Internal liquid suction heat exchanger

a heat exchanger and liquid suction technology, which is applied in indirect heat exchangers, lighting and heating apparatuses, refrigeration components, etc., can solve the problems of excessive oil circulation, low discharge superheat, and oil may not be effectively separated from the discharge gas in the oil separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

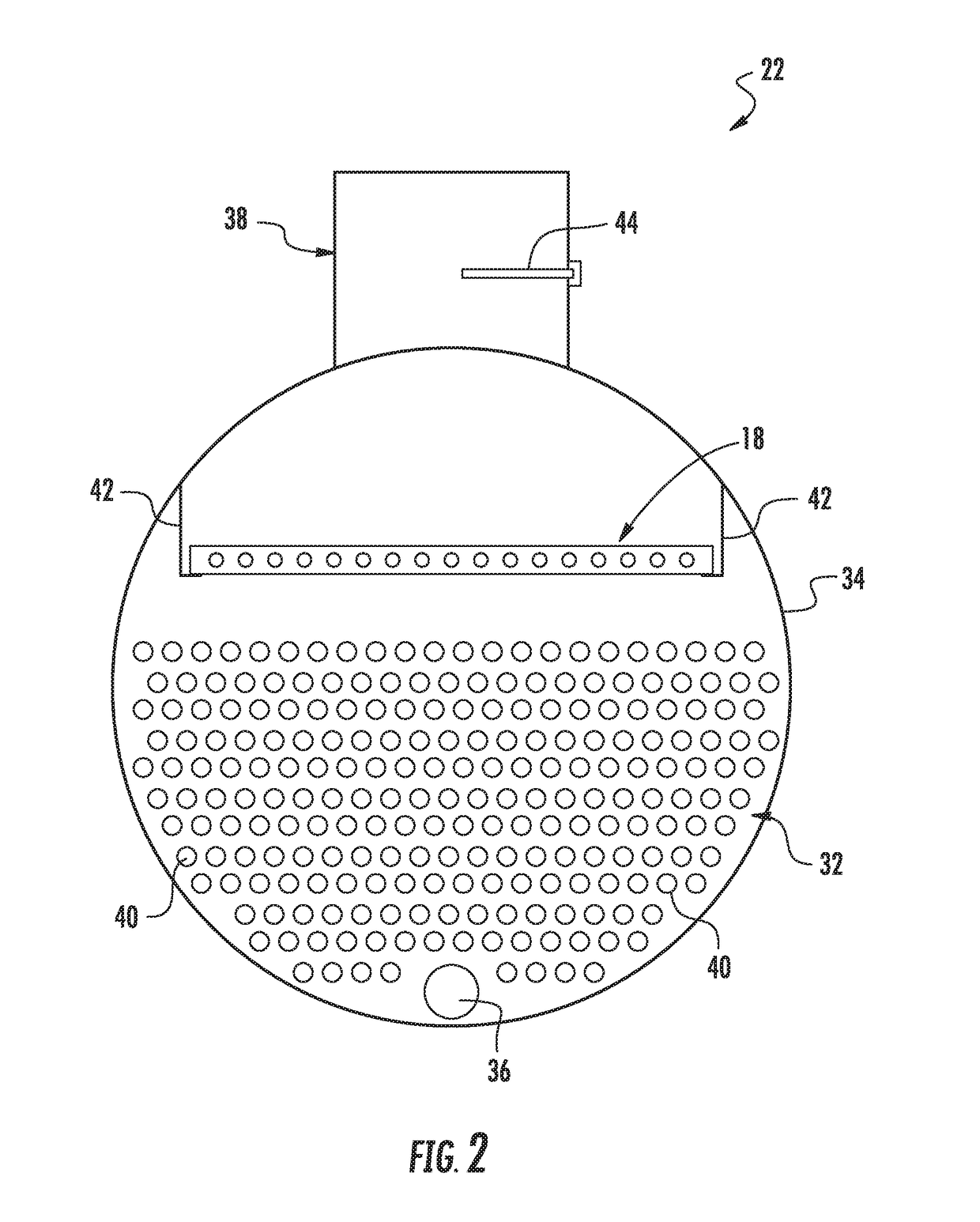

[0012]Described herein is an evaporator or chiller that includes a liquid suction heat exchanger installed inside the evaporator. The liquid suction heat exchanger increases suction superheat, by transferring heat form the liquid refrigerant leaving the condenser to the refrigerant gas existing in the evaporator heat exchanger, thereby increasing system efficiency and capacity. Transferring heat from the refrigerant gas leaving the evaporator to the liquid refrigerant is a cycle enhancement that is used to improve the performance of a refrigeration system as well as add additional superheat to the suction gas to enable better control of refrigerant flow control devices (e.g., expansion valves).

