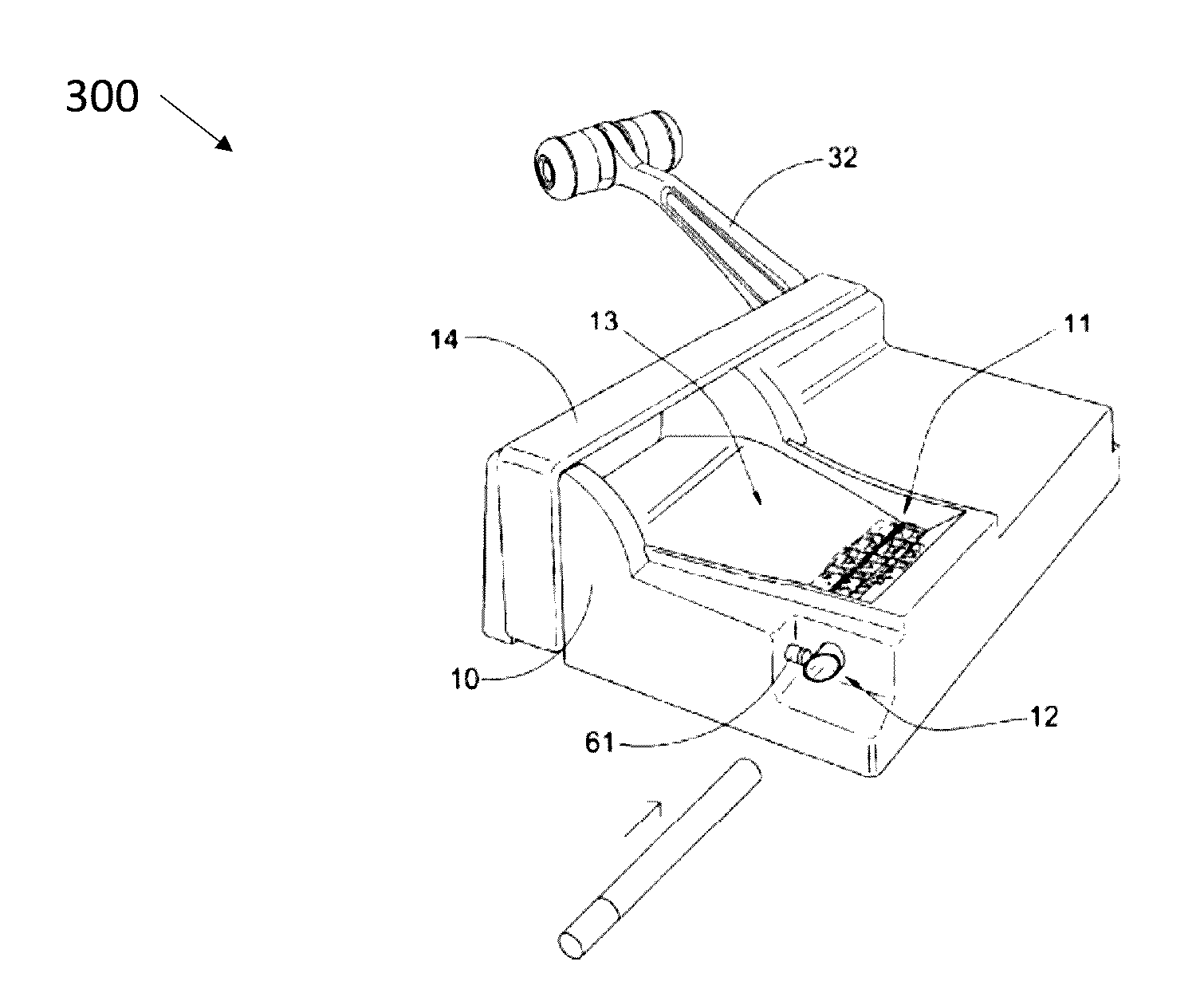

Apparatus, systems and methods for rotational drive modules for use with cigarette tobacco filling devices

a technology of cigarette tobacco and drive modules, which is applied in the field of driving modules for use with cigarette tobacco filling devices, can solve the problems of difficult to stuff tobacco leaves with uniform and proper compactness, difficult to smoke cigarettes, and unwanted movement of the device during operation, so as to prevent any unwanted movement of the device, effectively actuate the enclosing window and the plunger, and effectively transmit the effect of rotatable for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Before the present subject matter is described in detail, it is to be understood that this disclosure is not limited to the particular embodiments described, as such may vary. It is also to be understood that the terminology used herein is for the purpose of describing particular embodiments only, and is not intended to be limiting, since the scope of the present disclosure will be limited only by the appended claims.

