Clutch and motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

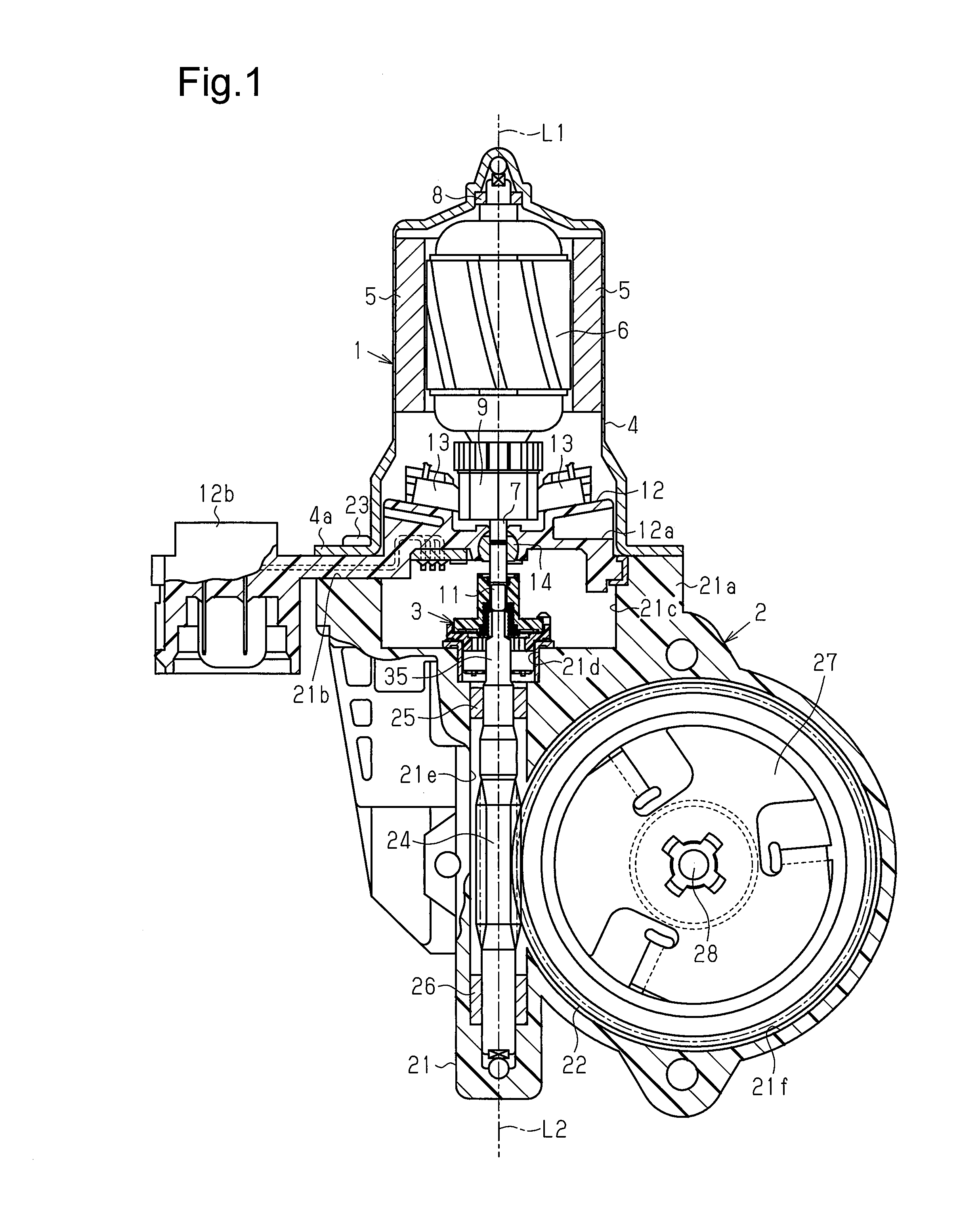

[0024]One embodiment of a motor will now be described.

[0025]As shown in FIG. 1, a motor includes a motor unit 1, an output unit 2, and a clutch 3 serving as a coupling portion. The motor of the present embodiment is fixed to a vehicle with the output unit 2 located closer to the ground than the motor unit 1.

