Patents

Literature

32results about How to "Property variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

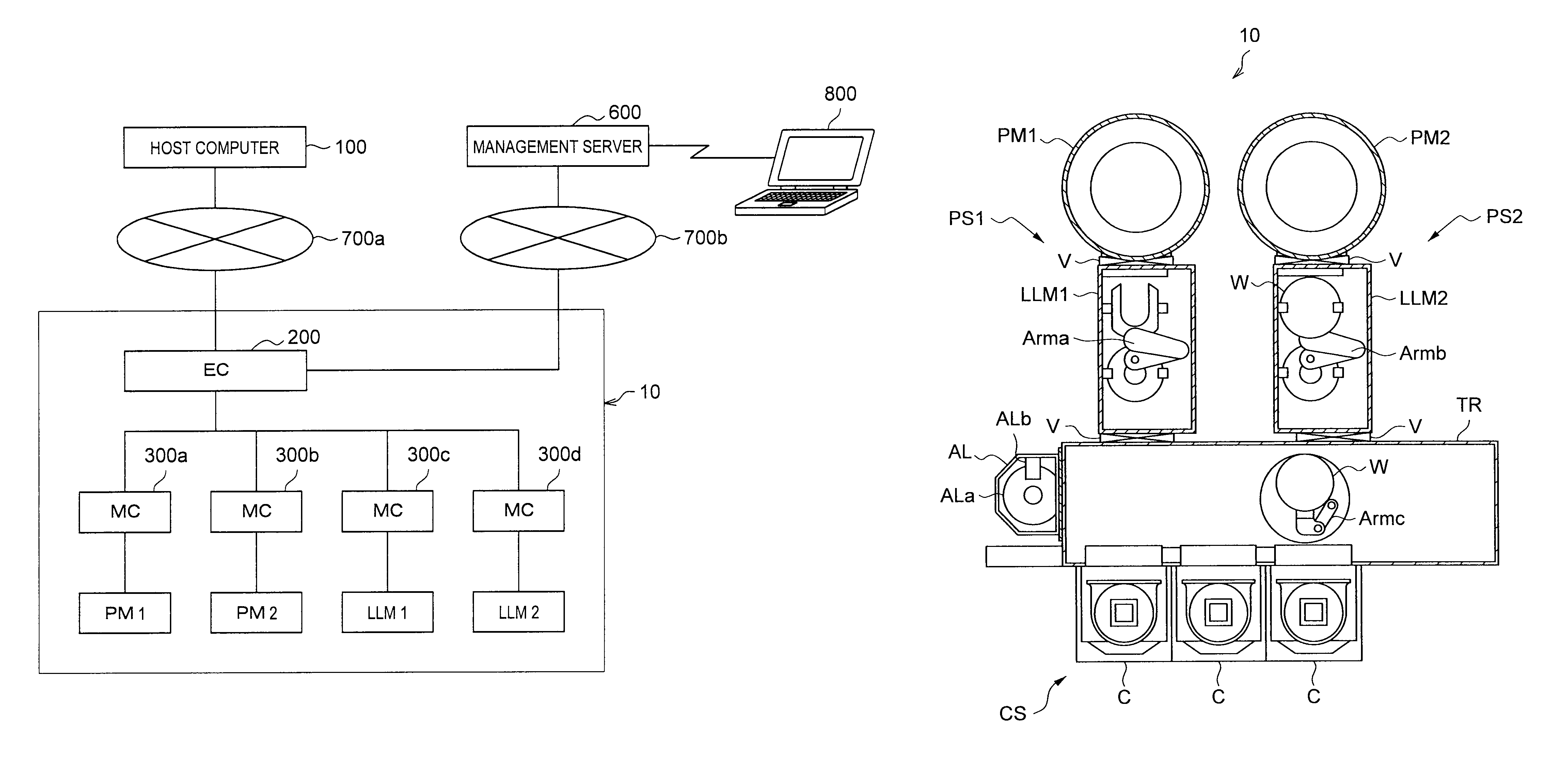

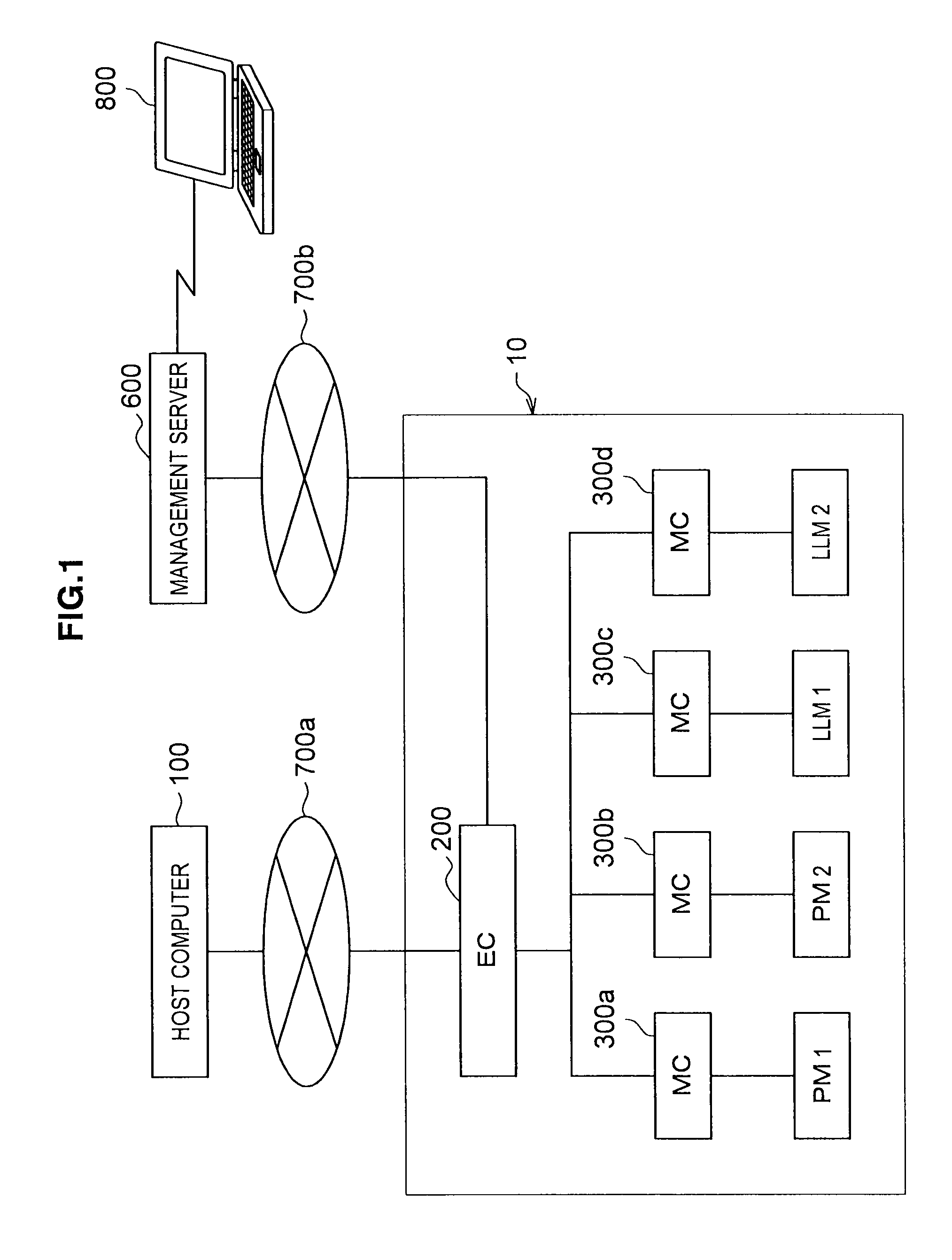

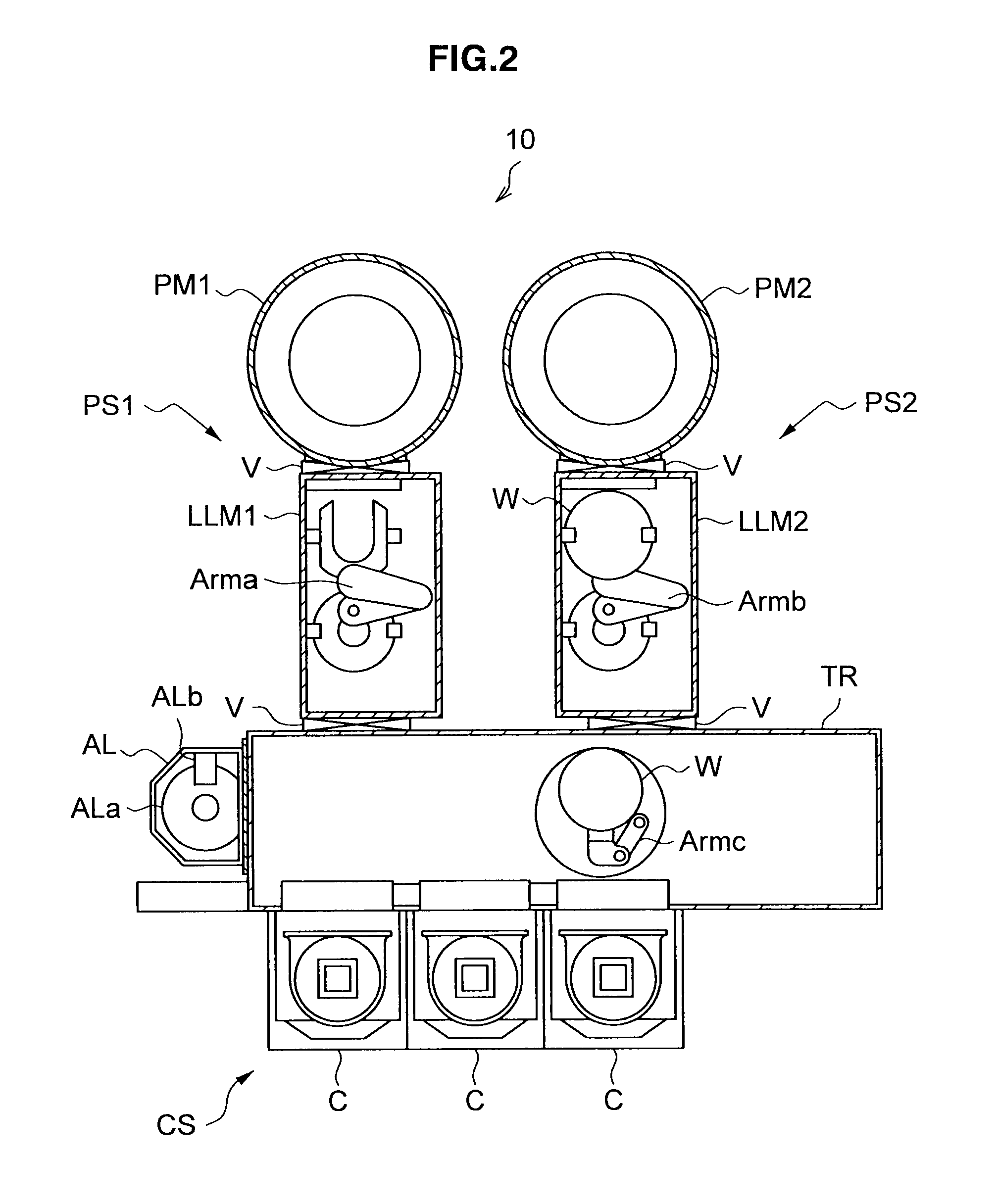

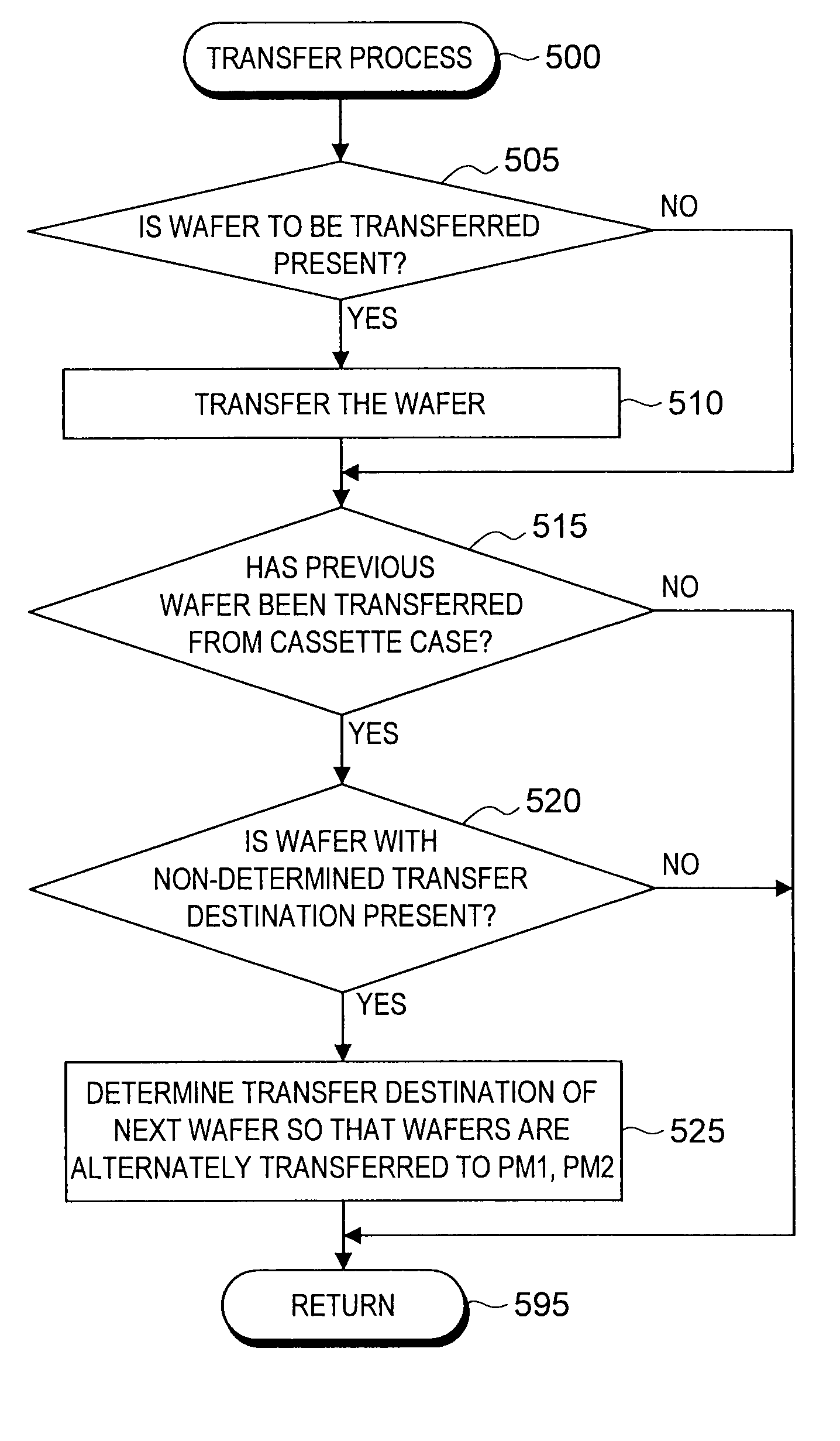

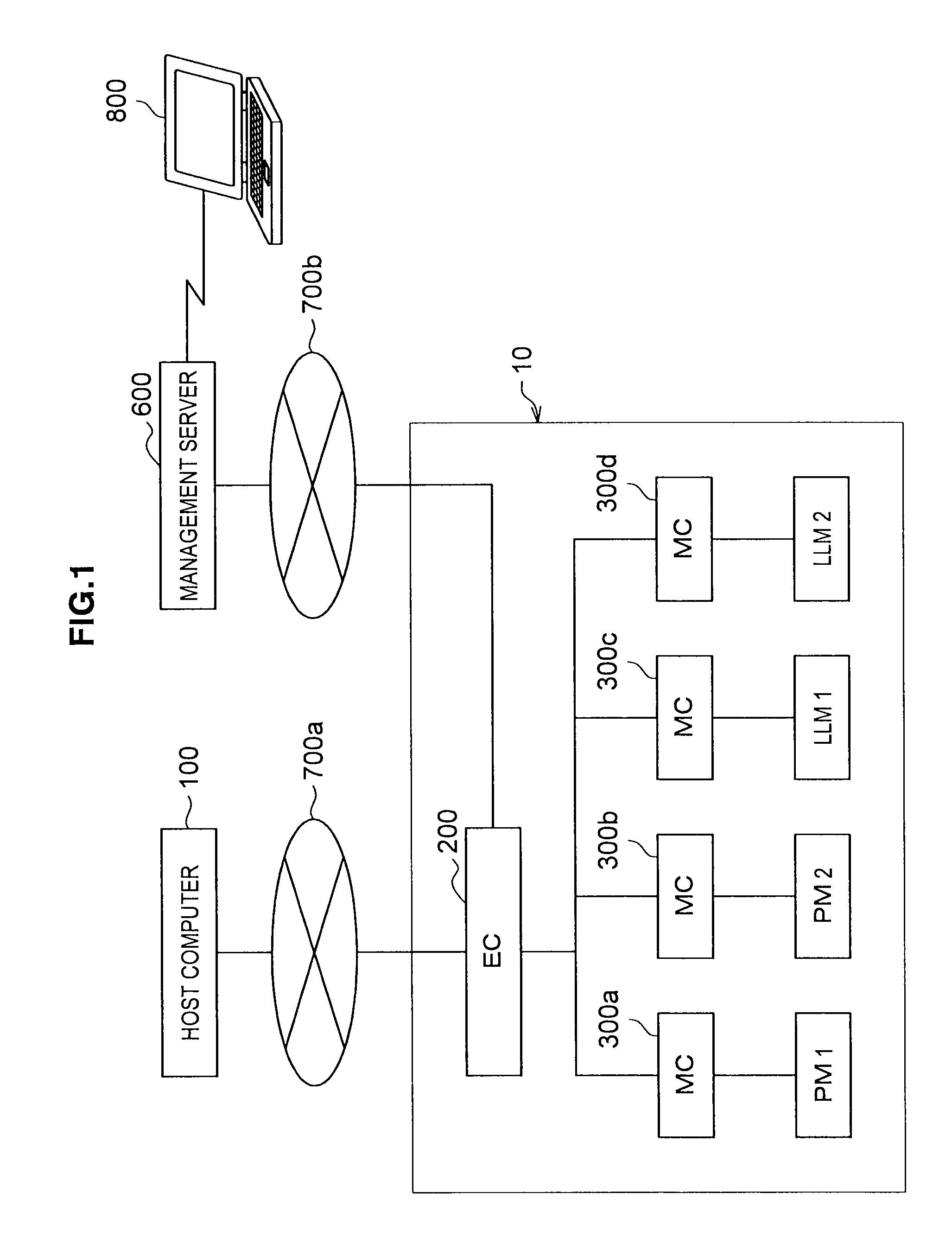

Device for controlling processing system, method for controlling processing system and computer-readable storage medium stored processing program

ActiveUS8055378B2Production of product can be suppressedIncrease productionProgramme controlDigital data processing detailsProcess moduleComputer module

A processing system includes process modules, load lock modules, an equipment controller, and a machine controller. The equipment controller controls transfer and processing of wafers in the processing system. A transfer destination determining portion determines the transfer destination of each wafer such that each wafer is sequentially transferred to a normally operating process module. When an abnormality occurs in a process module, an evacuation portion temporarily evacuates to a cassette stage the wafer determined is to be transferred to the abnormal process module and that has not yet been transferred to the abnormal process module. When a new transfer destination of the evacuated wafer is determined, if a process that is performed immediately before processing the evacuated wafer in the processing module as the new transfer destination satisfies a predetermined condition, a transfer inhibition portion inhibits the transfer of the evacuated wafer to the new transfer destination.

