Light-emitting element and display device having the light-emitting element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

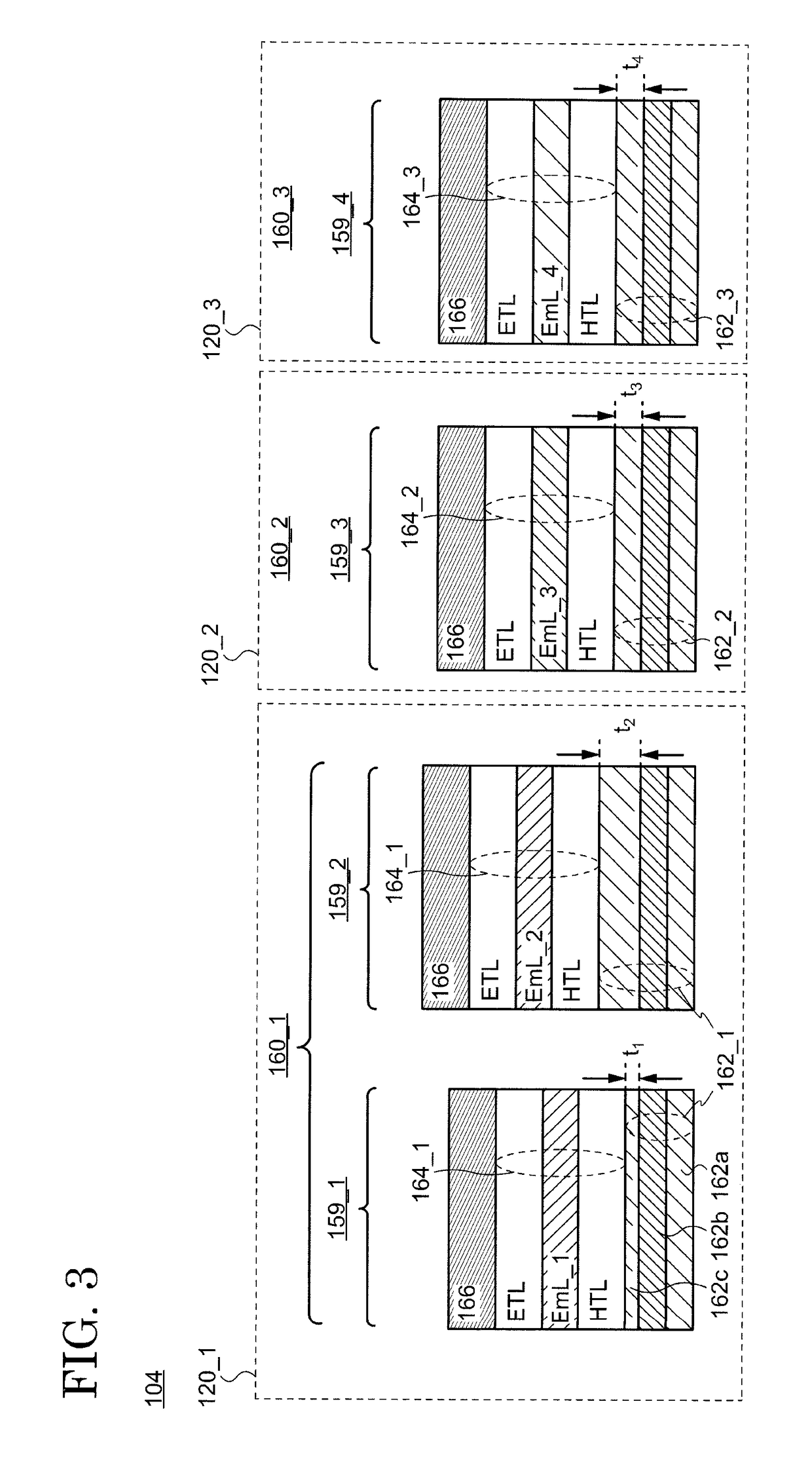

[0029]In the present embodiment, an explanation is made focusing on a structure of a light-emitting element included in a display device 100 according to an embodiment.

