Chemically temperable glass sheet

a technology of glass sheet and chemical tempering, applied in the field of glass sheet, can solve the problems of reducing the strengthening effect, increasing the density of glass sheet, and forming reams, and achieve the effect of easy chemical tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091]Powder raw materials were mixed together and placed in melting crucibles, according to the compositions specified in the following table 1. The raw material mix was then heated up in an electrical furnace to a temperature allowing complete melting of the raw material.

TABLE 1Wt %Ex1.1Ex1.2Ex1.3Ex2.1Ex2.2Ex2.3SiO272.171.471.071.971.270.6Na2O14.211.29.314.311.29.3K2O0.14.87.90.14.87.9Al2O31.11.11.11.11.11.1CaO8.17.16.48.07.16.5MgO4.24.24.24.14.24.2Fe2O30.210.190.180.480.450.42K2O / (Na2O + 0.010.300.460.010.300.46K2O)

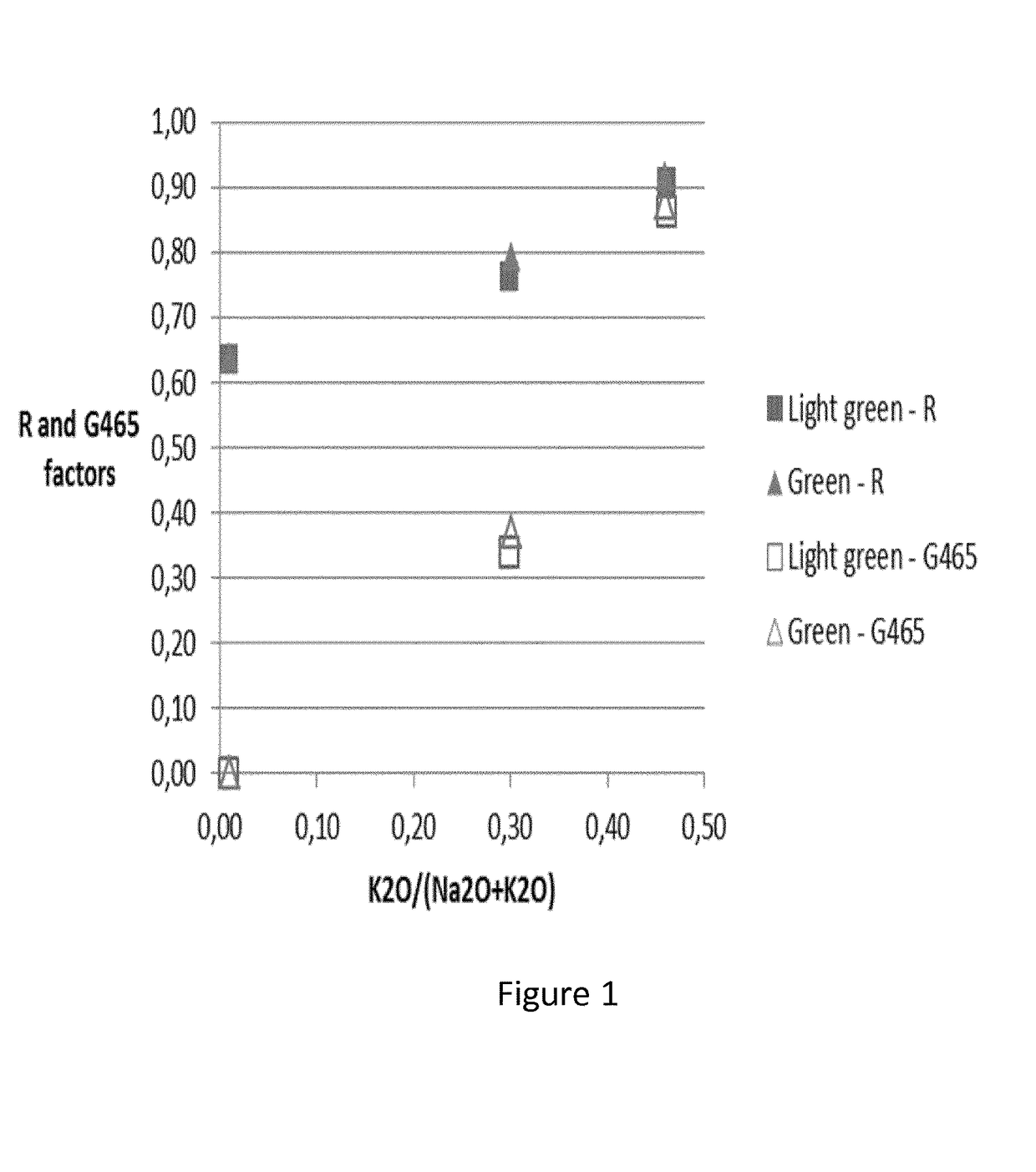

[0092]In those samples, the base molar composition was kept constant, and the proportion between Na2O and K2O was varied in the range of the invention while keeping constant the molar fraction of alkali (Na2O+K2O˜13.3 mol %) over the total composition. Two glass tints were prepared, characterized by their levels of iron: ˜0.2% wt % of Fe2O3 in the series of examples 1.x (˜light green glass), and ˜0.45 wt % of Fe2O3 in the series 2.x (˜green glass). For each series, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com