[0026]Two magnets 5 are opposed to each other and fixed to an inner circumferential surface of a tubular yoke 4 of the motor unit 1, which has a closed end. An armature 6 is arranged at the inner sides of the magnets 5. The armature 6 includes a rotation shaft 7 located at a central portion of the yoke 4. The rotation shaft 7 includes a basal portion (upper end in FIG. 1), supported by a bearing 8 that is arranged at the center of the closed end of the yoke 4, and a distal portion, to which a tubular commutator 9 is fixed.

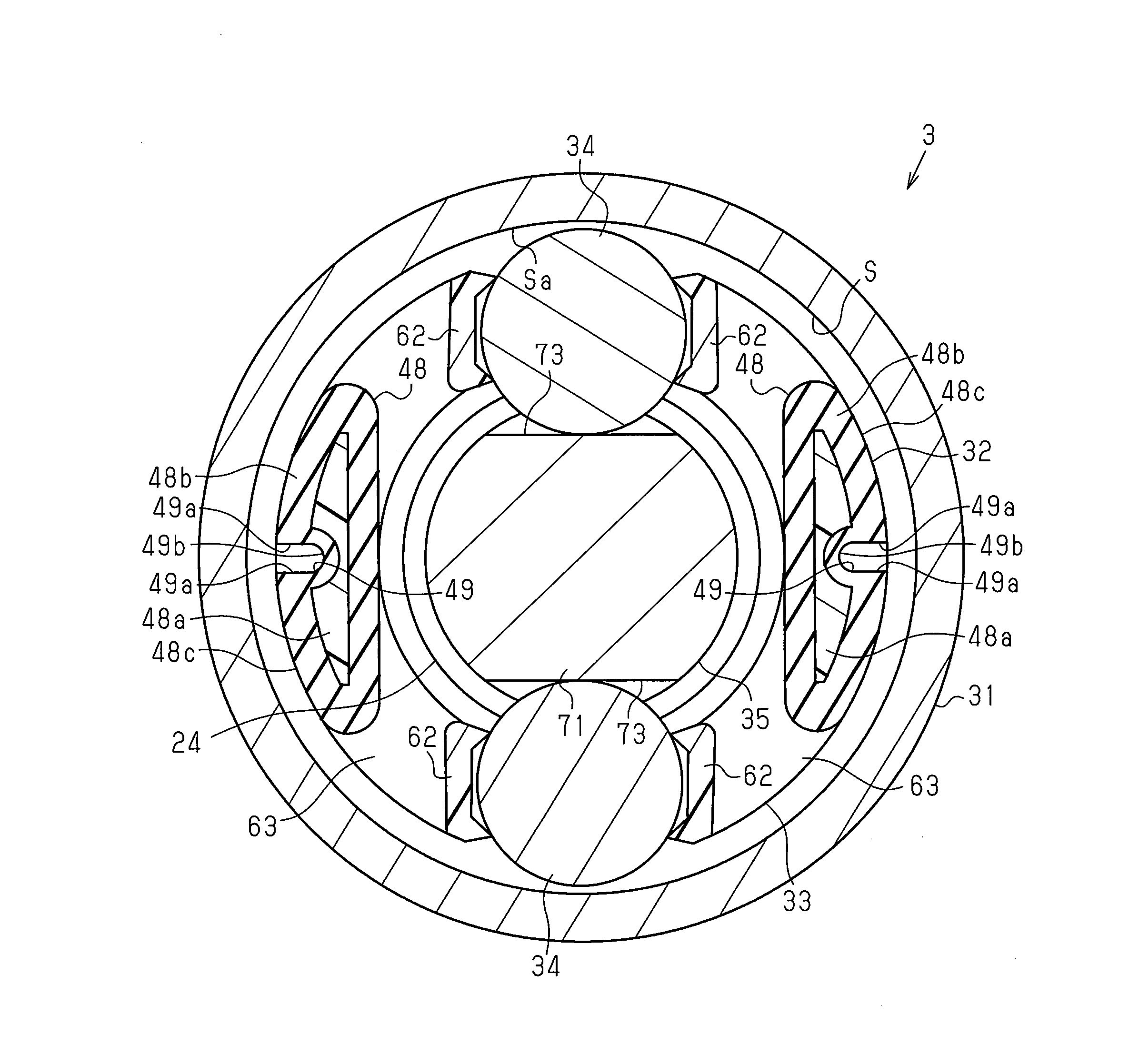

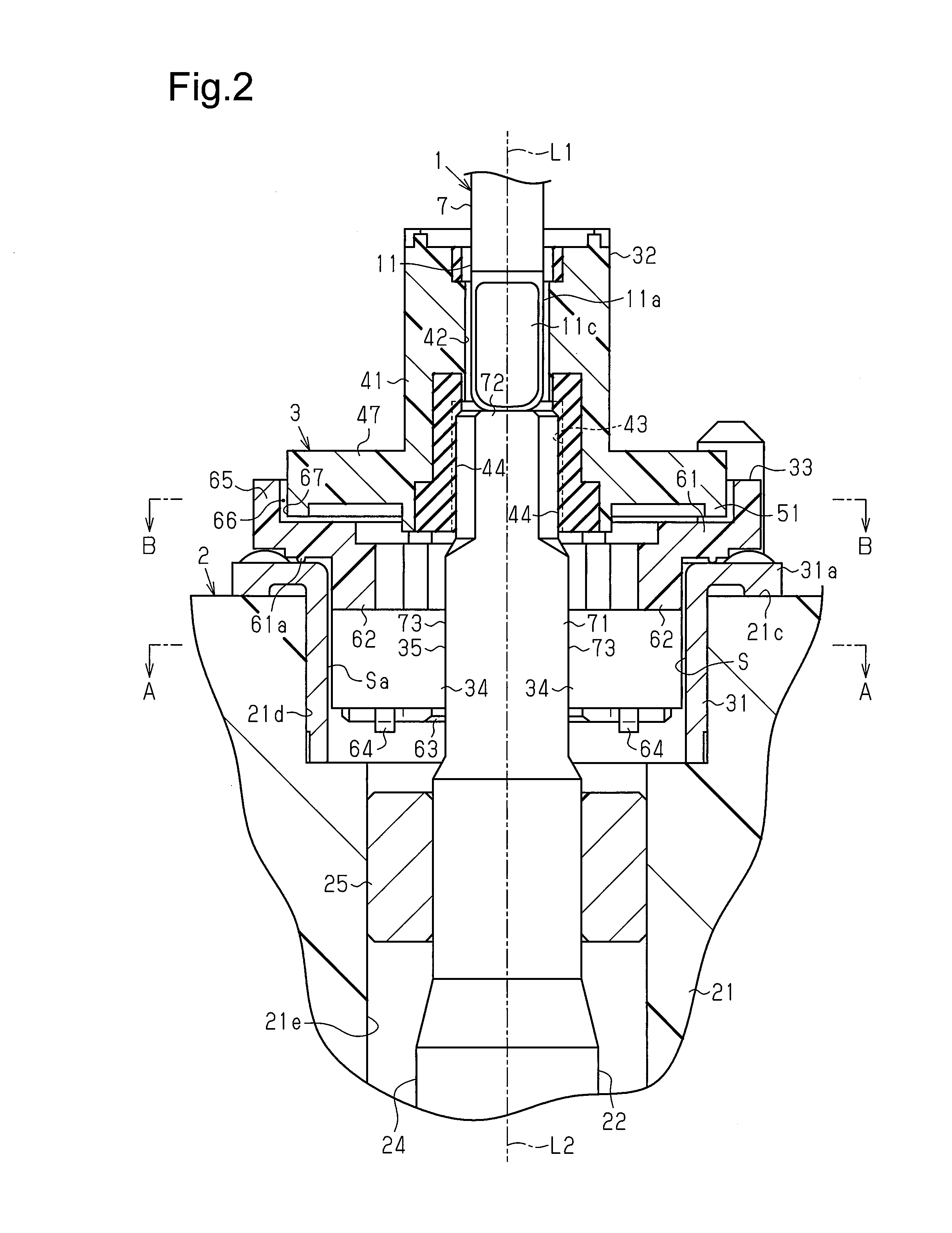

[0027]As shown in FIGS. 2 and 3, a drive insertion portion 11 is defined by the distal portion of the rotation shaft 7. The drive insertion portion 11 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com