Owner:TOKYO ELECTRON LTD

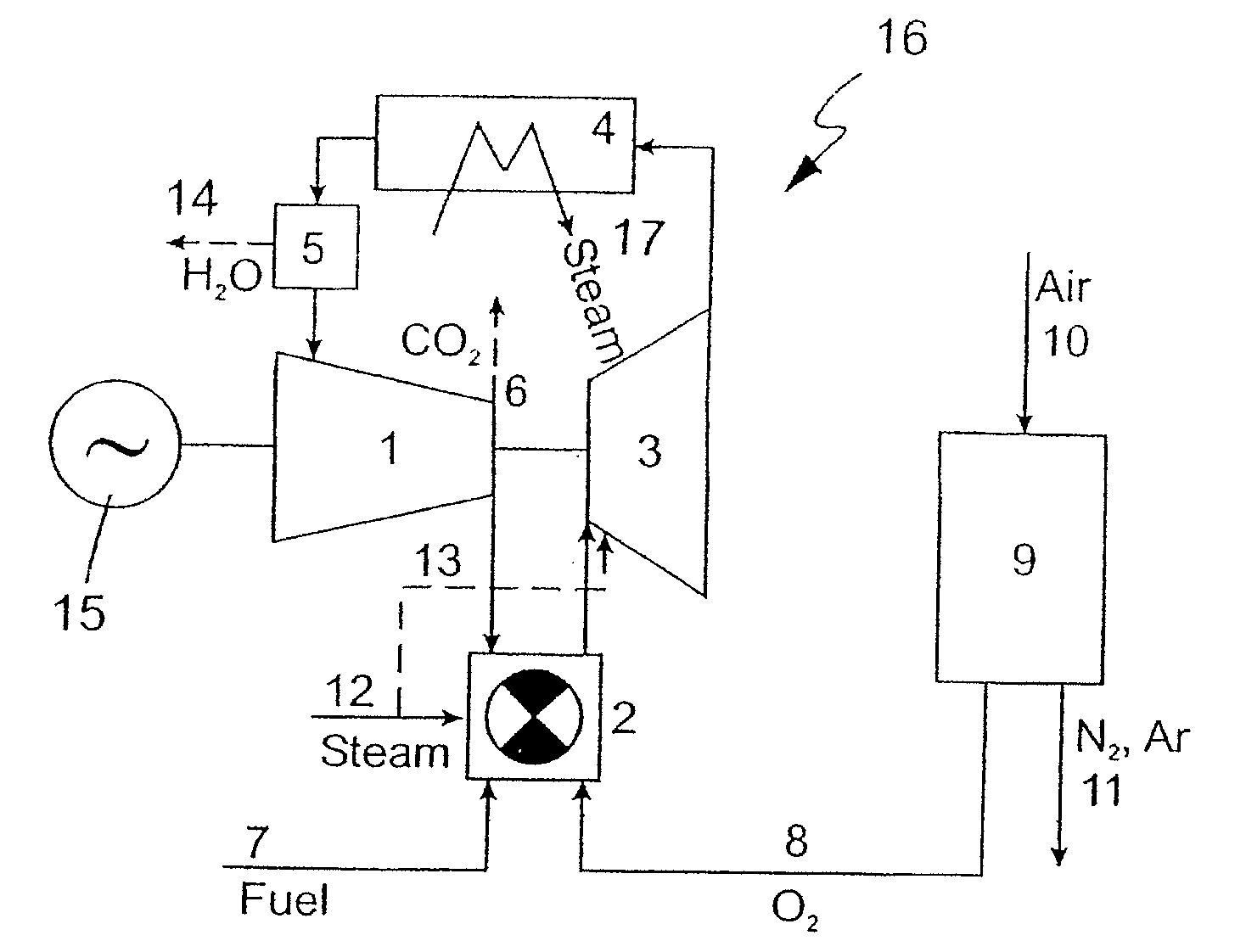

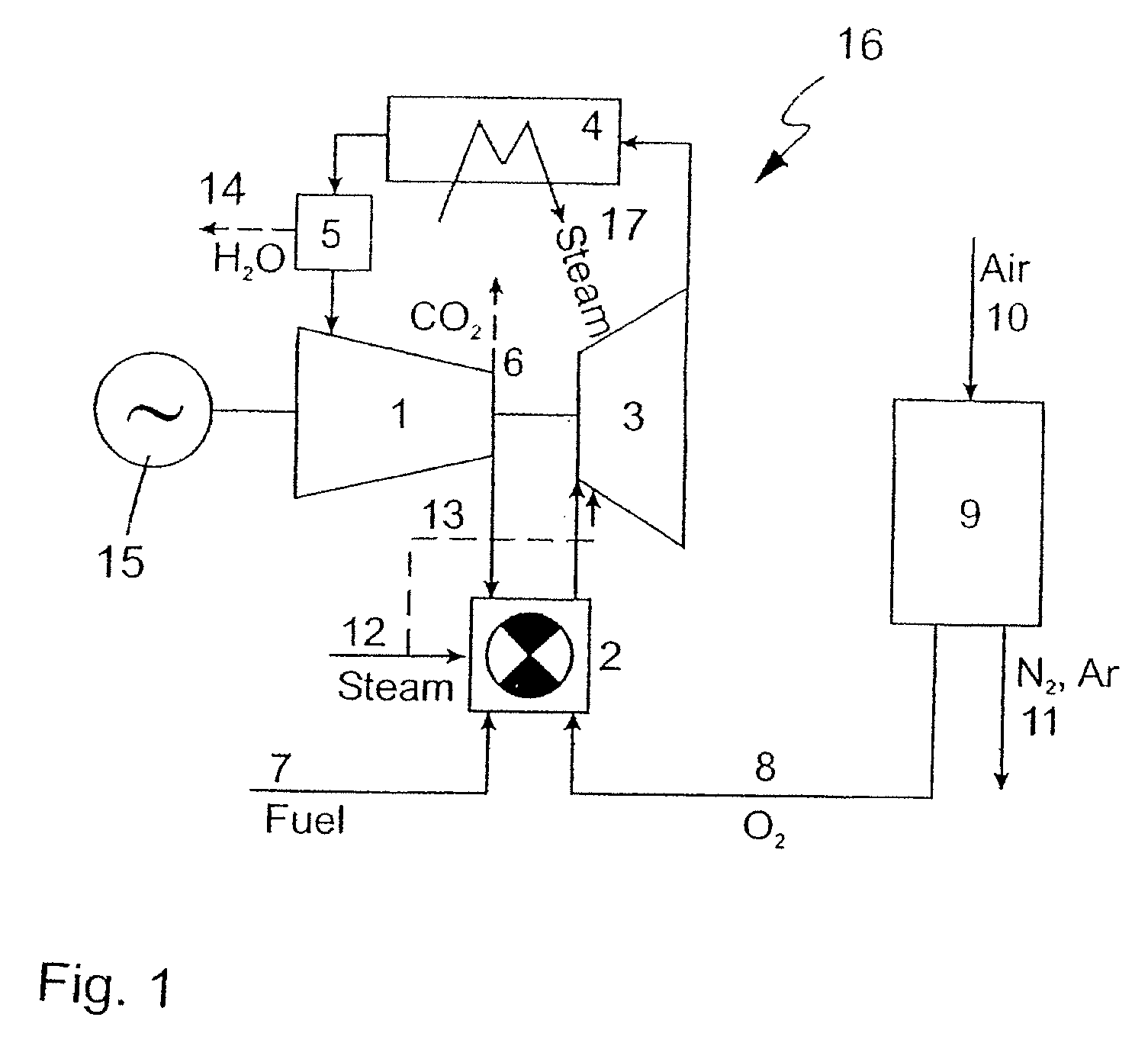

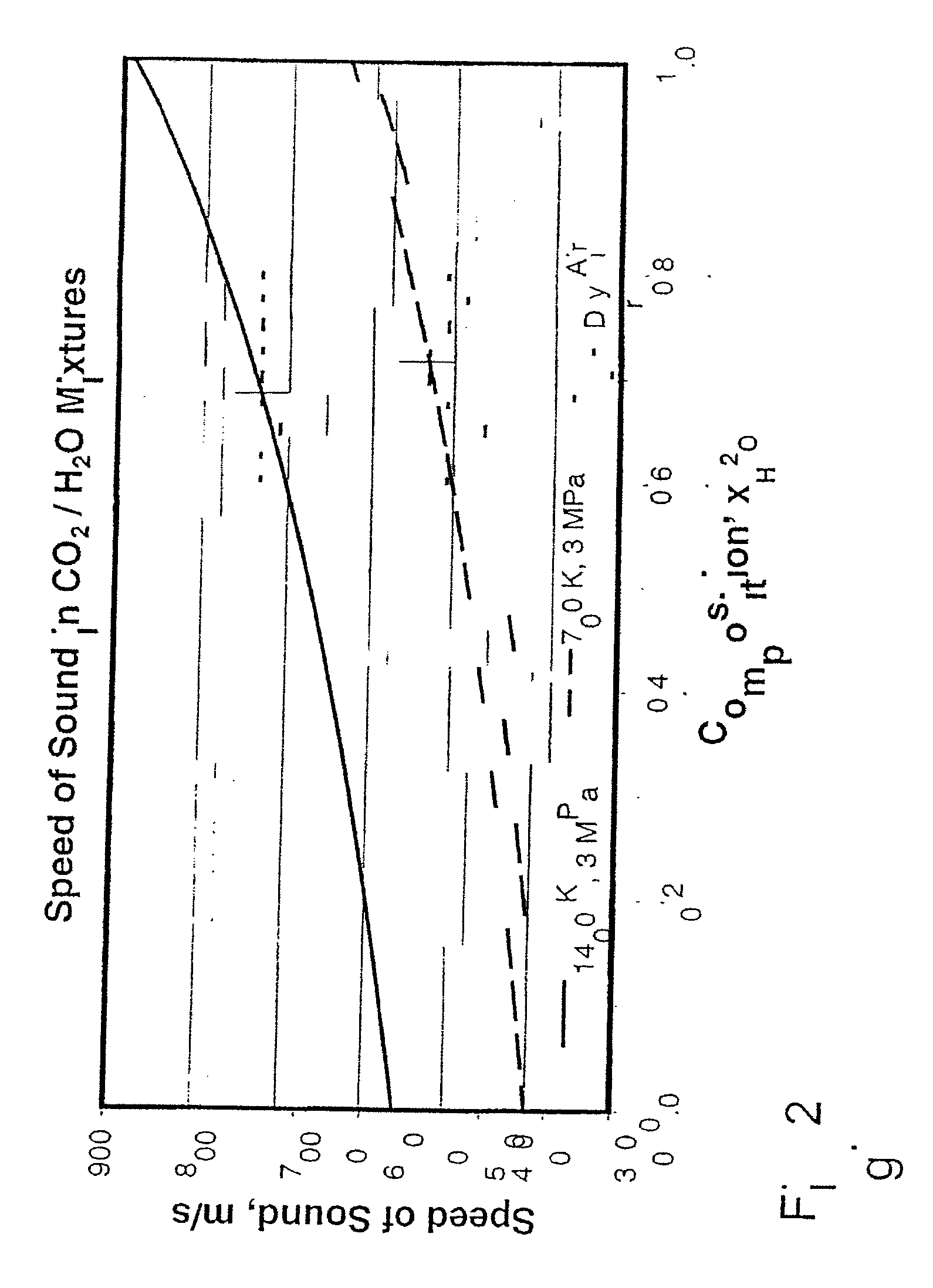

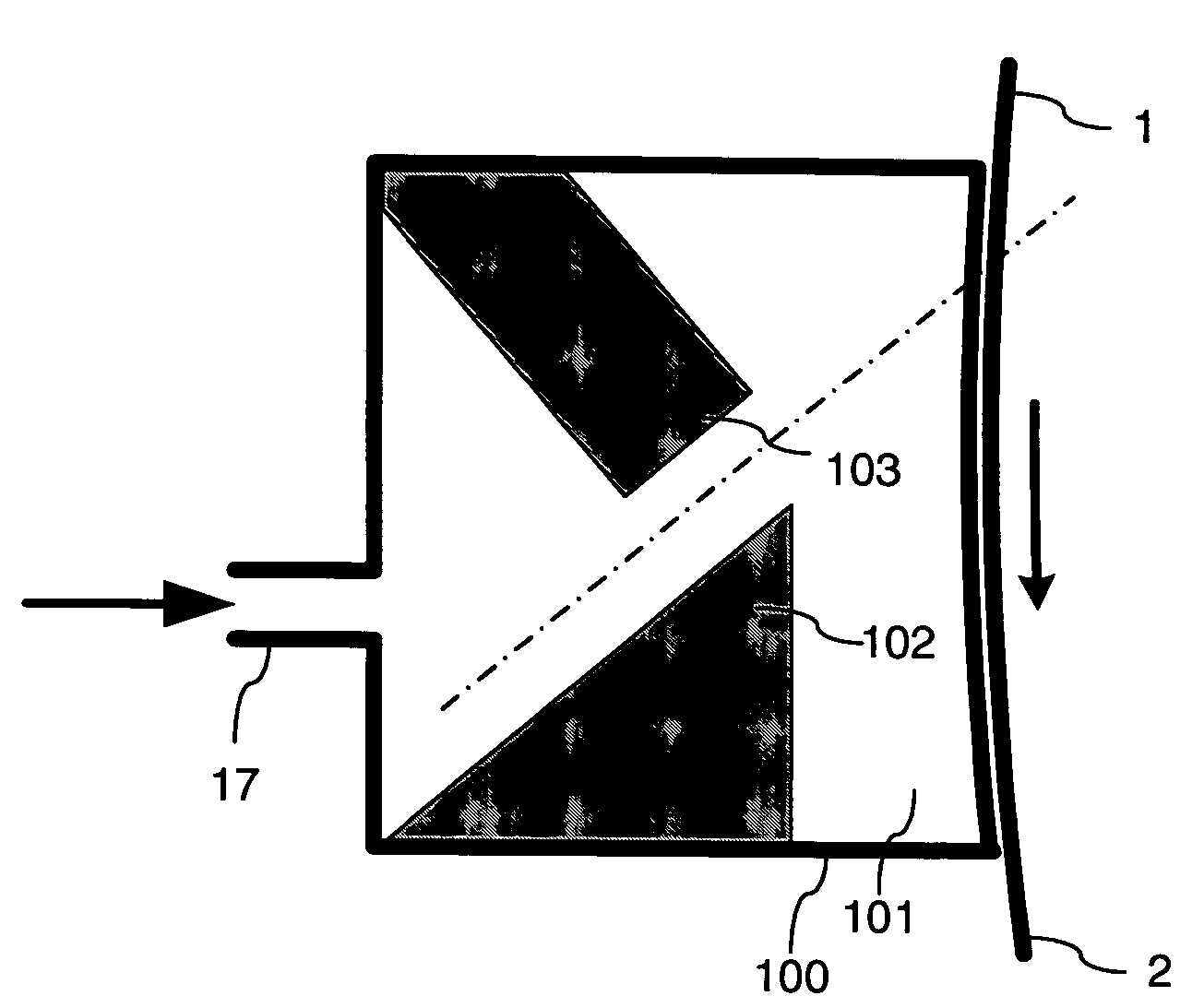

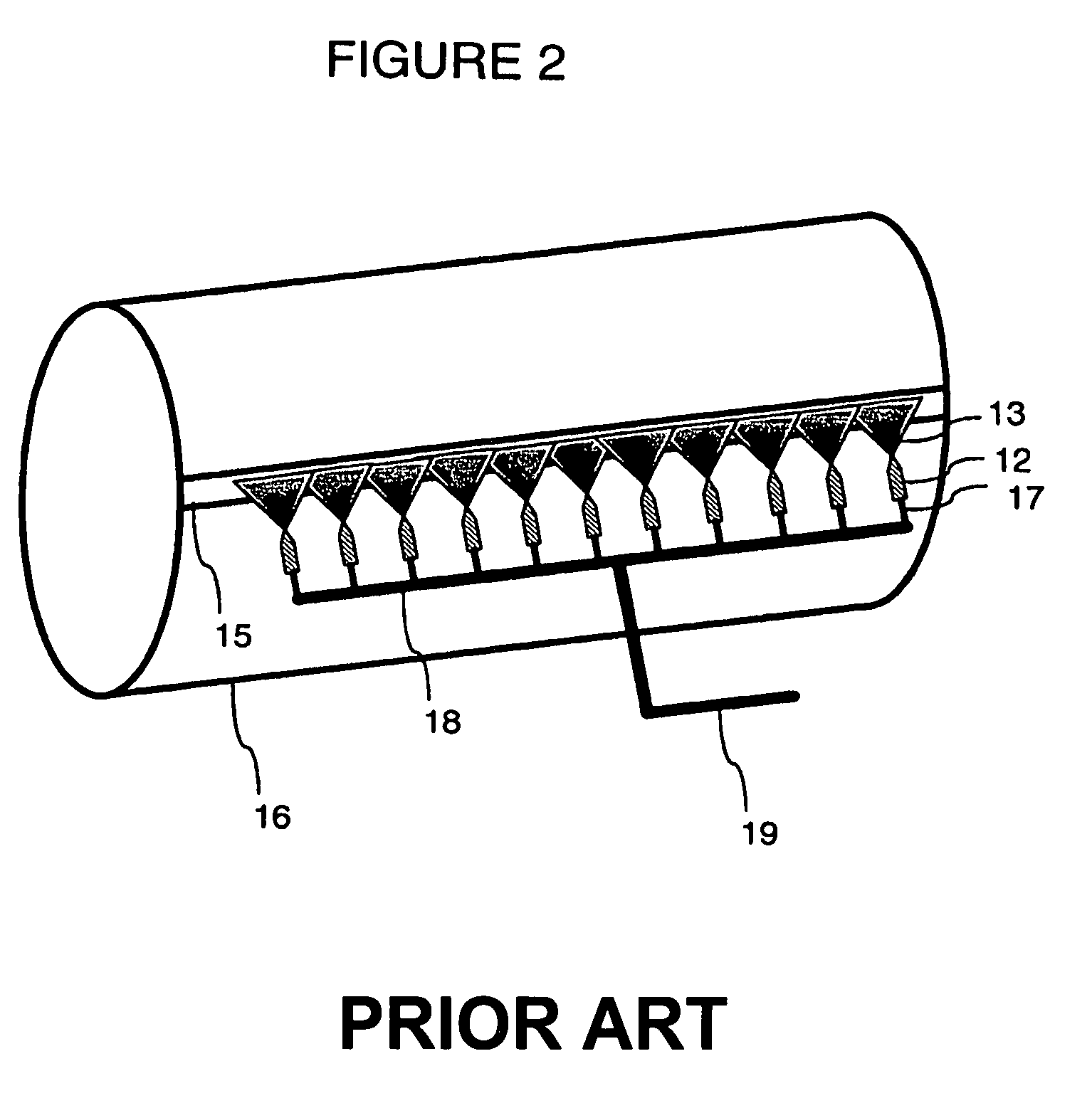

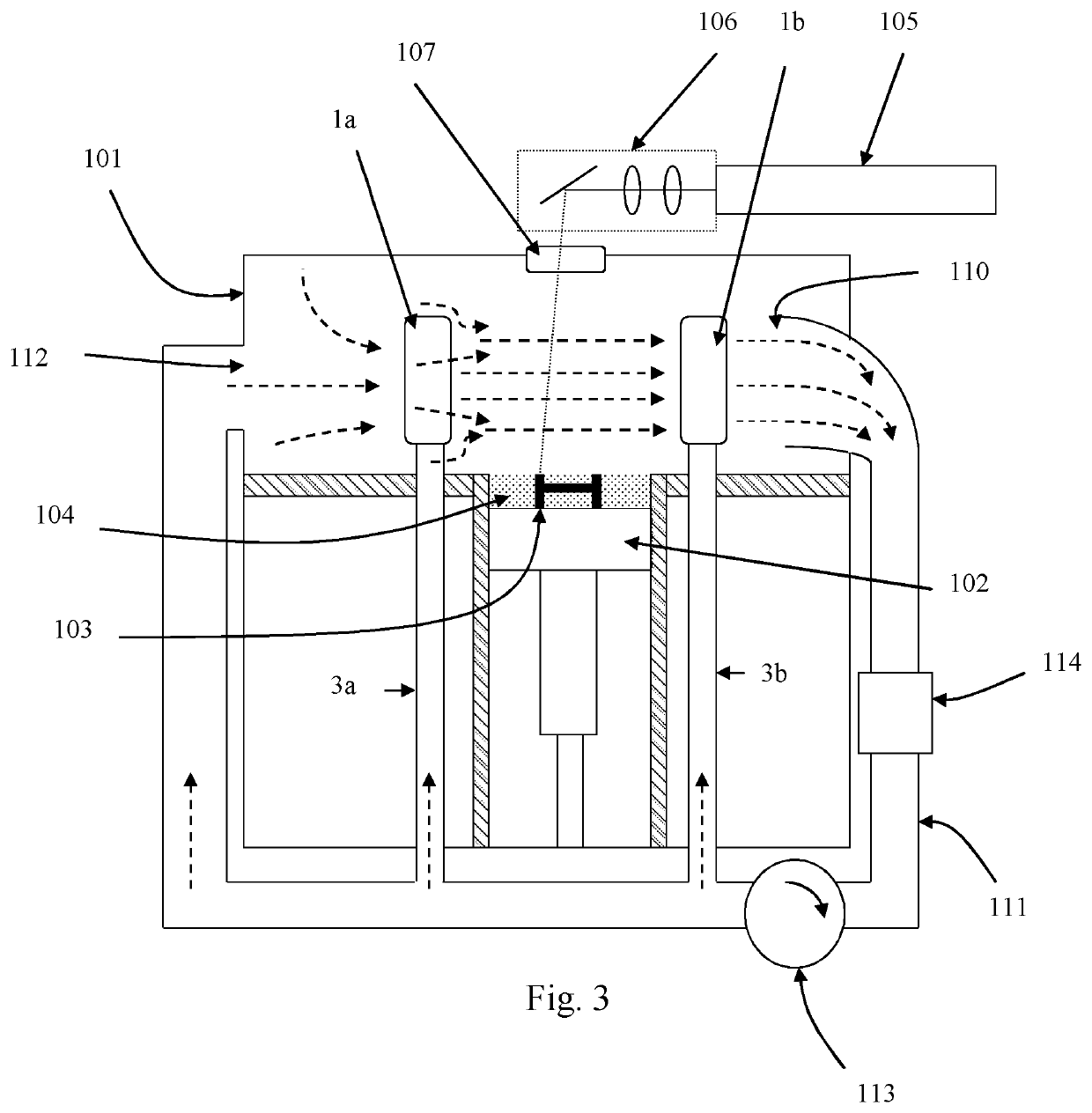

Gas turbine plant for a working medium in the form of a carbon dioxide/water mixture

InactiveUS20080066443A1Simple and cost-effective wayProperty variationGas turbine plantsEngine componentsCombustion chamberHydrocotyle bowlesioides

A gas turbine plant with a compressor, a combustion chamber, a turbine and at least one heat sink is operated with a working medium in the form of a carbon dioxide / water mixture. A hydrocarbon reacts as fuel with oxygen in the combustion chamber, and the excess carbon dioxide and water thereby occurring is tapped from the circuit. The compressor and the turbine have in each case a rotor with moving blades and a casing with flow ducts and with guide blade cascades. In the compressor and / or the turbine, matching to the expansion behavior of the working medium, which is different from that of air, is brought about by modifications of the flow ducts, of the moving blades and / or of the guide blade cascades.

Owner:ALSTOM TECH LTD

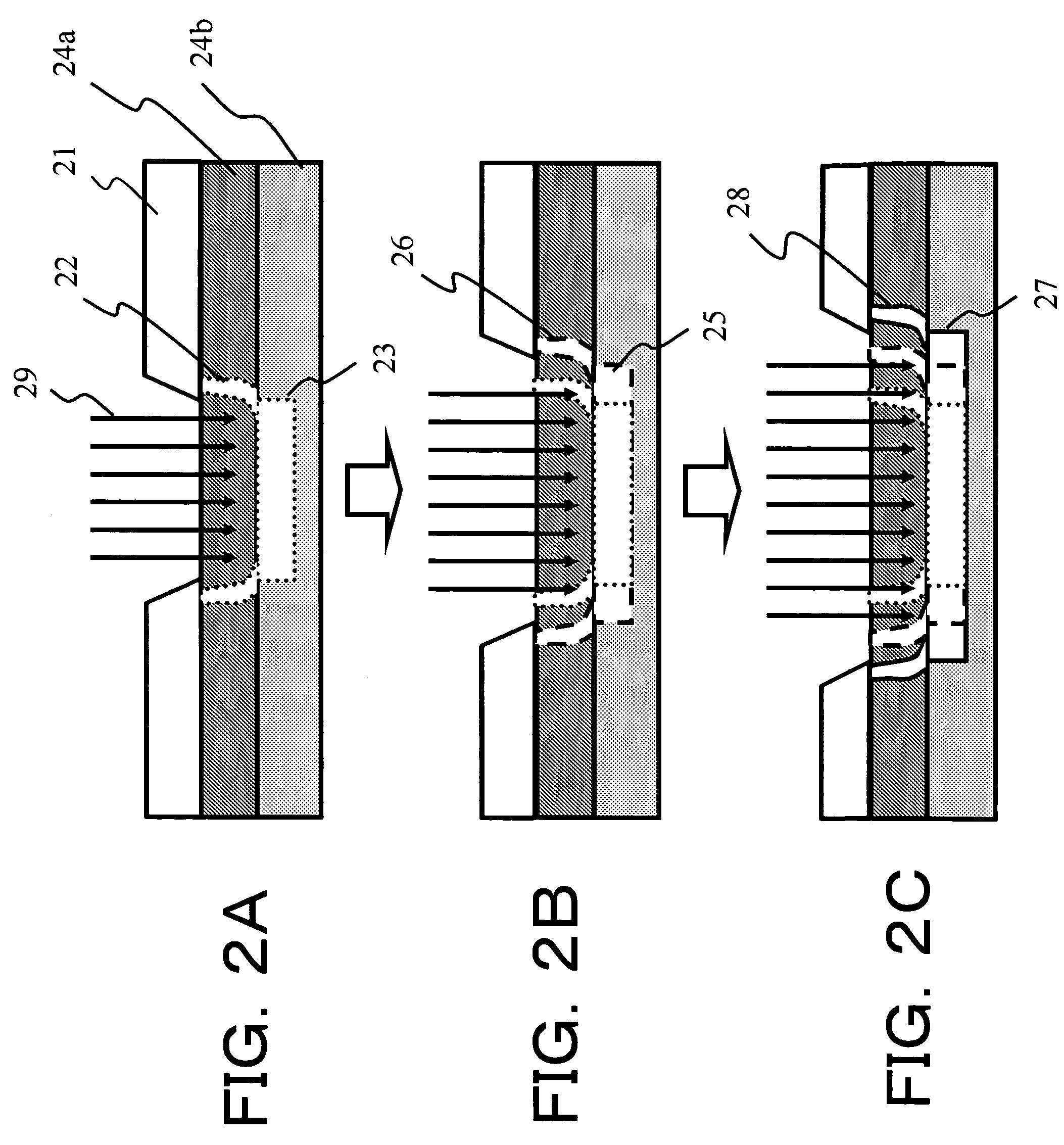

Soft film

InactiveUS7364687B2Improve functionalityImprove propertiesSpray nozzlesCeramic shaping apparatusElectrical and Electronics engineeringThin membrane

Owner:TREDEGAR FILM PROD CORP

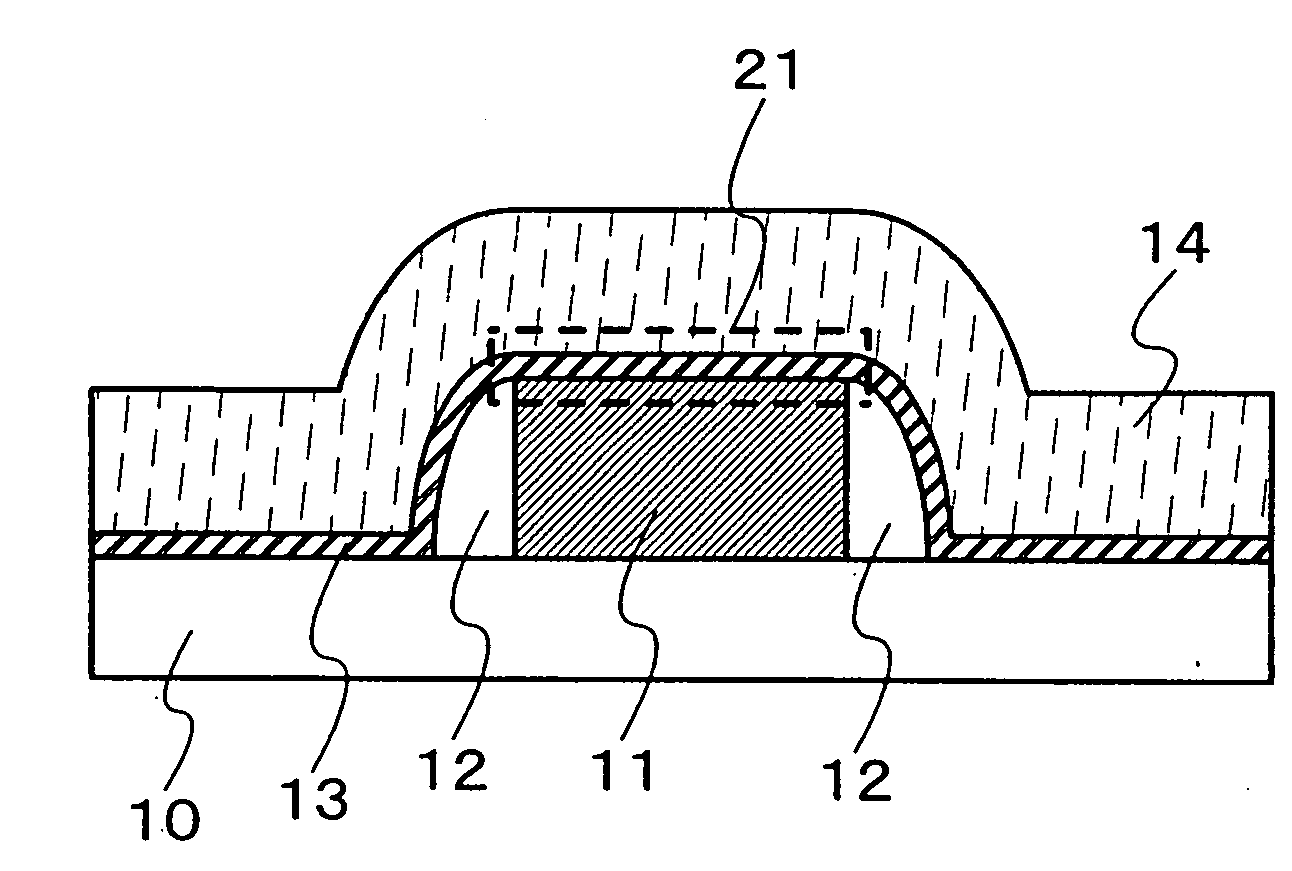

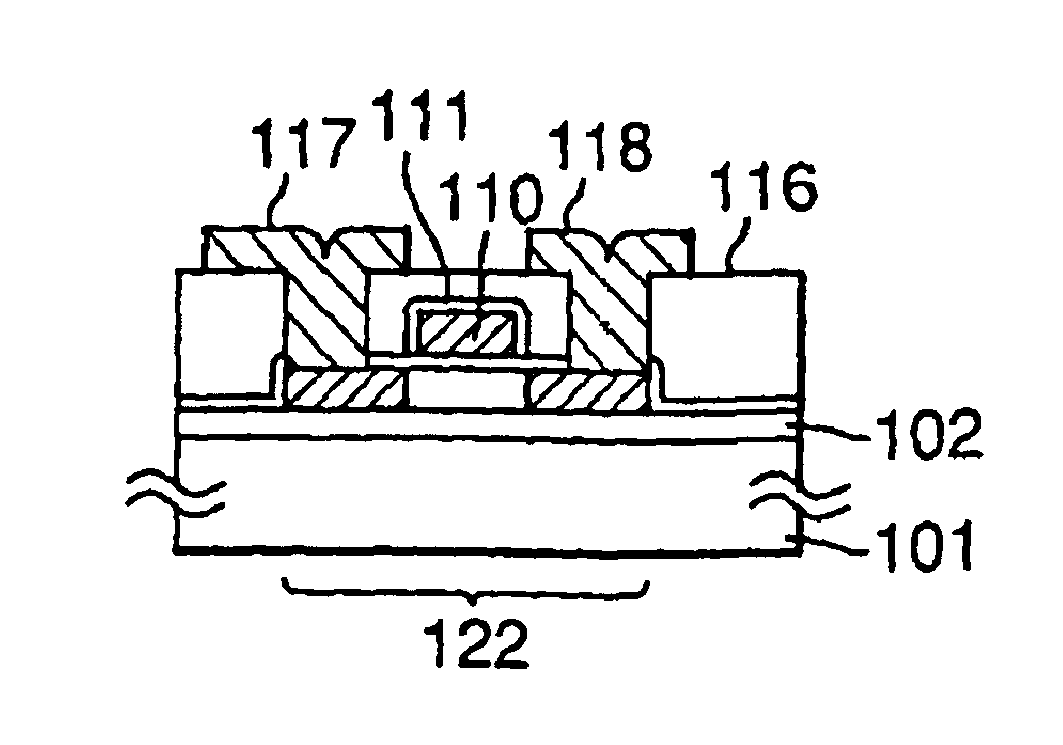

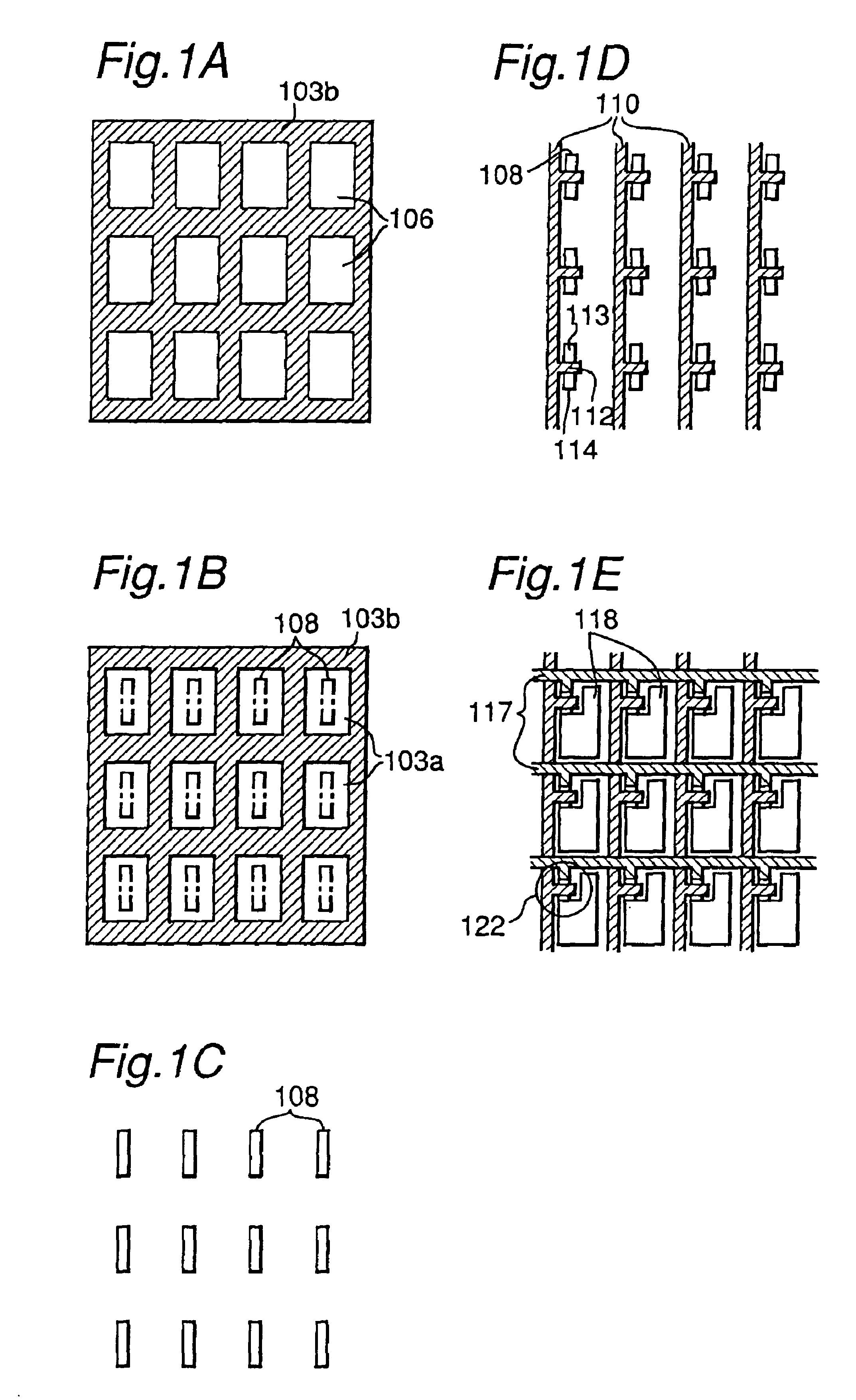

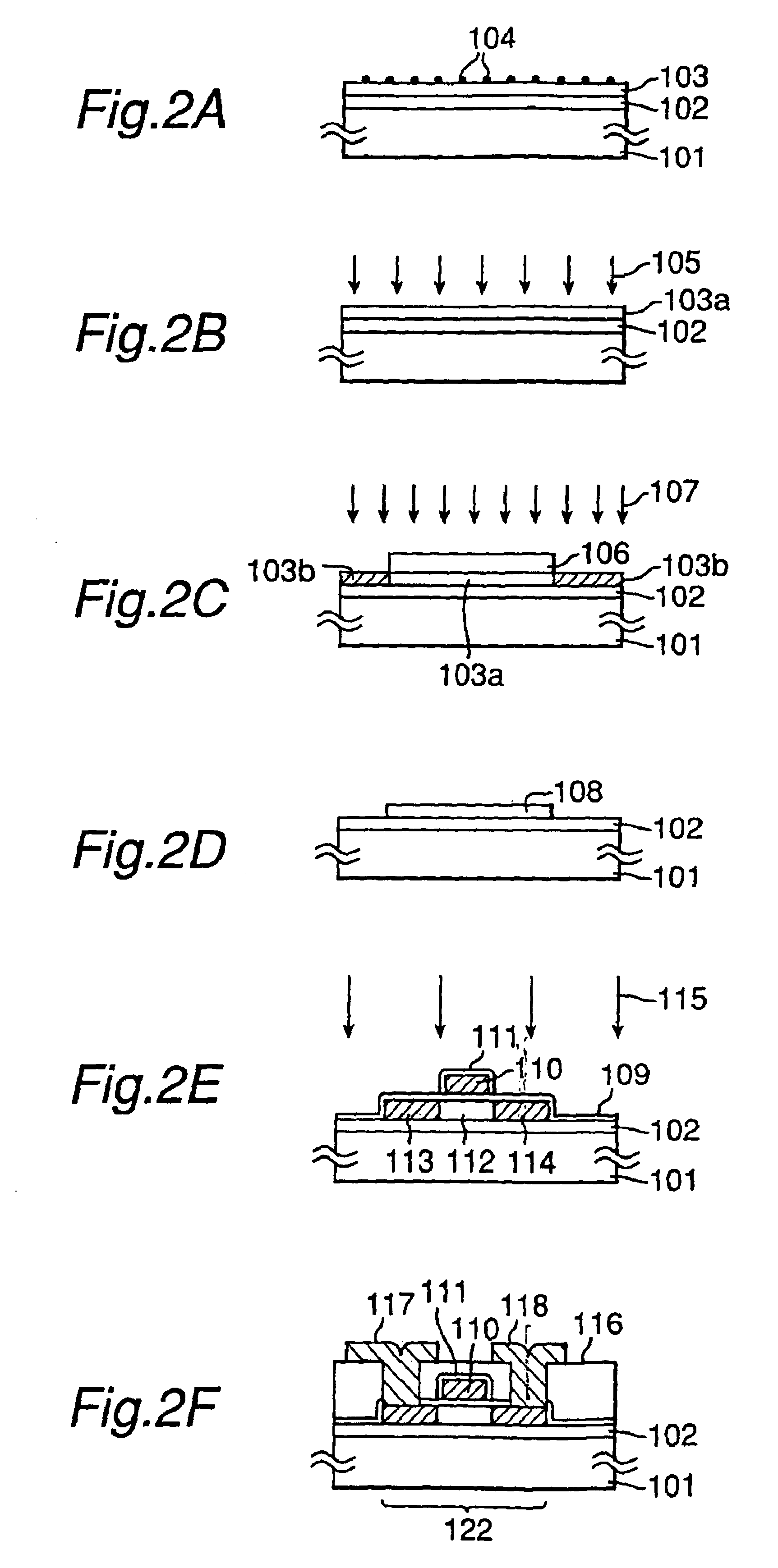

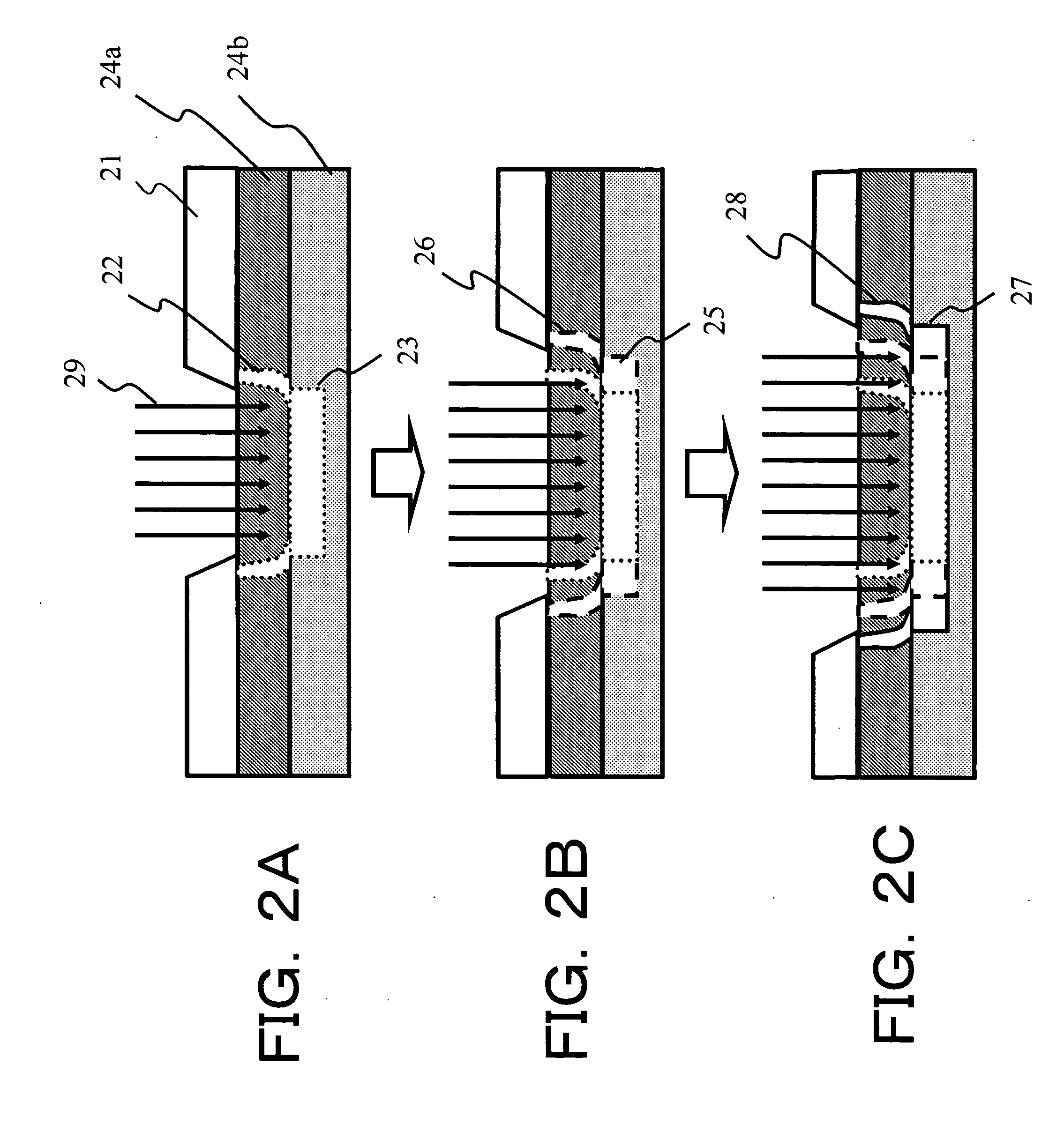

Semiconductor device and method for manufacturing the same

InactiveUS20080116500A1Reduce variationProperty variationTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor device which does not reduce writing property of a memory element and a method for manufacturing the same are proposed even in the case of forming a silicon film at a step portion formed by a surface of a substrate and a wiring formed over the substrate. The semiconductor device includes a plurality of the memory elements comprising a first electrode formed over a substrate having an insulating surface, sidewall insulating layer formed on side surface of the first electrode, a silicon film formed to cover the first electrode and the sidewall insulating layer, and a second electrode formed over the silicon film, and at least one of the first electrode and the second electrode is formed with a material being capable of being alloyed with the silicon film.