[0044]A conventional cigarette machine generally comprises an injection device received in a casing and a manually actuation device for actuating the injection device. The injection device comprises a plunger being actuated by the actuation device for filling a predetermined amount of tobacco into an empty cigarette tube.

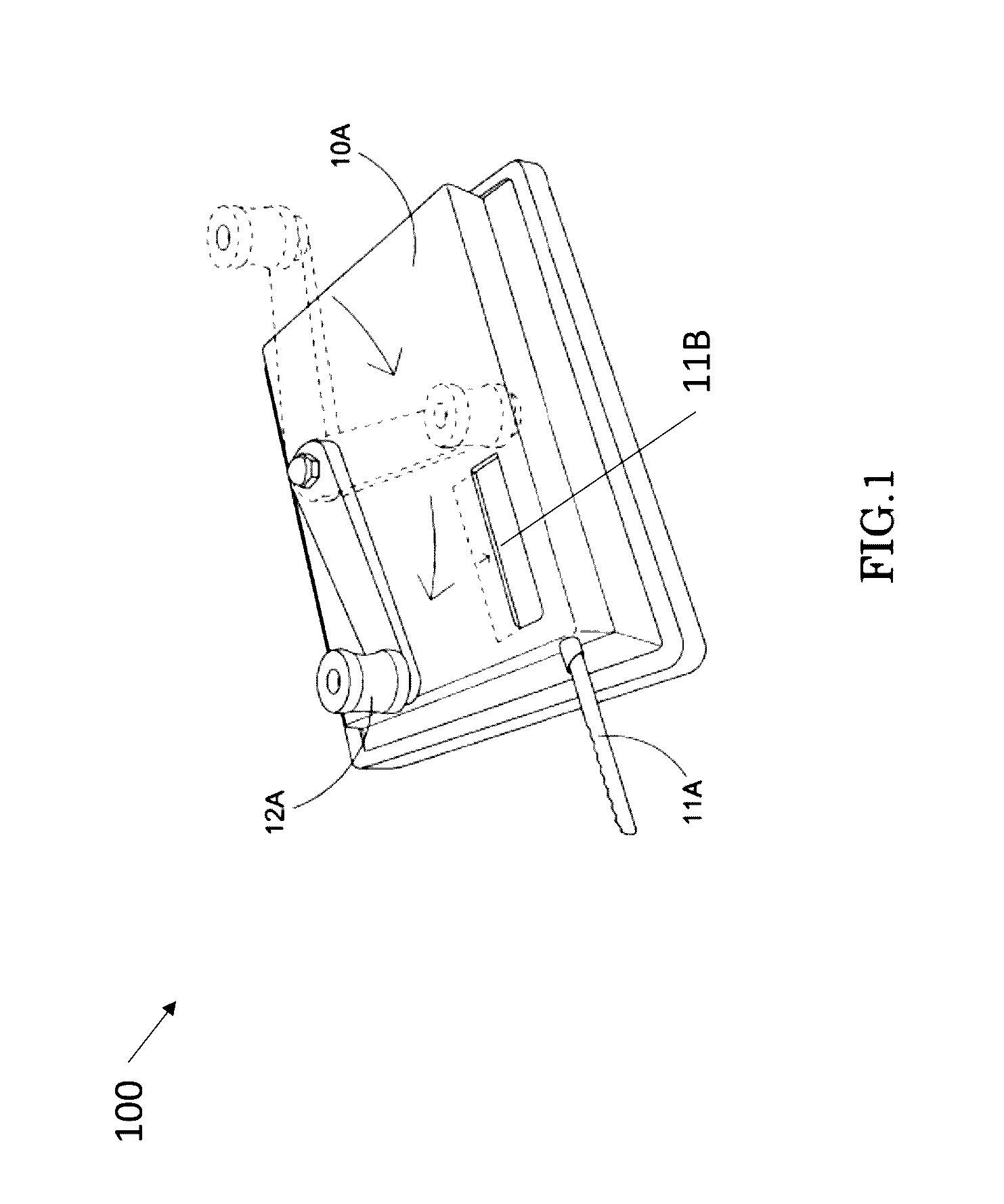

[0045]FIG. 1 is an example embodiment of a perspective view of a conventional cigarette making machine 100, illustrating a rotatable handle 12A being rotated above the top side of a casing 10A, thereby extending a plunger 11A.

