Modular flotation system

a flotation system and modular technology, applied in underwater equipment, special-purpose vessels, transportation and packaging, etc., can solve the problems of not always desirable or cost-effective permanent installation of flotation on equipment, and the flotation arrangement for one mission may not be apt for another mission, so as to facilitate temporary installation of modular flotation arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

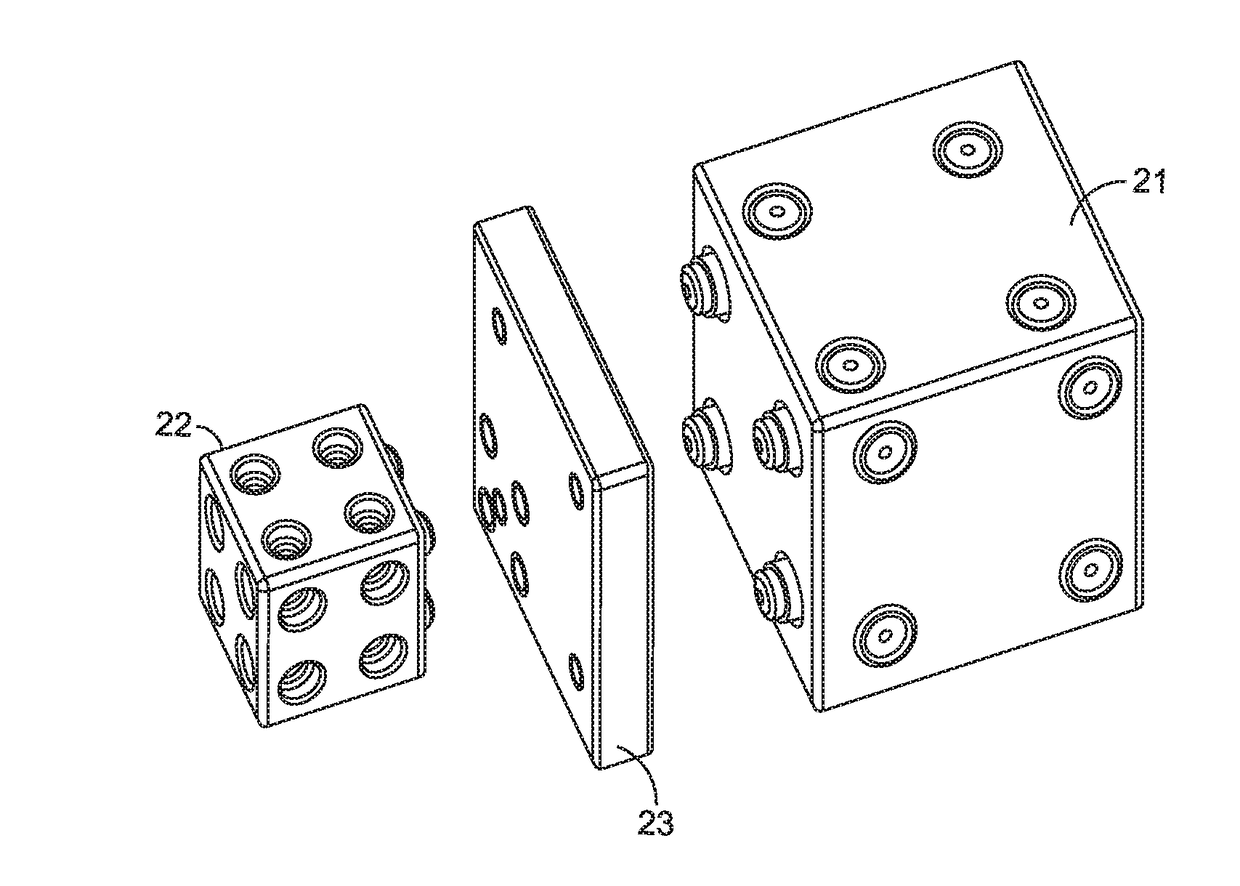

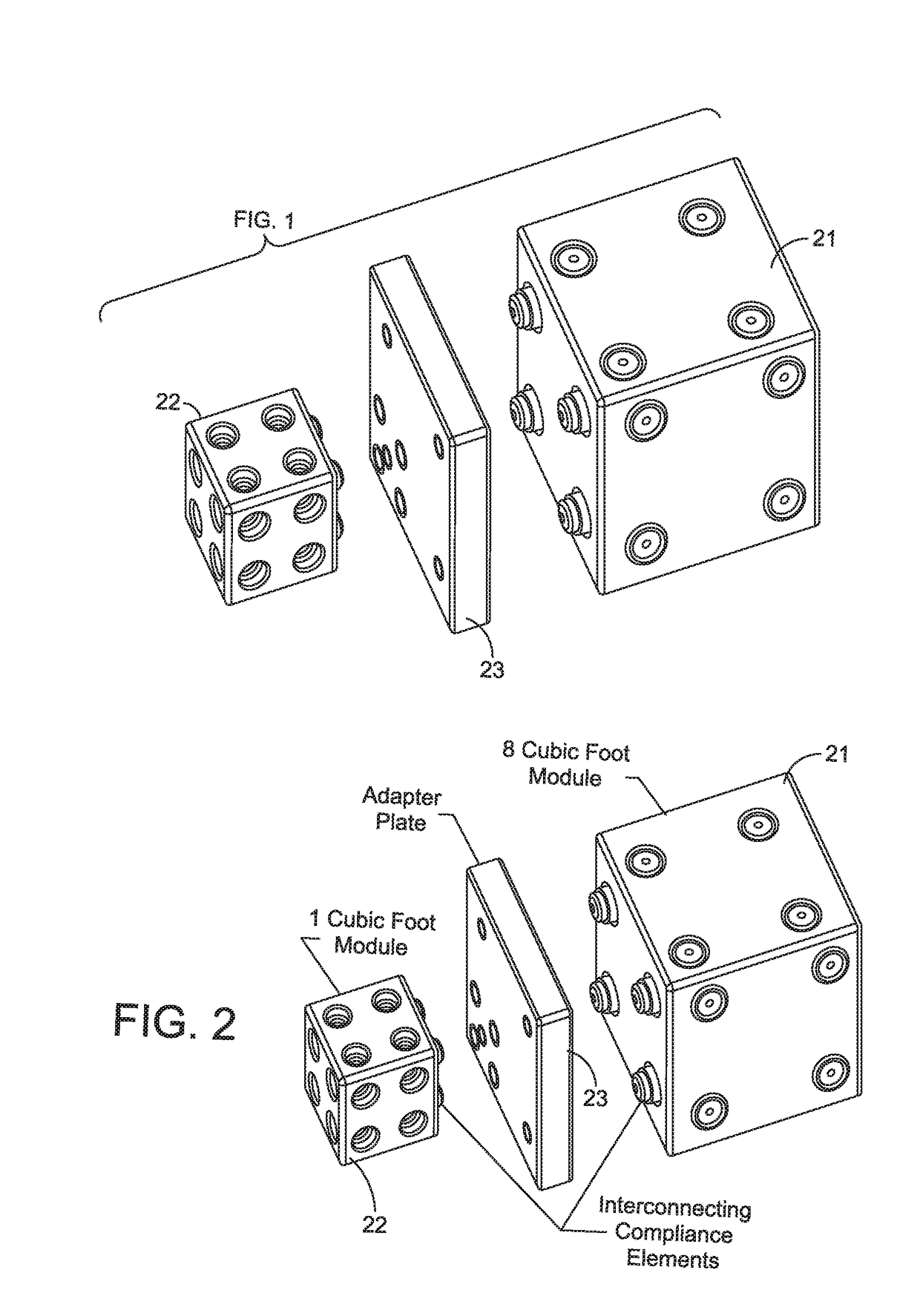

[0029]The invention comprises one or more arrays of two or more interlocking standardized flotation modules 21. The modules can be of equal size, or as shown in FIG. 1, modules 21, 22 of different sizes can be configured to be attachable and detachable directly or indirectly through interface elements 23 to form arrays. For making the structural attachments between modules and to structures that are external to the array such as loads or submersible vehicles, related fixtures and hardware including structural members and components are provided for detachable connection and positioning as described in detail herein. These parts enable a user to create any number of configurations of plural preferably-standardized flotation module arrays, by selecting among modules and attaching the selected modules to one another in a building block manner to form arrays of plural connected modules.

