Coil component and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

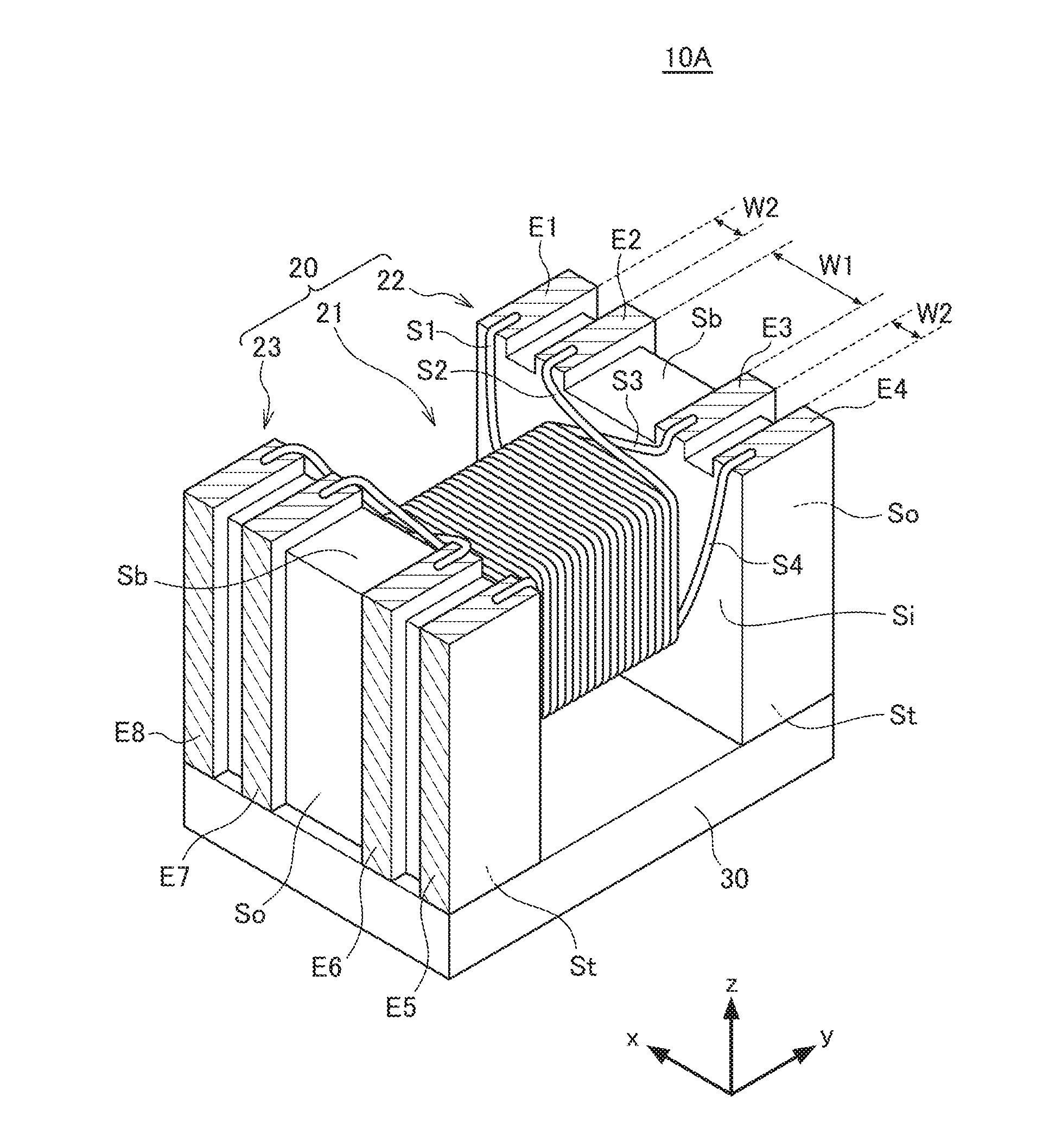

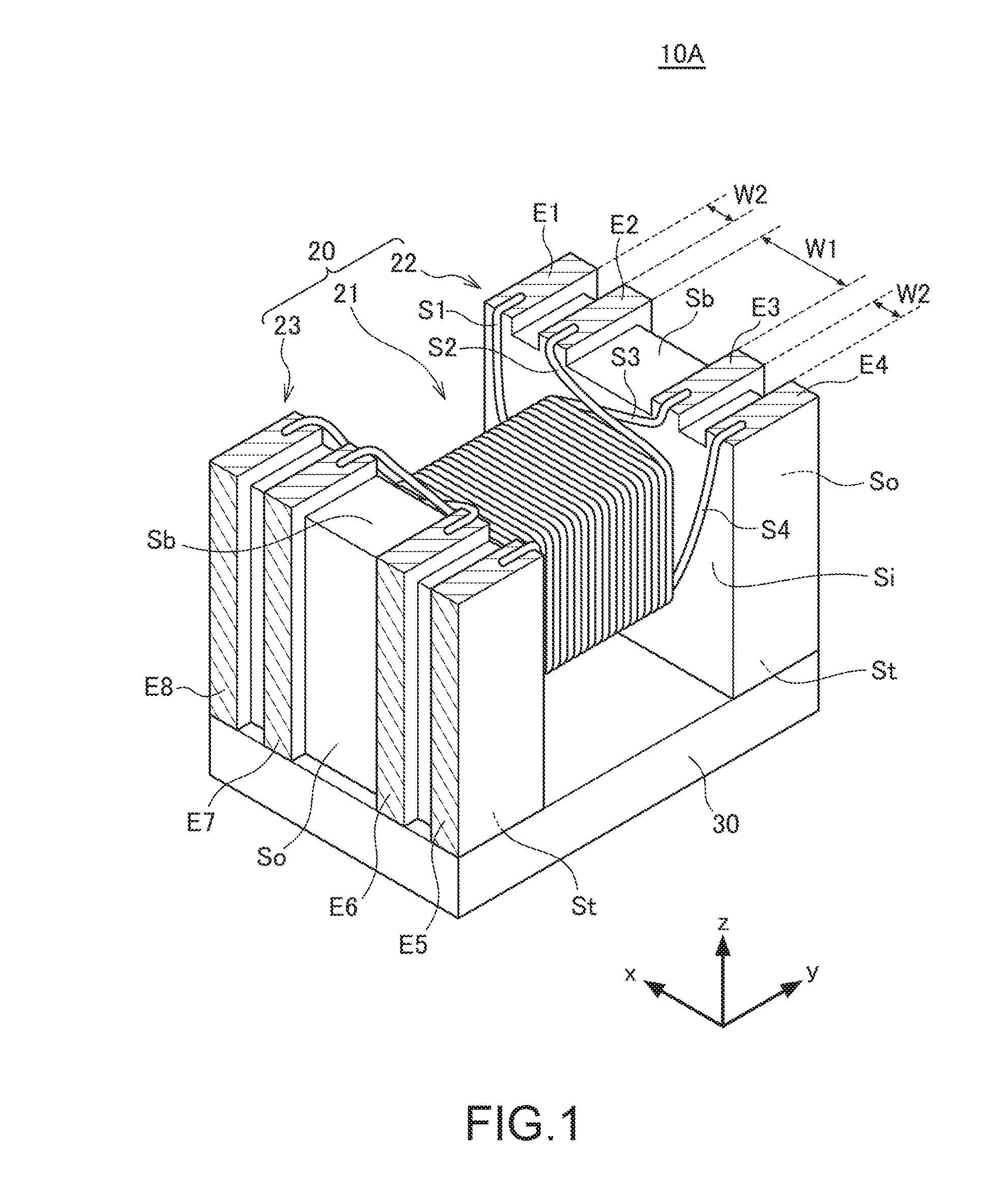

[0028]FIG. 1 is a schematic perspective view showing an appearance of a coil component 10A according to the present invention.