Owner:SEMICON ENERGY LAB CO LTD

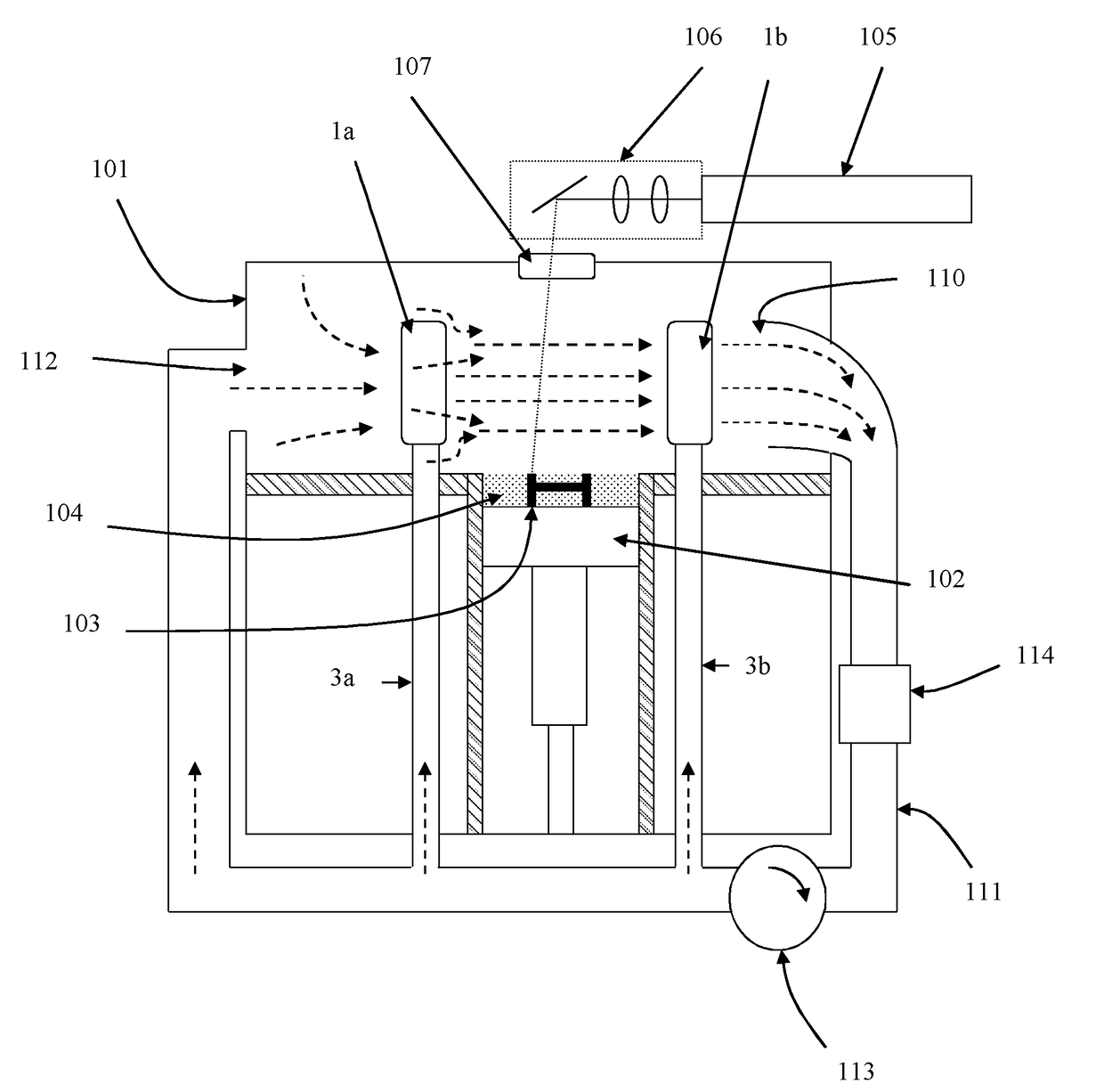

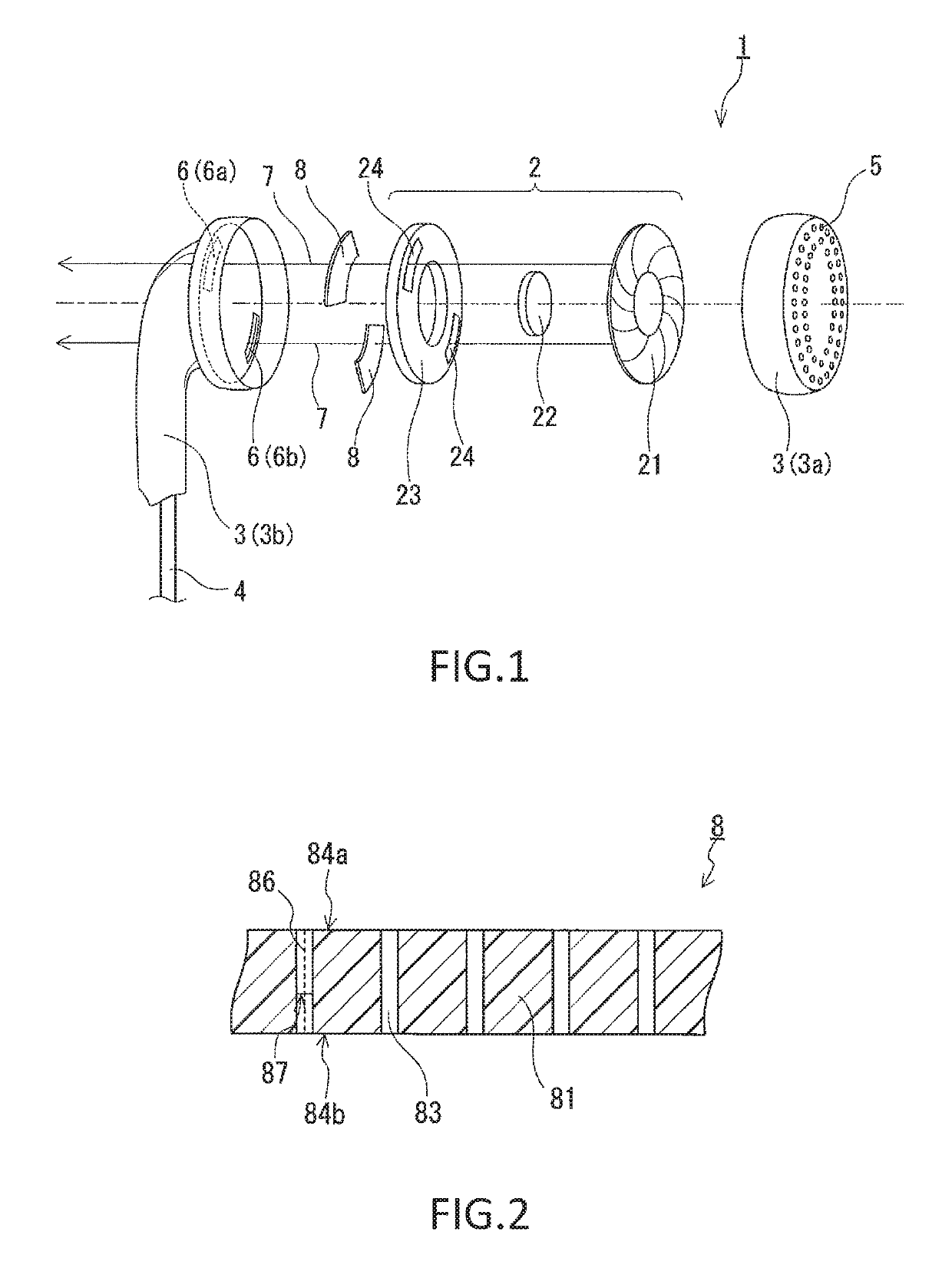

Additive manufacturing apparatus and a flow device for use with such apparatus

ActiveUS20170120330A1Improve entrapmentImprove transportAdditive manufacturing apparatusIncreasing energy efficiencyManufactured apparatusEngineering

Owner:RENISHAW PLC

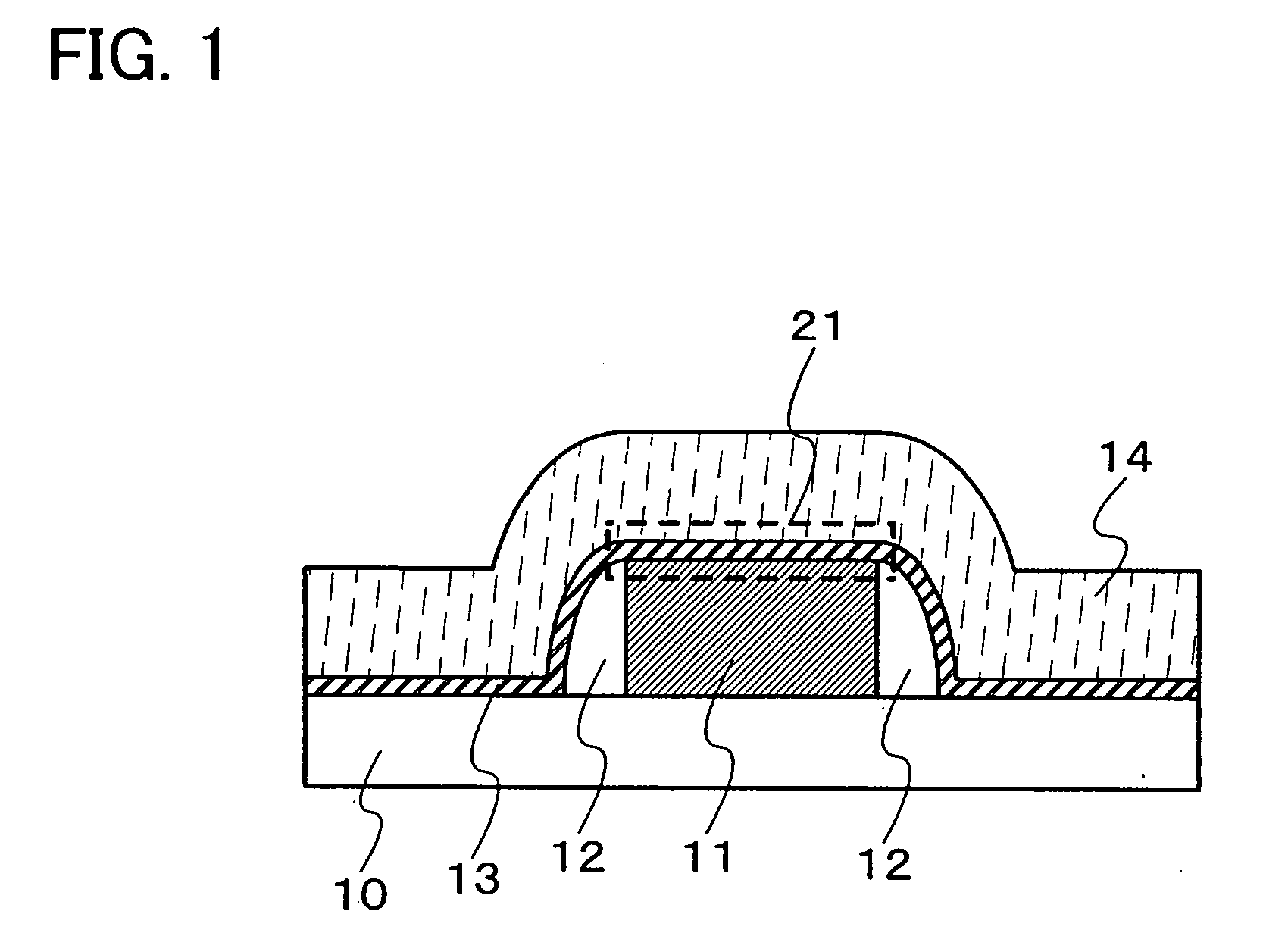

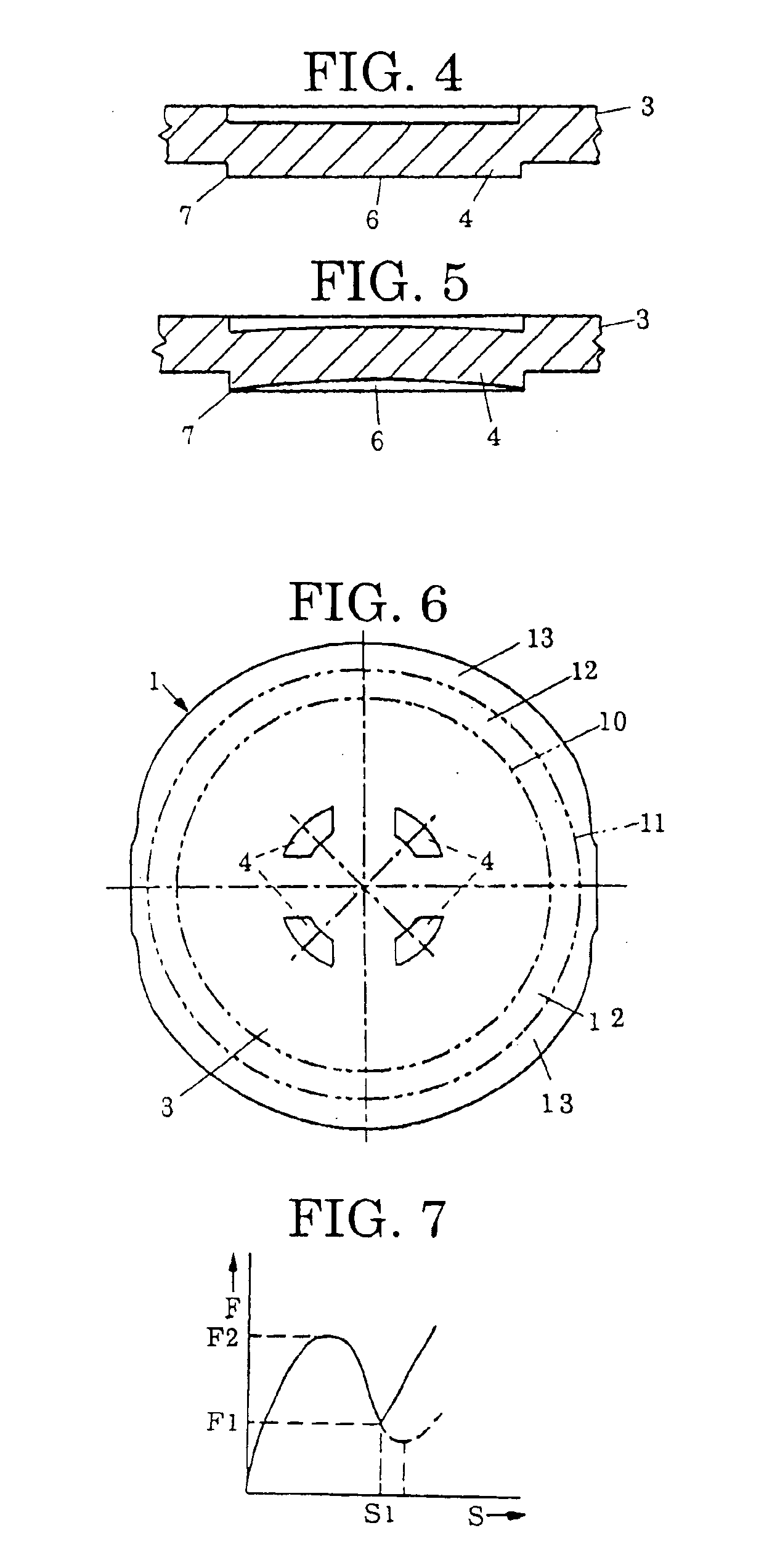

Method of producing semiconductor device

InactiveUS6927107B1Improve performanceProperty variationTransistorPolycrystalline material growthAmorphous siliconSilicon membrane

In a production method of a semiconductor device, a catalyst element, e.g. Ni, is added to an amorphous silicon film, formed on a substrate with an insulating surface, for promoting crystallization of the amorphous silicon film. Thereafter, the amorphous silicon film is subjected to heat treatment to cause crystal growth therein. Next, the crystal growth is stopped in a state where minute amorphous regions (uncrystallized regions) remain in the film. Next, the silicon film is irradiated with strong light (laser light) so as to be further crystallized. As a result, a crystalline silicon film that has high quality and is excellent in uniformity is obtained.

Owner:SHARP KK

Method of inhibiting water content variation of composition and use thereof

InactiveUS20060172059A1Suppress mutationReduce nutritionCosmetic preparationsPre-extraction tea treatmentAdditive ingredientMoisture

The present invention has objects for providing a method for inhibiting the moisture variation in compositions, a composition whose moisture variation is inhibited, and an agent for inhibiting the moisture variation in compositions. The objects are solved by providing a method for inhibiting the moisture variation in compositions comprising incorporating into a composition a saccharide-derivative(s) of α,α-trehalose as an effective ingredient, a composition whose moisture variation is inhibited by incorporating the saccharide-derivative(s), a moisture variation inhibiting agent containing the saccharide-derivative(s) as an effective ingredient, and uses thereof.

Owner:TAKEUCHI KANOU +2

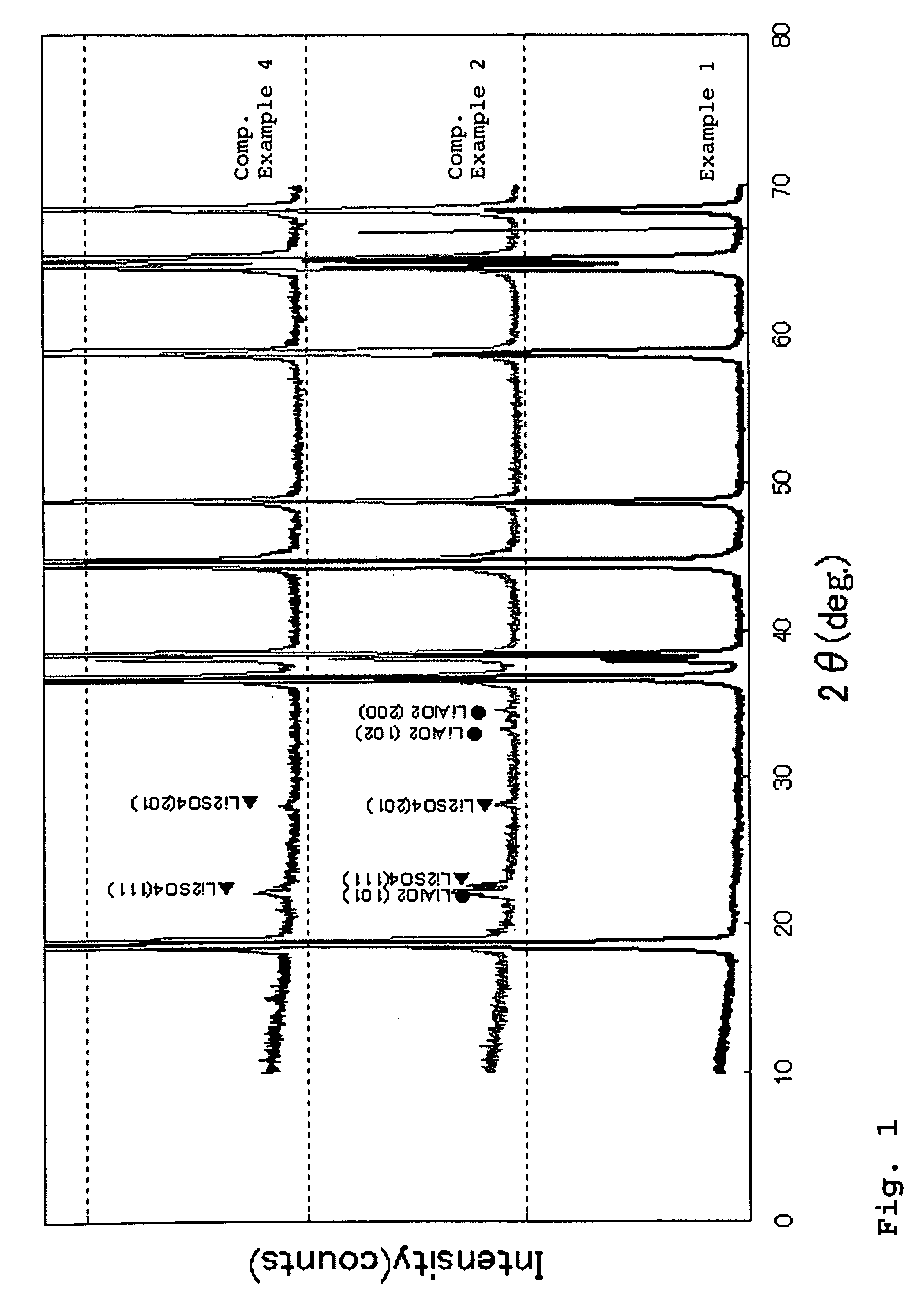

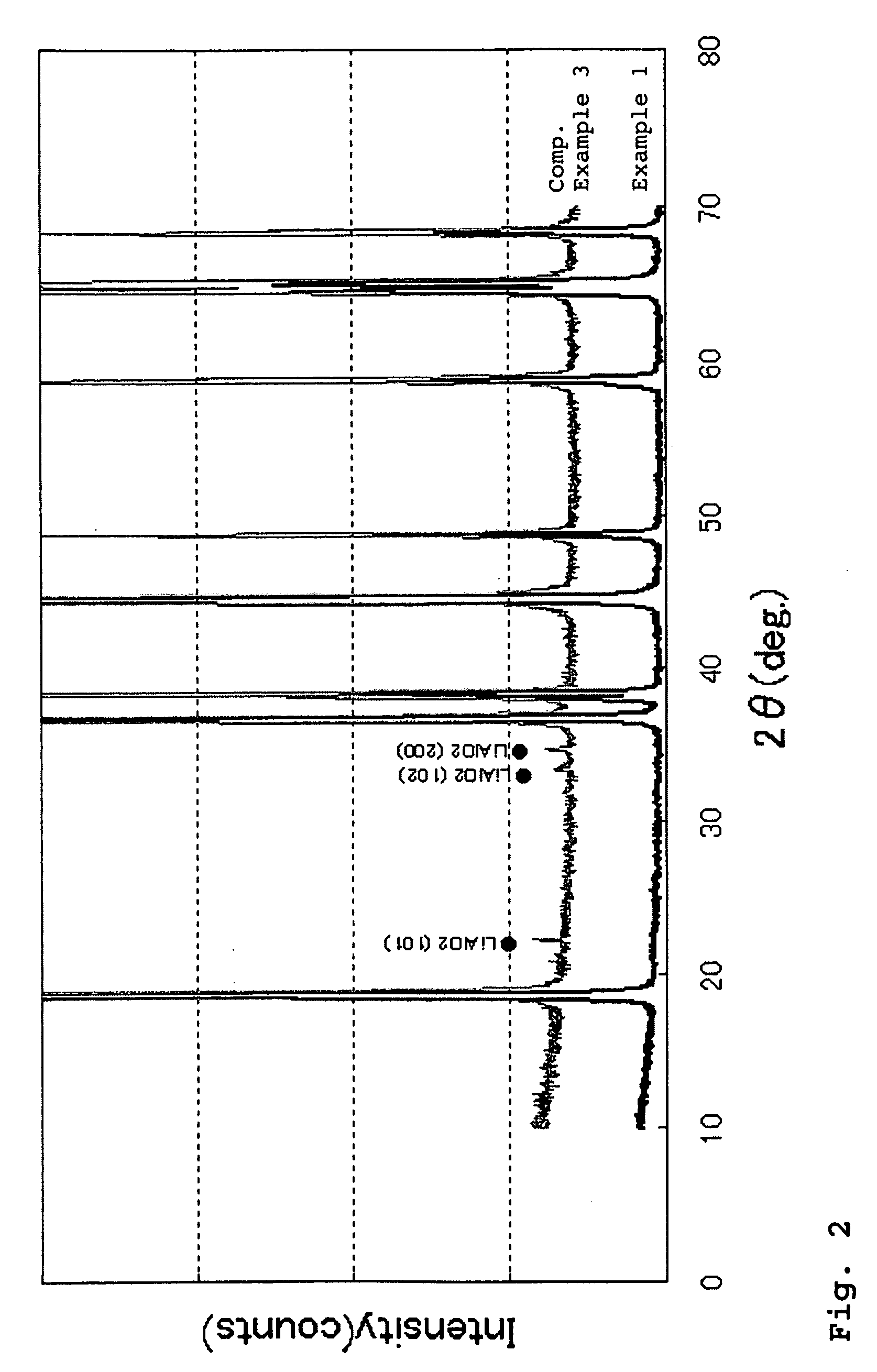

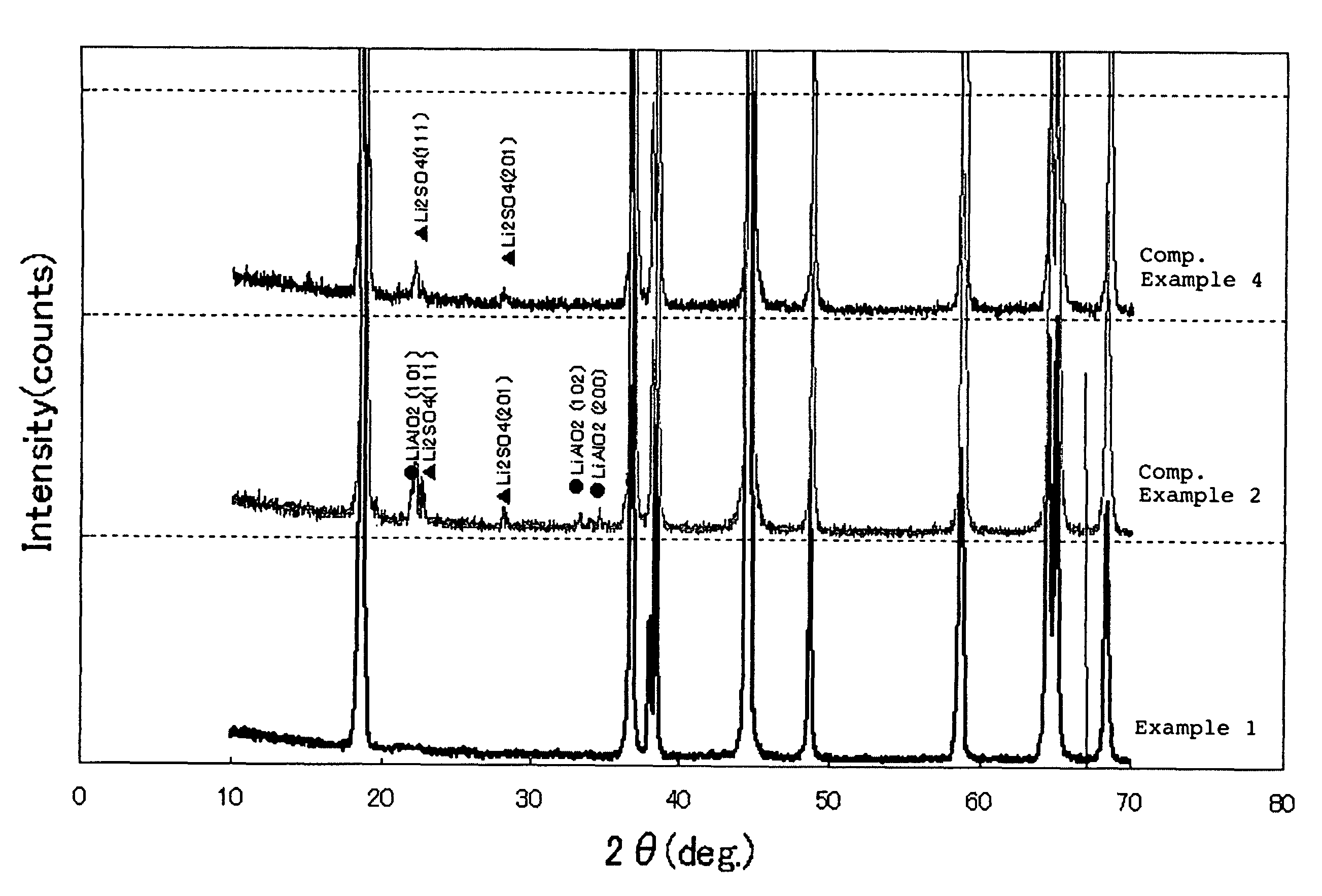

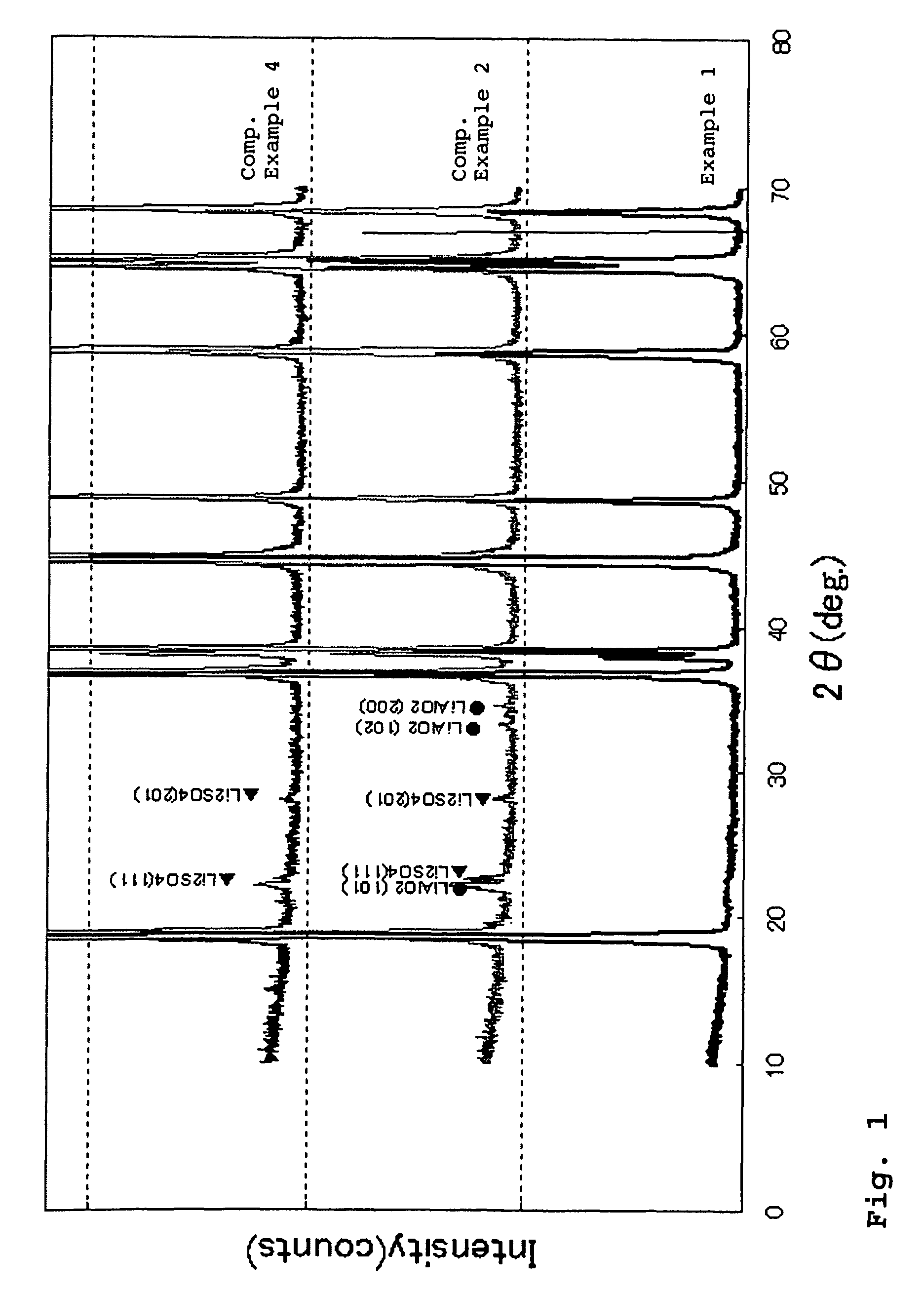

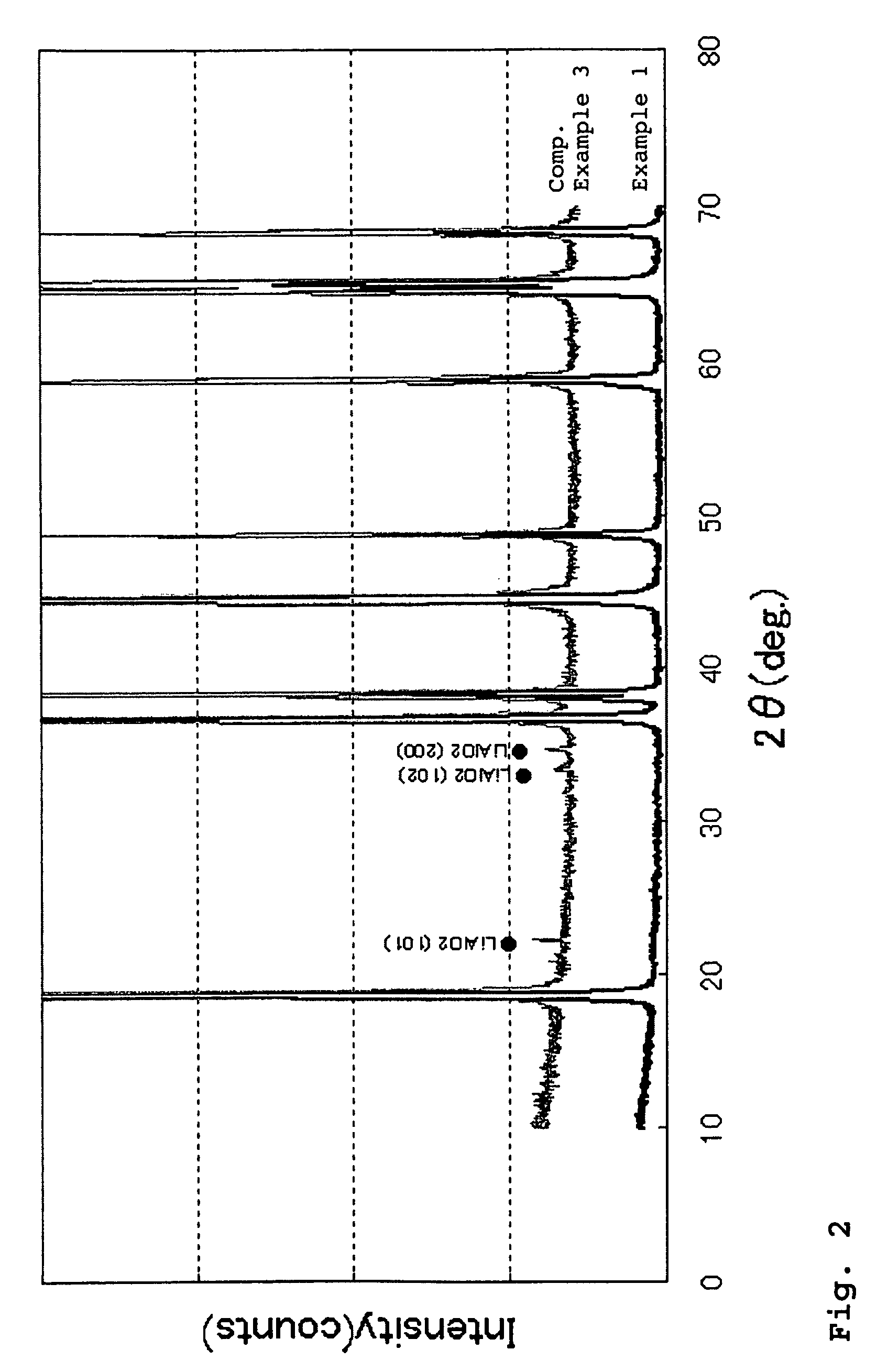

Li-Ni COMPOSITE OXIDE PARTICLES FOR NON-AQUEOUS ELECTROLYTE SECONDARY CELL, PROCESS FOR PRODUCING THE SAME, AND NON-AQUEOUS ELECTROLYTE SECONDARY CELL

ActiveUS20090272940A1Reduce variationInhibitionElectrode manufacturing processesConductive materialPhysical chemistrySULFATE ION

The present invention relates to Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a large charge / discharge capacity, an excellent packing density and excellent storage performance. The Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a composition represented by the formula:LixNi1-y-zCoyAlz02 in which 0.9<x<1.3; 0.1<y<0.3; and 0<z<0.3, wherein the composite oxide particles have a rate of change in specific surface area of not more than 10% as measured between before and after applying a pressure of 1 t / cm2 thereto, and a sulfate ion content of not more than 1.0%, can be produced by mixing Ni—Co hydroxide particles having a sulfate ion content of not more than 1.0% whose surface is coated with an Al compound having a primary particle diameter of not more than 1 μm, with a lithium compound; and calcining the resulting mixture.

