Needle-manufactured textile garment with improved durability and decorative elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

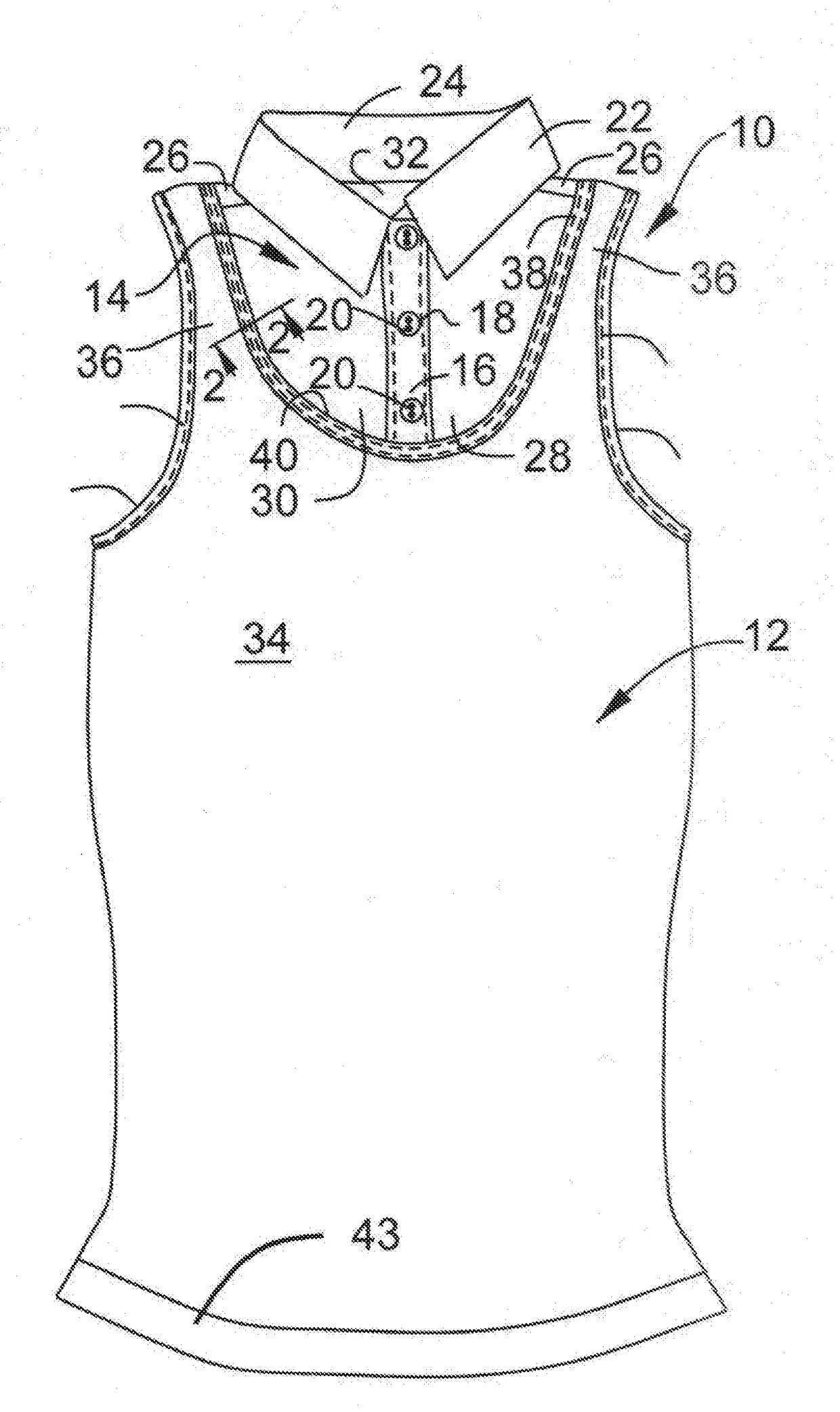

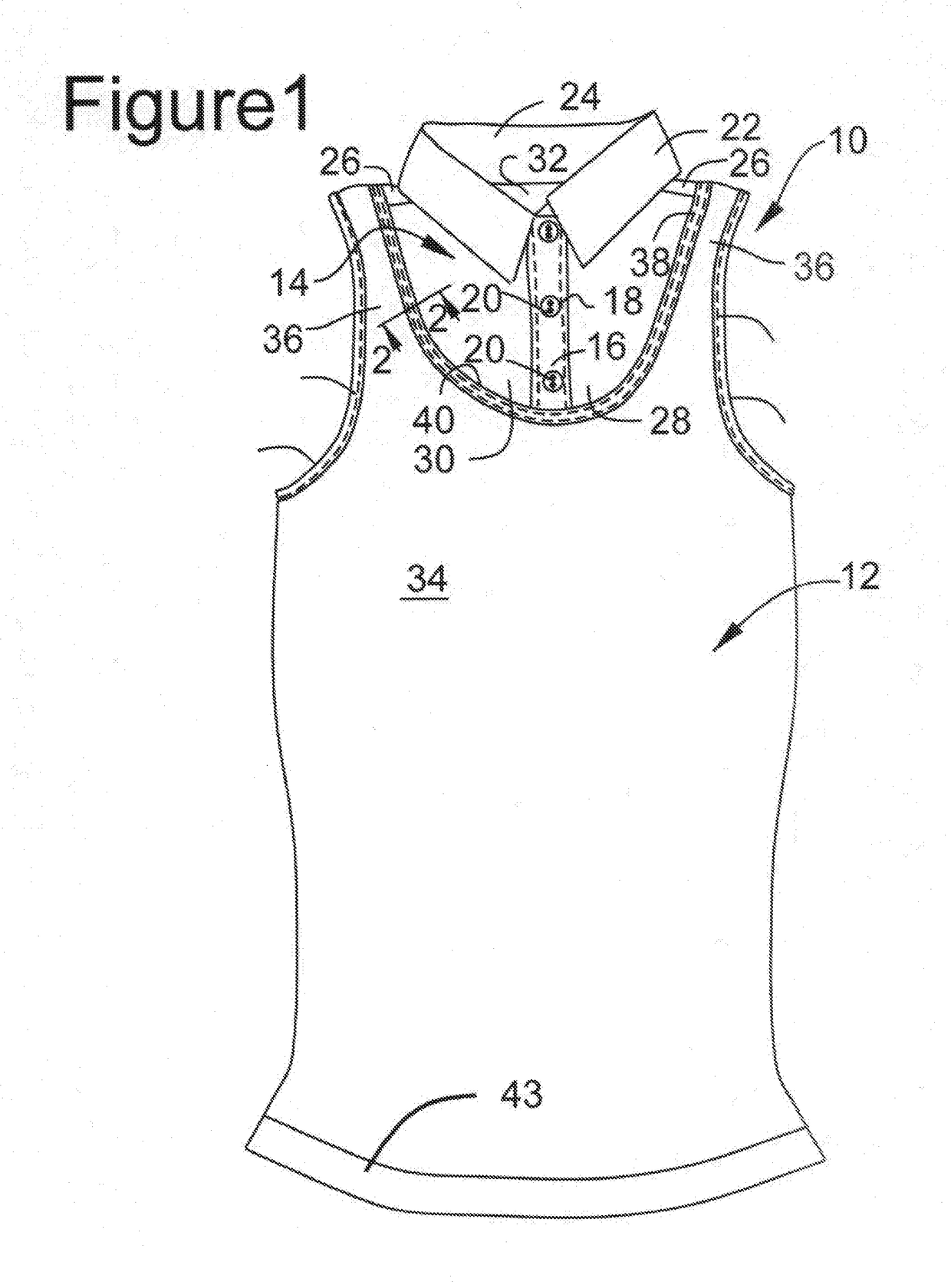

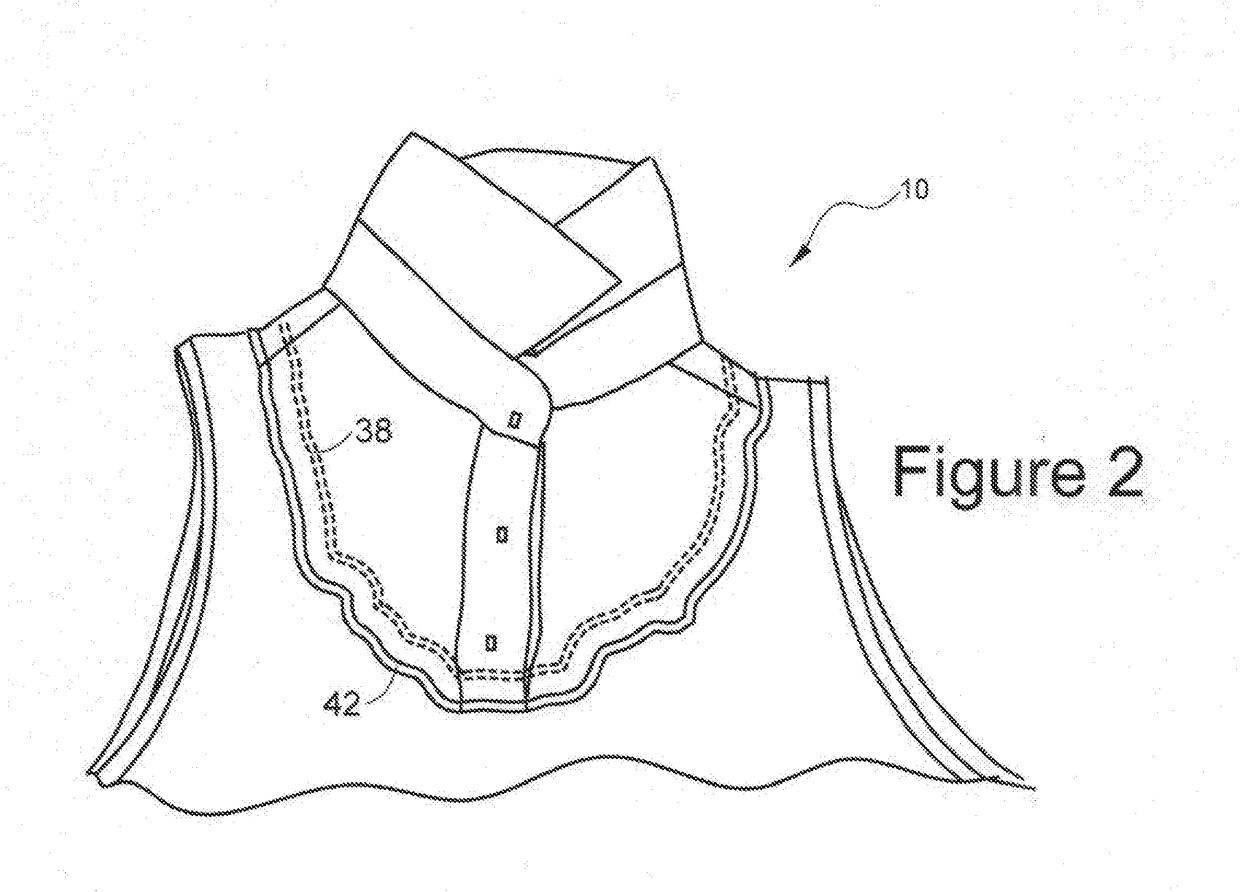

[0033]With reference to FIGS. 1 through 4, the inventive garment 10 may take the form of a sleeveless, needle-manufactured fabric (for example, knitted) garment. Garment 10 comprises a lower body portion 12 which surrounds the trunk of the wearer. Lower body portion 12 is attached to a decorative member 14 which is configured, dimensioned, and positioned to cover the upper chest of the wearer.

[0034]Decorative member 14 may take a wide variety of forms simulating the look of the upper portions of virtually any type of known shirt, for example, a simple Oxford style, as illustrated in FIGS. 1-4. In the illustrated embodiment, a box plate 16, of conventional design held together by stitches 18. Buttons 20 provide for closure of the garment with the result of a fashionable look, while also providing warmth when closed and allowing the inventive garment to be easily put on and taken off by the wearer when the buttons are unbuttoned.

[0035]Further functional and decorative features are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com