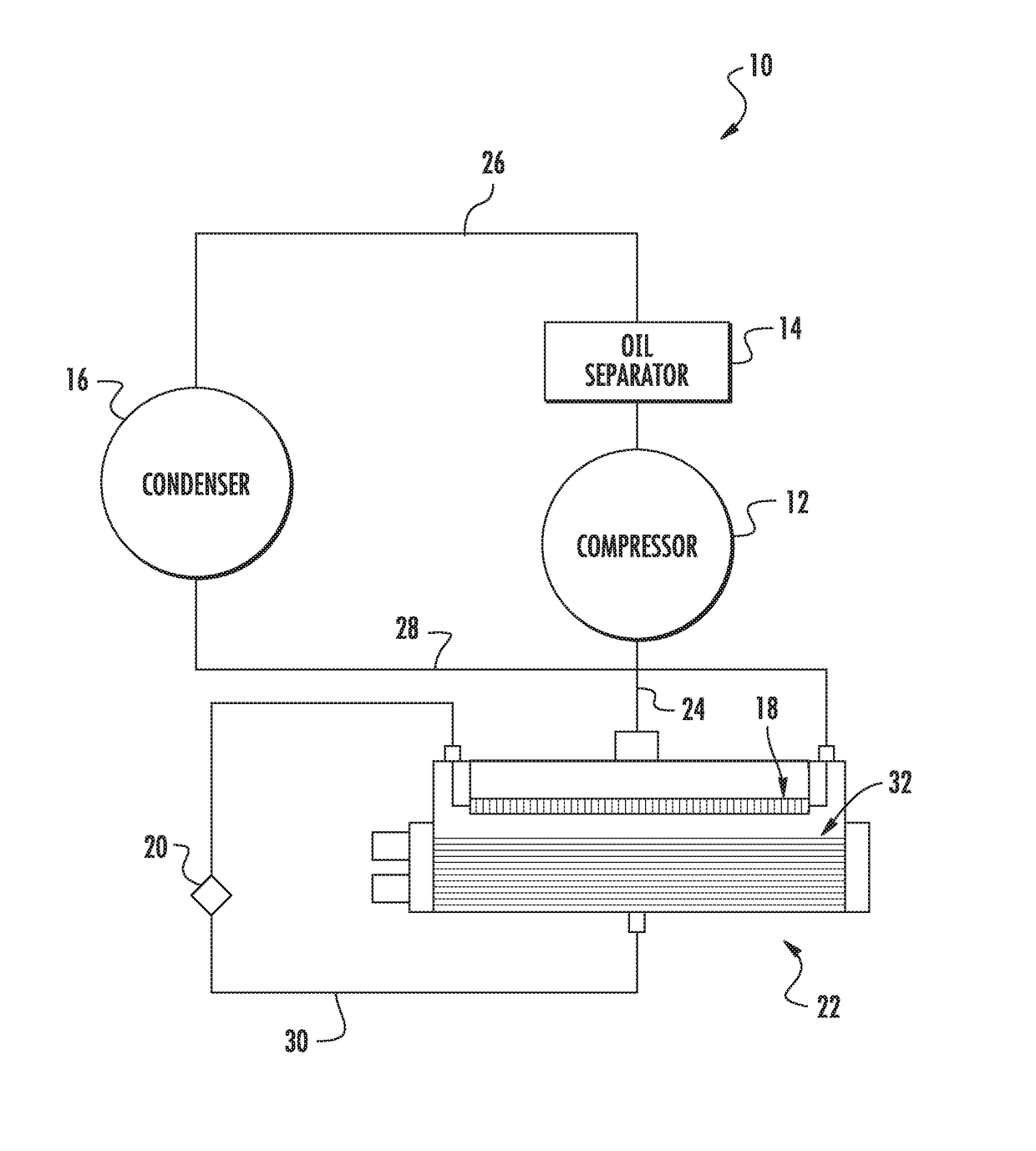

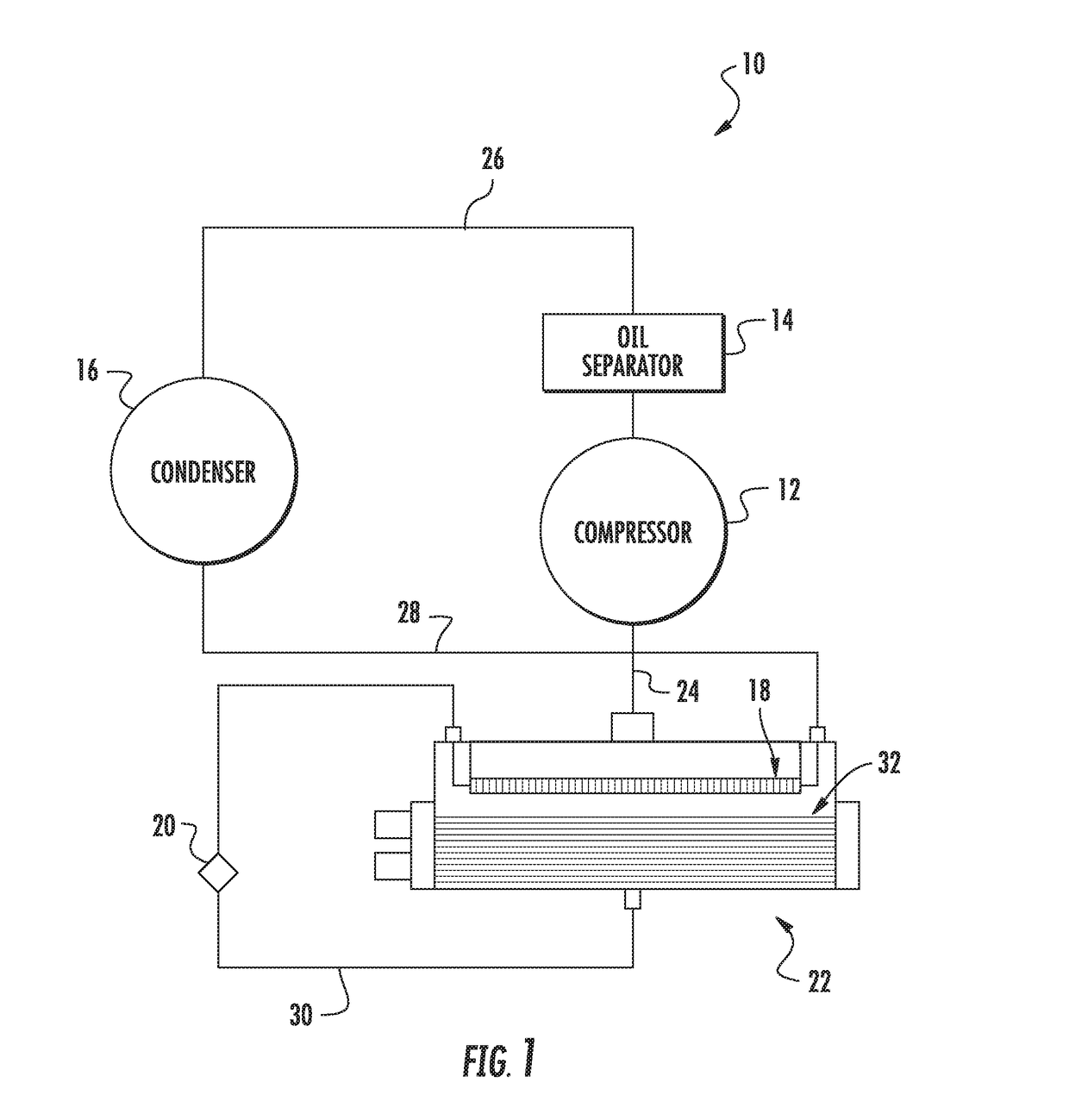

[0013]FIG. 1 illustrates an exemplary refrigeration system 10 that generally includes a compressor 12, an oil separator 14, a condenser 16, a liquid suction heat exchanger 18, an expansion valve 20, and an evaporator 22. In the exemplary embodiment, compressor 12 is a screw compressor and evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com