Owner:TODA IND

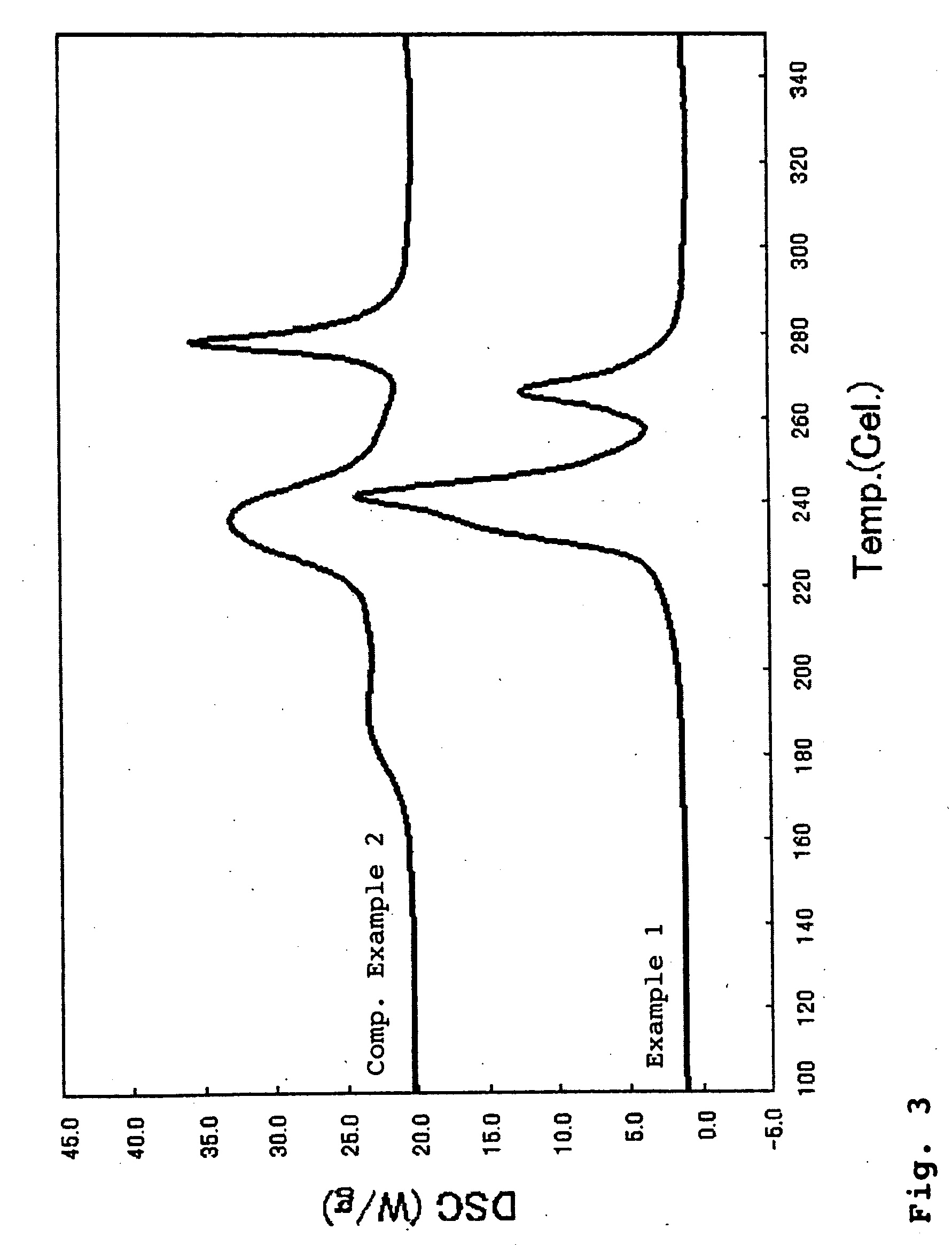

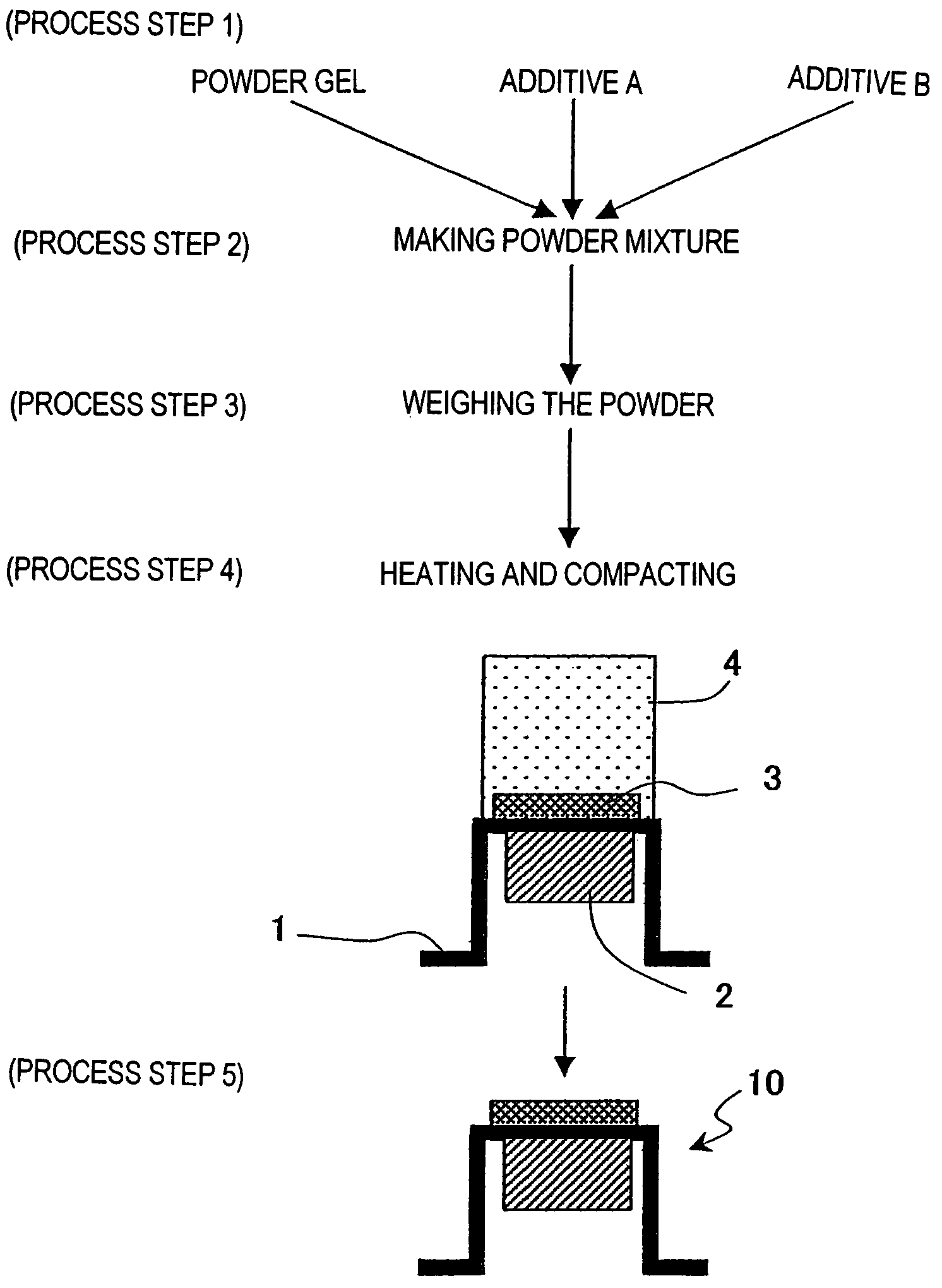

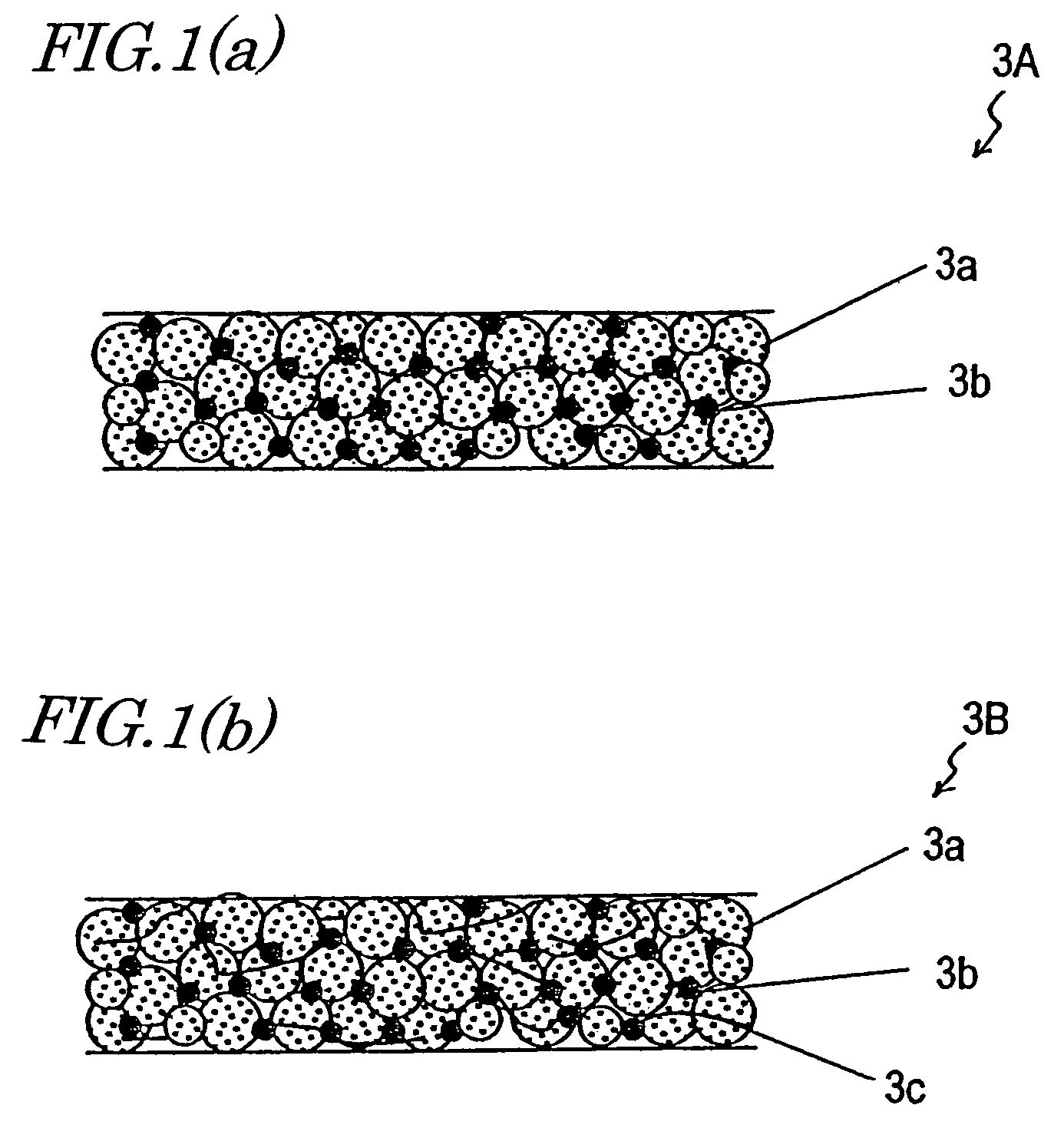

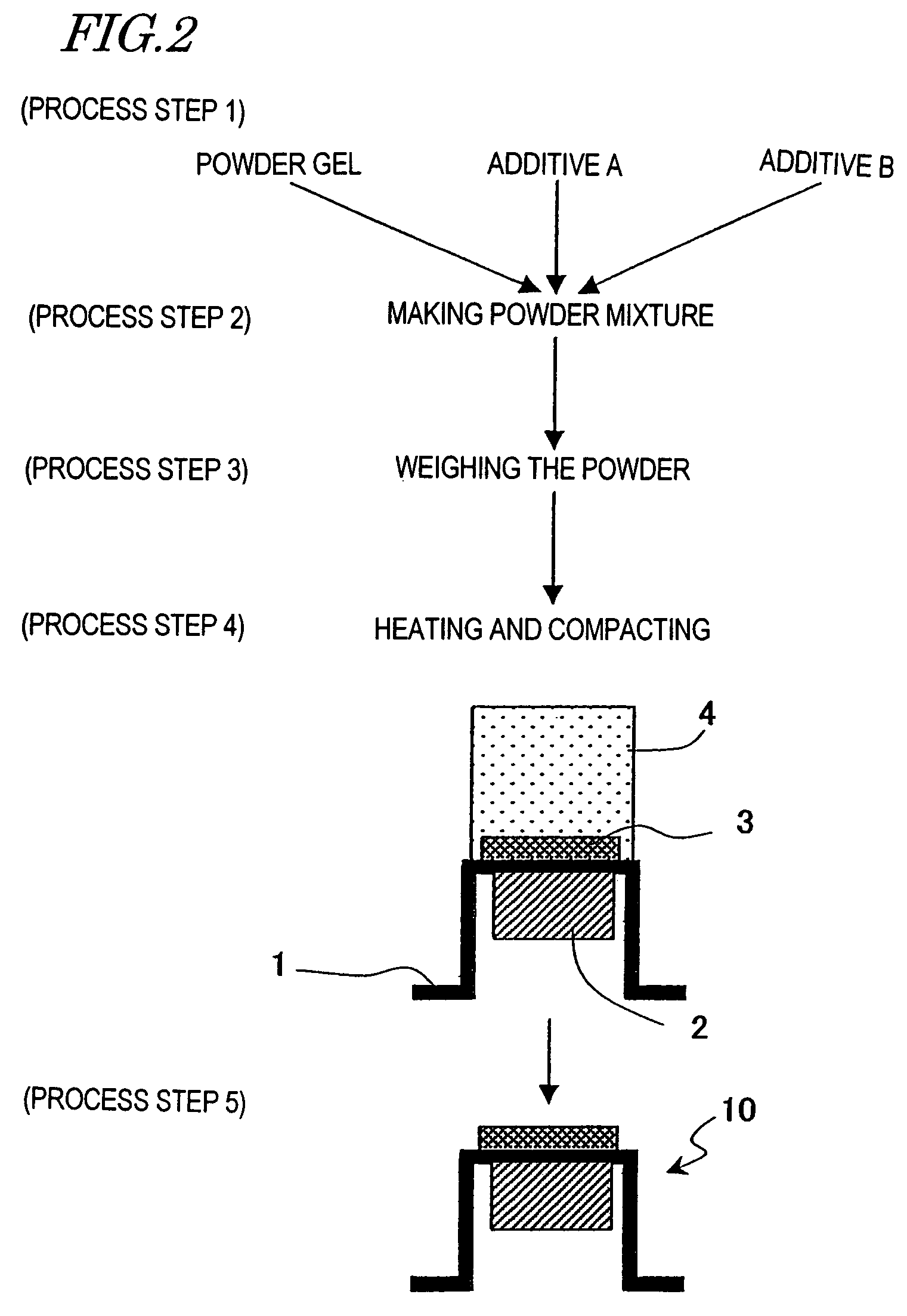

Acoustic matching layer and ultrasonic transducer

InactiveUS6969943B2Property variationPiezoelectric/electrostriction/magnetostriction machinesVolume/mass flow measurementUltrasonic sensorPore diameter

Owner:PANASONIC CORP

Li-Ni composite oxide particles for non-aqueous electrolyte secondary cell, process for producing the same, and non-aqueous electrolyte secondary cell

ActiveUS8066913B2InhibitionIncrease resistanceElectrode manufacturing processesConductive materialPhysical chemistryLithium compound

The present invention relates to Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a large charge / discharge capacity, an excellent packing density and excellent storage performance. The Li—Ni composite oxide particles for a non-aqueous electrolyte secondary cell which have a composition represented by the formula:LixNi1-y-zCoyAlz02 in which 0.9<x<1.3; 0.1<y<0.3; and 0<z<0.3, wherein the composite oxide particles have a rate of change in specific surface area of not more than 10% as measured between before and after applying a pressure of 1 t / cm2 thereto, and a sulfate ion content of not more than 1.0%, can be produced by mixing Ni—Co hydroxide particles having a sulfate ion content of not more than 1.0% whose surface is coated with an Al compound having a primary particle diameter of not more than 1 μm, with a lithium compound; and calcining the resulting mixture.

Owner:TODA IND

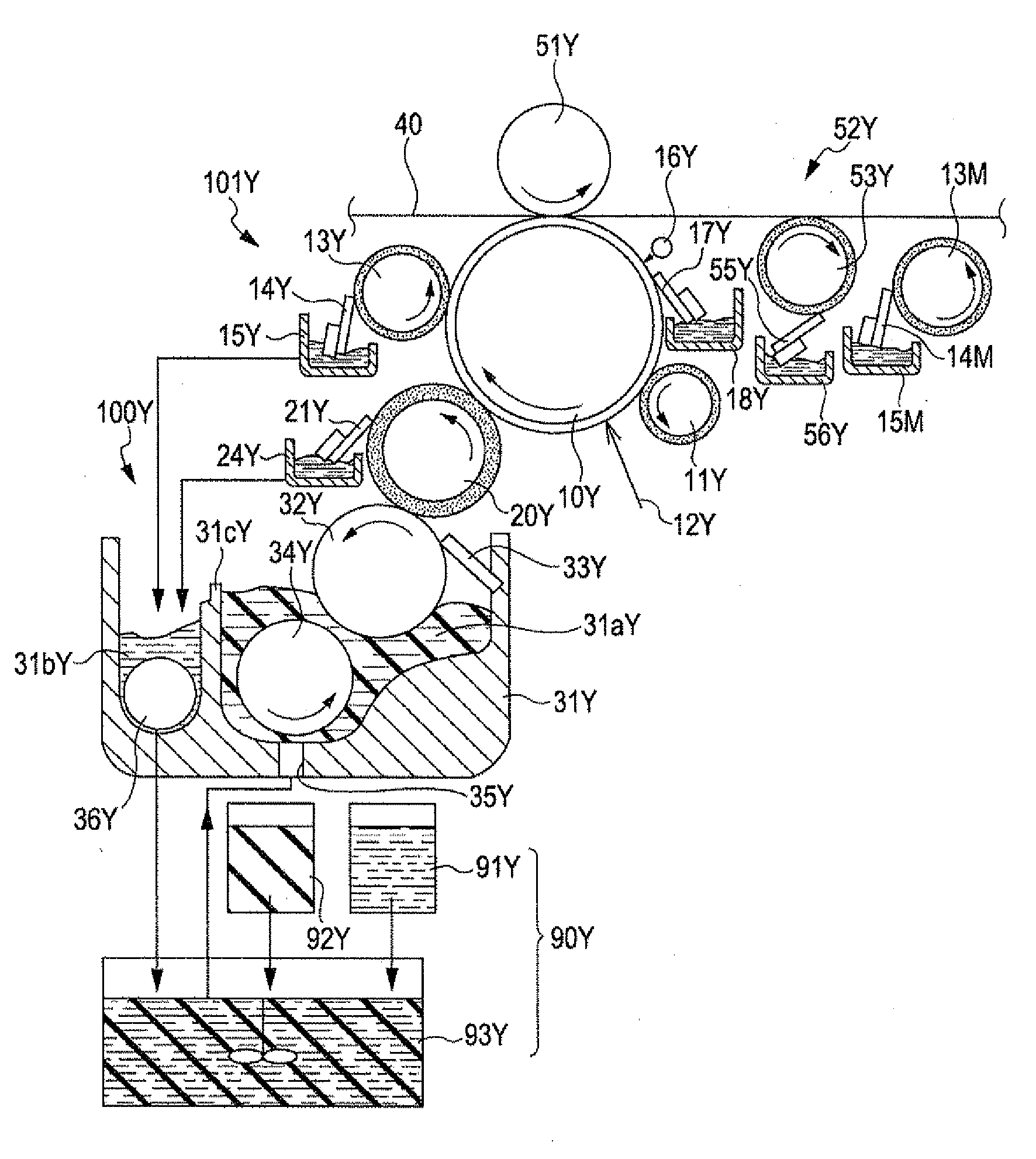

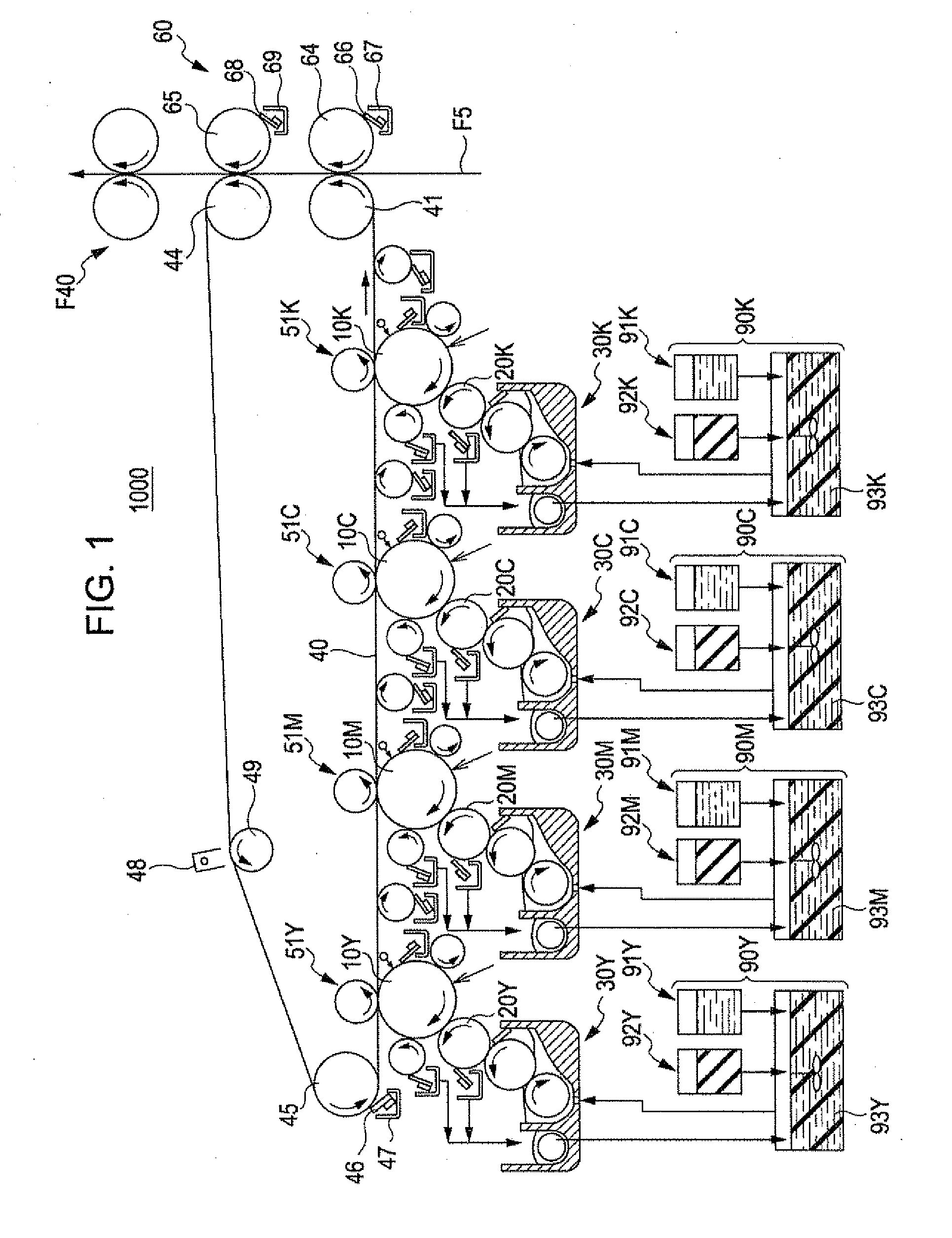

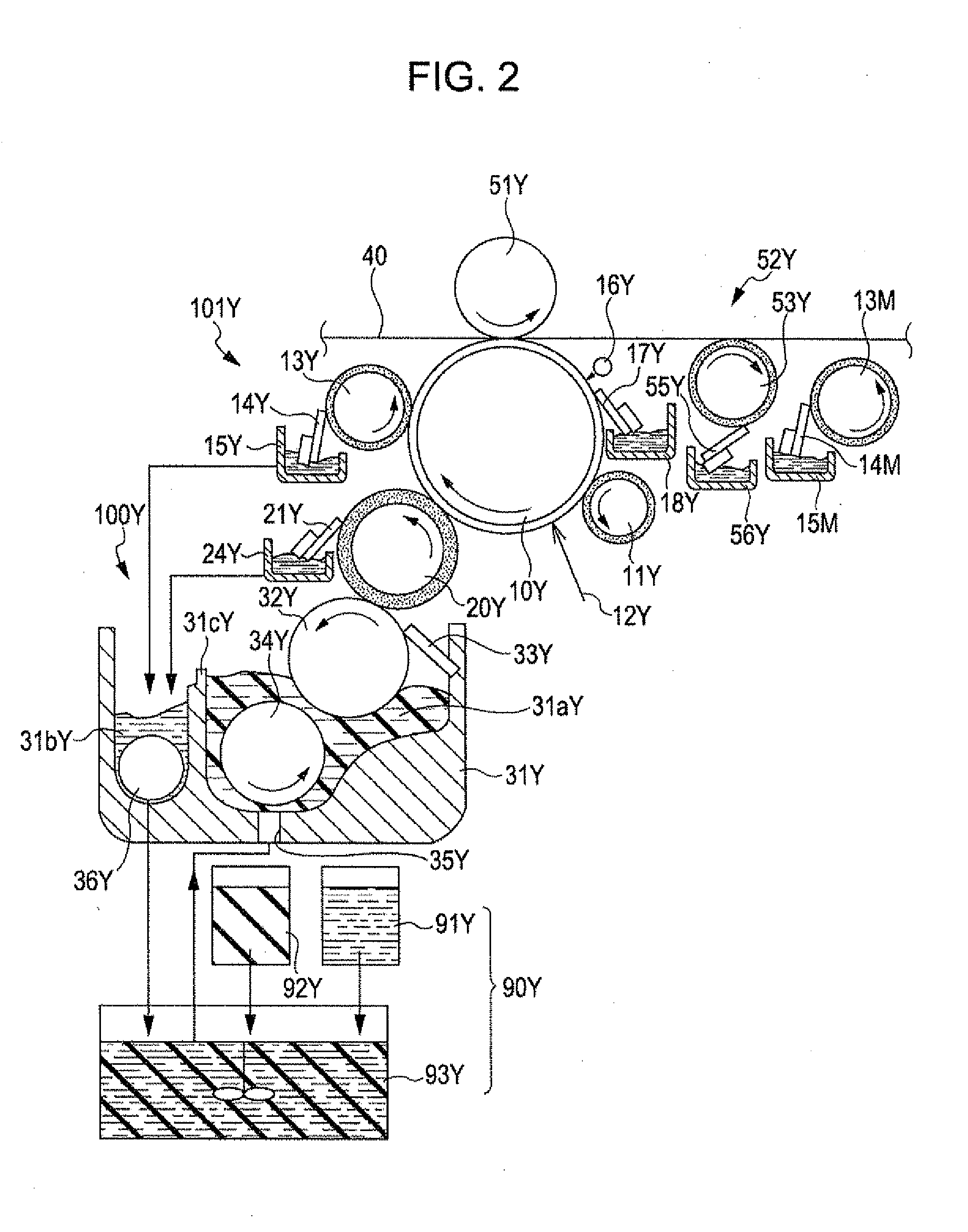

Liquid Developer and Image-Forming Apparatus

InactiveUS20110177448A1Superior long-term dispersion stabilitySuperior positive charging propertyDevelopersElectrographic process apparatusLiquid hydrocarbonsEngineering

A liquid developer contains a liquid insulator formed of a liquid hydrocarbon, toner particles formed by chemically modifying surfaces of mother toner particles formed of a material containing a rosin-based resin and a polyester resin with a polyalkyleneimine, and a metal soap dissolved in the liquid insulator.

