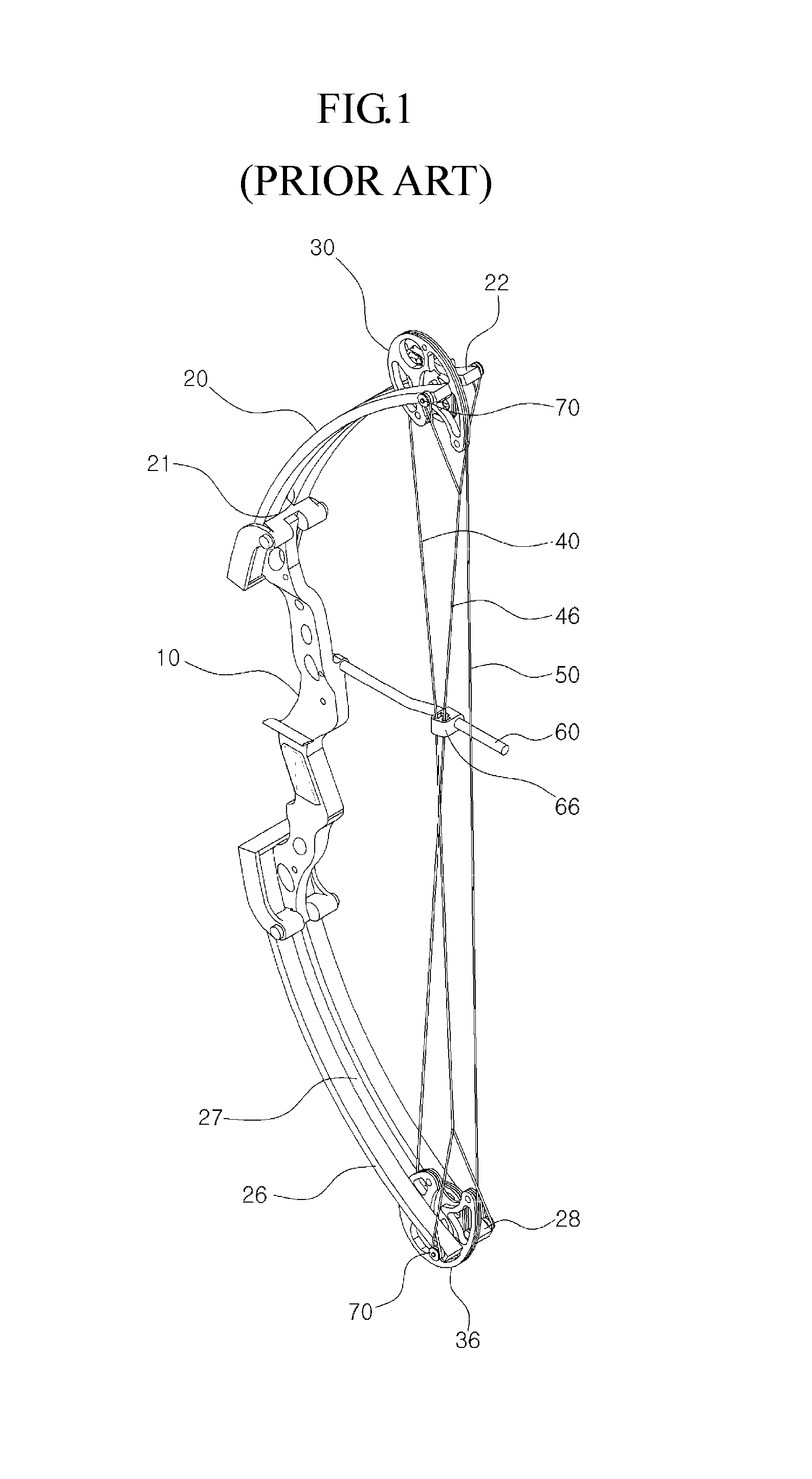

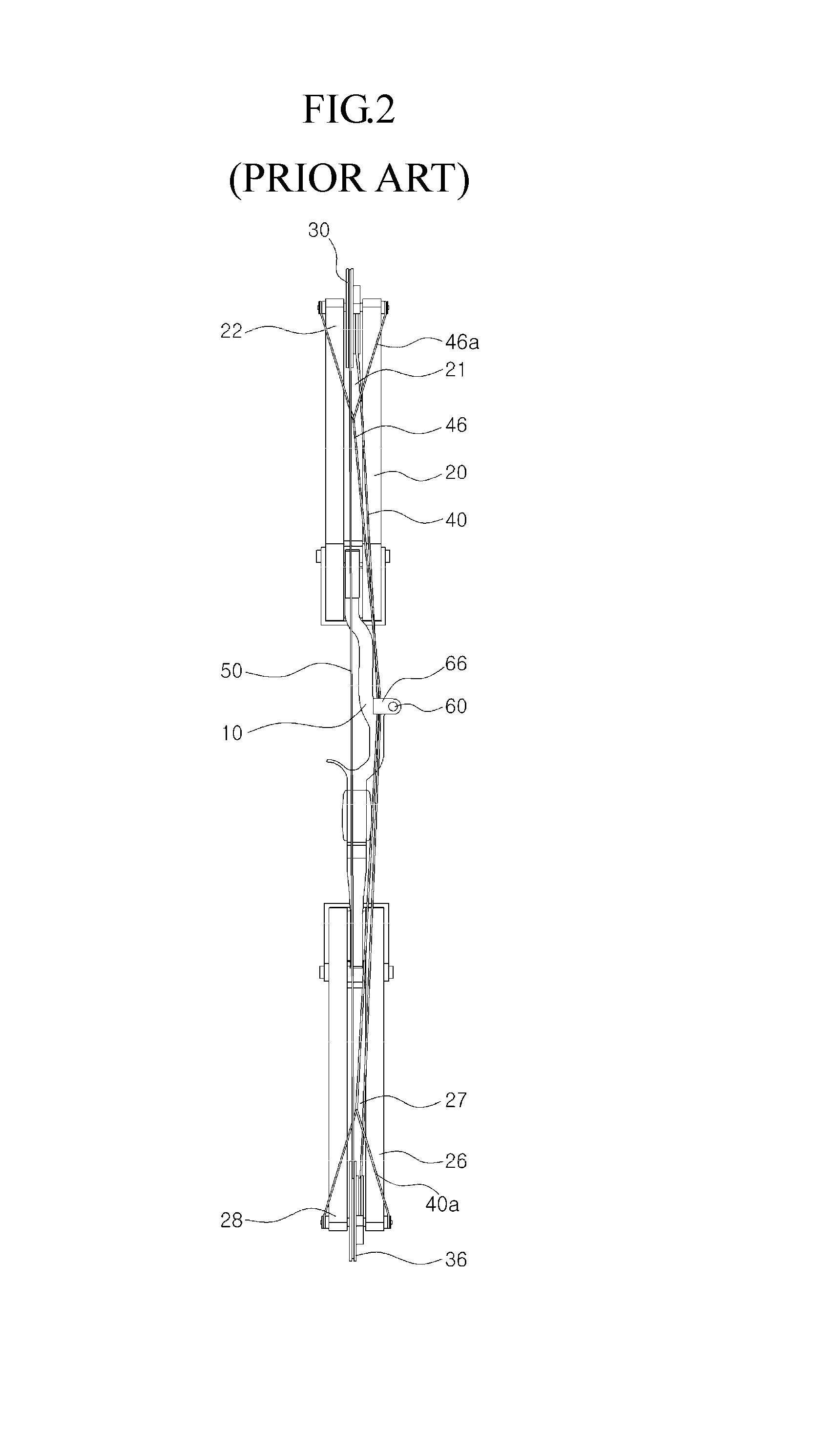

[0041]Referring to FIGS. 4 to 12, a compound bow according to a first embodiment of the present invention comprises: a bow main body 300 including a pair of limbs 303 that are respectively coupled to both ends of a handle 302; upper and lower pulley assemblies 307 and 308 that are respectively coupled to the rear end of each limb 303; a bowstring 340; first and second cam cables 352 and 351 that are wound around a cam 400, 500 of each of the upper and lower pulley assemblies 307 and 308 as the bowstring 340 is pulled.

[0042]As shown, the compound bow according to the present invention will be described below in more detail. First, the bow main body 300 includes a handle 302 at a central portion of which a grip portion is formed so as to be gripped by a user, and a pair of limbs 303 that are respectively coupled to both ends of the handle 30...

second embodiment

[0077]In addition, when the first and second cam cables 353 and 354 in the second embodiment will be described, as shown in FIG. 13, the first cam cable 353 includes a first cable 353b, and a second cable 353a that is connected to the first cable 353b by a spacing member (a ring 700 in some embodiments of this invention), and the second cam cable 354 includes a first cable 354b, and a second cable 354a that is connected to the first cable 354b by a spacing member (a ring 700 in some embodiments of this invention). The first and second cam cables 353 and 354 have a vertically symmetric image.

[0078]Therefore, the first cam cable 353 will be described as an example. The second cable 353a in the first cam cable 353 is extended to the upper pulley assembly 308 and is wound around the cam cable winding portion 320 through which the rotating shaft 301 is penetrated in the upper pulley 310, and then the upper end of the second cable 353a is fixed to the fixing projection 530 formed in the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com