Cleaner head for a vacuum cleaner

a vacuum cleaner and cleaner head technology, applied in the field of vacuum cleaners, can solve the problems of cleaner heads that suffer from increased weight and bulk, drop in performance, and increase complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

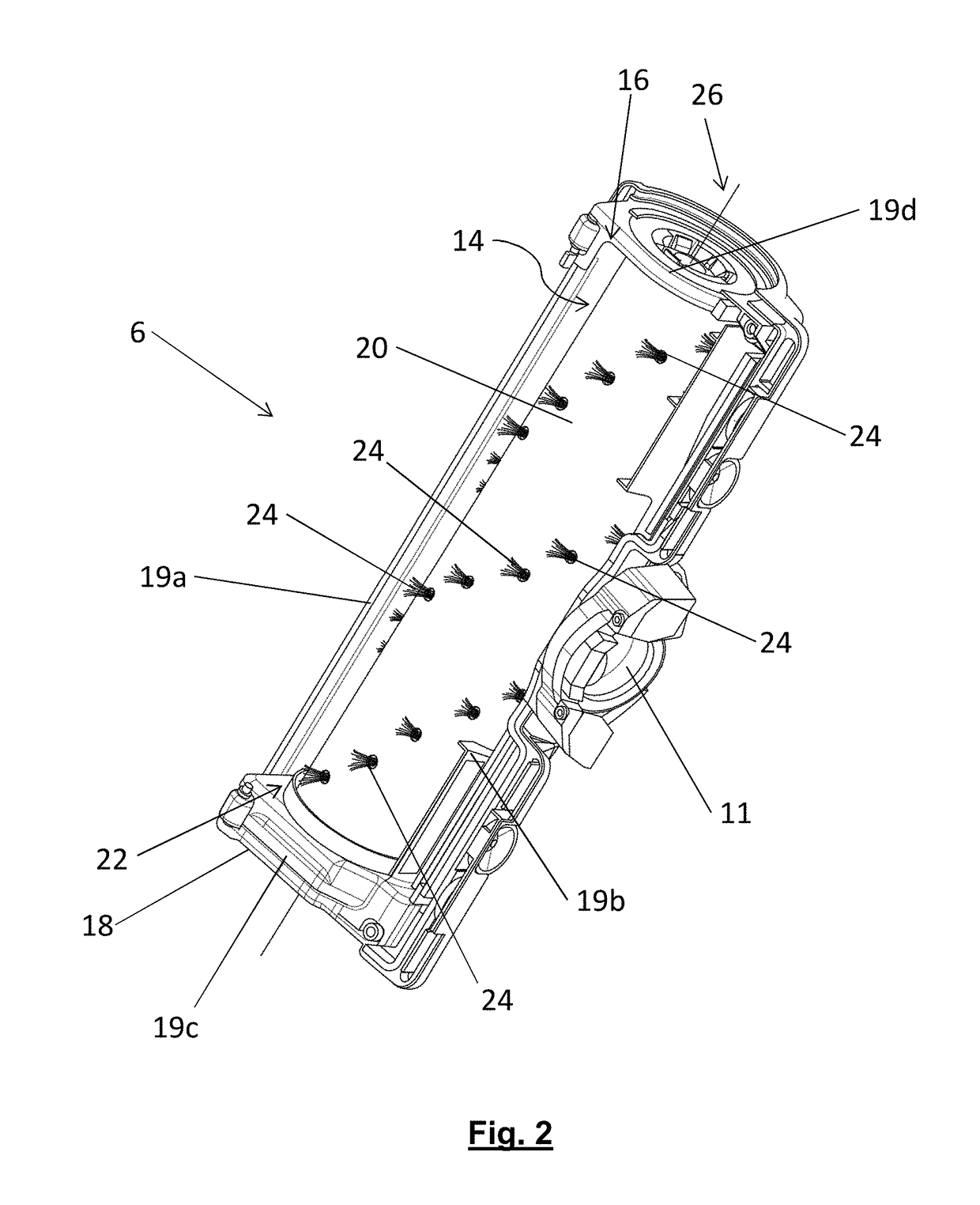

[0057]Throughout the description and drawings, corresponding reference numerals denote corresponding features.

