Multi-pass and multi-slab folded microchannel heat exchanger

a microchannel heat exchanger and multi-pass technology, applied in indirect heat exchangers, refrigeration components, light and heating apparatus, etc., can solve the problems of reducing the efficiency and functionality of heat exchangers and hvac&r systems, reducing the utilization time of useful heat exchangers, and reducing overall performance. , to achieve the effect of reducing the formation of fros

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

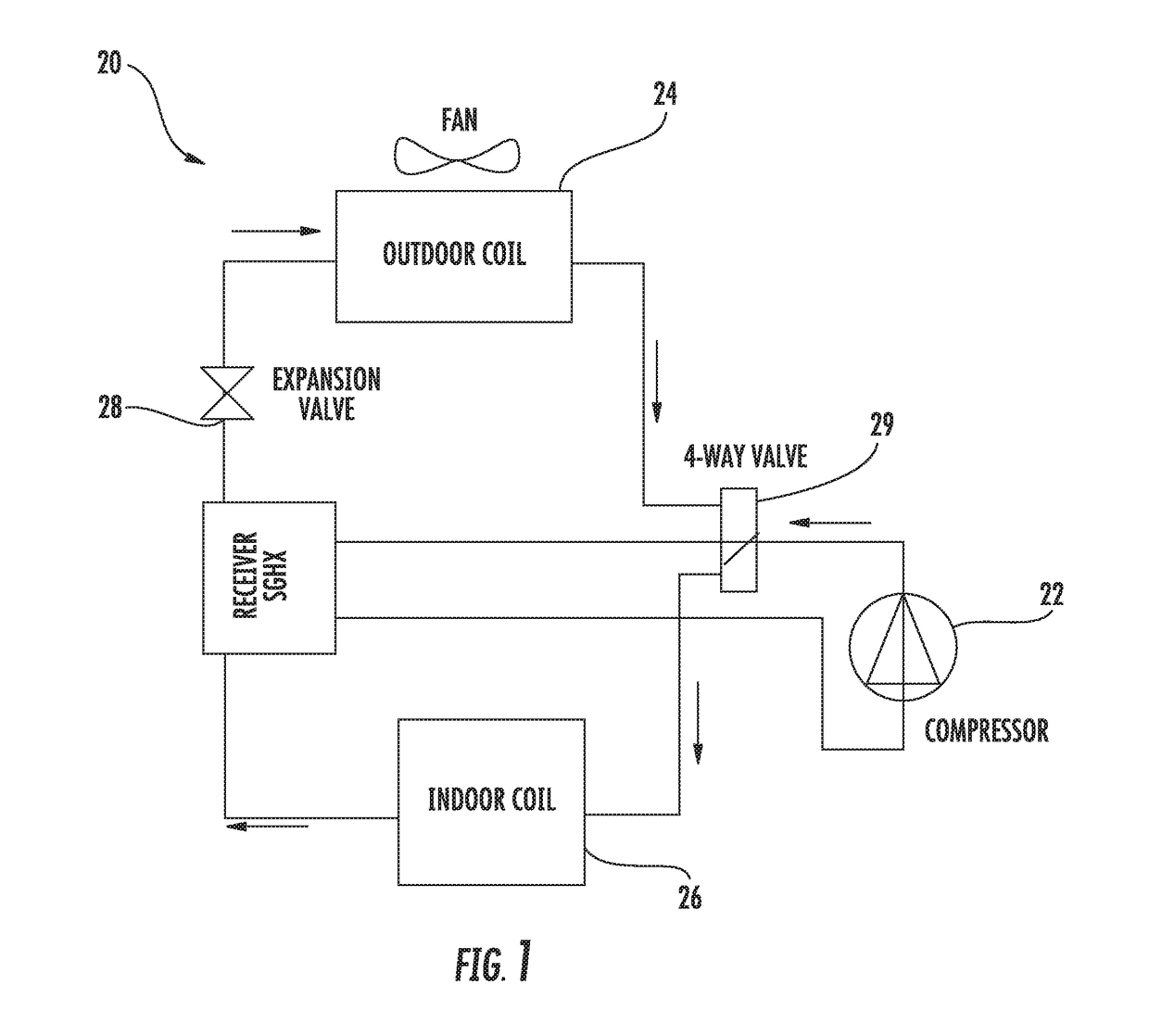

[0034]Referring now to FIG. 1, a vapor compression refrigerant cycle 20 of an air conditioning or refrigeration system is schematically illustrated. Exemplary air conditioning or refrigeration systems include, but are not limited to, split, packaged, chiller, rooftop, supermarket, and transport refrigeration systems for example. A refrigerant R is configured to circulate through the vapor compression cycle 20 such that the refrigerant R absorbs heat when evaporated at a low temperature and pressure and releases heat when condensed at a higher temperature and pressure.

[0035]Within this cycle 20, the refrigerant R flows in a counterclockwise direction as indicated by the arrow. The compressor 22 receives refrigerant vapor from the evaporator 24 and compresses it to a higher temperature and pressure, with the relatively hot vapor then passing to the condenser 26 where it is cooled and condensed to a liquid state by a heat exchange relationship with a cooling medium (not shown) such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com