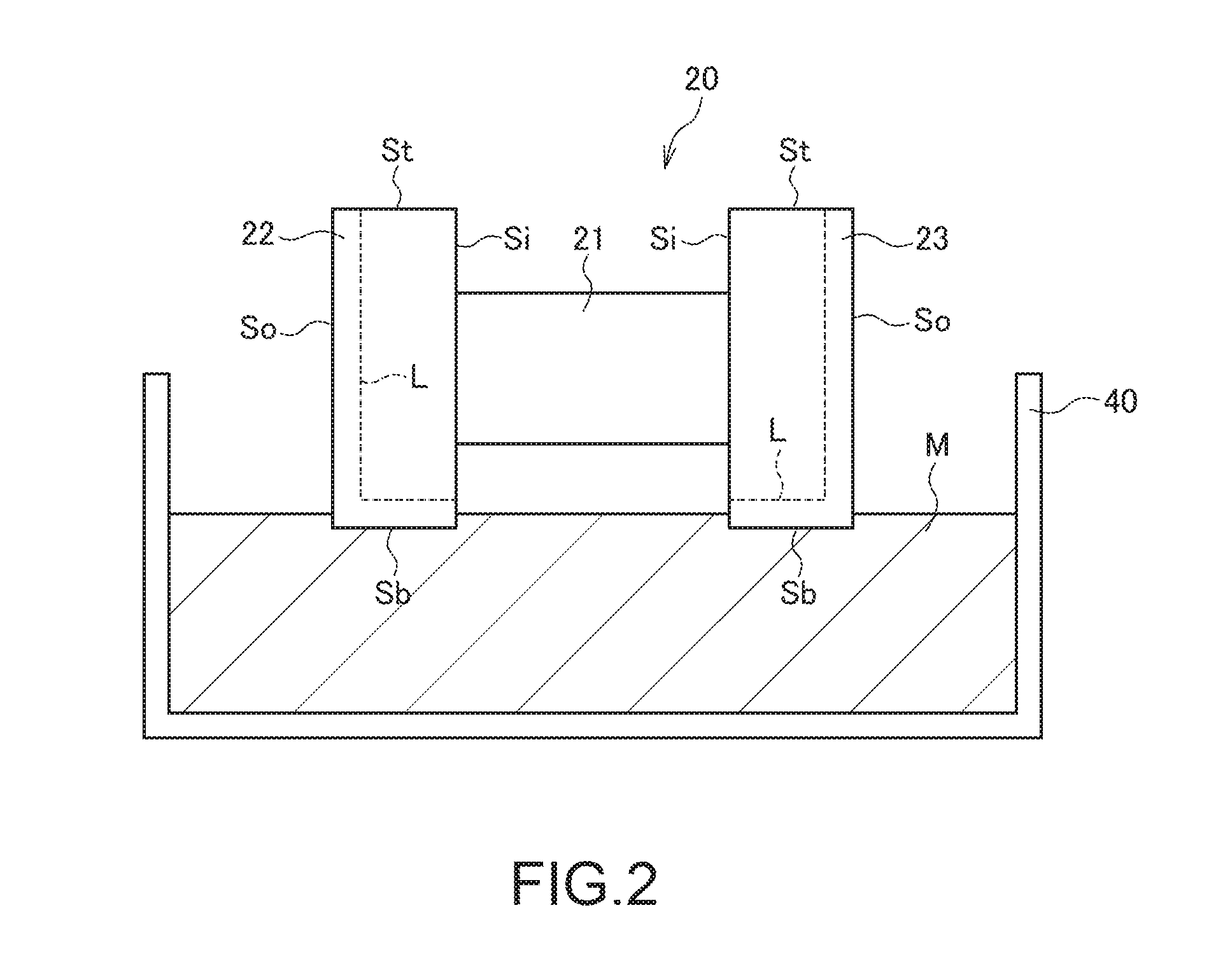

[0029]The coil component 10A of the present embodiment is a pulse transformer of a surface-mount type. As shown in FIG. 1, the coil component 10 includes a drum core 20, a plate core 30 that is bonded to the drum core 20, and conductive wires S1 to S4 that are wound around a winding core portion 21 of the drum core 20. The coil component of the present invention is not limited to the pulse transformer. The coil component of the present invention may be any other transformer component such as a balun transformer or step-up transformer, or may be a filter component such as a common mode choke coil.

[0030]The drum core 20 and the plate core 30 are made of a magnetic material that is relatively high in magnetic permeability such as a sintered composite of Ni—Zn ferrite or Mn—Zn ferrite, for example. Incidentally, the magnetic material that is high in magnetic perm...

second embodiment

[0045]FIG. 4 is a schematic perspective view showing an appearance of a coil component 10B according to the present invention.

[0046]The coil component 10B according to the second embodiment differs from the coil component 10A according to the first embodiment, in that the width in x direction of the ridges formed on the outer side surface So gradually increases, from the mount surface Sb toward the adhesion surface St. The width in x direction of the terminal electrodes E1 to E8 provided on the outer side surface So also gradually increases, from the mount surface Sb toward the adhesion surface St. As a result, the terminal electrodes E1 to E8 provided on the outer side surface So are broader than the terminal electrodes E1 to E8 provided on the mount surface Sb. In any other structural respect, the coil component 10B is identical to the coil component 10A according to the first embodiment. The parts identical to those of the coil component 10A are specified by the same reference nu...

third embodiment

[0048]FIG. 5 is a schematic perspective view showing an appearance of a coil component 10C according to the present invention.

[0049]In the coil component 10C according to the third embodiment, the terminal electrodes E3 and E4 provided on the outer side surface So are integrated into one terminal electrode, and the terminal electrodes E7 and E8 are integrated into one terminal electrode. Hence, on the outer side surface So, the ridges associated with the terminal electrodes E3 and E4 are integrated into one ridge, and the ridges associated with the terminal electrodes E3 and E4 are integrated into one ridge. In any other structural respect, the coil component 10C is identical to the coil component 10A according to the first embodiment. The parts identical to those of the coil component 10A are specified by the same reference numerals, and will not be described repeatedly.

[0050]In the coil component 10C according to the third embodiment, on each outer side surface So, some of the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com