Owner:SEIKO EPSON CORP

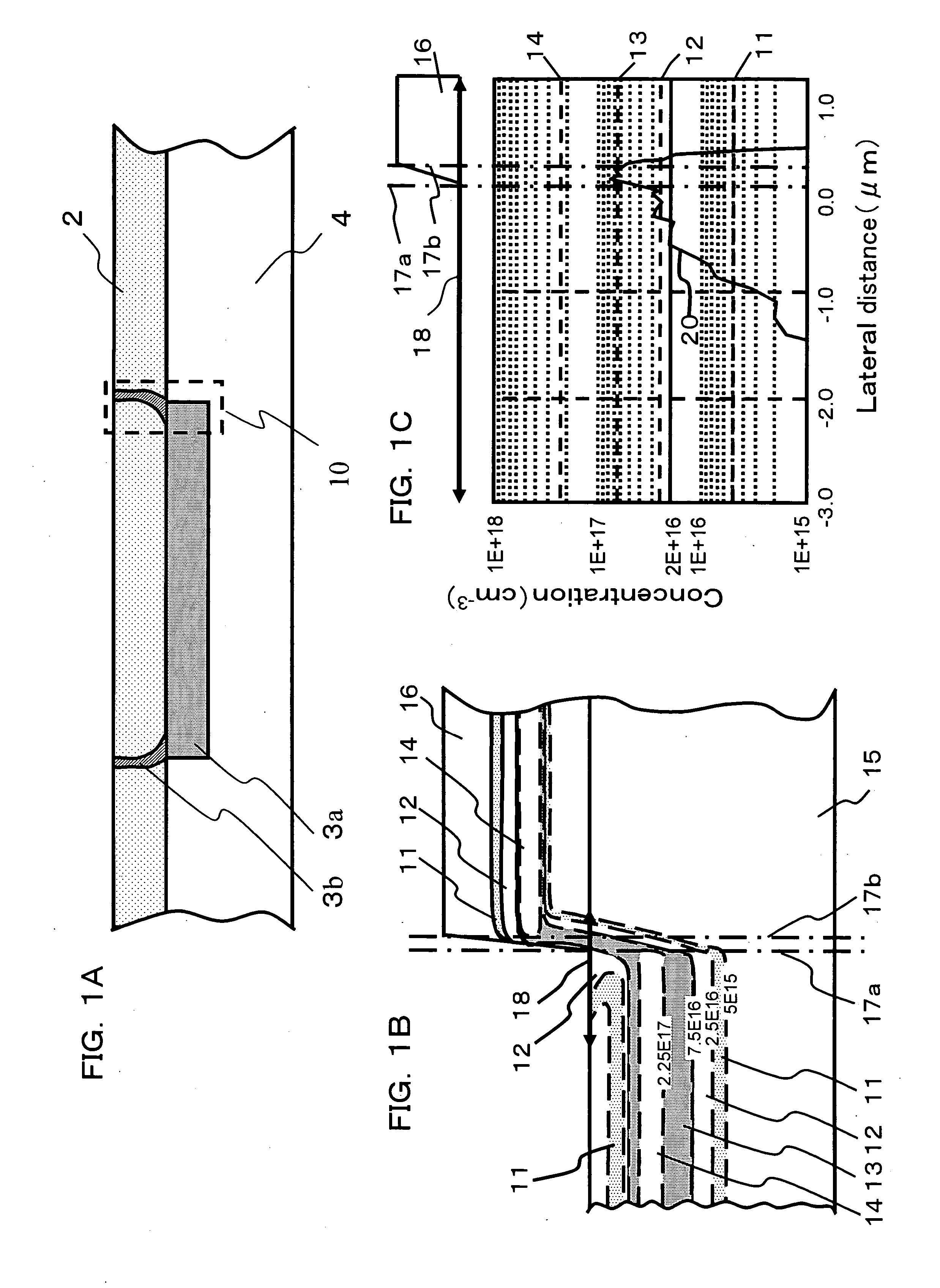

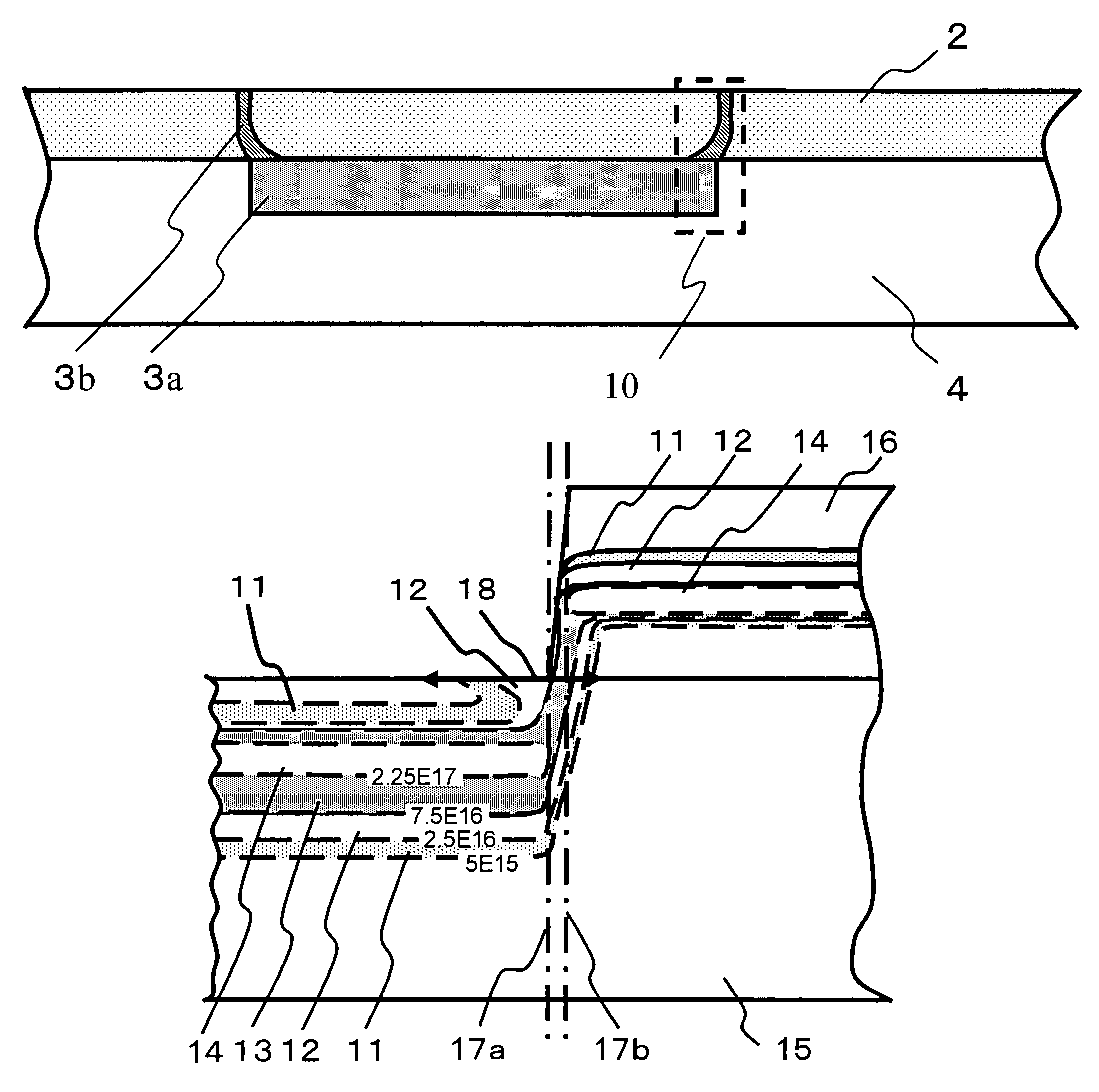

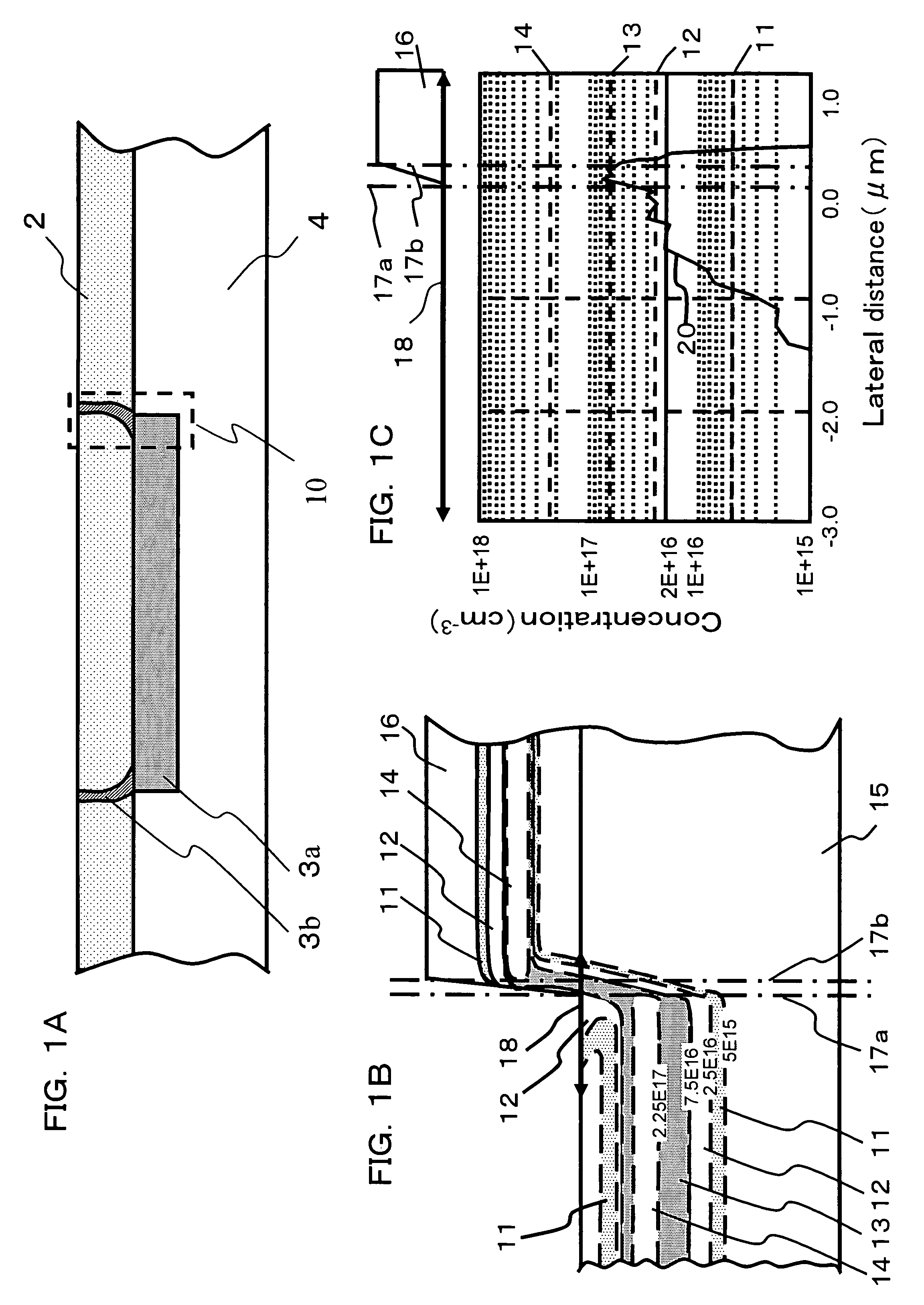

Semiconductor device and method for manufacturing the same

InactiveUS20070054451A1Property variationSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialIon implantation

The present invention provides a method for manufacturing a semiconductor device which includes a step of forming one optional impurity region in a semiconductor substrate at a place apart from the surface thereof, and in the method described above, ion implantation is performed a plurality of times while the position of an end portion of a mask pattern used for ion implantation is changed.

Owner:FUJITSU SEMICON LTD

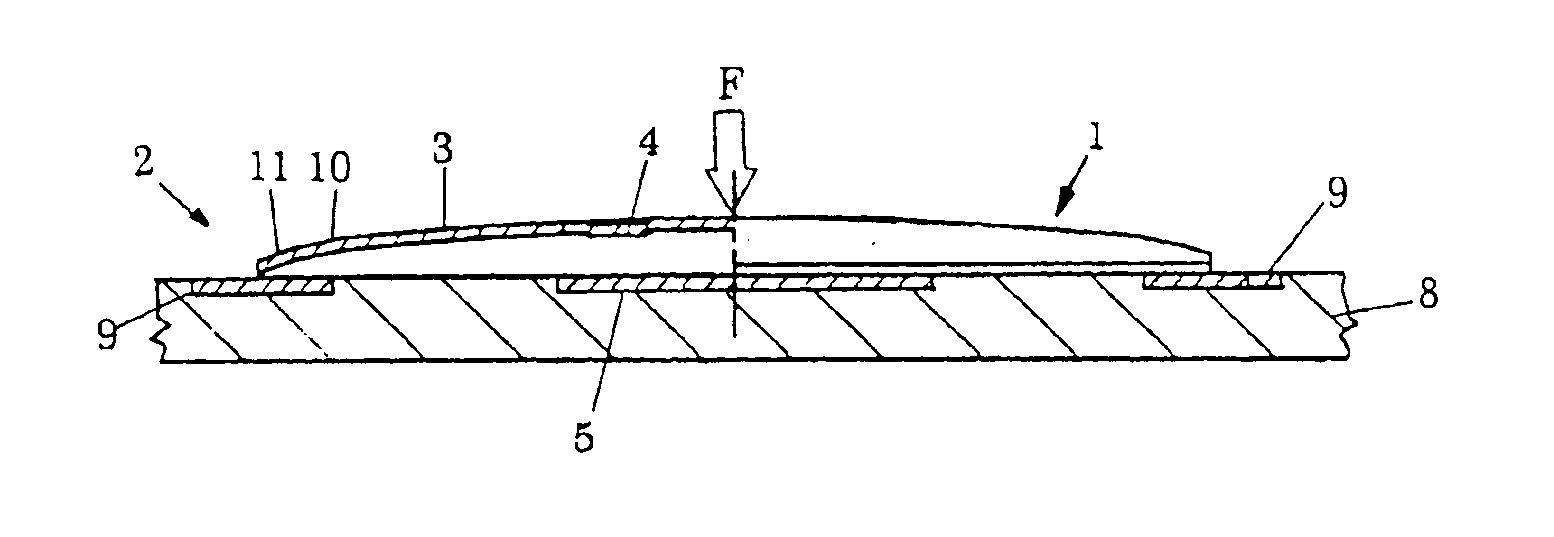

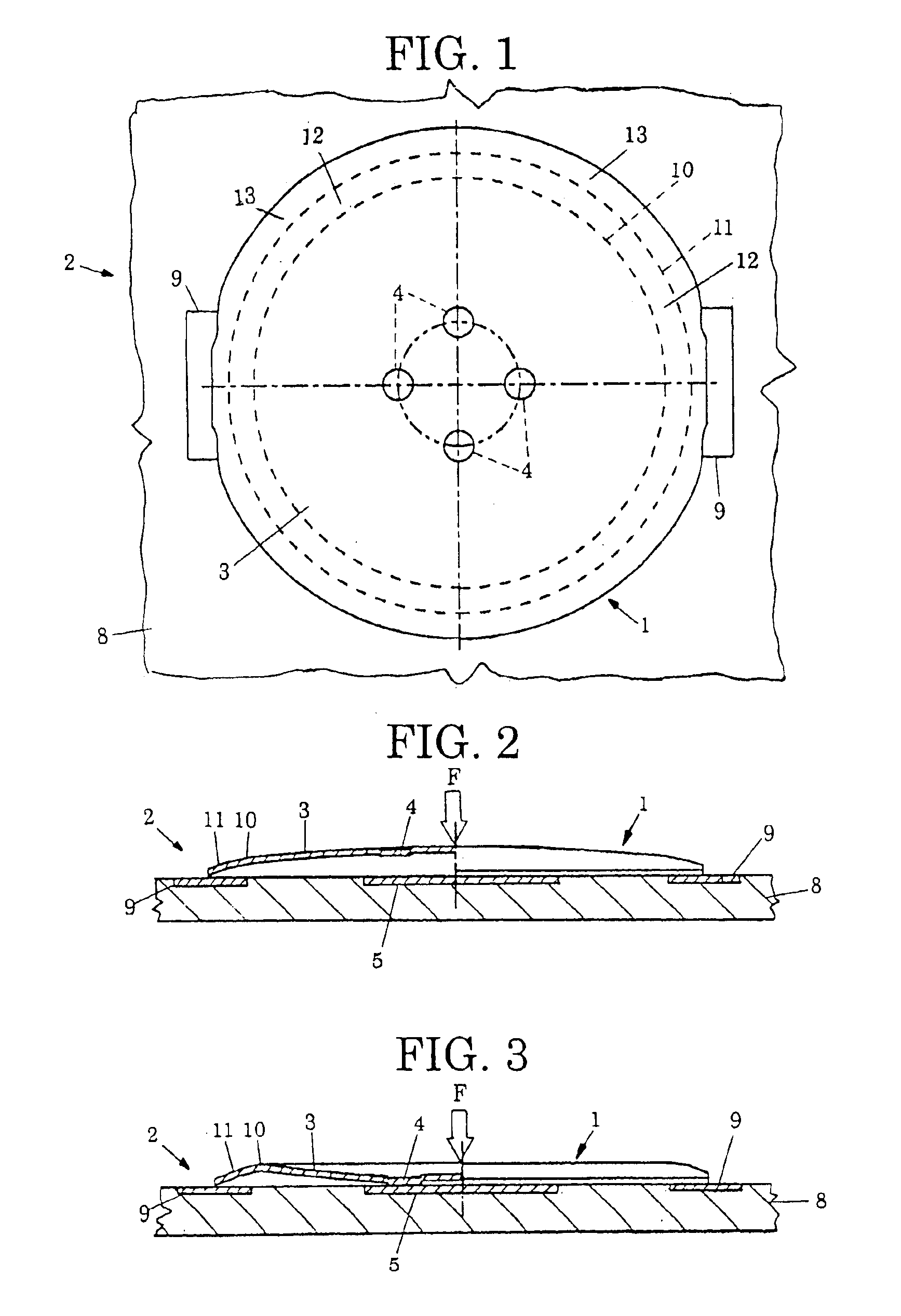

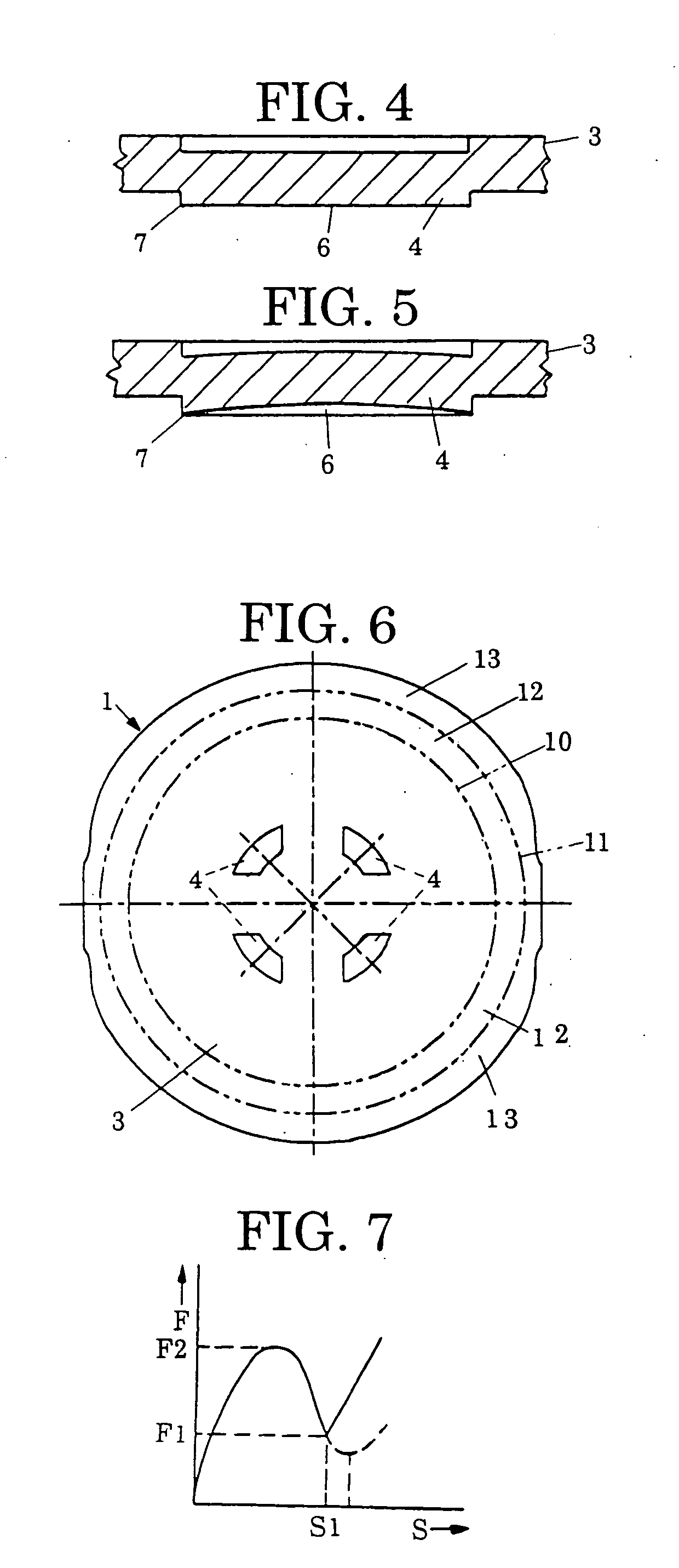

Contact spring

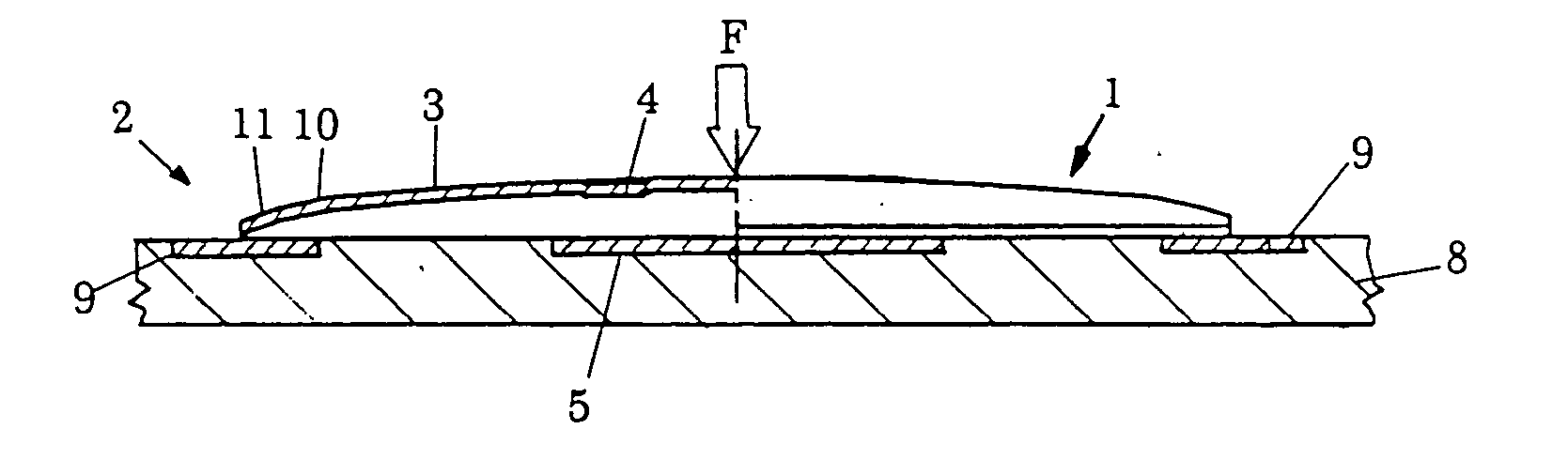

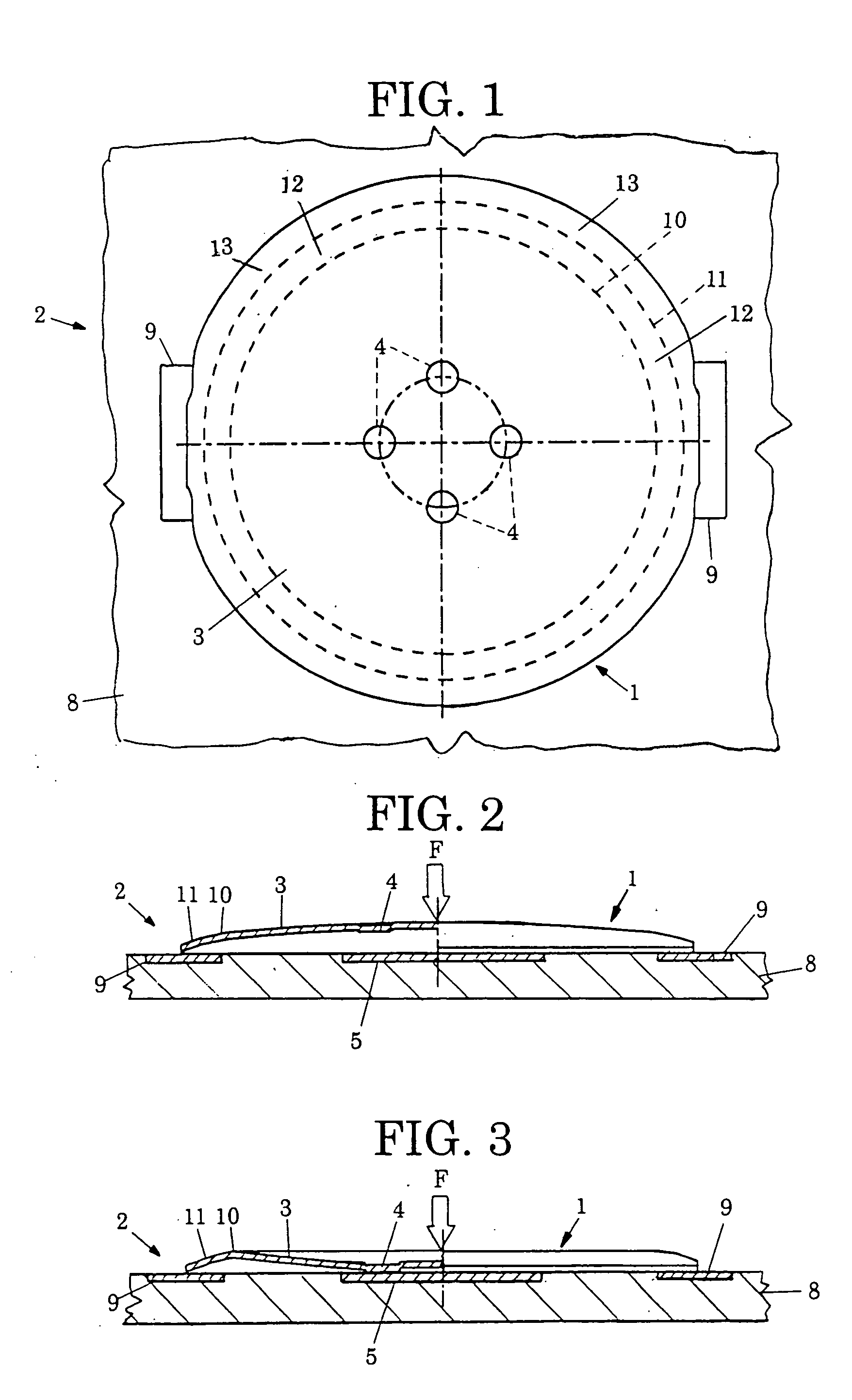

ActiveUS6855900B1Lessen contact obstacleReduce variationContact surface shape/structureMowersEngineeringPush-button

There is provided a contact spring in a small-sized push-button switch capable of lessening contact obstacle between contacts caused by fine dust, and reducing variation in load characteristics even if heat is applied thereto or the switch is repetitively operated. The contact spring in the switch for allowing a movable contact provided at an inner side of a movable contact spring to contact or break off the contact with an opposed fixed contact so as to render the movable contact and the fixed contact to be in one of an electrically on or off state, wherein multiple movable contacts are formed by protruding a material of the movable contact spring by a thickness of not more than two thirds of a thickness of the movable contact spring on a circumference about a central portion of the movable contact spring and positioned at an equal central angle relative to the center of the movable contact spring in a direction from an outside to an inner side of the movable contact spring by means of half-cut working while forming a peripheral edge of a protruded contact surface in a sharp blade-shape.