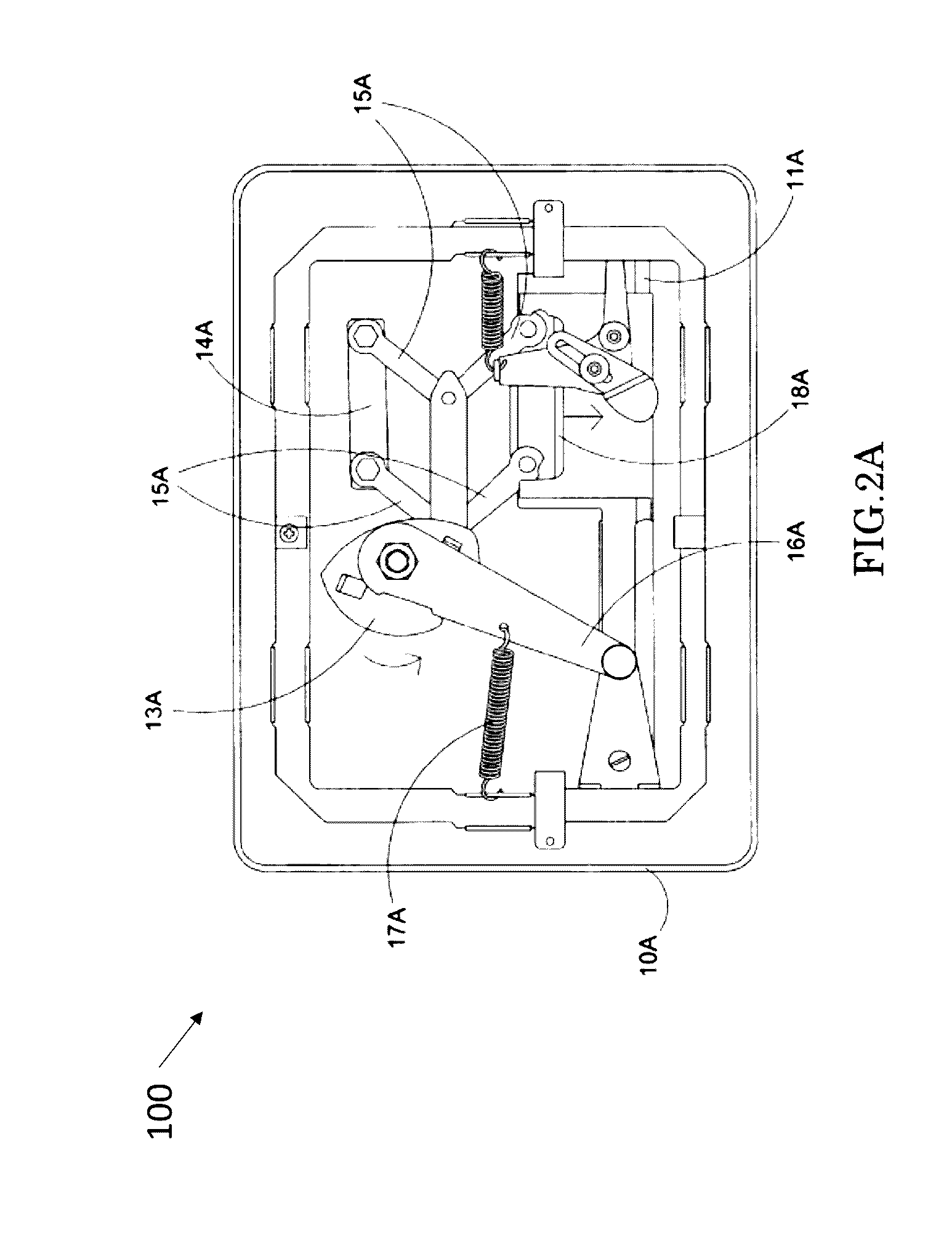

[0046]FIGS. 2A to 2C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com