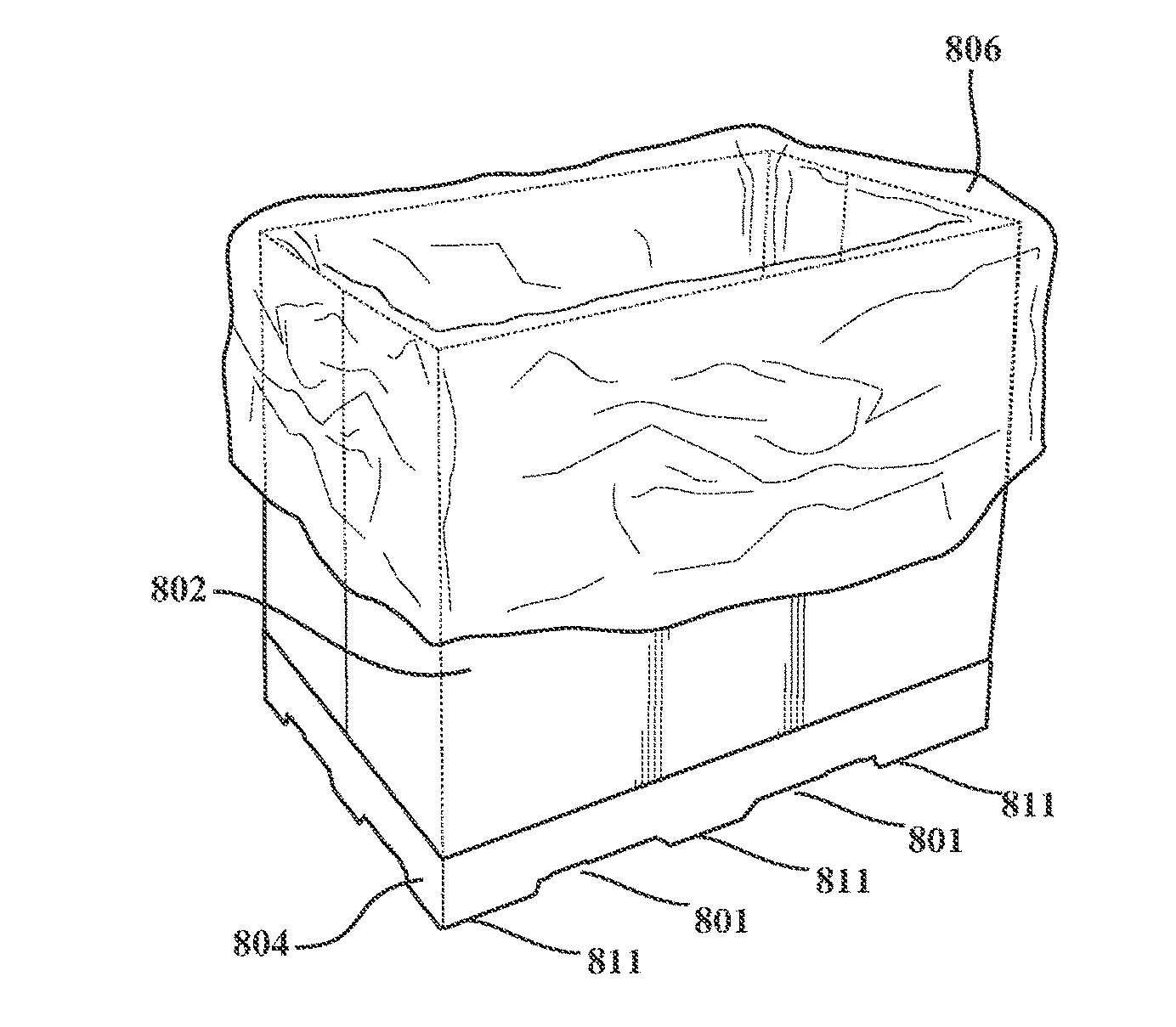

Bin for transporting waste or recyclable material

a technology for recycling bins and waste materials, applied in the field of computing and information technology systems, devices, etc., can solve the problems of difficult identification of the relative contribution made by each of the different stores, difficulty in tracking how individual stores are performing, individually or relative to one another, and in respect of recycling efficiency and goal compliance. achieve the effect of facilitating the determination or calculation of weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

