Isolated bidirectional constant-current maintenance system based on power supply source of shared device

a maintenance system and power supply technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of increasing the risk of overcharging/over-discharging batteries, reducing the utilization rate of battery packs at the same time, and accelerating the damage to batteries. , to achieve the effect of ensuring the consistency of battery packs, prolonging the service life of battery packs, and enhancing the energy utilization rate of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention is described in further detail in conjunction with the attached drawings and embodiments.

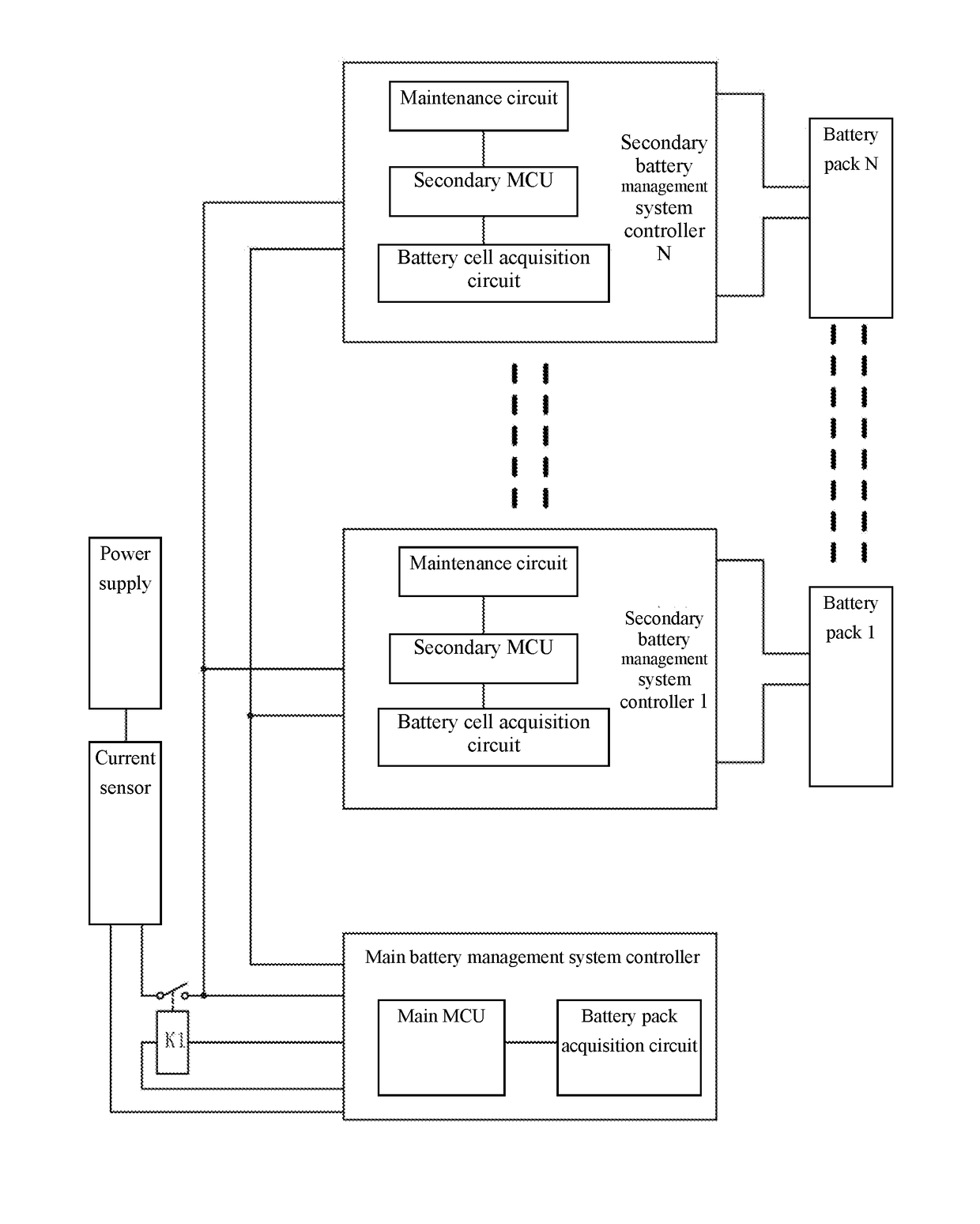

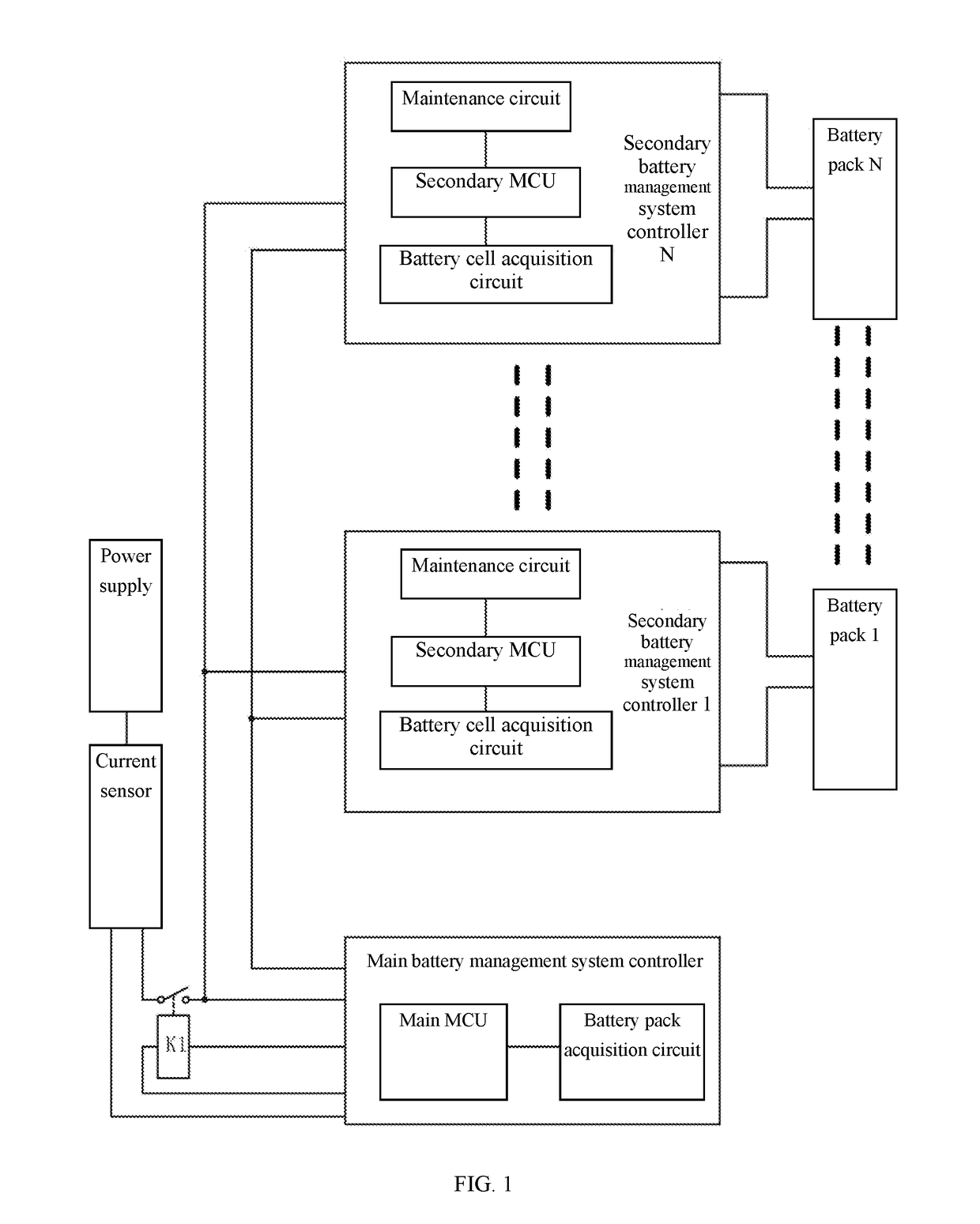

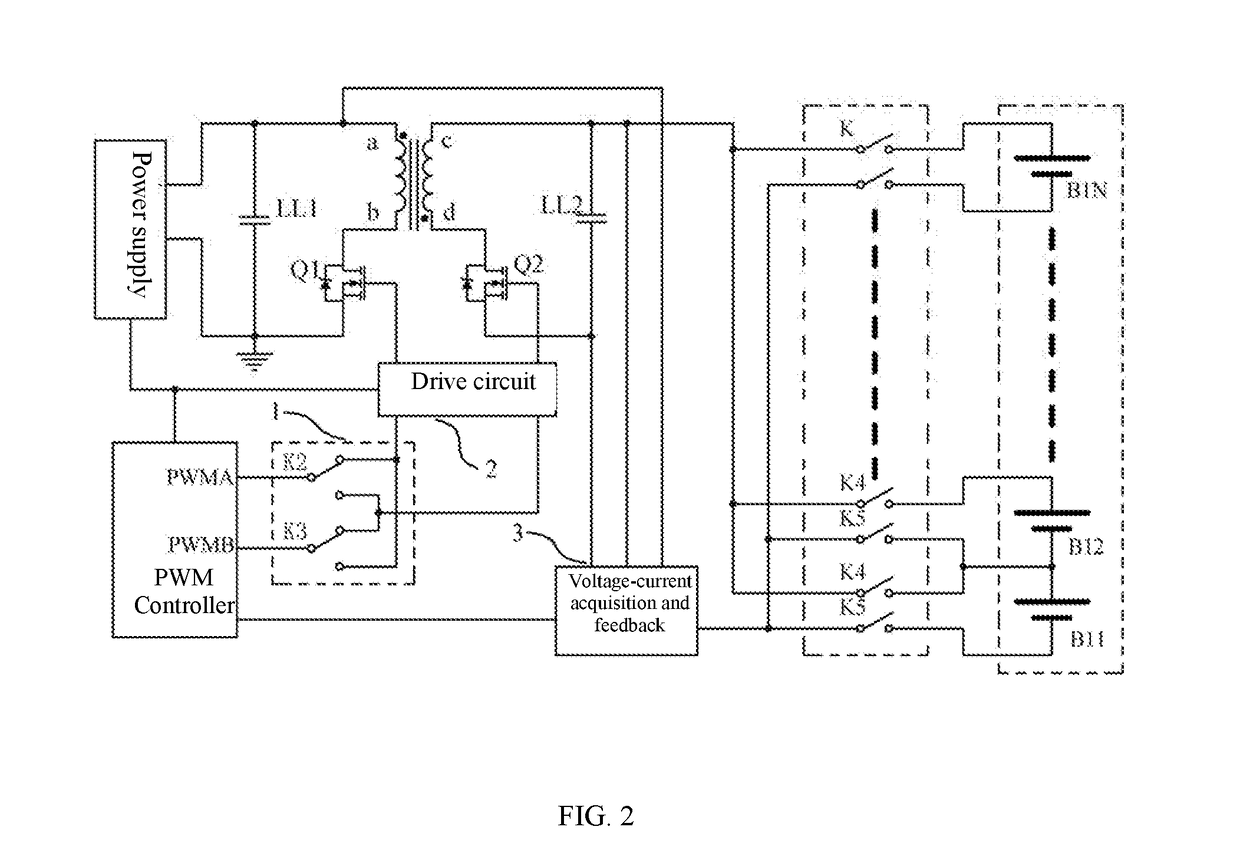

[0020]As shown in FIG. 1, an isolating two-way constant-current maintenance system based on a power supply of shared equipment is used for maintaining battery packs consisting of battery cells, including a power supply, an electronic switch K1, a current sensor, a main battery management system controller, and a plurality of secondary battery management system controllers, wherein the power supply is connected with the current sensor; the current sensor is respectively connected with the electronic switch K1 and the main battery management system controller; the electronic switch is respectively connected with the main battery management system controller and the secondary battery management system controllers; the main battery management system controller is respectively in a communication connection with the plurality of secondary battery management system controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com