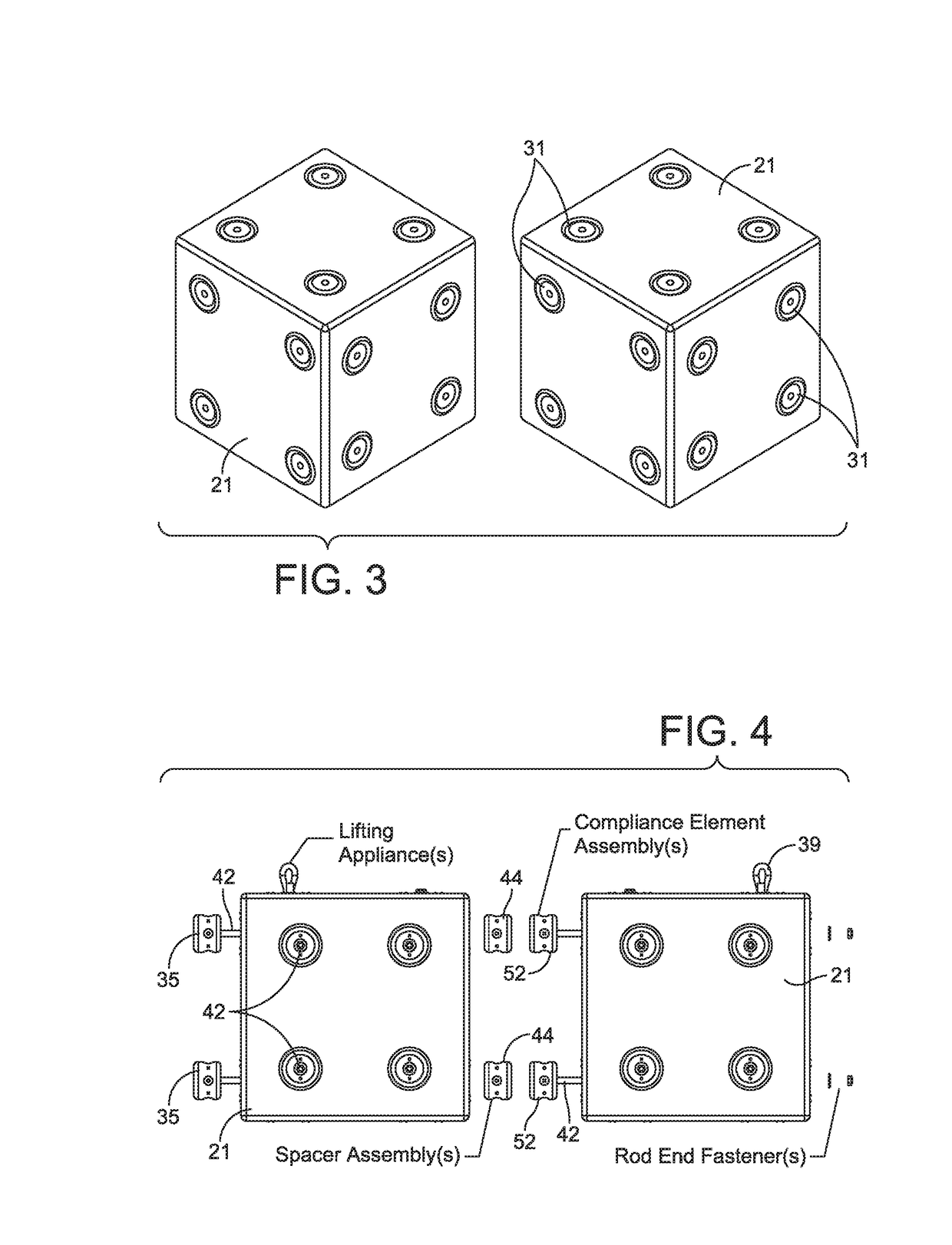

[0030]The arrays of plural modules can be elongated by abutting and attaching modules in one, two or t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com