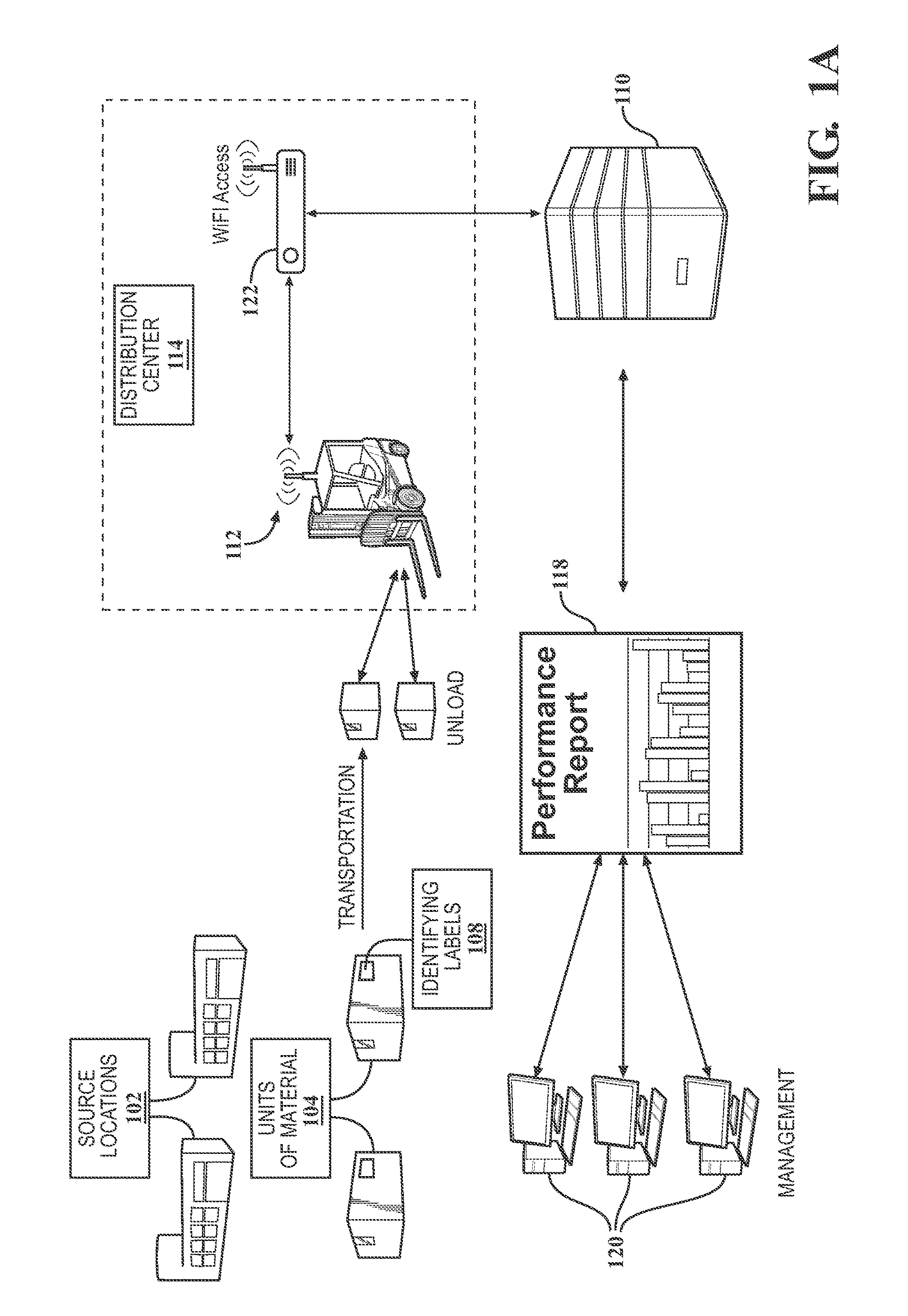

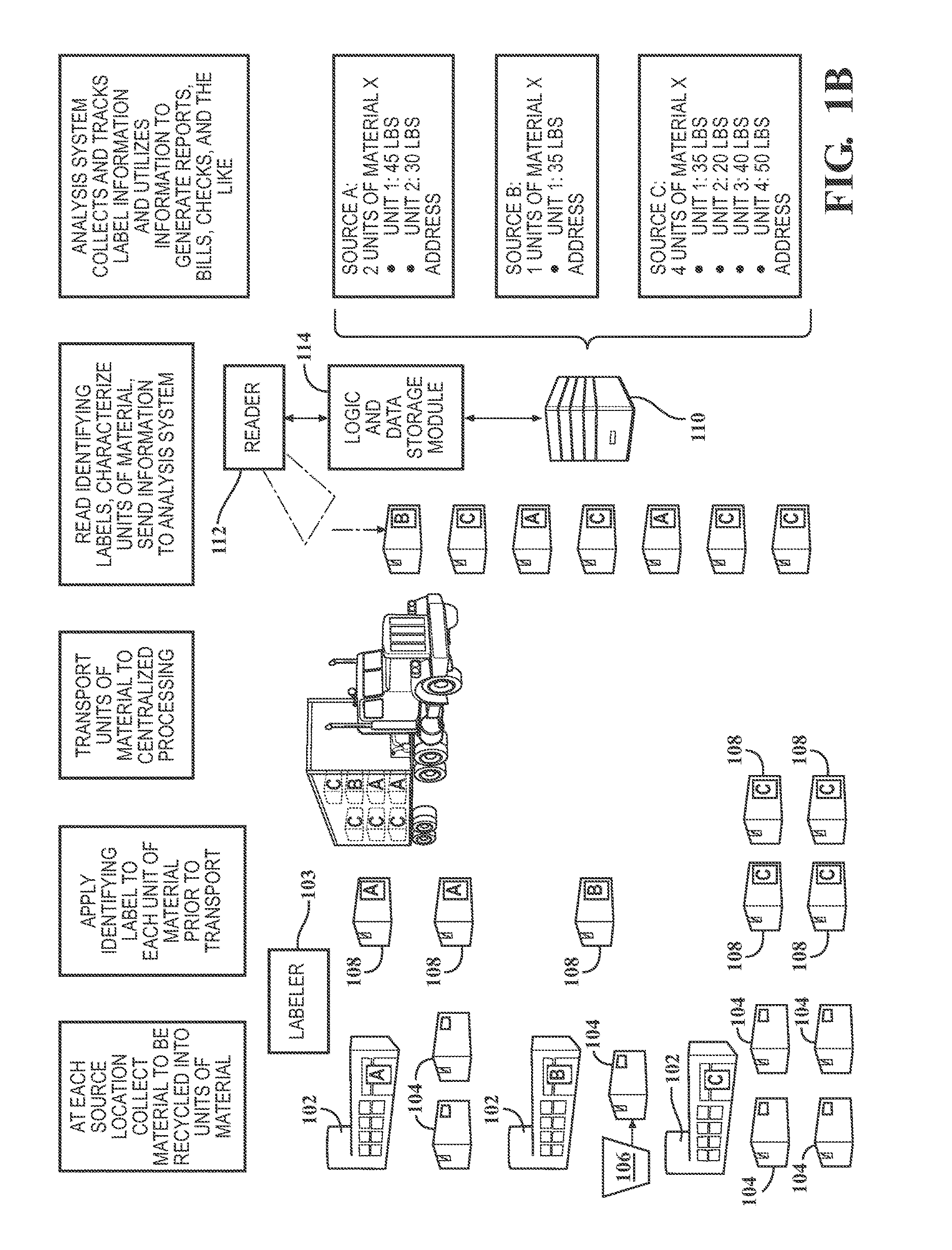

[0157]High-Level Description of Tracking System

[0158]Referring to FIGS. 1A and 1B, various components, methods and systems for managing and tracking materials from a plurality of source locations are described herein. At each source location 102, quantities of material 104 (also referred to herein as batches or units of material) may be uniquely identified with an identifying label 108, and then enter a transported material stream and be transported to a remote location 114 such as a material handling site, distribution center, recycling center, disposal location, recovery and processing center, and the like. In certain alternative embodiments, an identifying label may be associated with one or more batches of material 104 during transport or upon arrival at one or more remote locations 114. Batches or units of material 104 may be further trans-shipped between remote locations 114. At one or more locations, such as at the source location 102, during shipping, at one or more remote l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| liquid | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com