Apparatus and method

a substrate surface and apparatus technology, applied in the direction of chemical vapor deposition coating, metal material coating process, coating, etc., can solve the problems of limiting the use of ald method in many applications, not being able to process pieces, and using ald method according, so as to reduce the amount of waste produced, reduce the amount of waste, and the effect of efficient starting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

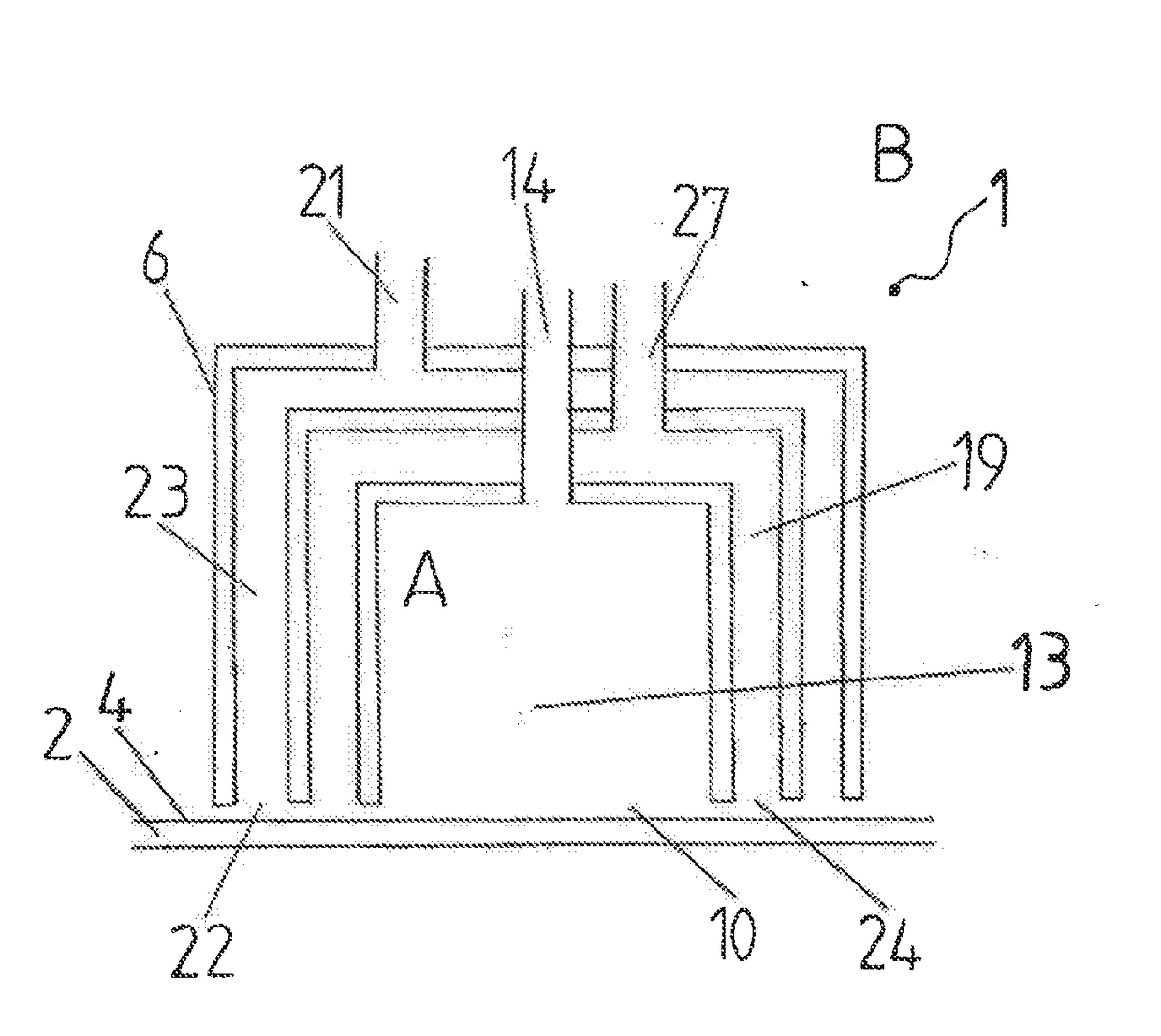

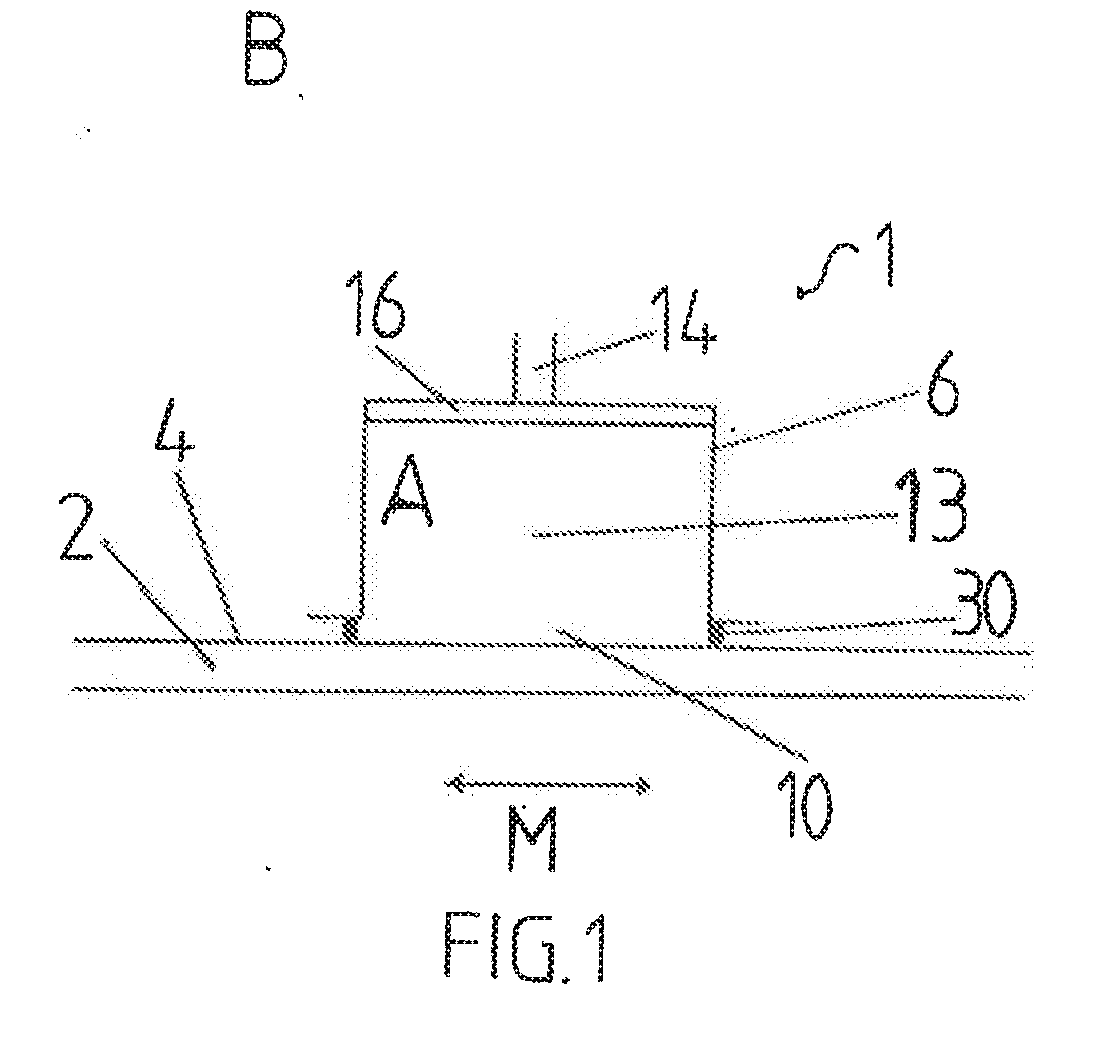

