Burner Nozzle Configuration and its Use

a technology of burner nozzle and nozzle, which is applied in the direction of combustion types, lighting and heating apparatus, incinerator apparatus, etc., can solve the problems of known high temperature of gasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

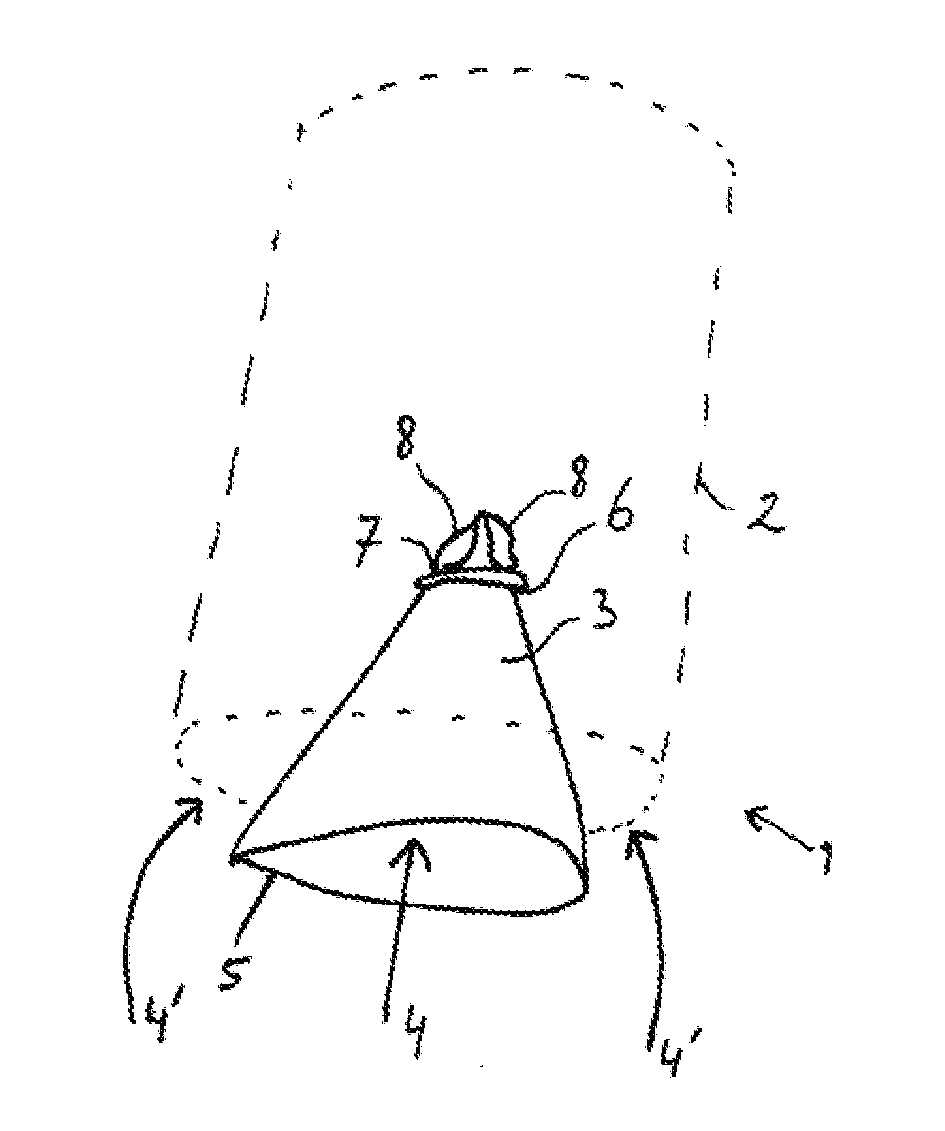

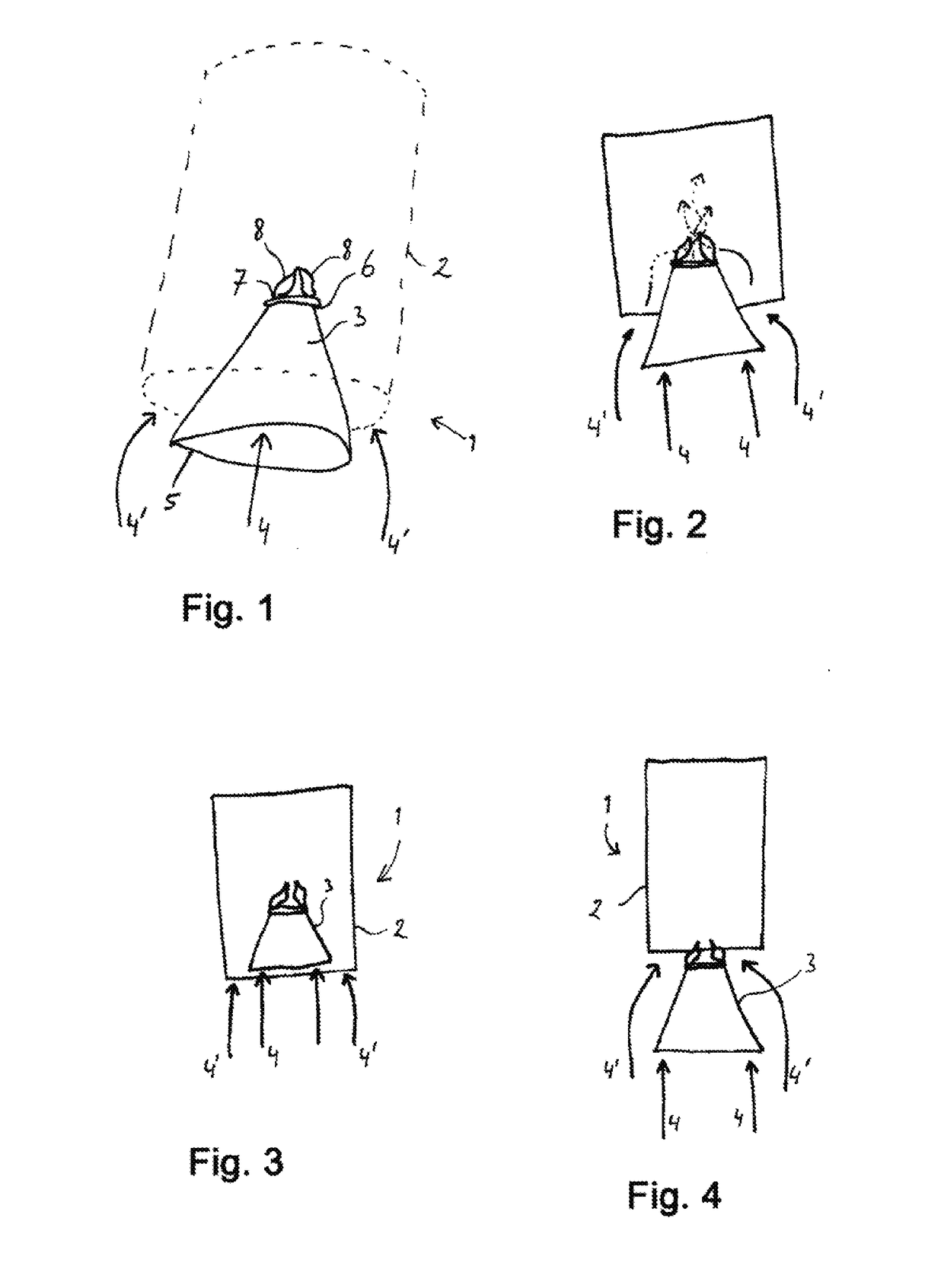

[0037]In the figures similar parts are referred to with the same reference numbers. However, for sake of ease of understanding, not all parts that are required for a practical embodiment are shown in the drawing.

[0038]FIG. 1 shows a perspective view of a burner configuration, hereinafter also called burner 1, according to the present invention. The burner 1 comprises a (shown in dashed line) cylinder 2 and a cone 3, serving as a conductor for at least part of the gas mixture to be cleaned. The flow direction of the gas mixture to be cleaned is shown by means of arrows 4, 4′. Part of the gas mixture that is supplied through the cone is referred to by reference numeral 4, whereas part of the gas mixture that is supplied around the cone is referred to by reference number 4′. The cone 3 is positioned with its broad or wide side 5 relatively upstream and with the narrow side relatively downstream.

[0039]At the narrow side 6 a burner nozzle 7 is provided. At the burner nozzle a fuel is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com