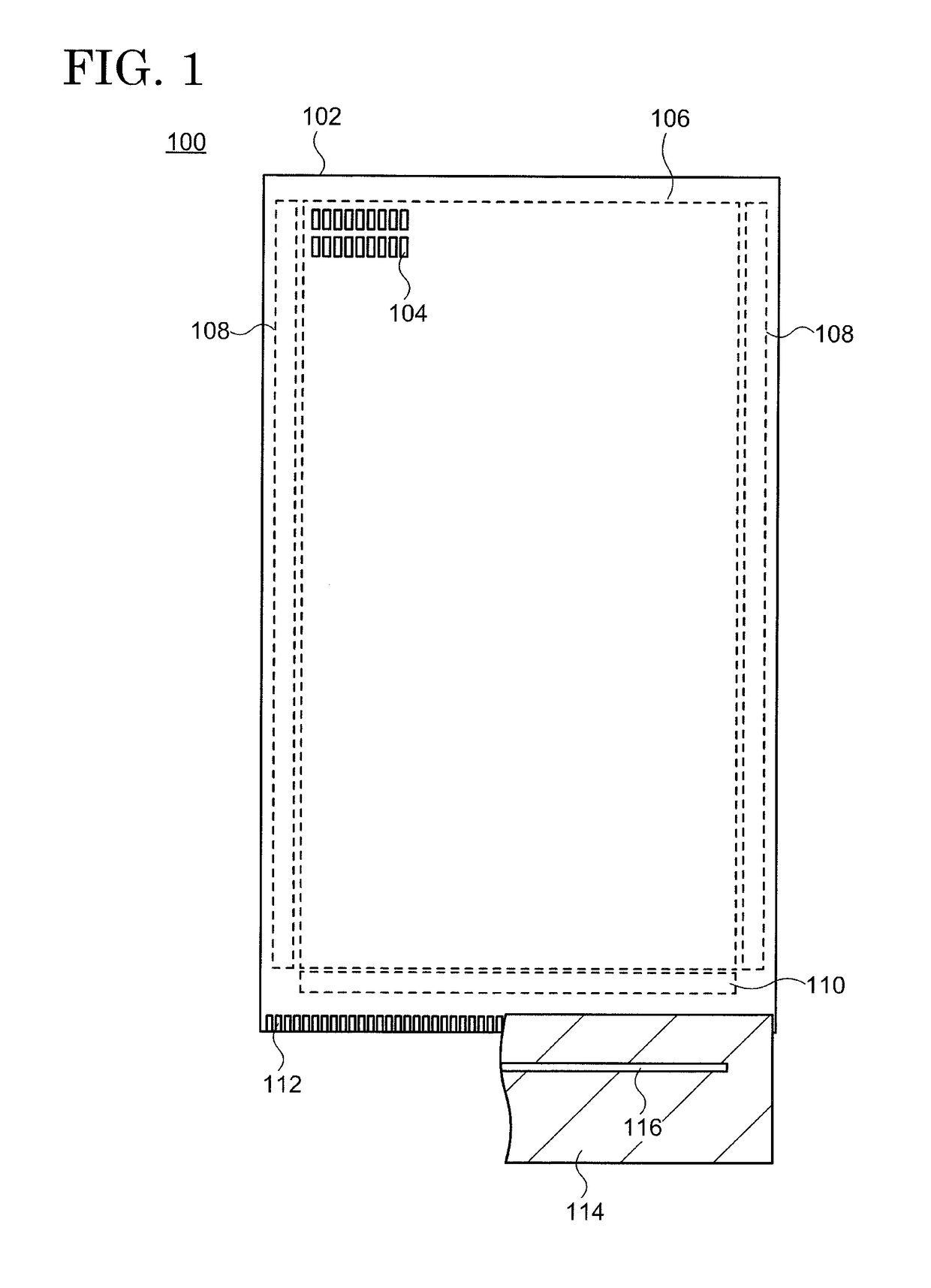

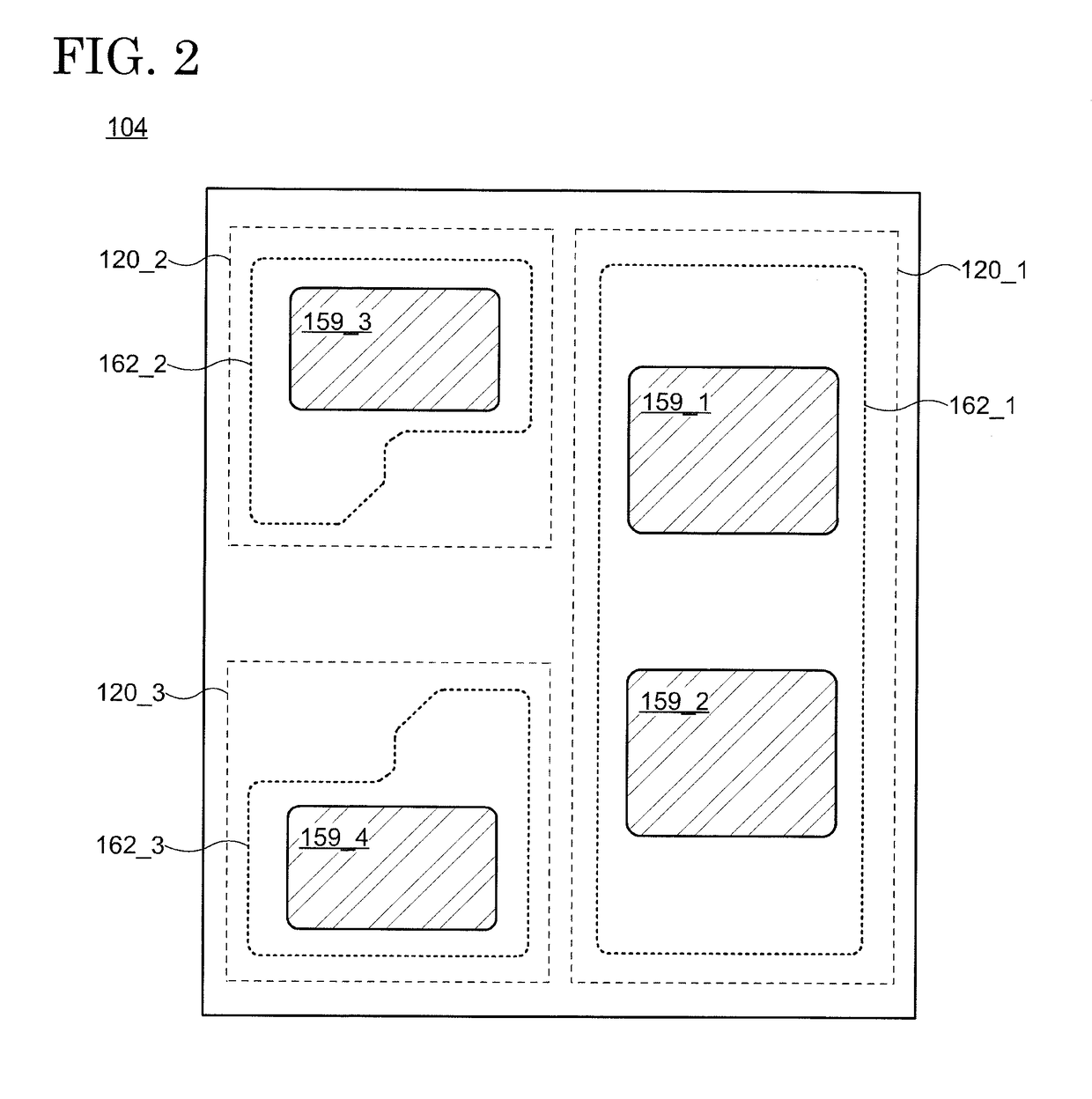

1. Outline Structure

[0030]A schematic top view of the display device 100 is shown in FIG. 1. The display device 100 has a substrate 102 over which a plurality of pixel groups 104 is formed. A display region 106 is defined by the plurality of pixel groups 104, and driver circuits for driving the pixel groups 104 are provided in a region (peripheral region) surrounding the display region 106. In the example shown in FIG. 1, two gate-side driver circuits 108 sandwiching the display region 106, and a source-side driver circuit 110 including analogue switches and the like are disposed. Wirings which are not illustrated extend from the display region 106, the gate-side driver circuits 108, and the source-side driver circuit 110 to a side of the substrate 102 and are exposed at an edge portion of the substrate 102 to form te...

second embodiment

[0053]In the present embodiment, a pixel group 104a with a structure different from that of the pixel group 104 described in the First Embodiment is explained. An explanation regarding the structure the same as or similar to that of the pixel group 104 may be omitted.

[0054]A schematic cross-sectional view of the pixel group 104a according to the present embodiment is shown in FIG. 6. The pixel group 104a is different from the pixel group 104 in that a thickness t4 of the third conductive layer 162c of the third light-emitting element 160_3 is larger than a thickness t3 of the third conductive layer 162c of the second light-emitting element 160_2. The thickness t3 is larger than the thickness t1 and smaller than the thickness t2. On the other hand, the thickness t4 may be the same as, larger than, or smaller than the thickness t2. Thus, one of the following relationships is satisfied.

t134≤t2

t1324

[0055]When the emission wavelength of the fourth electroluminescence layer 164_4 is lon...

third embodiment

[0056]In the present embodiment, a structure of the display device 100 and a manufacturing method thereof are explained. An explanation of the contents described in the First and Second Embodiments may be omitted.

1. Pixel Circuit

[0057]In each pixel 120, a variety of elements for driving the light-emitting element 160 is disposed in addition to the light-emitting element 160, by which a pixel circuit is fabricated. The structure of the pixel circuit may be arbitrarily selected, and an example is shown as an equivalent circuit in FIG. 7.

[0058]The pixel circuit shown in FIG. 7 includes a driving transistor 121, a first switching transistor 122, a second switching transistor 123, a storage capacitor 124, and a supplementary capacitor 125 in addition to the light-emitting element 160. The light-emitting element 160 is disposed between a high-potential power-source line 126 and a low-potential power-source line 127. The high-potential power-source line 126 is provided with a high potentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com