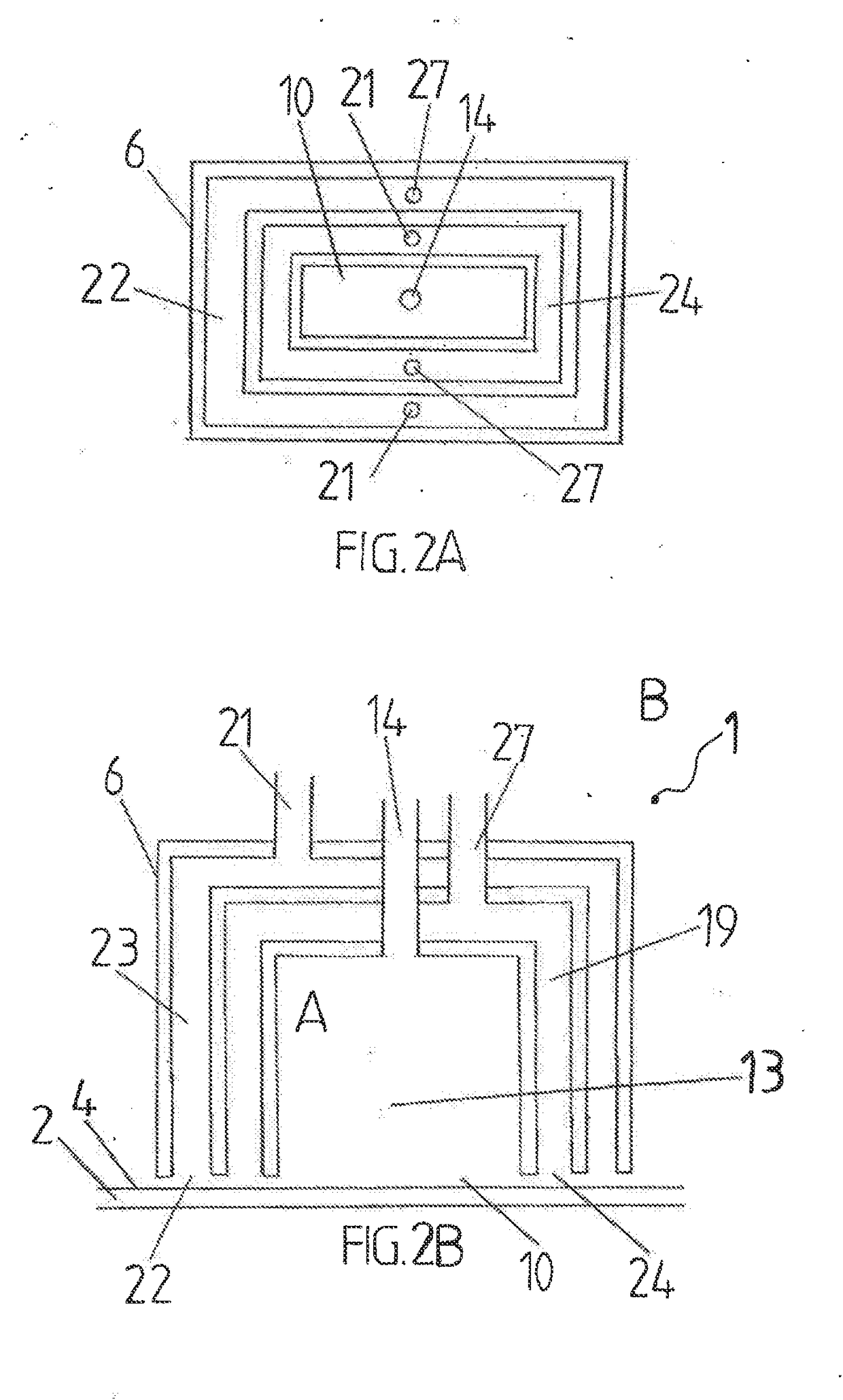

[0015]Referring to FIG. 1 a first embodiment of the apparatus of the present invention is shown. According to FIG. 1 the apparatus comprises a source 6, which may be positioned on the surface 4 of the substrate 2 to be processed. The source 6 comprises a nozzle surface, which is placed against the surface 4 of the substrate 2 to be processed or on the surface 4 within a distance from the surface 4 so that the nozzle surface will cover part of the surface 4 of the substrate 2. Thus, the nozzle surface means in this context the surface of the source 6, which is placed against the surface 4 of the substrate 2 or on the surface 4. By means of the source a first starting material A is conducted via nozzle surface on the surface 4 of the substrate 2 at the region covered by the nozzle surface so that at this region covered by the nozzle surface the surface 4 of the substrate 2 may be exposed to a first starting material A. The first starting material A may be fed together with a carrier g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com