Owner:FUJI ELECTRONICS IND

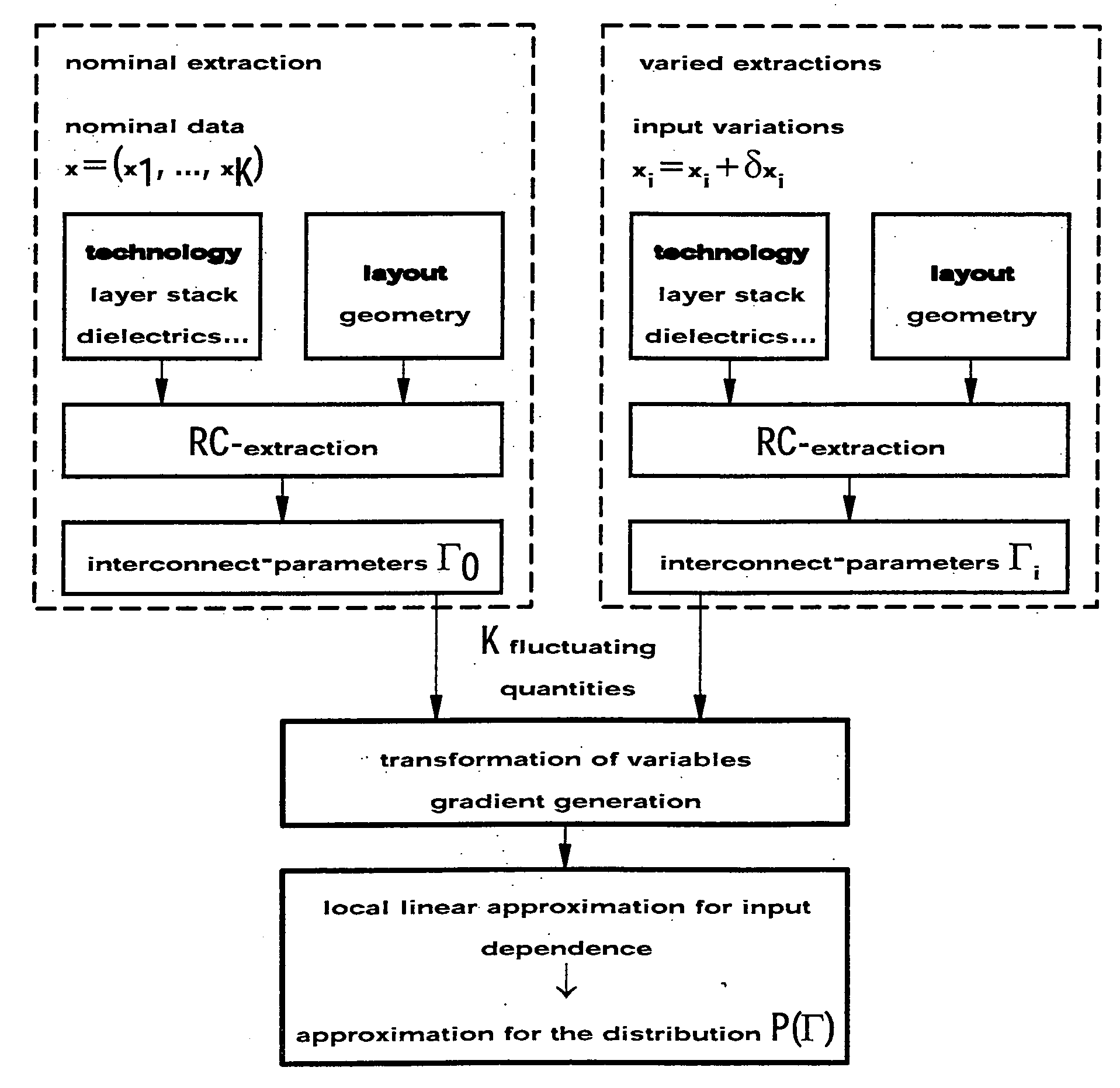

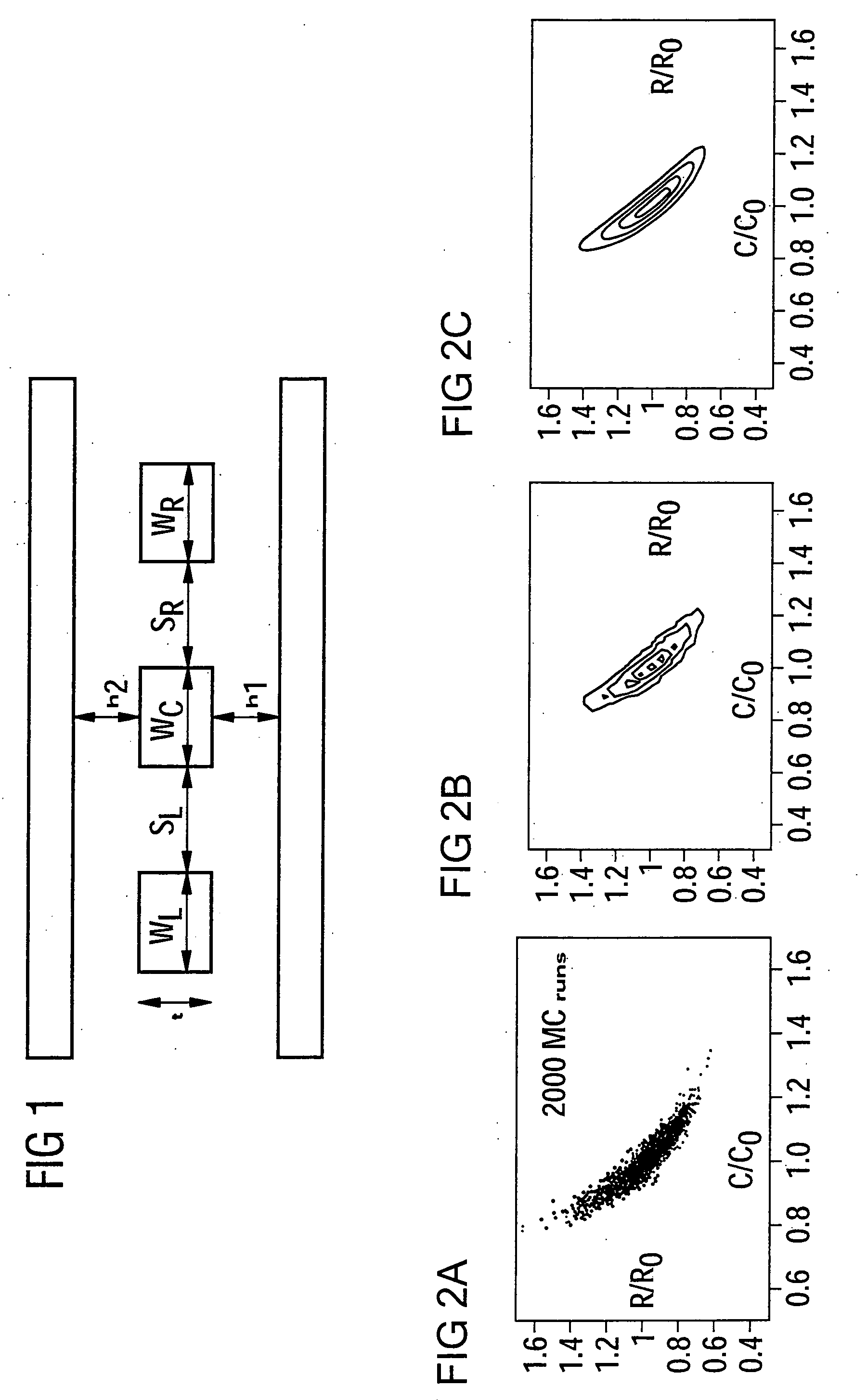

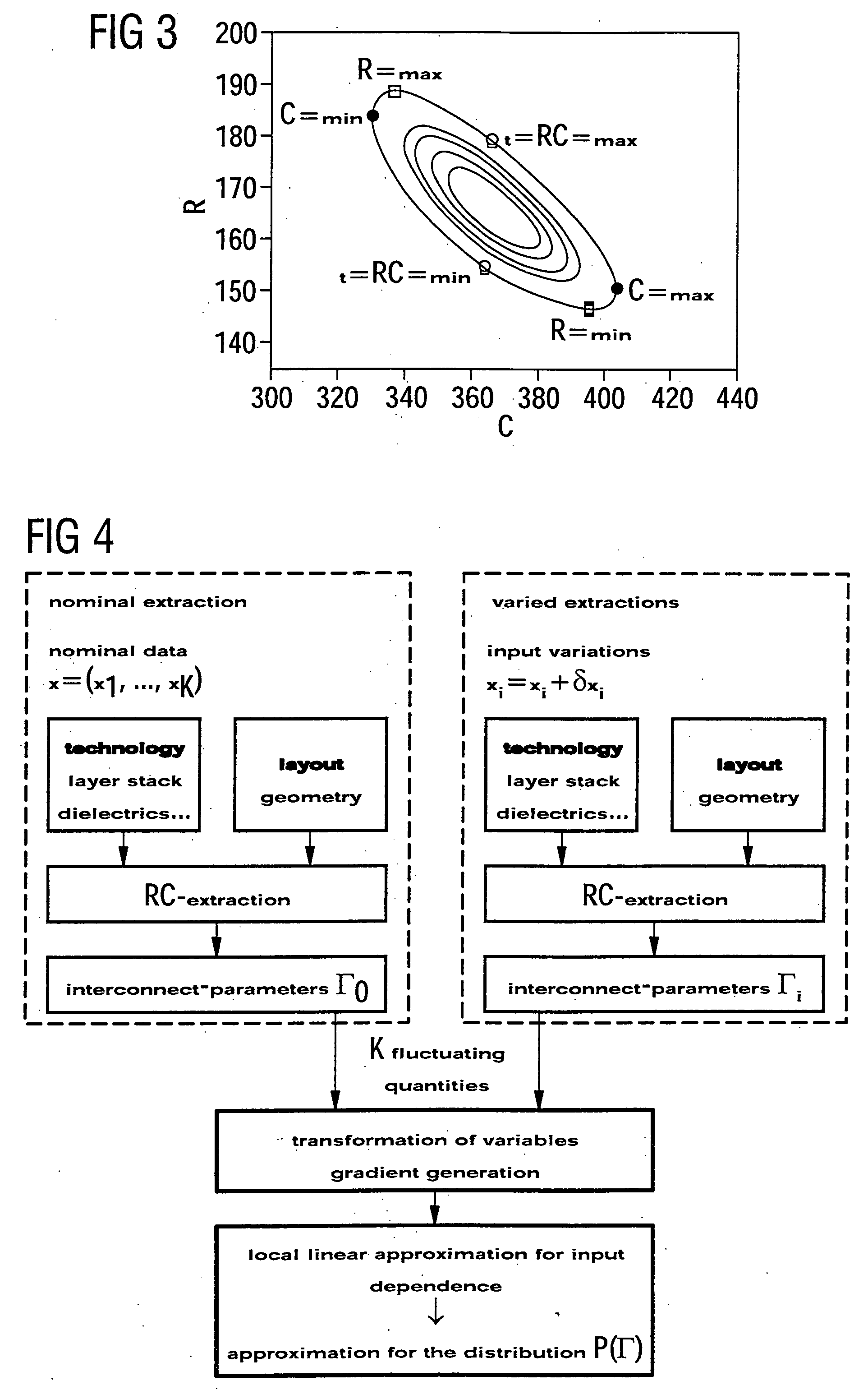

Method to simulate the influence of production-caused variations on electrical interconnect properties of semiconductor layouts

InactiveUS20050183048A1Improve efficiencyImprove accuracyDesign optimisation/simulationMulti-objective optimisationElectricityEngineering

A method is provided to simulate the influence of production-caused variations of interconnect properties in modern semiconductor-technology layouts. Fluctuations of the physical interconnect properties are extracted from a given layout where the geometric layout data and the corresponding technology characteristics serve as input parameters. Statistical distribution of characteristic interconnect properties are the resulting output. If the fluctuations of the interconnect properties or the resulting fluctuations in the system performance meet the specifications, the layout is accepted, otherwise it has to be rejected.

Owner:INFINEON TECH AG

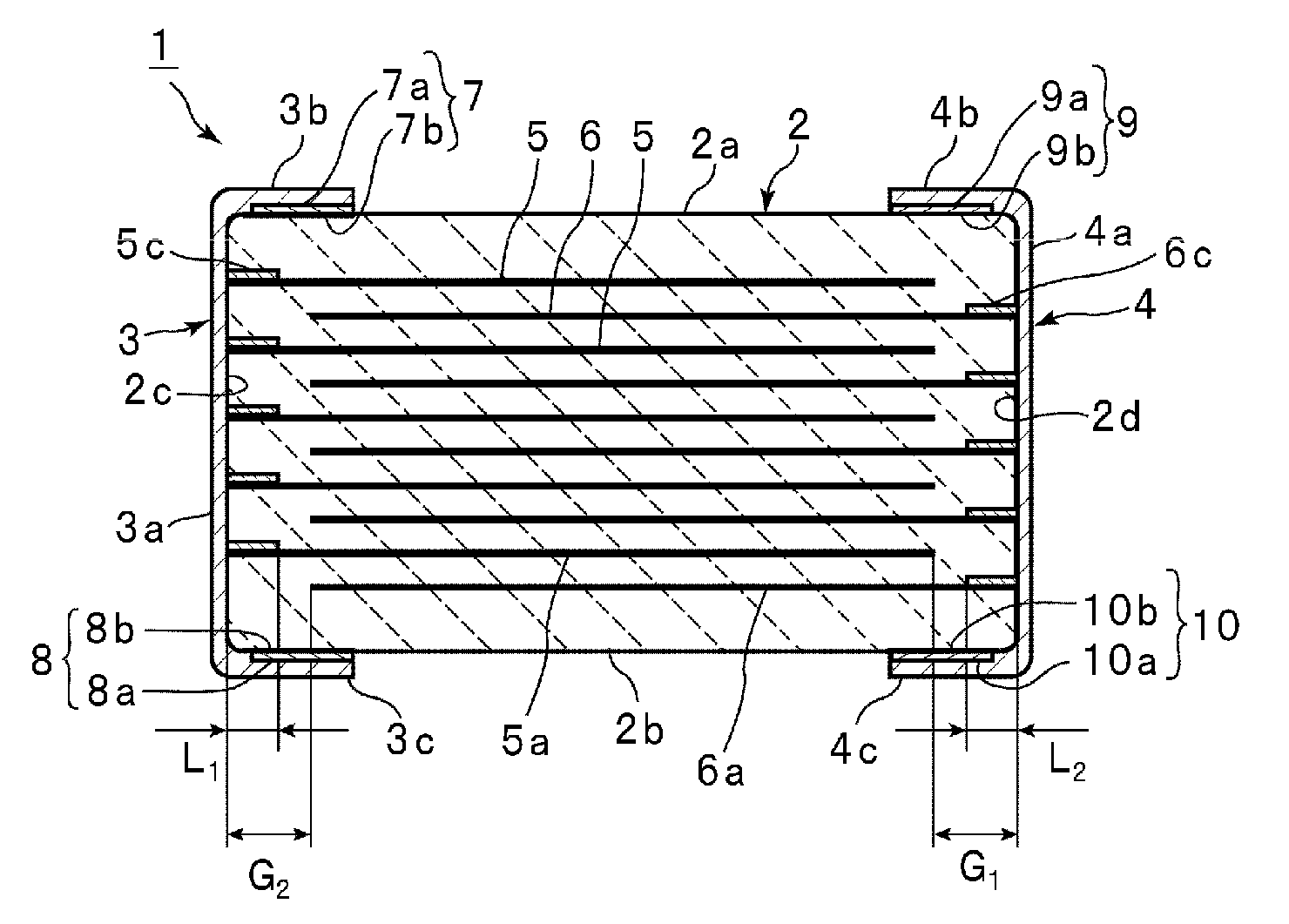

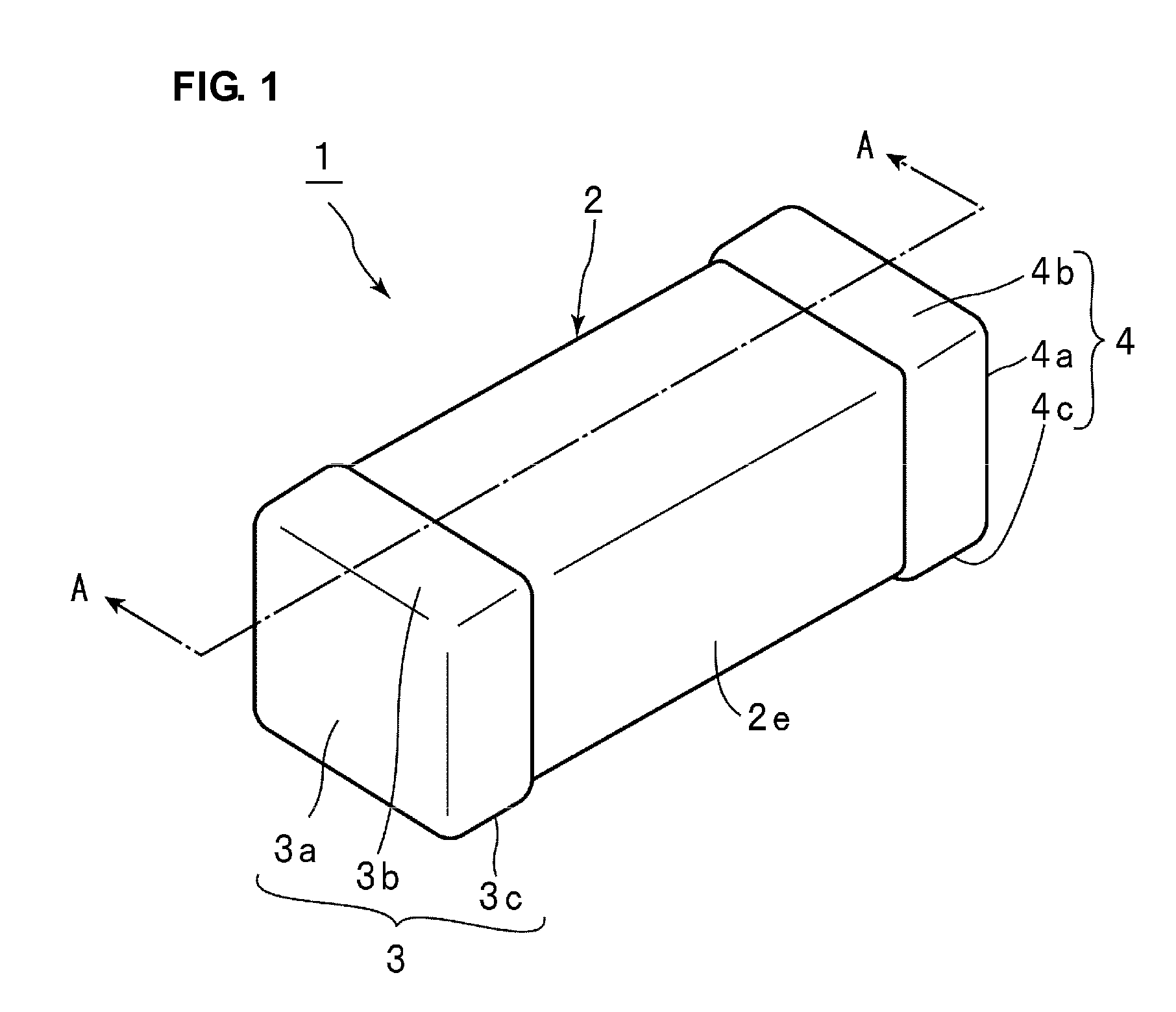

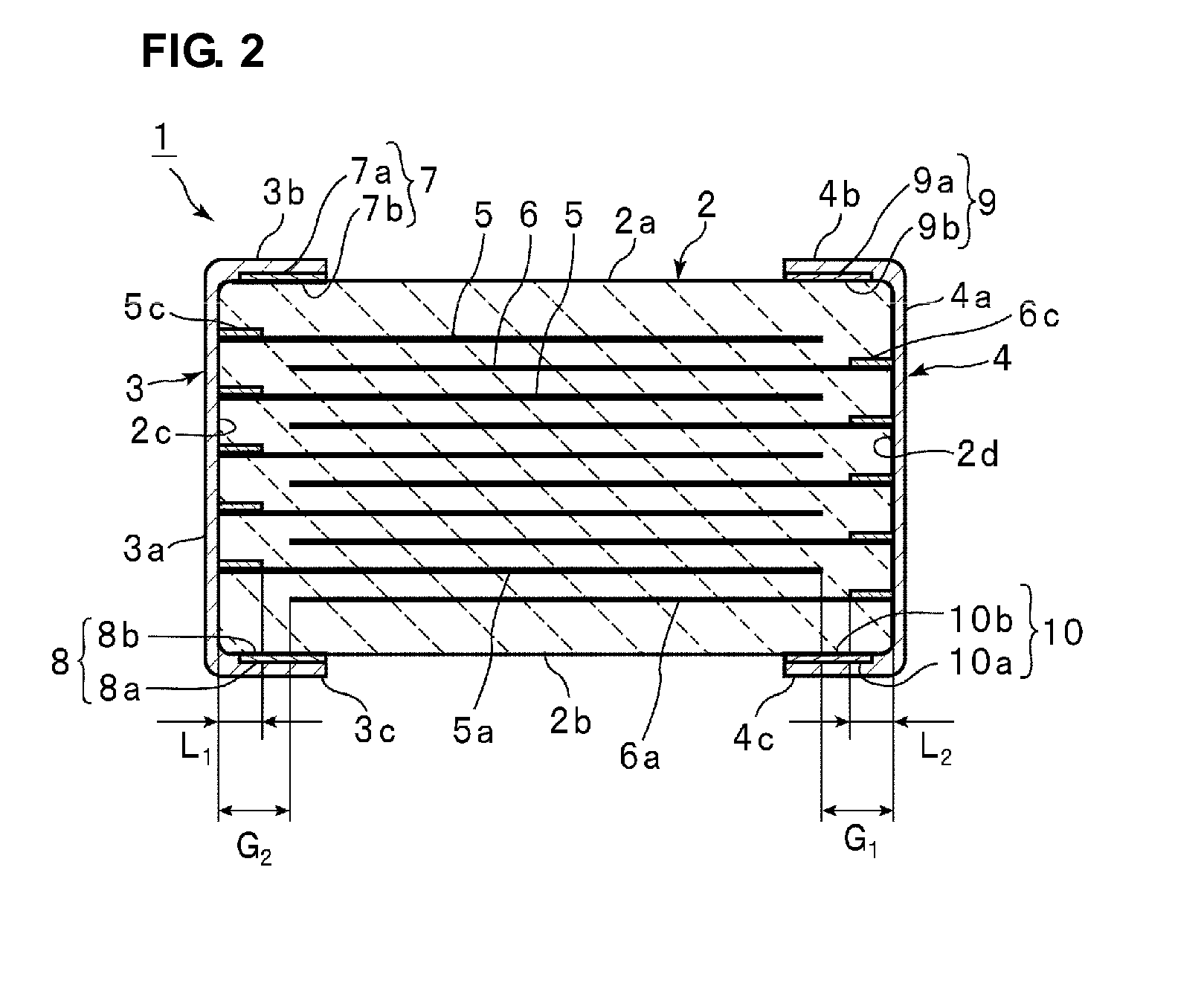

Laminated ceramic electronic component

ActiveUS8305729B2Variation in propertyVariation in resistanceFixed capacitor electrodesStacked capacitorsElectronic componentMaterials science

A laminated ceramic electronic component includes first internal electrodes and second internal electrodes that overlap each other through ceramic layers, each of the first and second internal electrodes having first and second effective portions, first and second connecting portions, and first and second extended portions whose film thickness is greater than that of the first and second connecting portions and which are exposed at the outer surface of a ceramic element assembly. When distances from side surfaces of the ceramic assembly on which first and second external electrodes are provided to the inner edges of the first and second extended portions are defined as L1 and L2, respectively, and a distance between side surfaces and the end of the second internal electrode or the end of the first internal electrode is defined as G2 or G1, G2>L1 and G1>L2 are satisfied.

Owner:MURATA MFG CO LTD

Semiconductor device and method for manufacturing the same

InactiveUS7659188B2Property variationSolid-state devicesSemiconductor/solid-state device manufacturingIon implantationSemiconductor

The present invention provides a method for manufacturing a semiconductor device which includes a step of forming one optional impurity region in a semiconductor substrate at a place apart from the surface thereof, and in the method described above, ion implantation is performed a plurality of times while the position of an end portion of a mask pattern used for ion implantation is changed.

