Detergent supply box of drum washing machine

a technology for detergent supply containers and drum washing machines, which is applied in the field of detergent supply containers for drum washing machines, can solve the problems of easy deterioration of the airtight or waterproof connection parts between the detergent supply containers and the washer body, inconvenient use, trouble or malfunction of electrical devices, etc., and achieves the effect of evenly and quickly washed out, easy detection of liquid detergent exhaustion, and convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

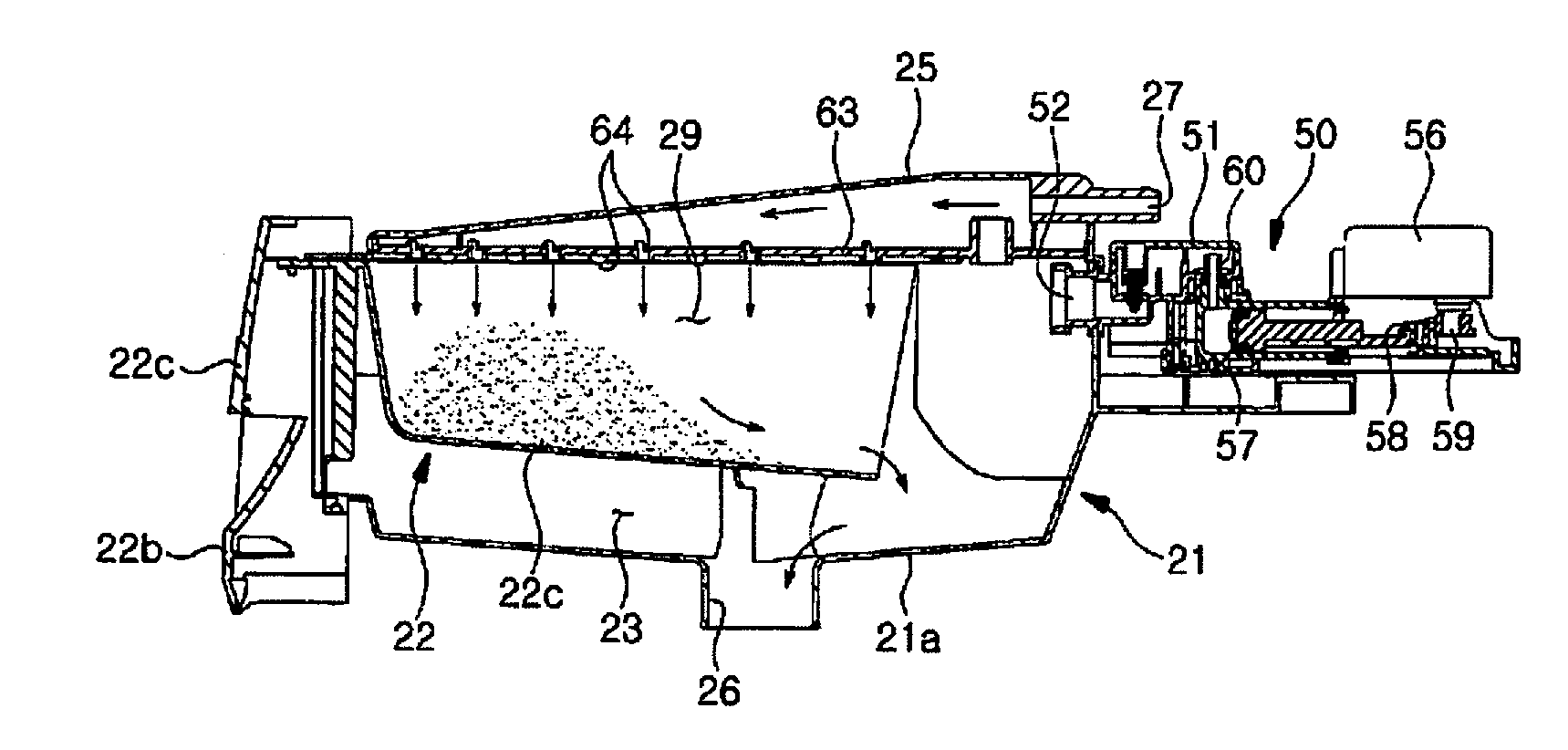

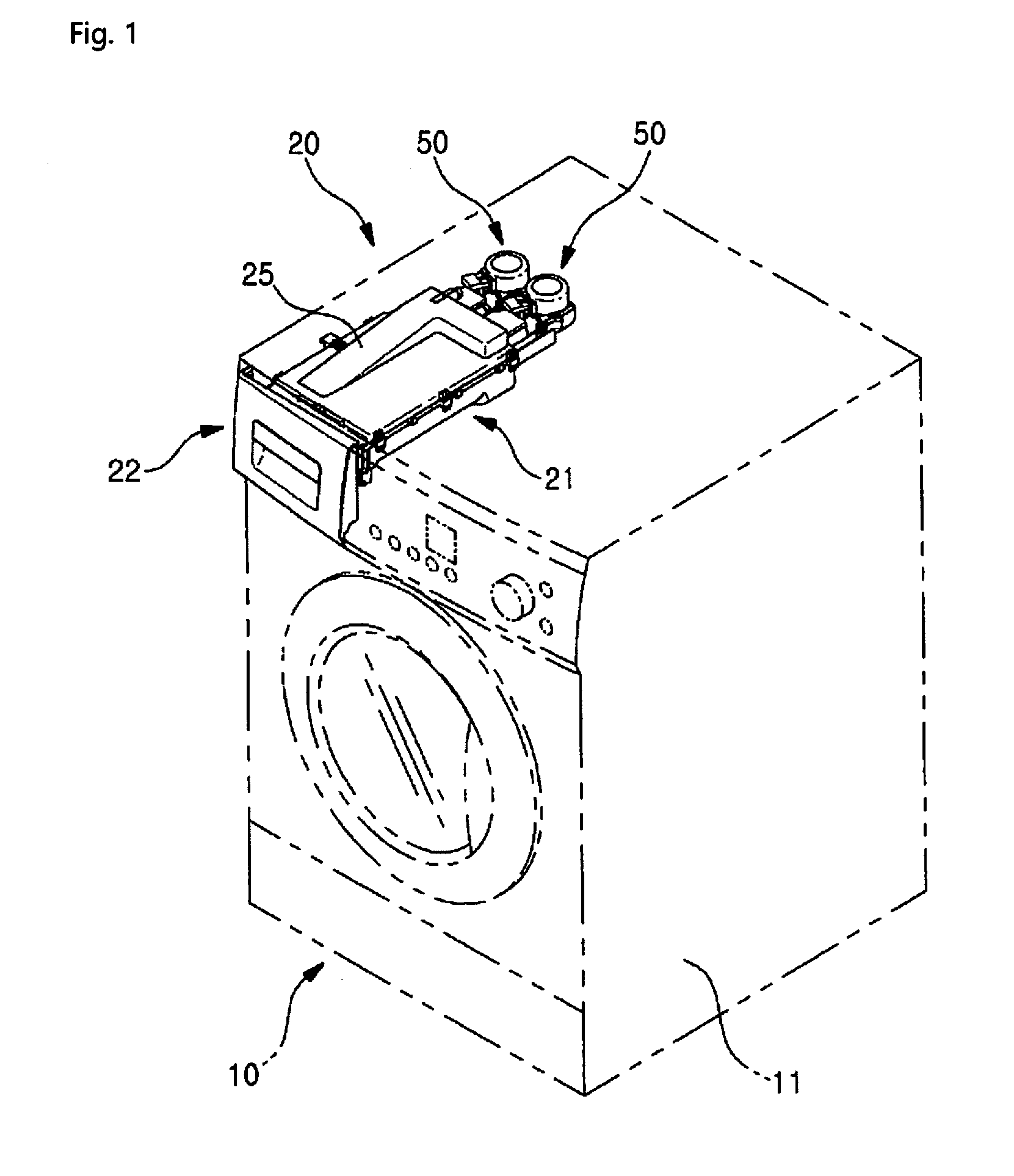

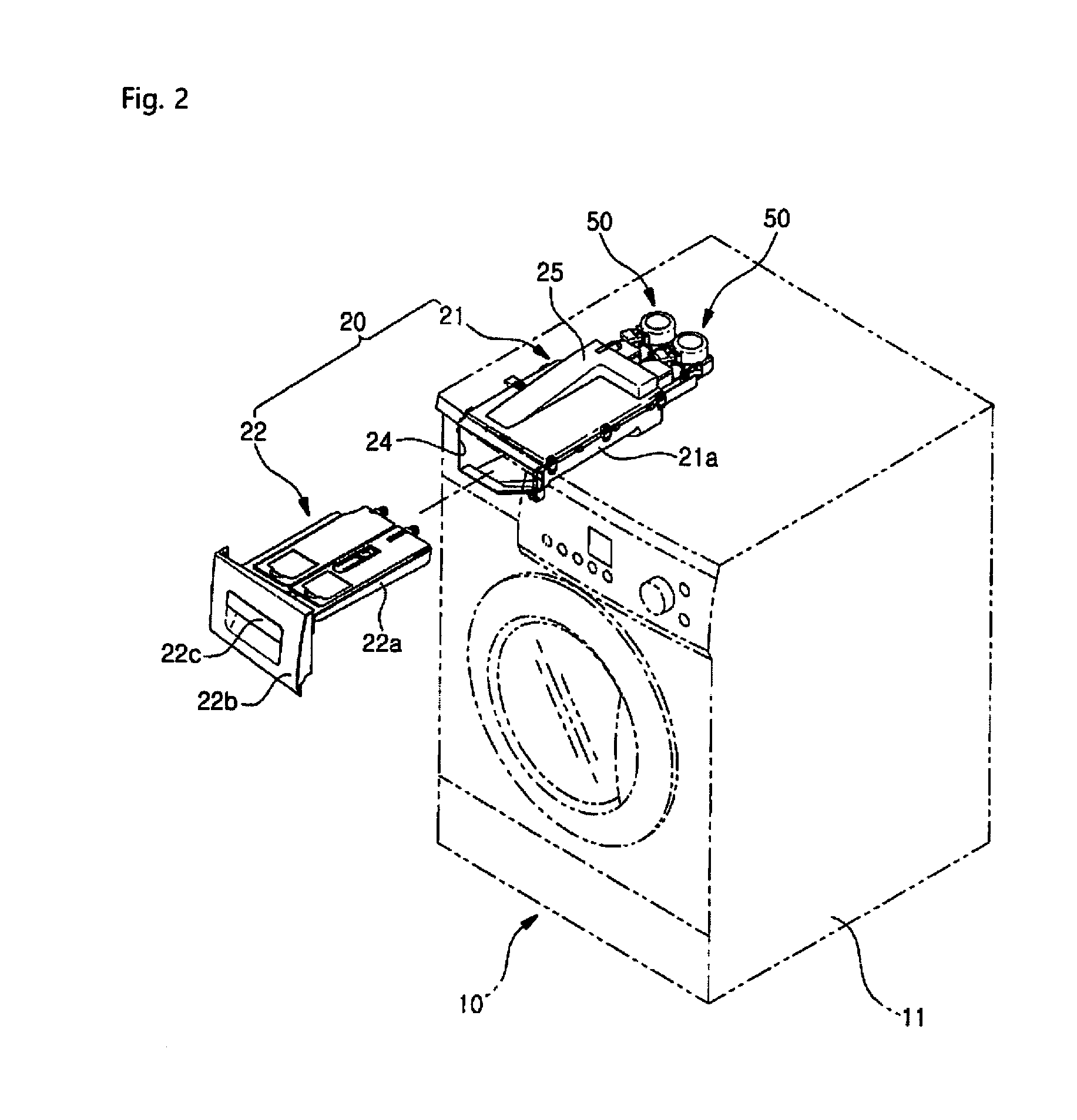

[0032]Hereinafter, the preferred embodiments of the invention will be described with reference to the drawings. FIG. 1 to FIG. 11 show various embodiments of the invention. As shown in FIG. 1 and FIG. 2, the invention is a detergent supply container 20 drawably provided on the upper and front part of a washer body 11 of a drum washer 10, which comprises a stationary body 21 fixed on the washer body 11 and a drawable body 22 drawably inserted in the stationary body 21. The stationary body 21 is in the shape of case having an accommodation space 23 and an inserting opening 24 on the front side of it, from which the drawable body 22 is drawn. A body cap 25 is engaged on the upper part of the stationary body 21 to cover the accommodation space 23. A pumping means 50 is provided on the outside of the rear part of the stationary body 21 to pump a liquid detergent filled in the drawable body 22.

[0033]The pumping means 50 is electrically connected to the controller provided on the washer bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com