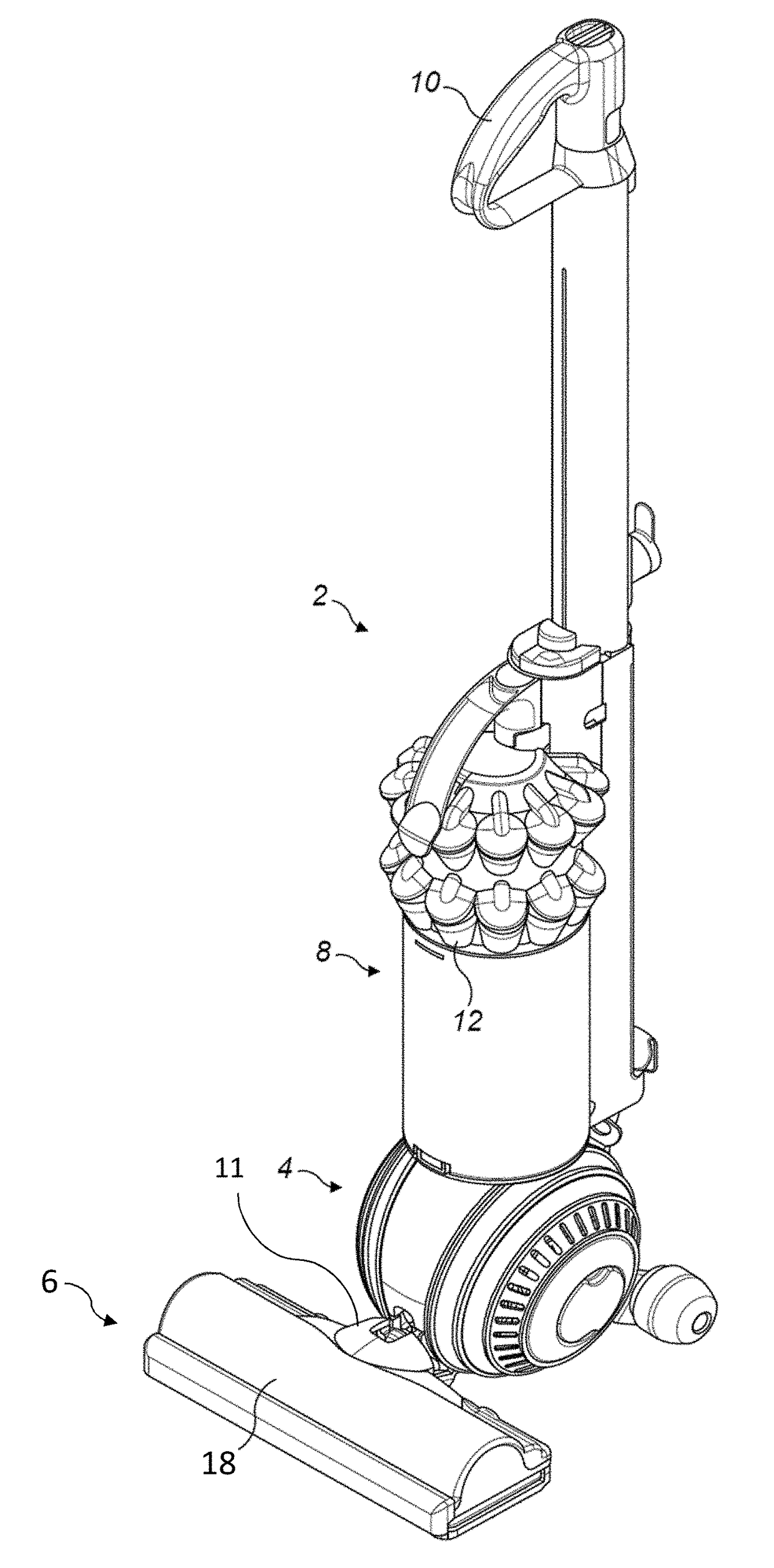

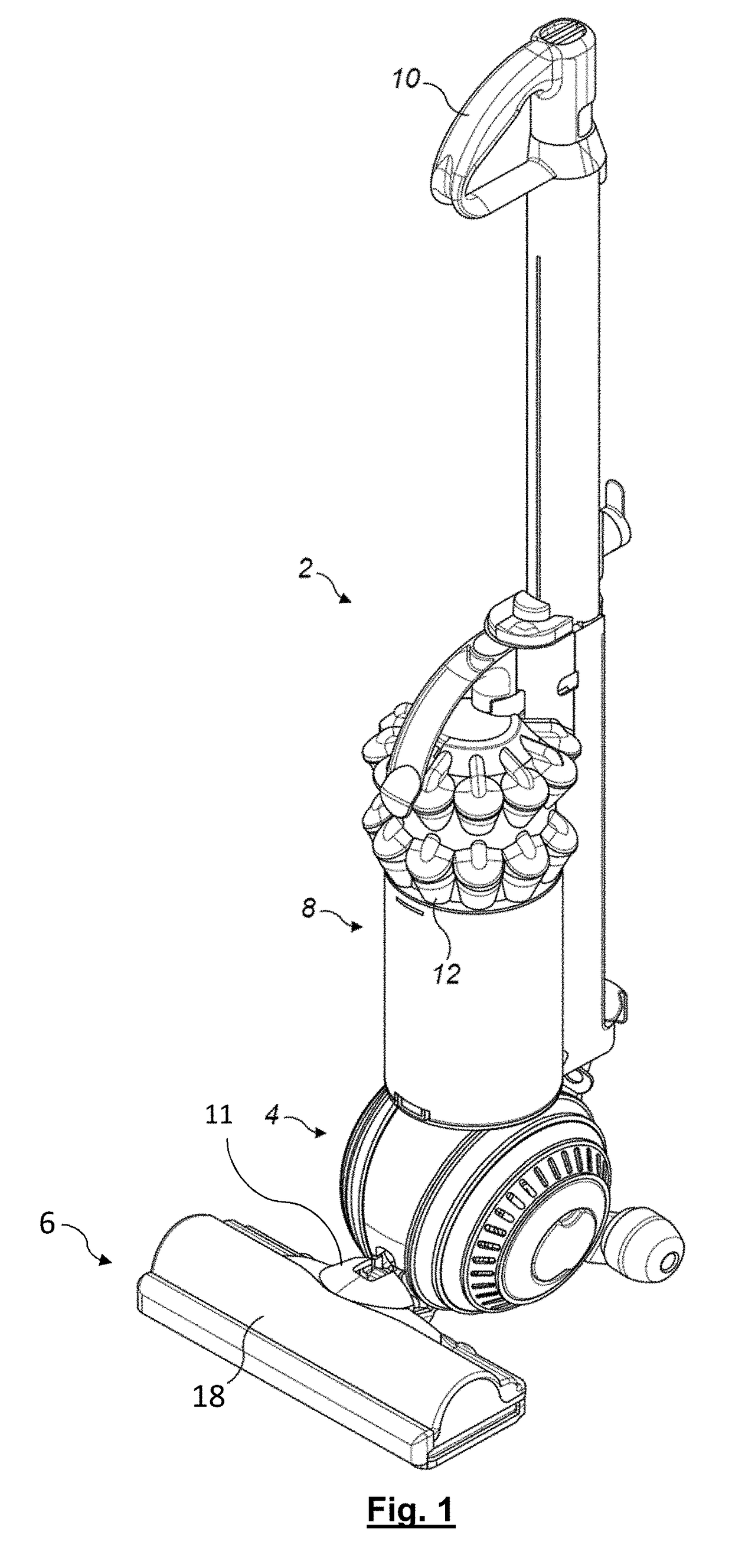

[0058]FIG. 1 shows a vacuum cleaner 2 which is useful for understanding the invention. This example is an upright vacuum cleaner 2. It has a rolling head assembly 4 which carries a fixed cleaner head 6, and an ‘upright’ body 8. The upright body can be reclined relative to the head assembly 4, and includes a handle 10 for maneuvering the vacuum cleaner 2 across the floor. In use, a user grasps the handle 10 and reclines the upright body 8 until the handle 10 is disposed at a convenient height for the user. The user can then roll the vacuum cleaner 2 across the floor using the handle 10 in order to pass the cleaner head 6 over the floor and pick up dust and other debris therefrom. The dust and debris is drawn into a suction chamber (not visible) of the cleaner head by a suction generator in the form of a motor-driven fan (not visible) housed on board the vacuum cleaner 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com