Owner:FUJITSU SEMICON LTD

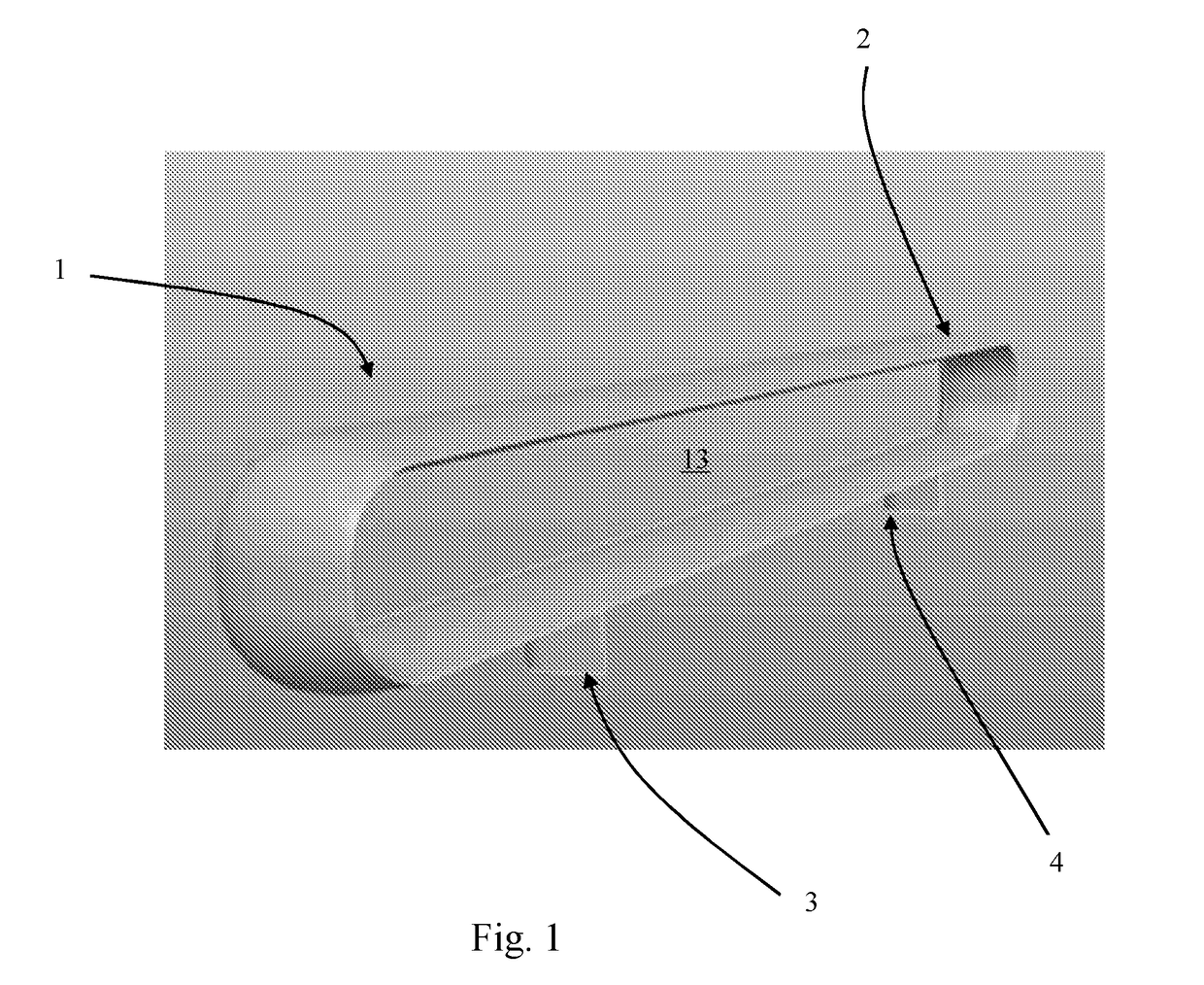

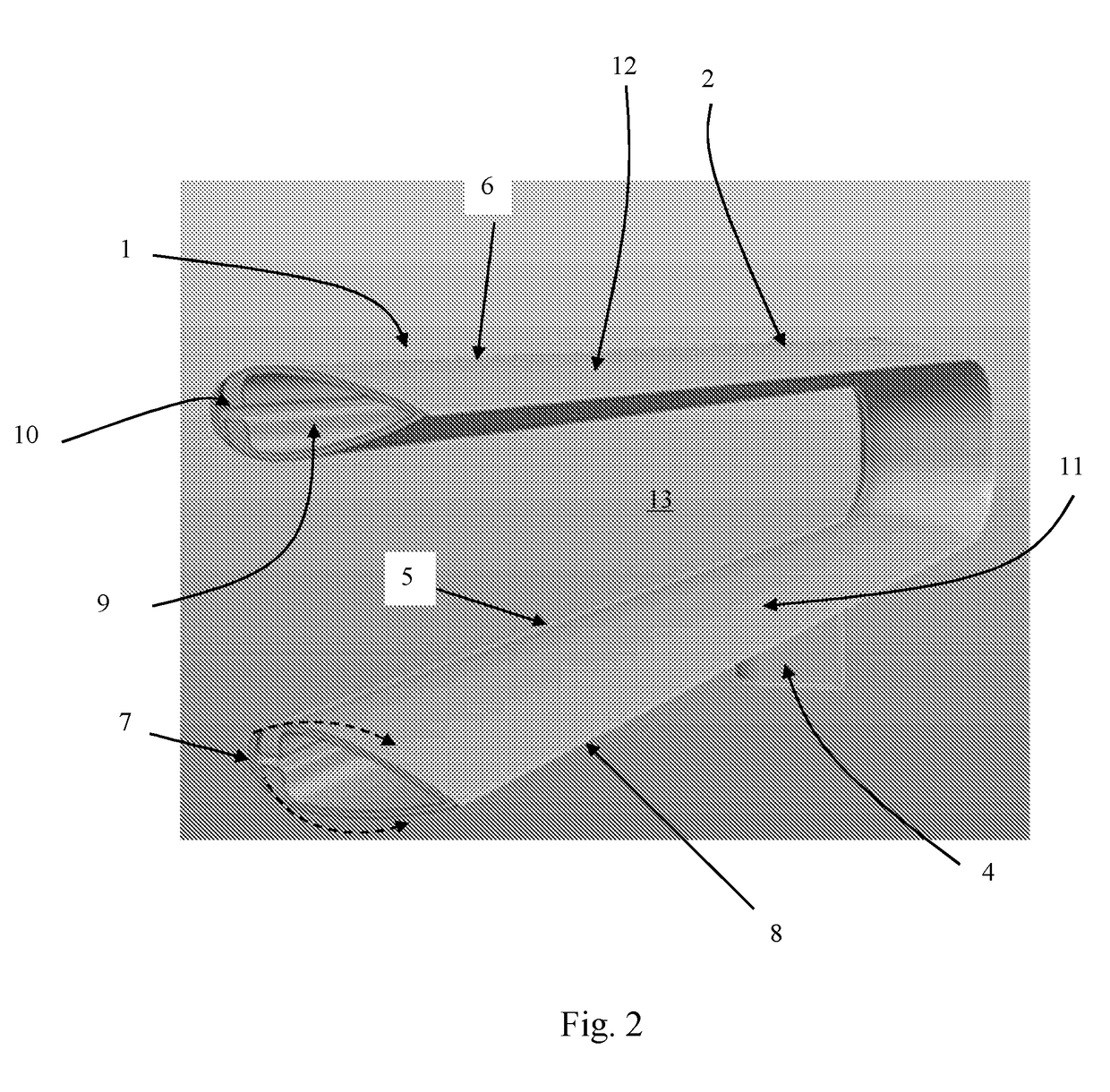

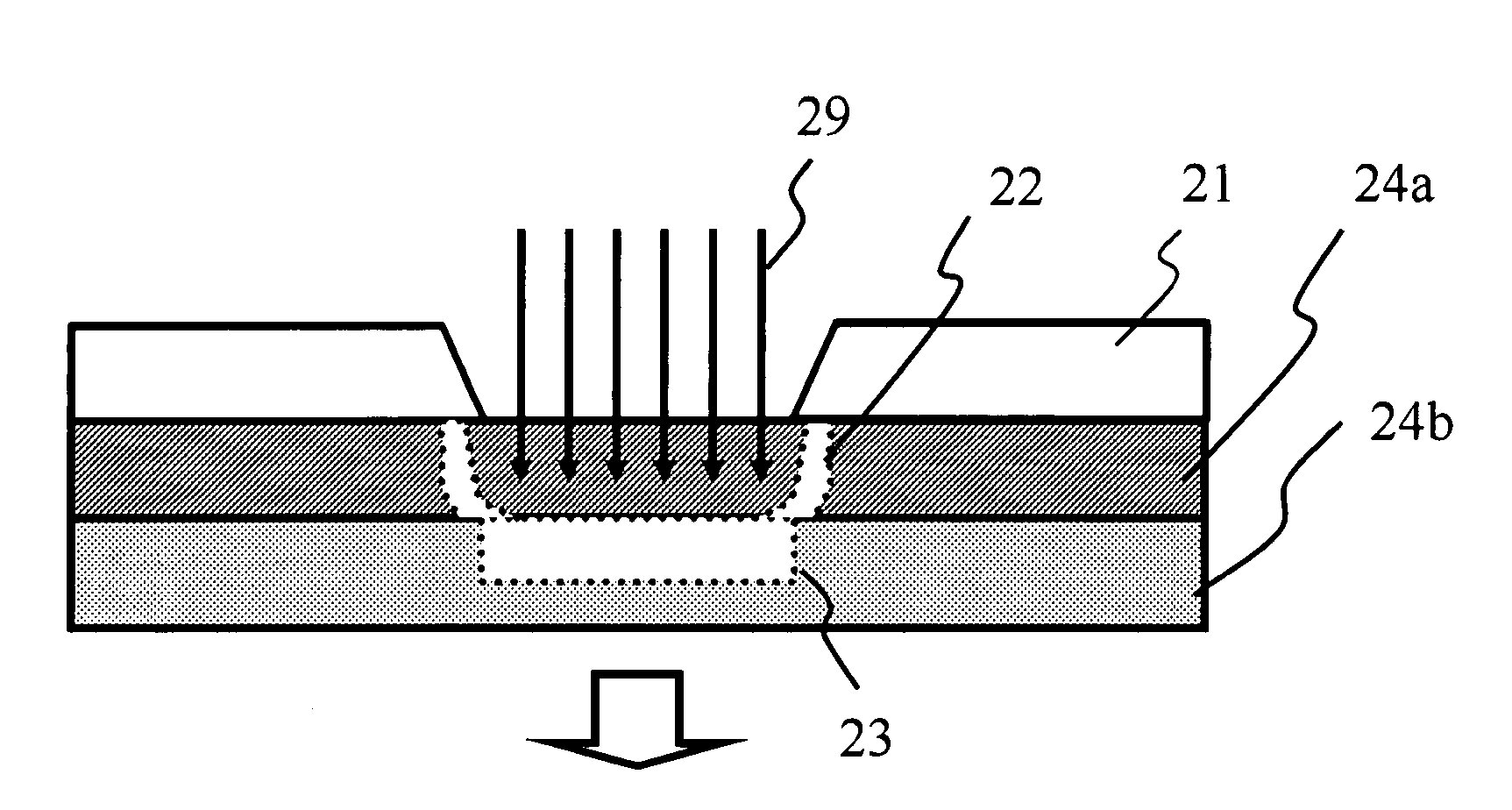

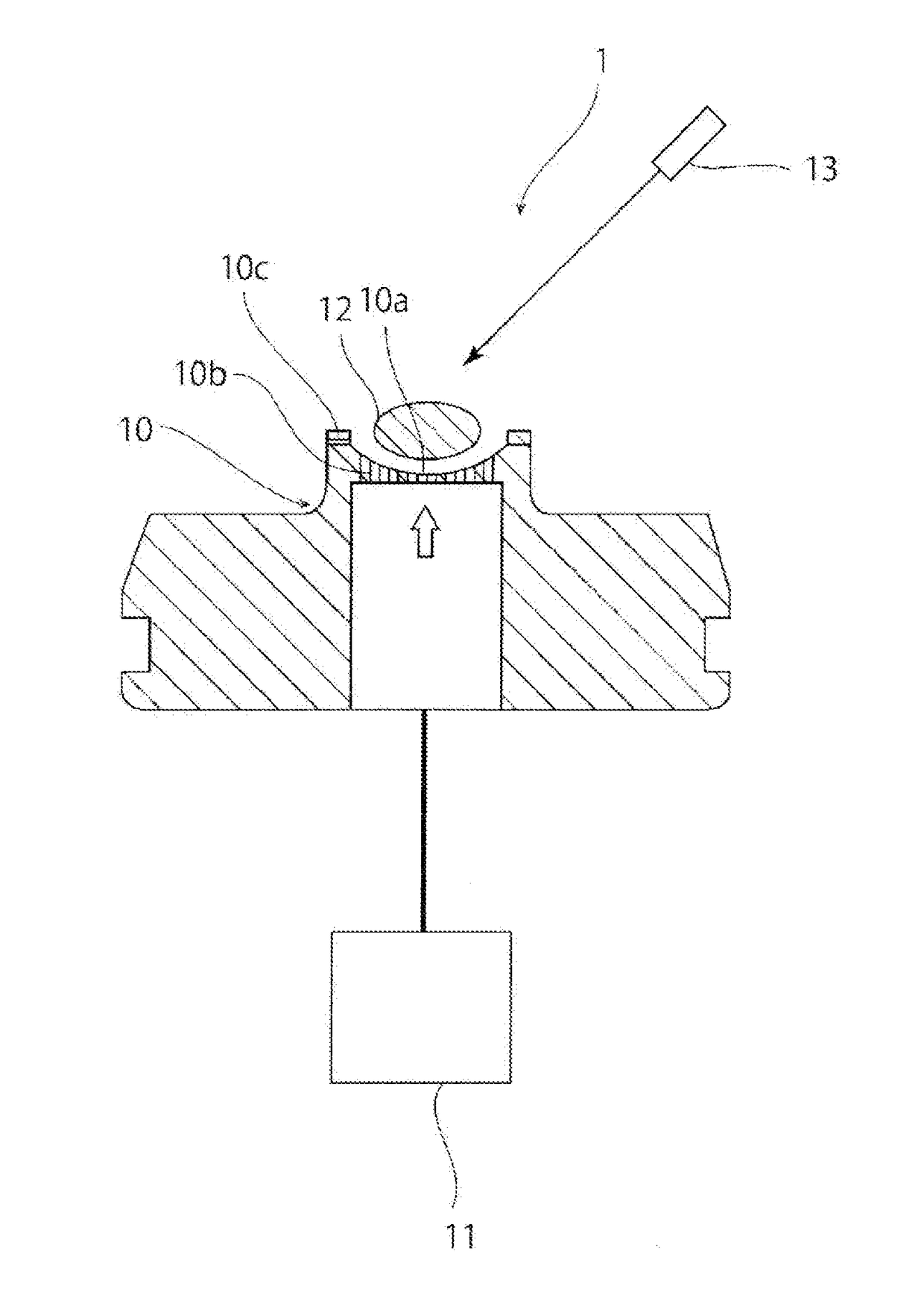

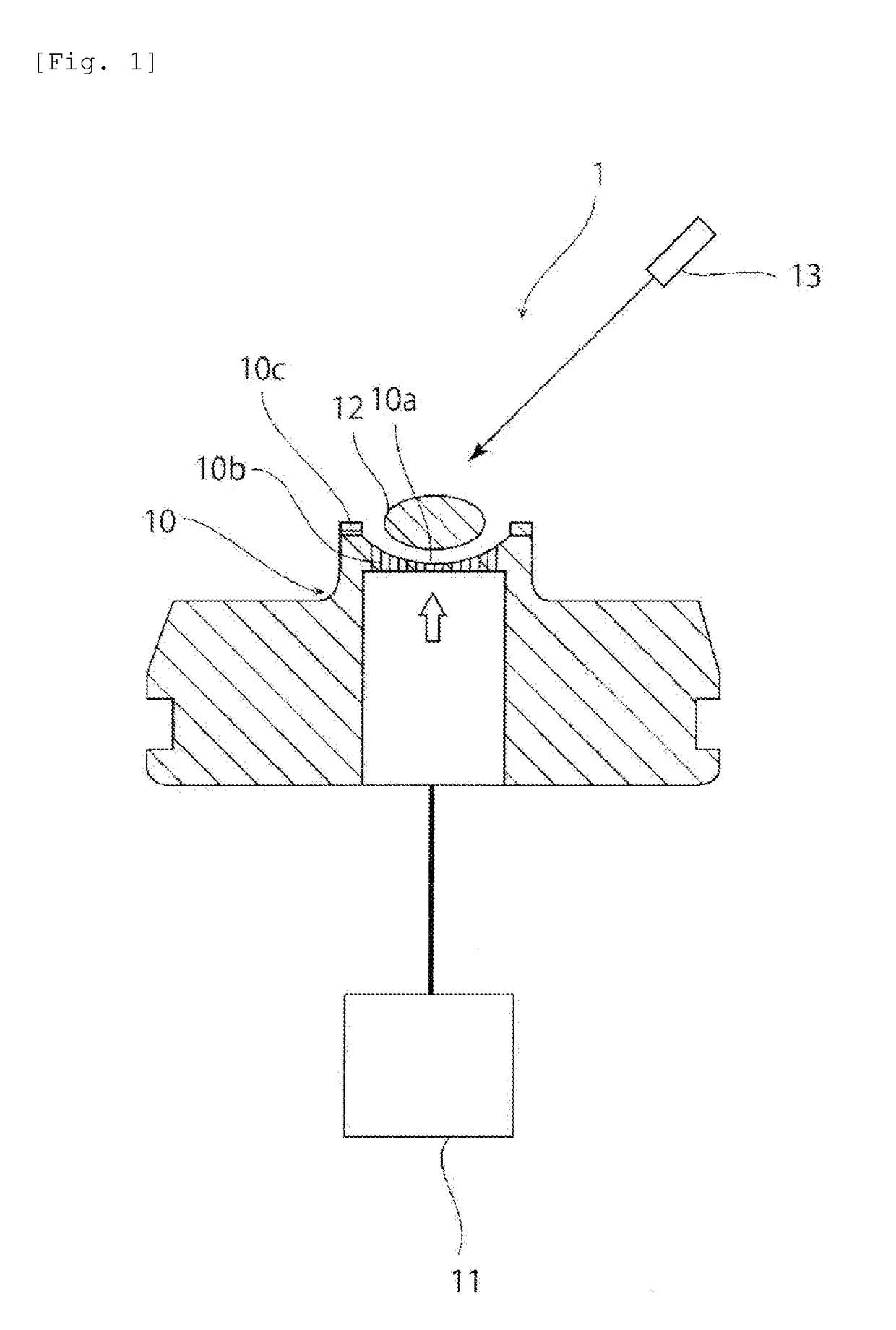

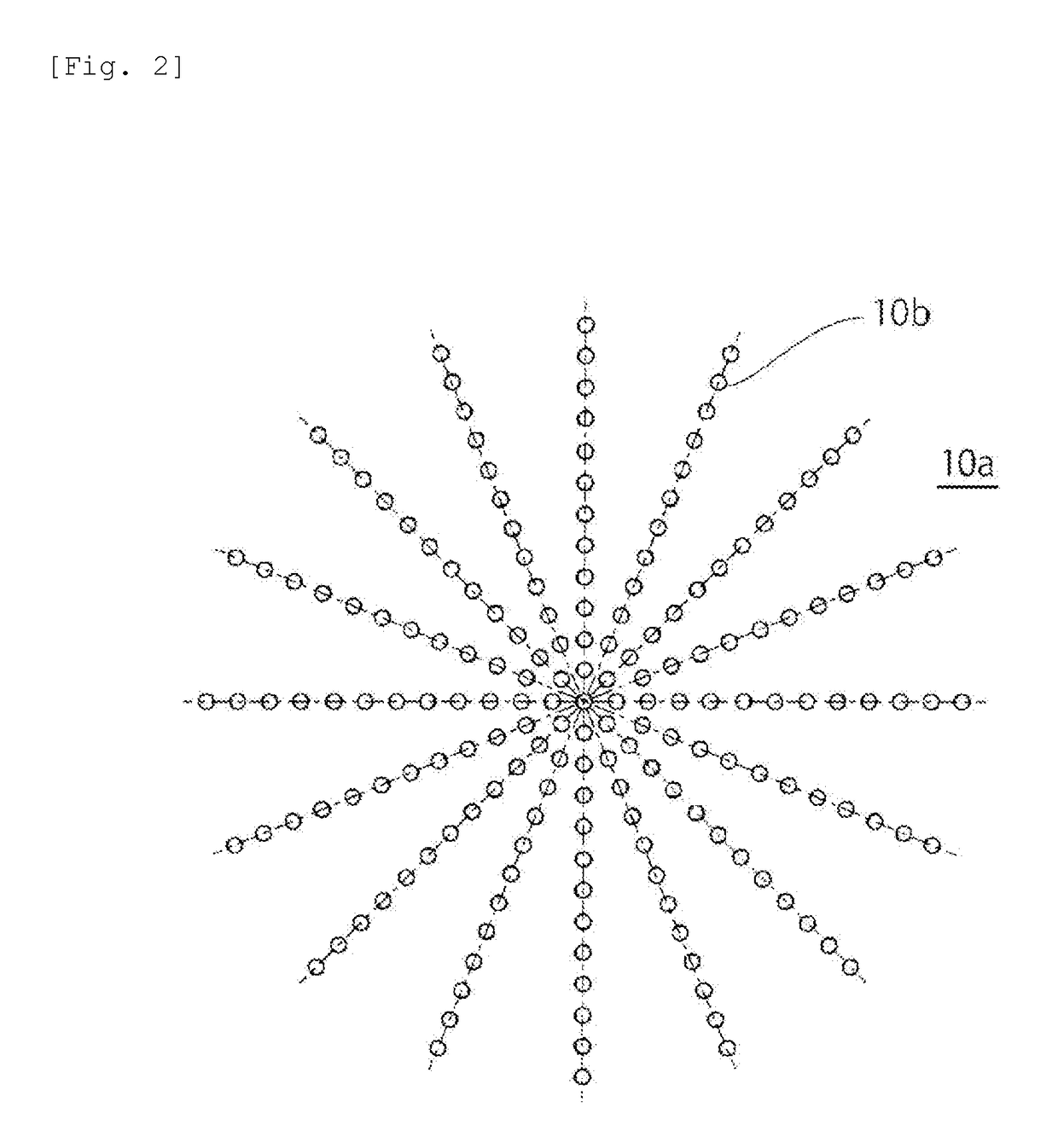

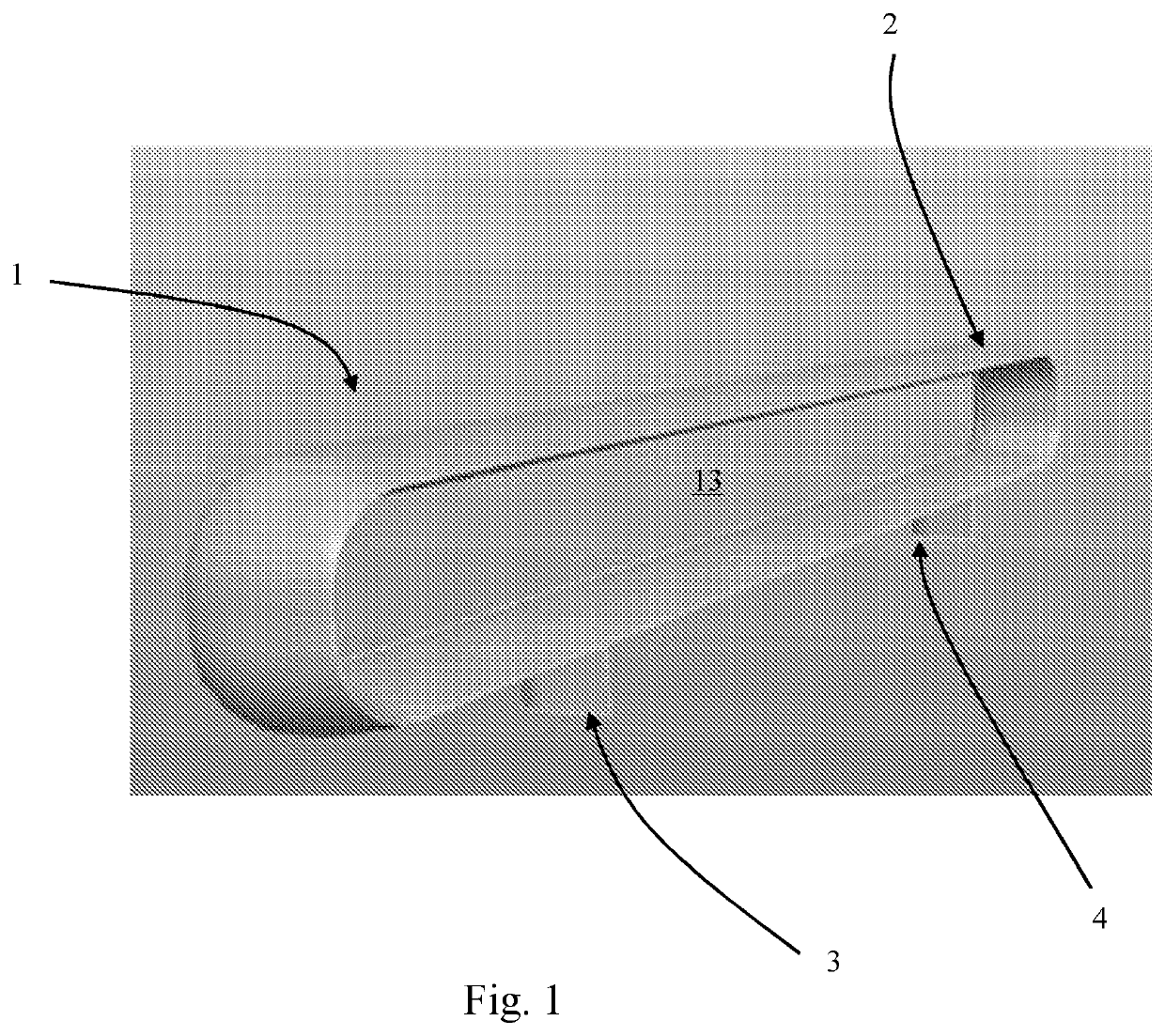

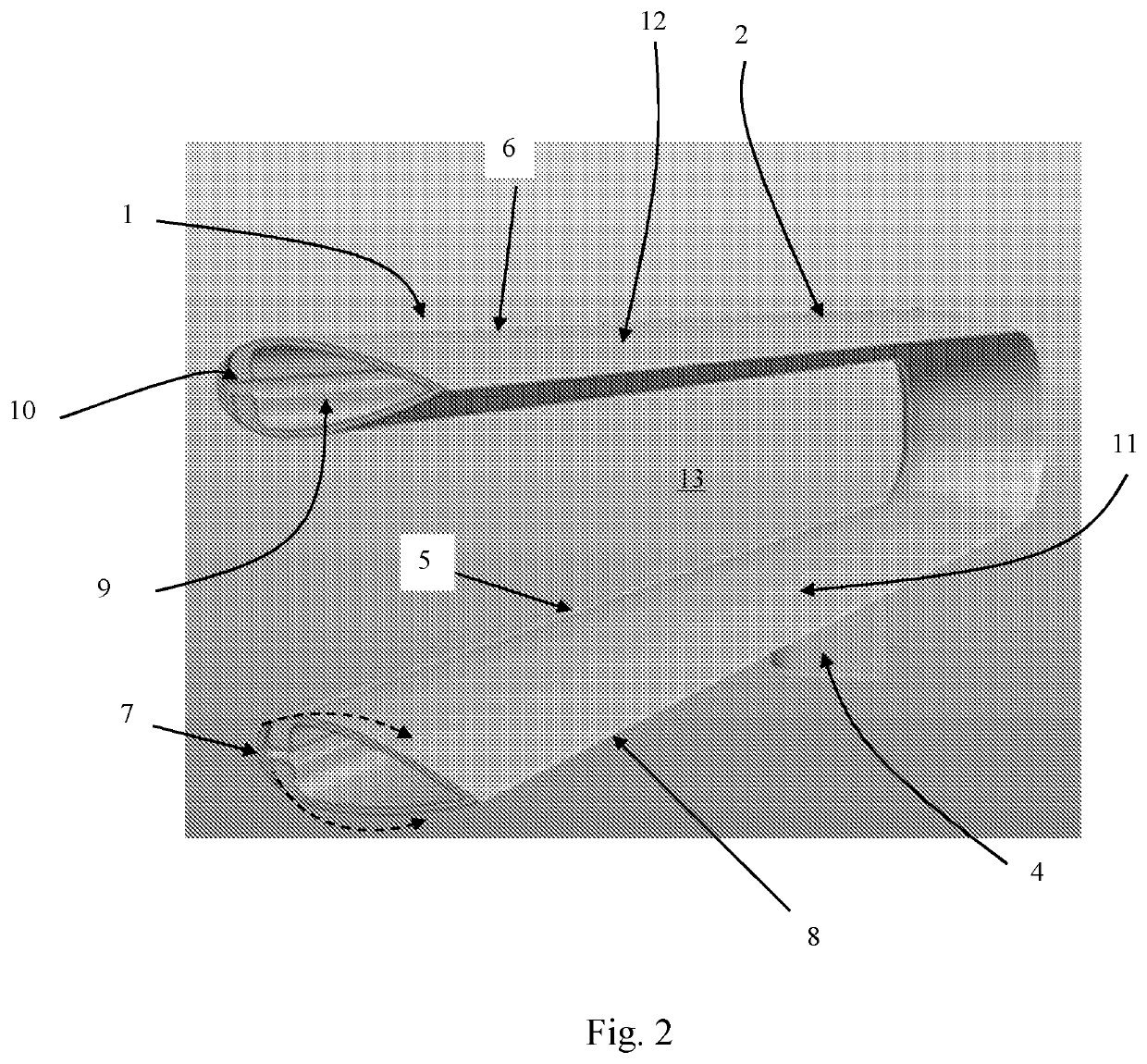

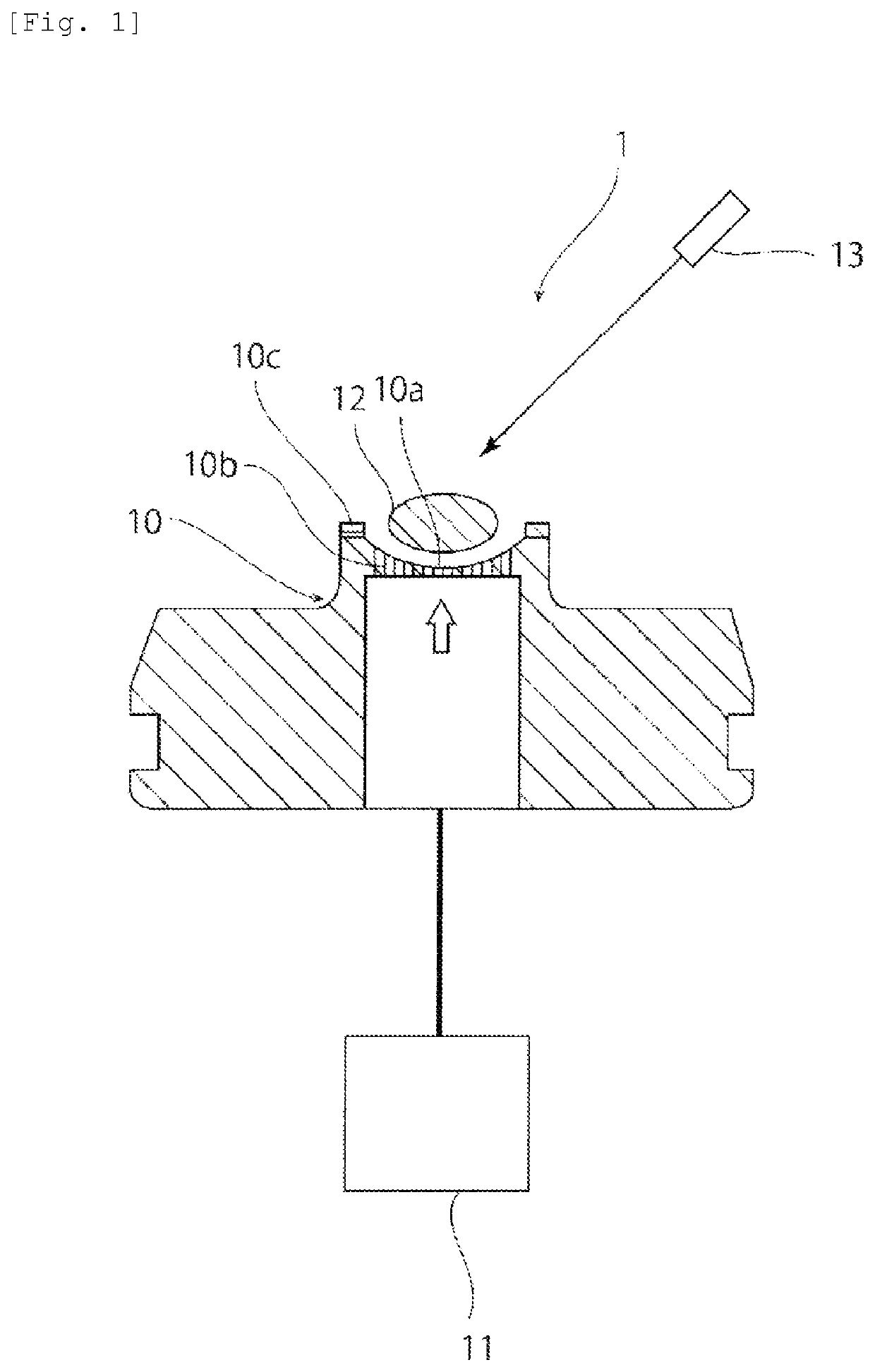

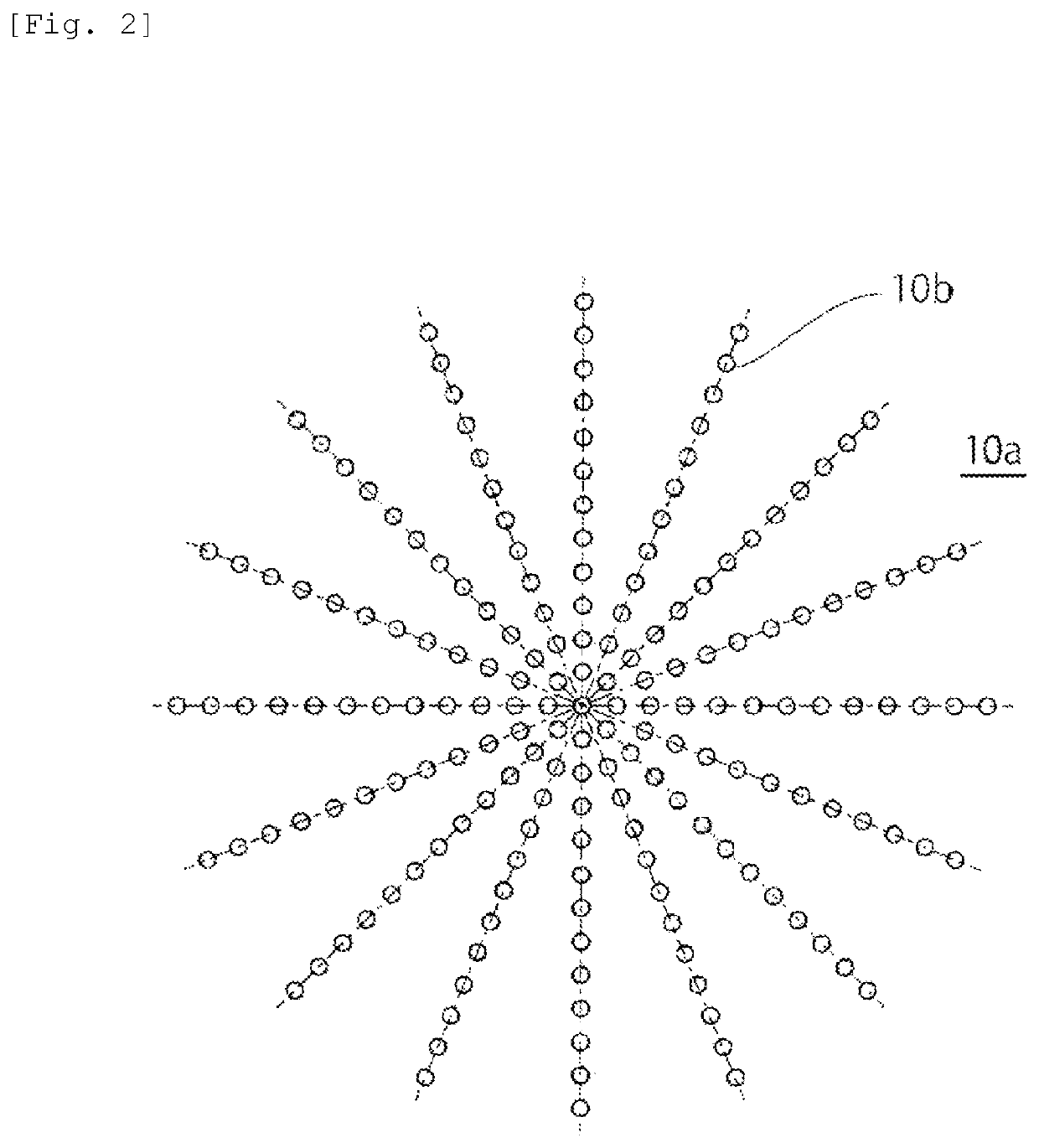

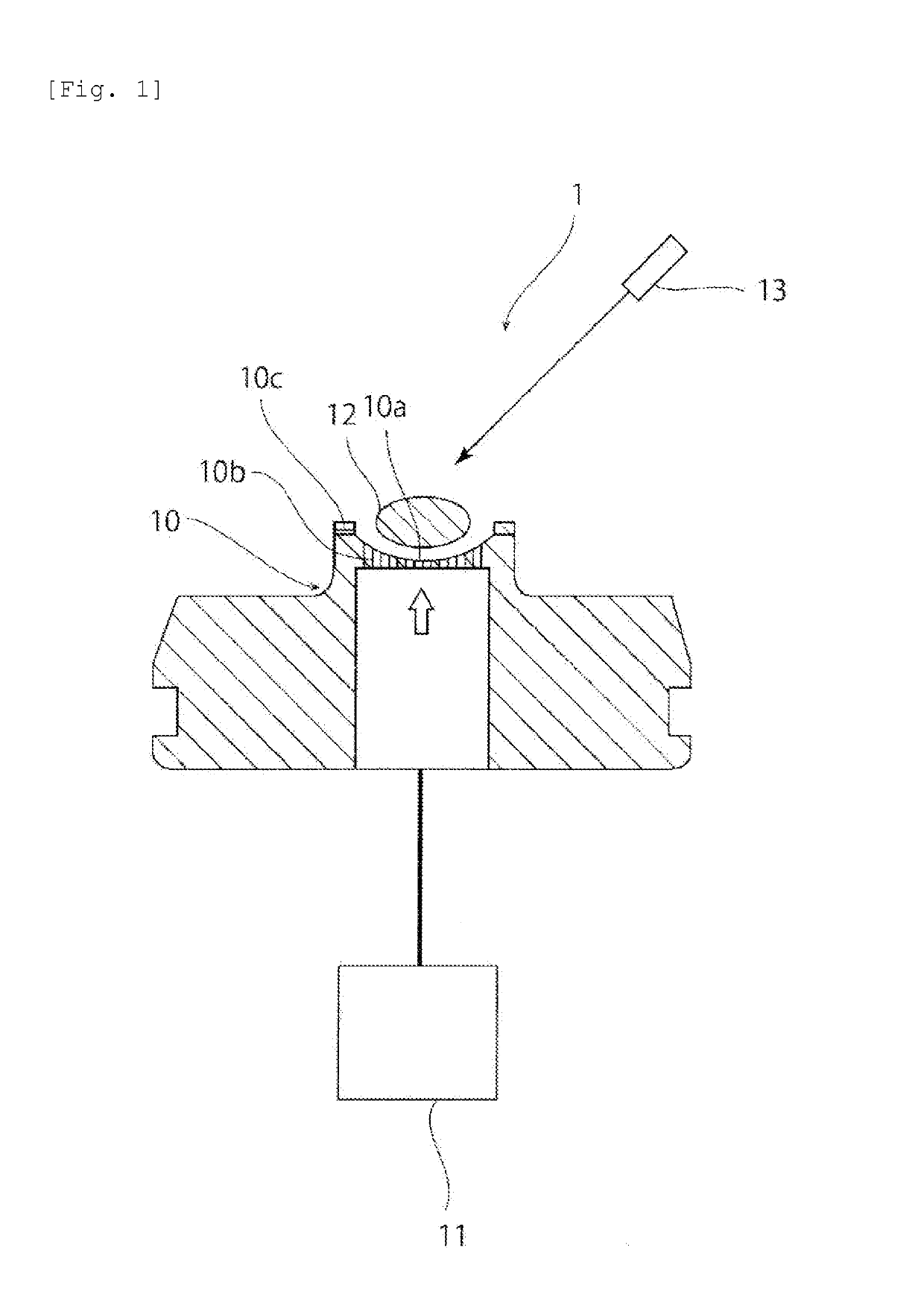

Glass material manufacturing method and glass material manufacturing device

ActiveUS20170190605A1Improve homogeneityProperty variationGlass furnace apparatusGlass reforming apparatusLevitationIrradiation

