Aircraft landing gear

a technology for landing gear and aircraft, applied in the direction of landing gear, undercarriage, transportation and packaging, etc., can solve the problems of large integration, price, weight, etc., and achieve the effect of reducing the effects of cavitation and excess pressure, low wear, and reliable and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

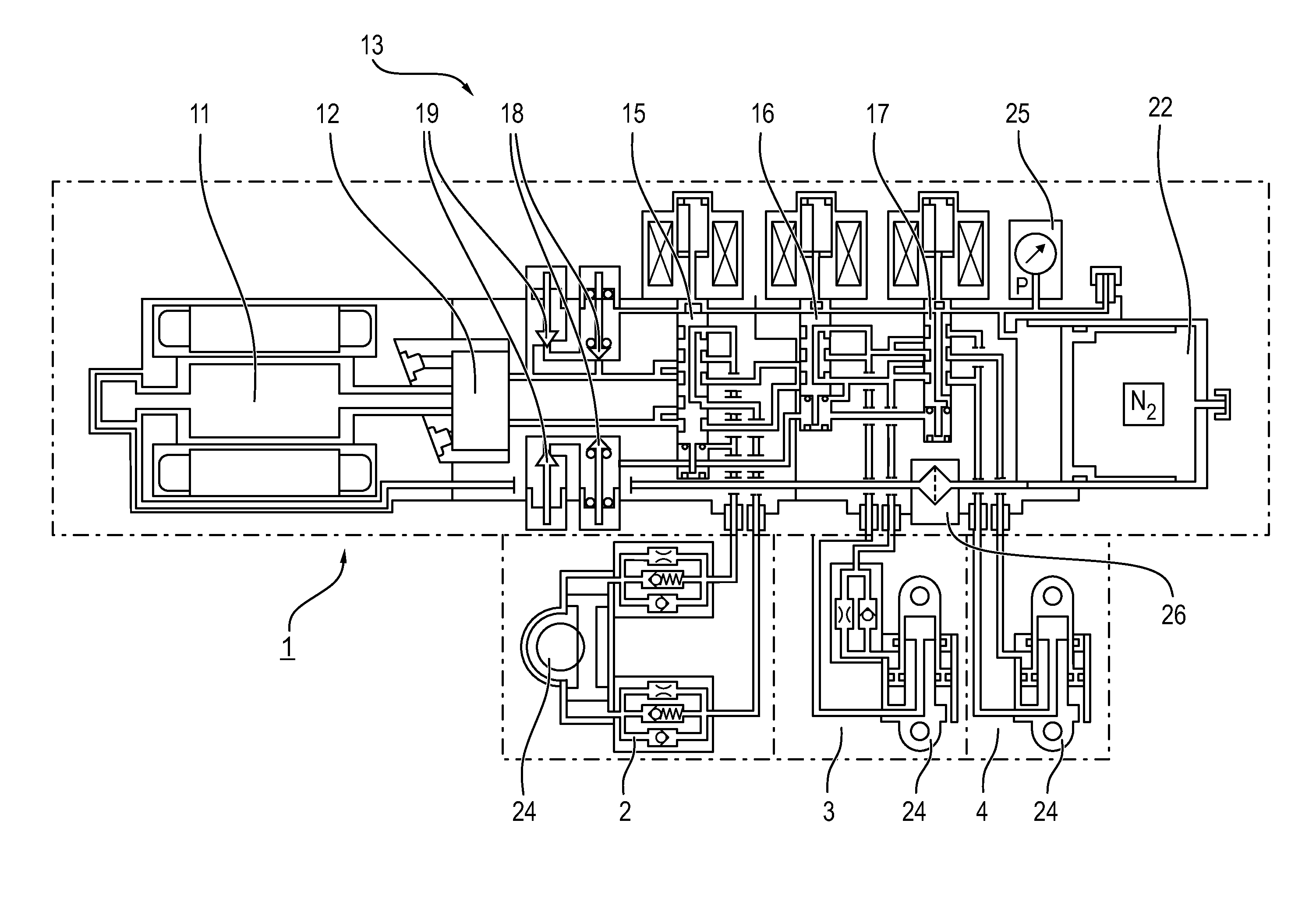

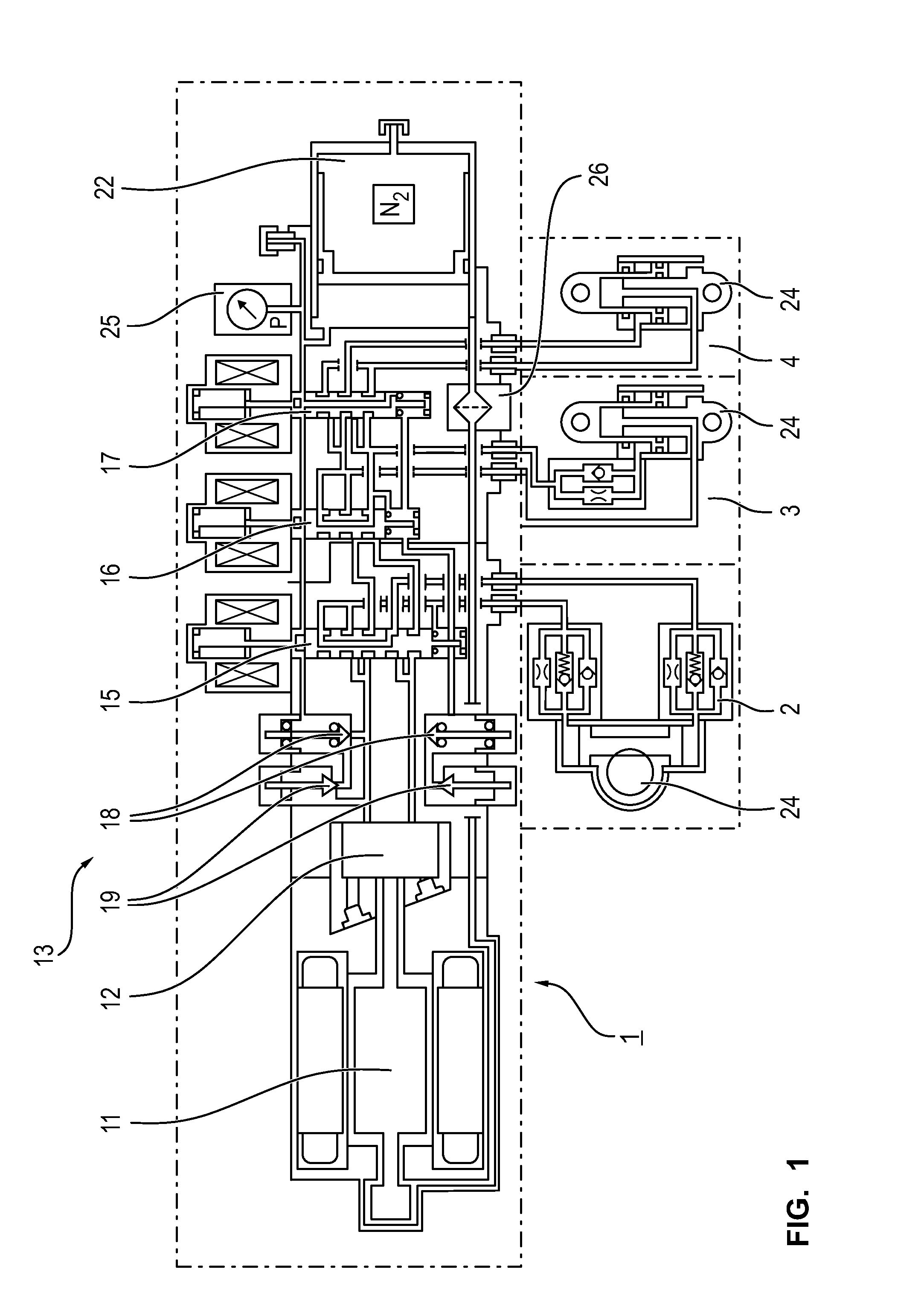

[0035]FIG. 1 shows a schematic representation of the electrohydraulic drive and control unit (EHDC unit) 1, with means provided on it for controlling different adjusting devices. In the embodiment depicted, the adjusting devices involve a landing gear control 2 with a corresponding hydraulic actuator or control motor, as the case may be, a landing gear retraction device and / or a landing gear extension device 3 with corresponding actuator, as well as a landing gear locking device 4 for locking or unlocking the landing gear, as the case may be.

[0036]The EHDC unit 1 comprises an electric motor 11, which can be designed as a regulated, brushless DC motor. A hydraulic pump 12, which can be designed as a fixed-delivery pump or an axial piston pump, as the case may be, is connected with the electric motor 11.

[0037]The operation of the hydraulic pump and, consequently, the function of the actuator or the actuators as well, is controlled or regulated by means of the rotational speed and / or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com