Heat exchanger

a technology of heat exchanger and heat exchanger body, which is applied in the direction of indirect heat exchanger, heat exchange apparatus safety devices, lighting and heating equipment, etc., can solve the problem of excessive noise called tube singing, and achieve the effect of simple mounting work, reduced weight and reduced nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Embodiments of the present invention will now be described in detail with reference to the accompanying drawings. It should be noted that, unless otherwise particularly specified, the sizes, materials, shapes, and relative arrangement or the like of constituent components described in these embodiments are not intended to limit the scope of this invention.

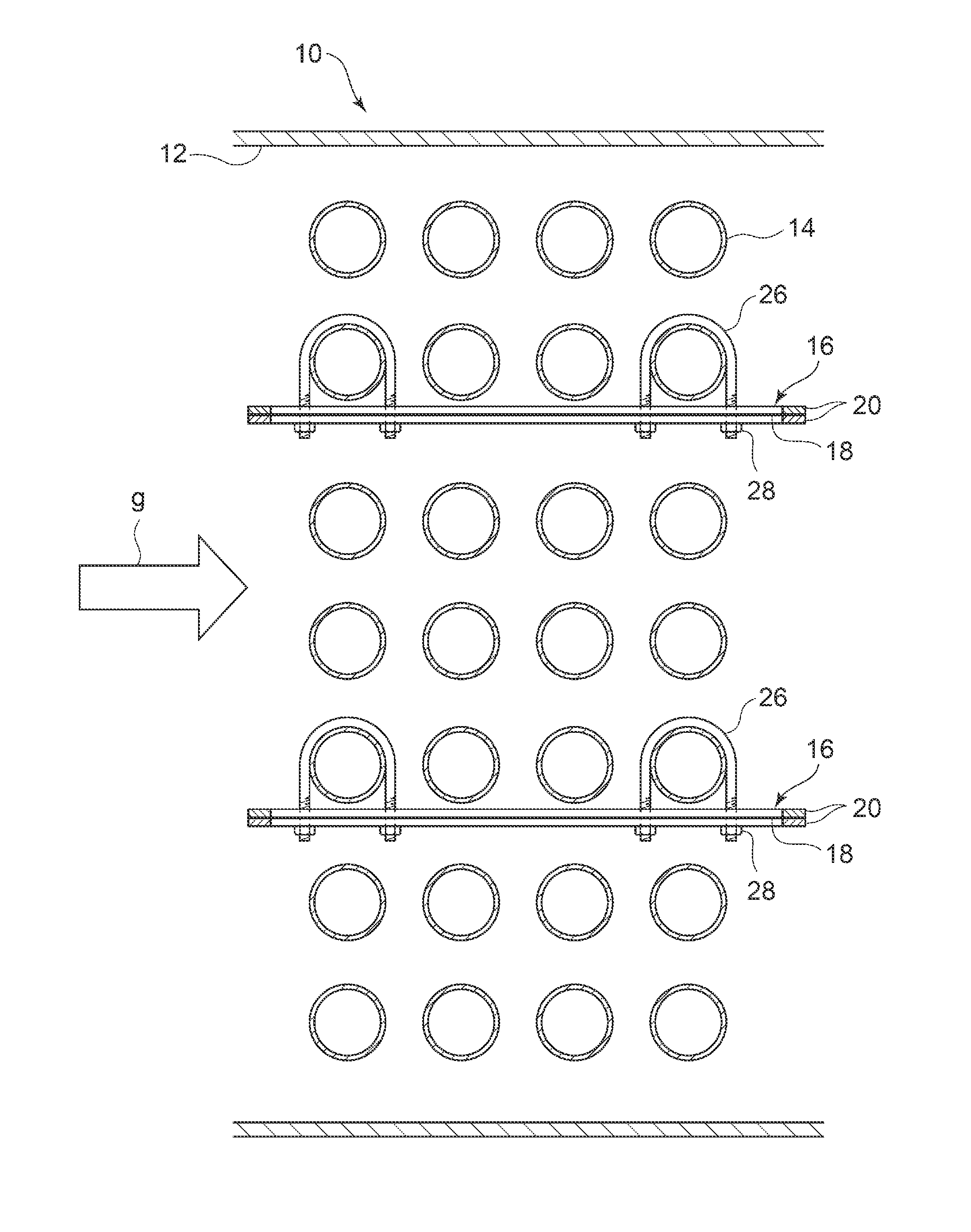

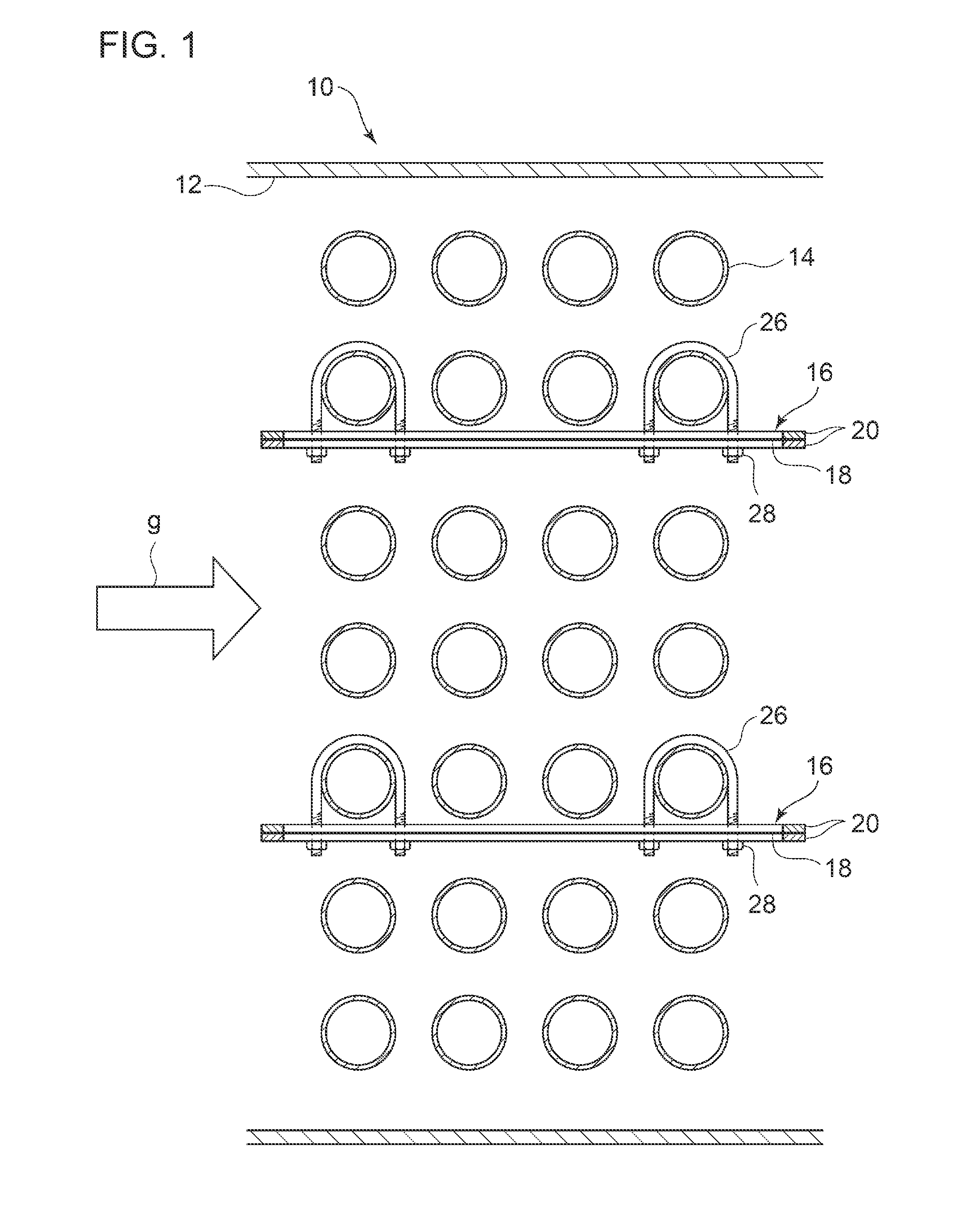

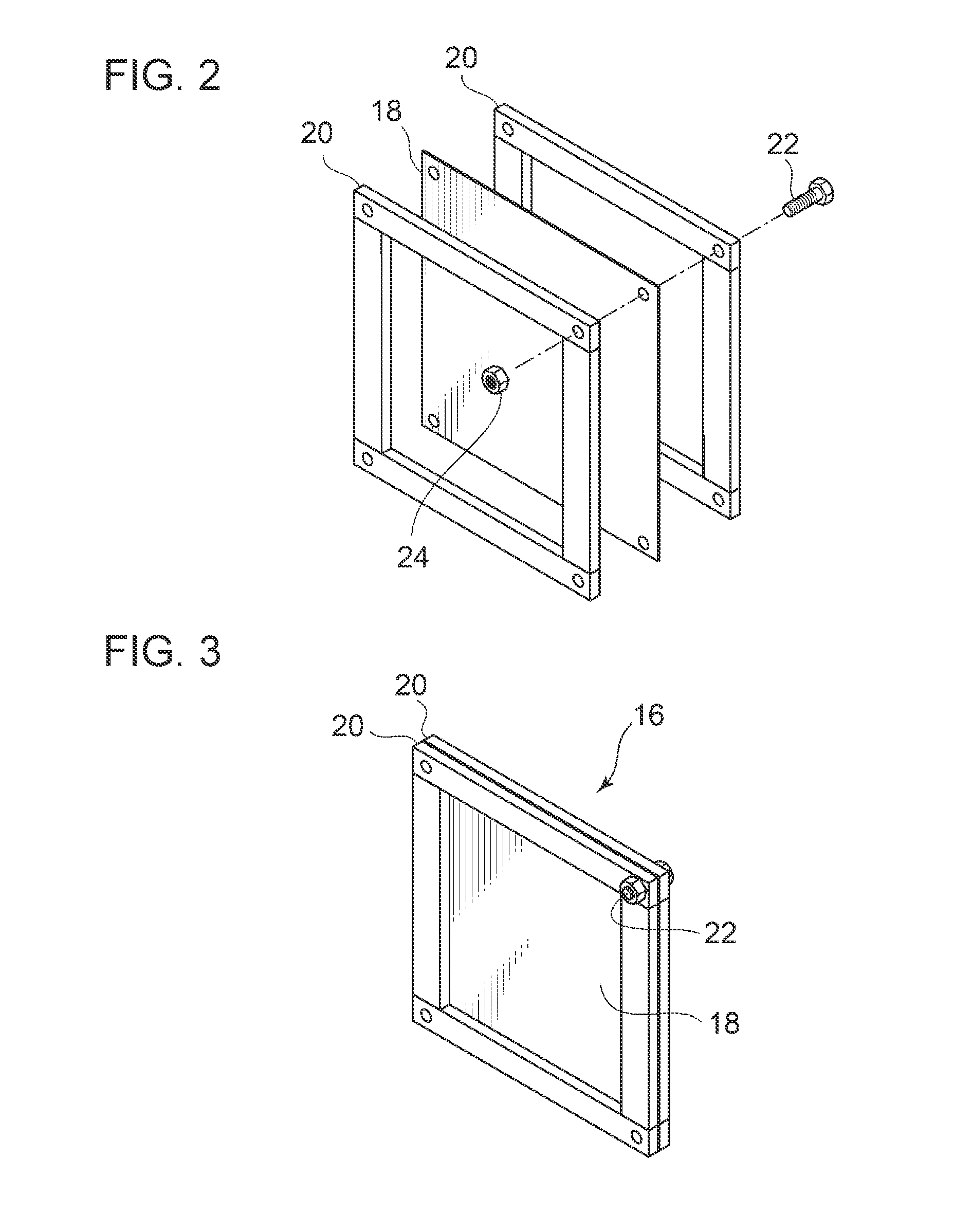

[0034]A heat exchanger according to the first embodiment of the present invention will be described with reference to FIGS. 1 and 3. The present embodiment is an example in which a heat exchanger 10 according to the first embodiment of the present invention is applied to a heat exchanger such as a super-heater, a re-heater, and an economizer, or to a waste-heat recovery boiler, for instance, disposed on a steam boiler incorporated into a thermal power generation plant.

[0035]In FIG. 1, a flow passage of combustion gas g is formed by a duct housing constituting the heat exchanger 10 of the present embodiment. A plurality of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com