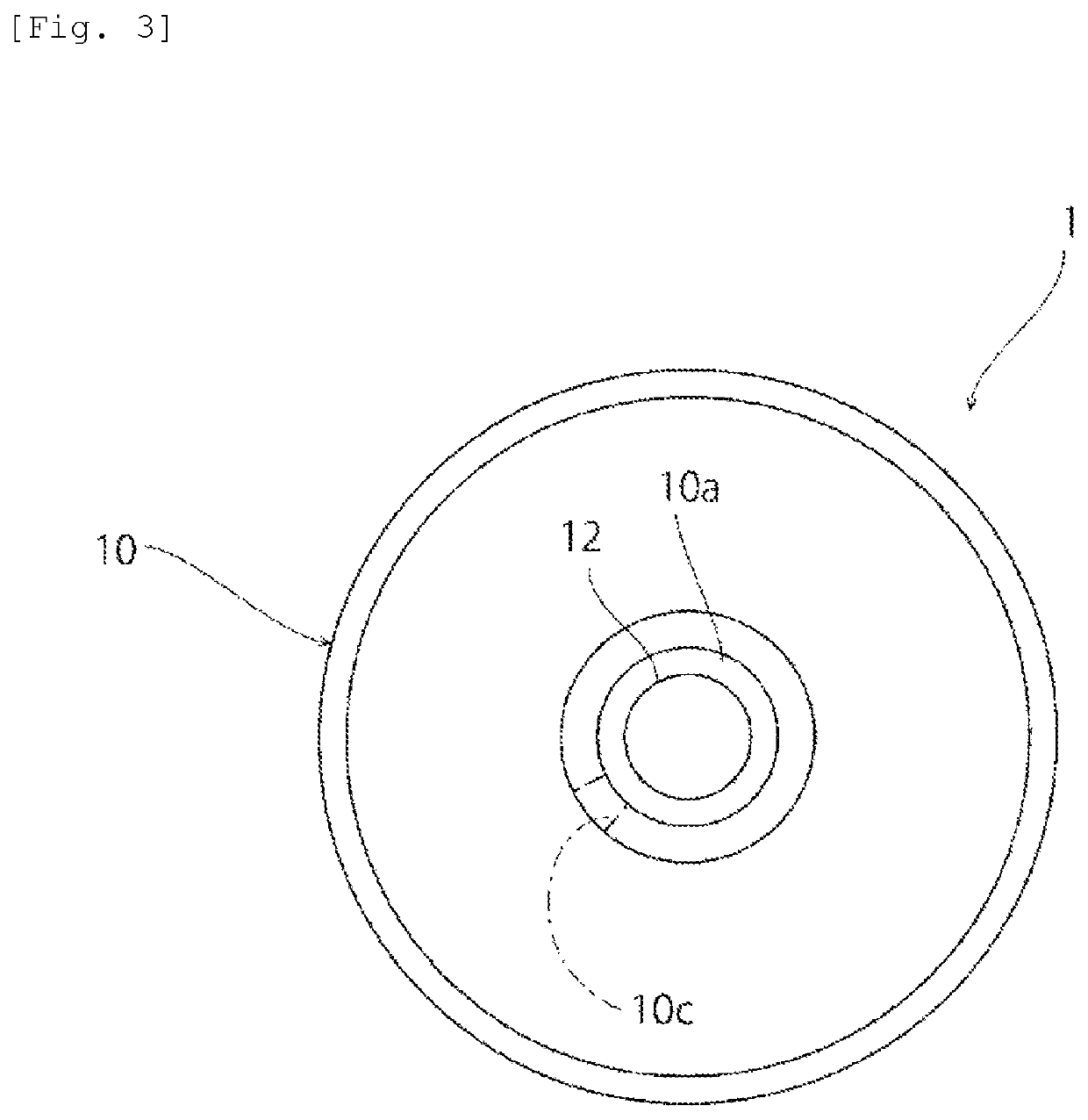

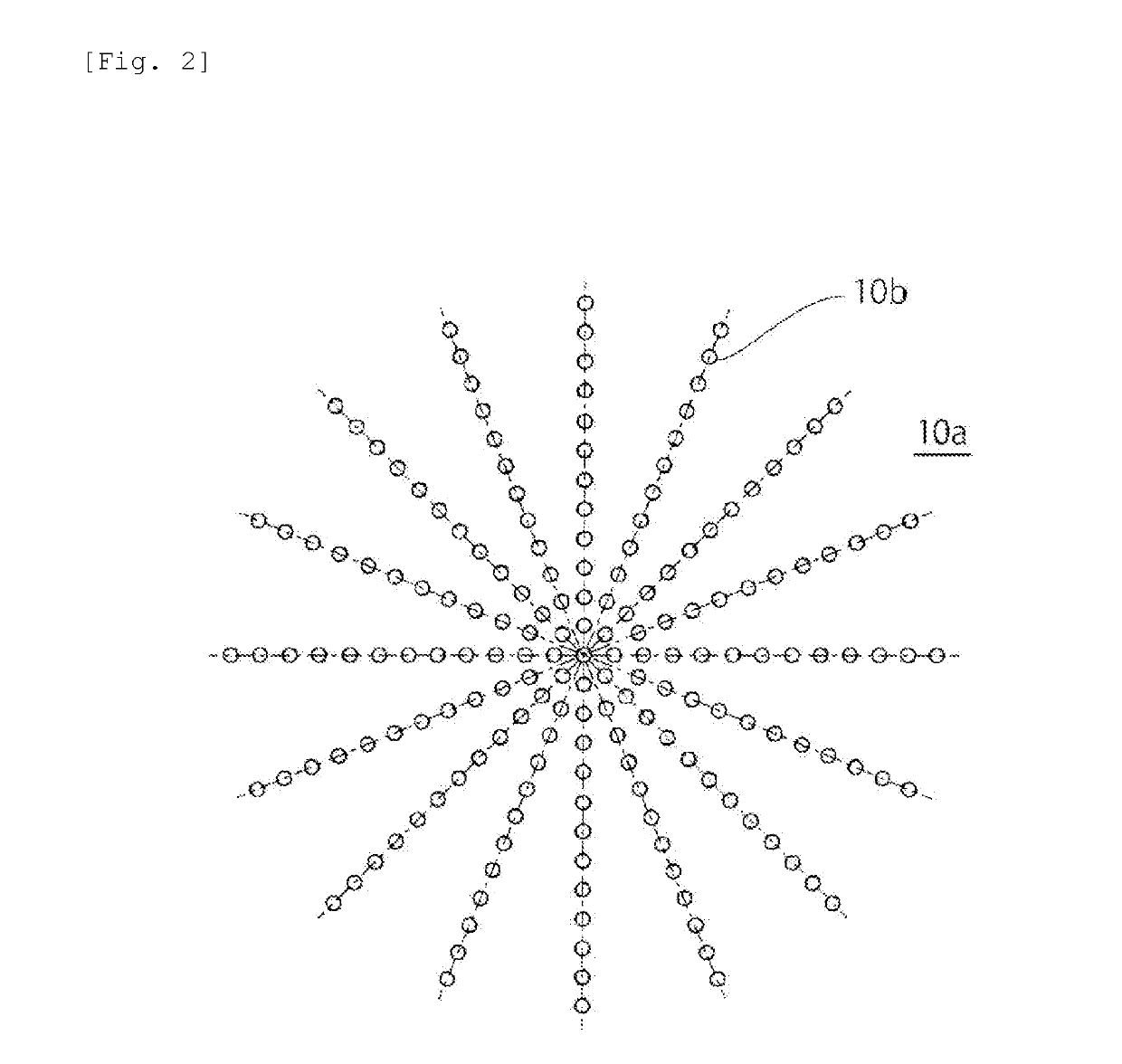

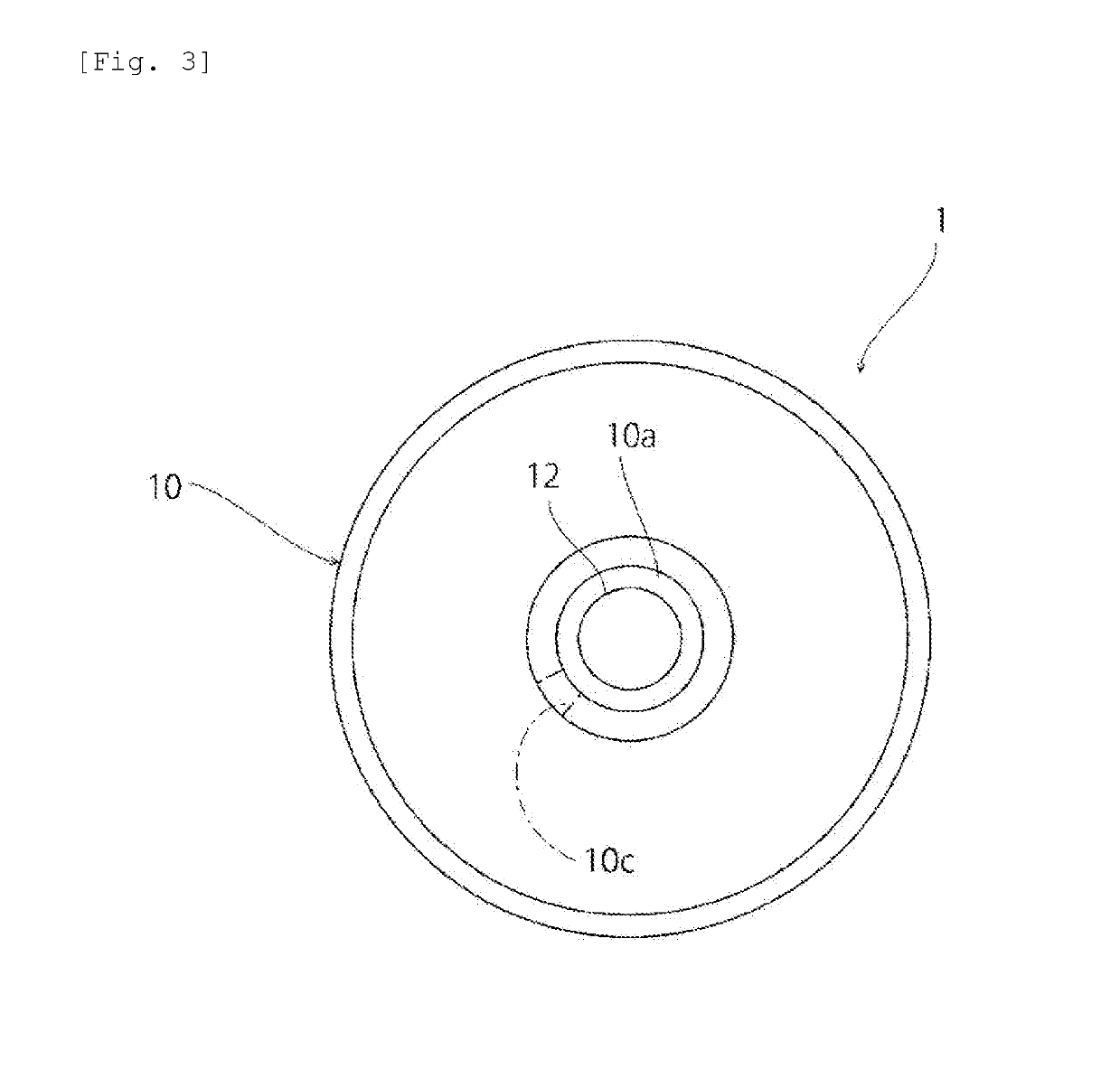

Provided is a method that can manufacture a glass material having excellent homogeneity by containerless levitation. With a block (12) of glass raw material held levitated above a forming surface (10a) of a forming die (10) by jetting gas through a gas jet hole (10b) opening on the forming surface (10a), the block (12) of glass raw material is heated and melted by irradiation with laser beam, thus obtaining a molten glass, and the molten glass is then cooled to obtain a glass material. Control gas is jetted to the block (12) of glass raw material along a direction different from a direction of jetting of the levitation gas for use in levitating the block (12) of glass raw material or the molten glass.

Owner:NIPPON ELECTRIC GLASS CO LTD

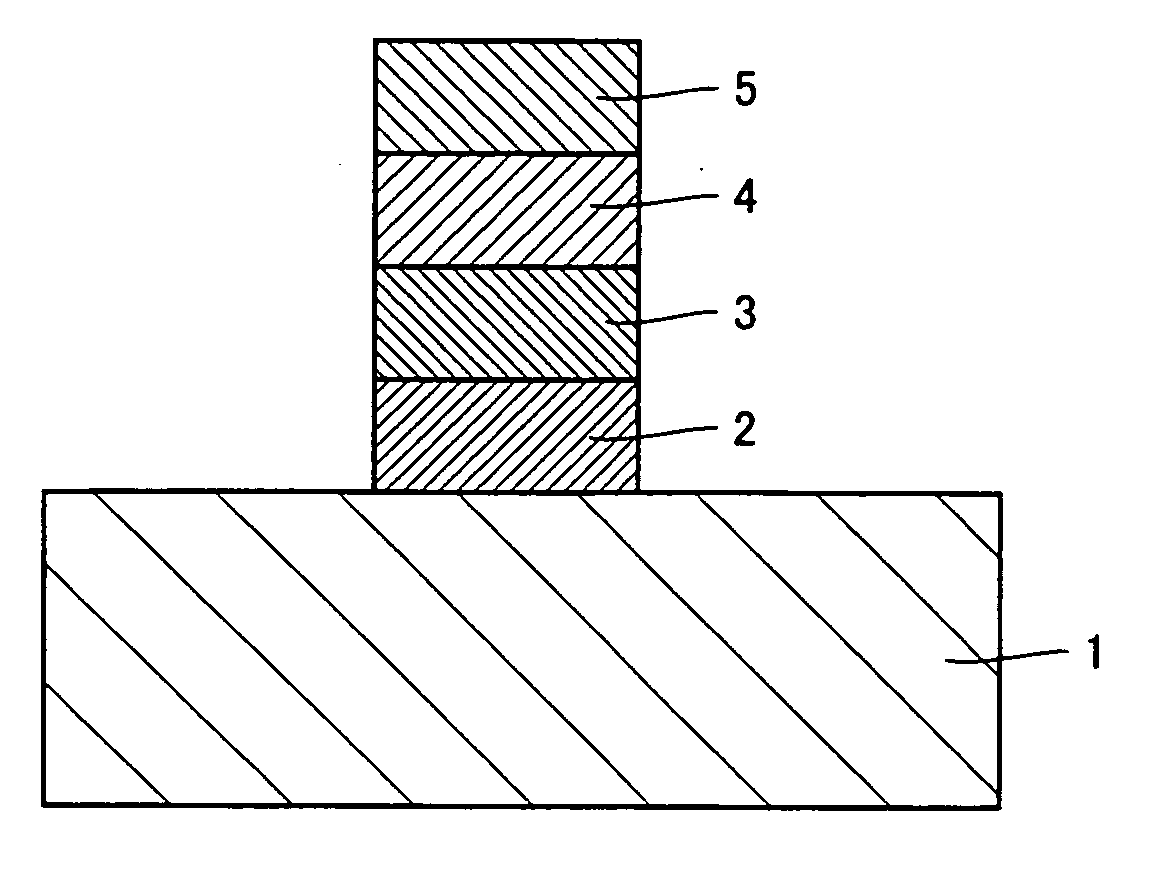

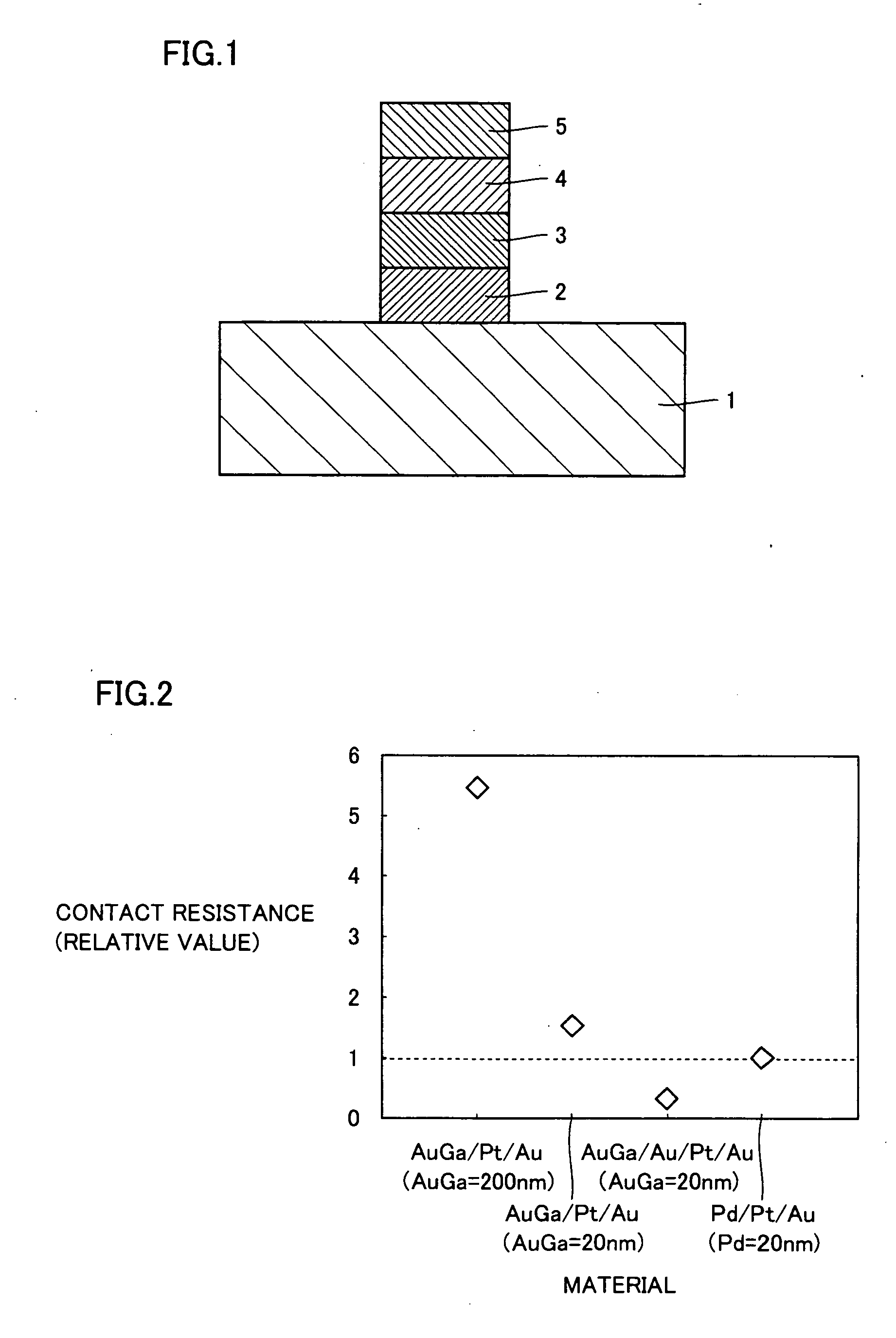

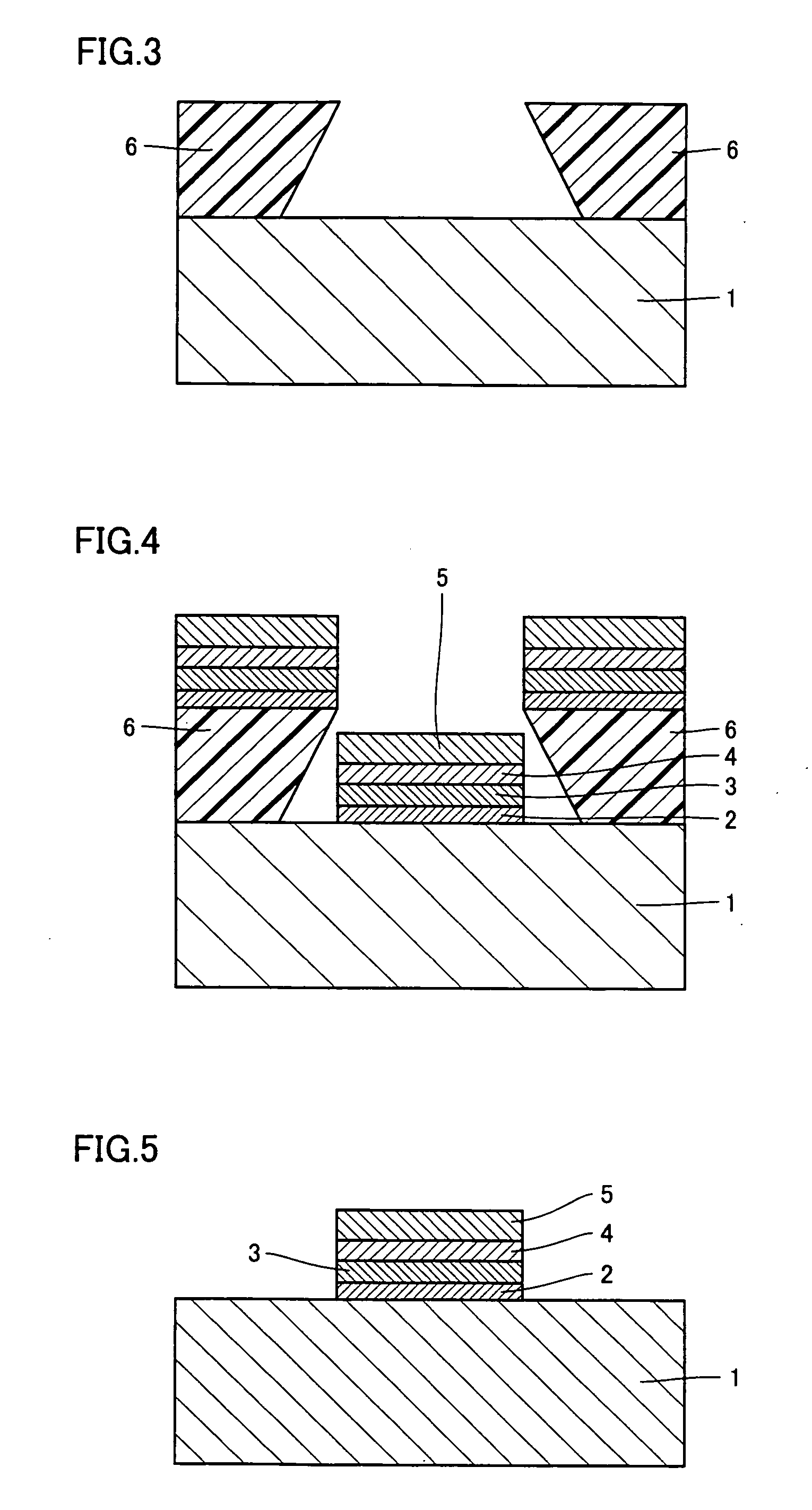

Nitride semiconductor device and method of manufacturing the same

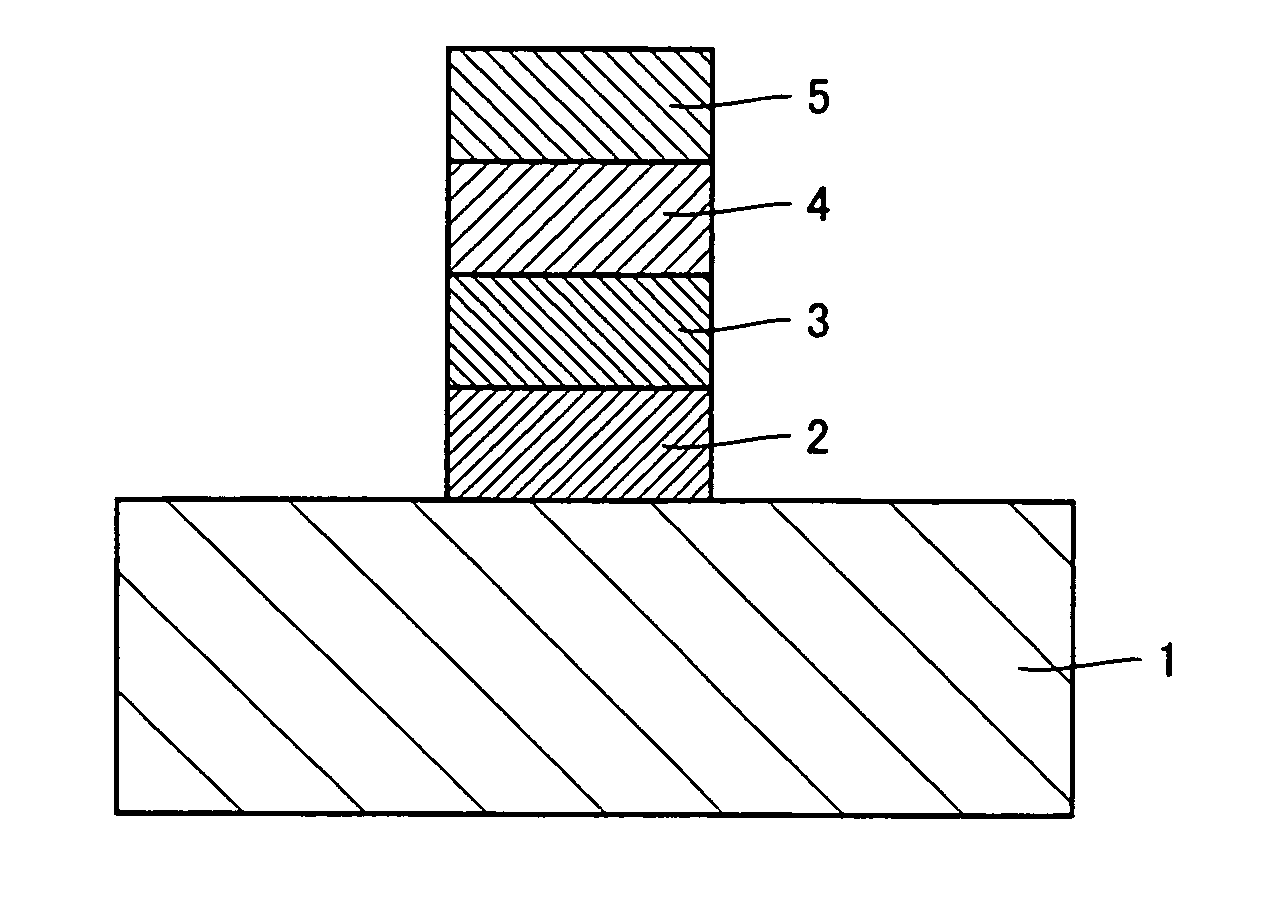

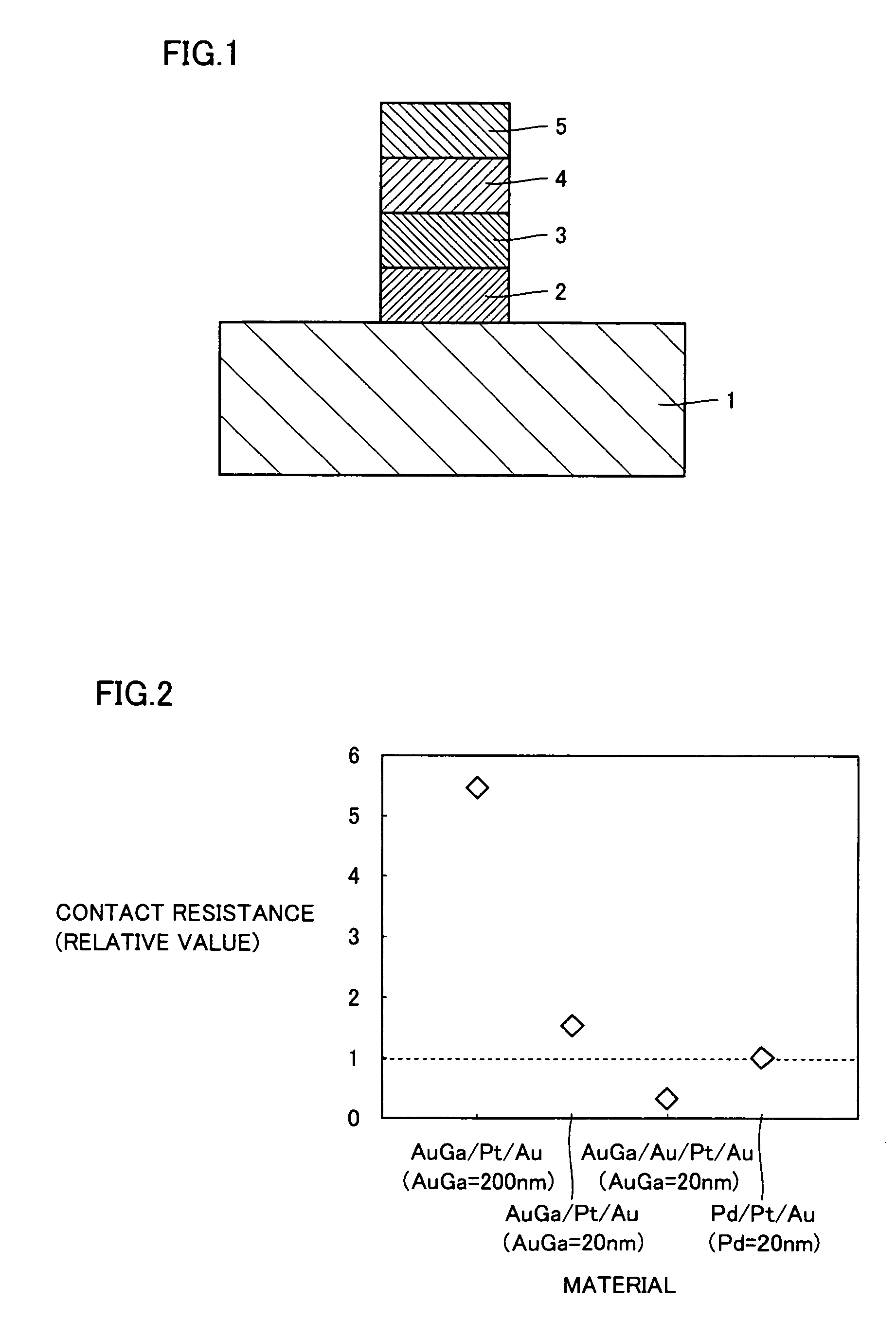

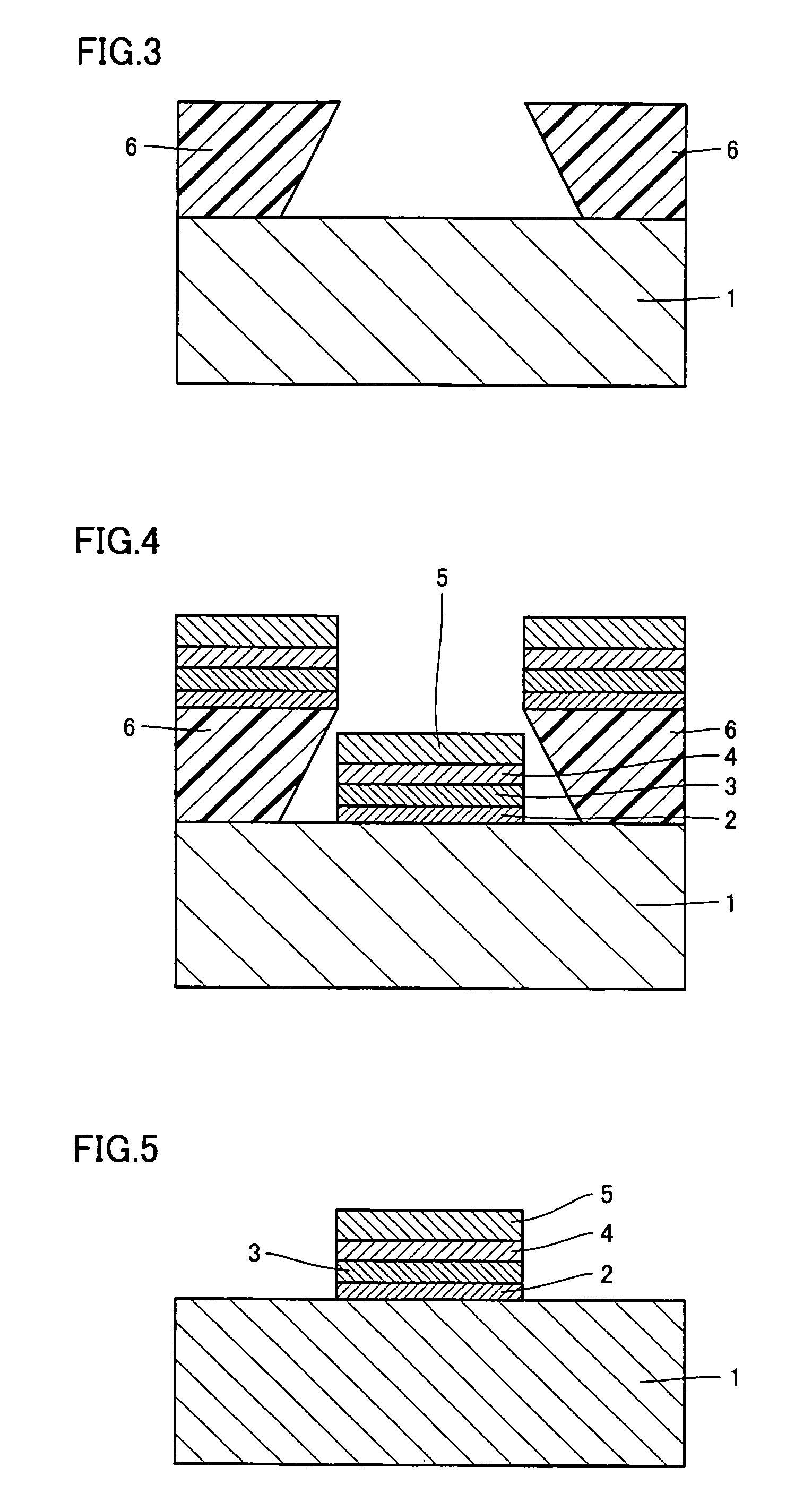

ActiveUS20060108596A1Low working voltageReduce variationSemiconductor/solid-state device manufacturingSemiconductor devicesContact layerContact resistance

A P-type electrode material is provided on a top surface of a P-type contact layer. The P-type electrode material is formed with an AuGa film, an Au film, a Pt film, and an Au film. The AuGa film is provided on the P-type contact layer. The Au film is provided on the AuGa film. The Pt film is provided on the Au film. The Au film is provided on the Pt film. With this, a nitride semiconductor device having a P-type electrode which can decrease a contact resistance between a P-type contact layer and the P-type electrode is obtained.

Owner:MITSUBISHI ELECTRIC CORP

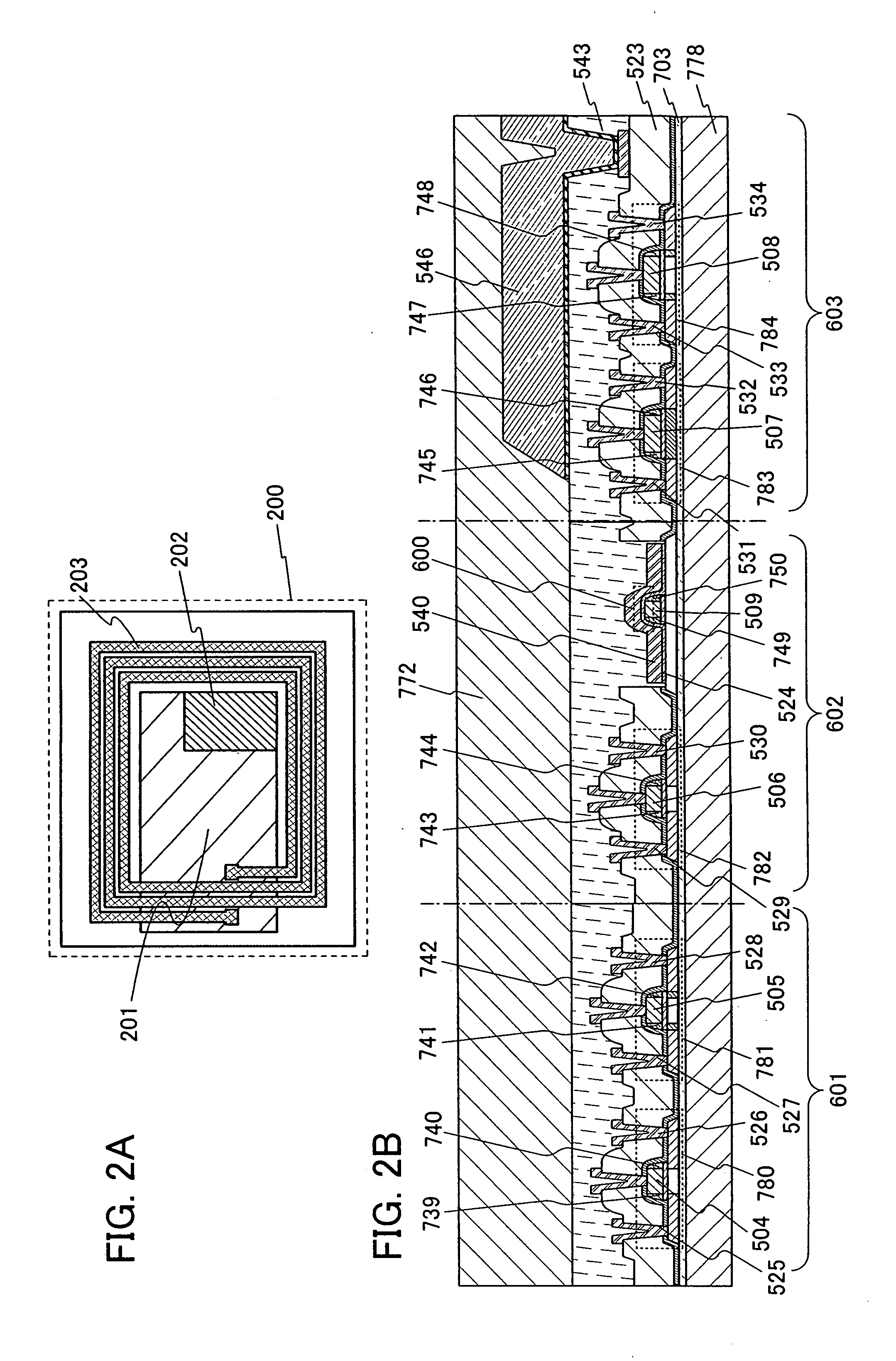

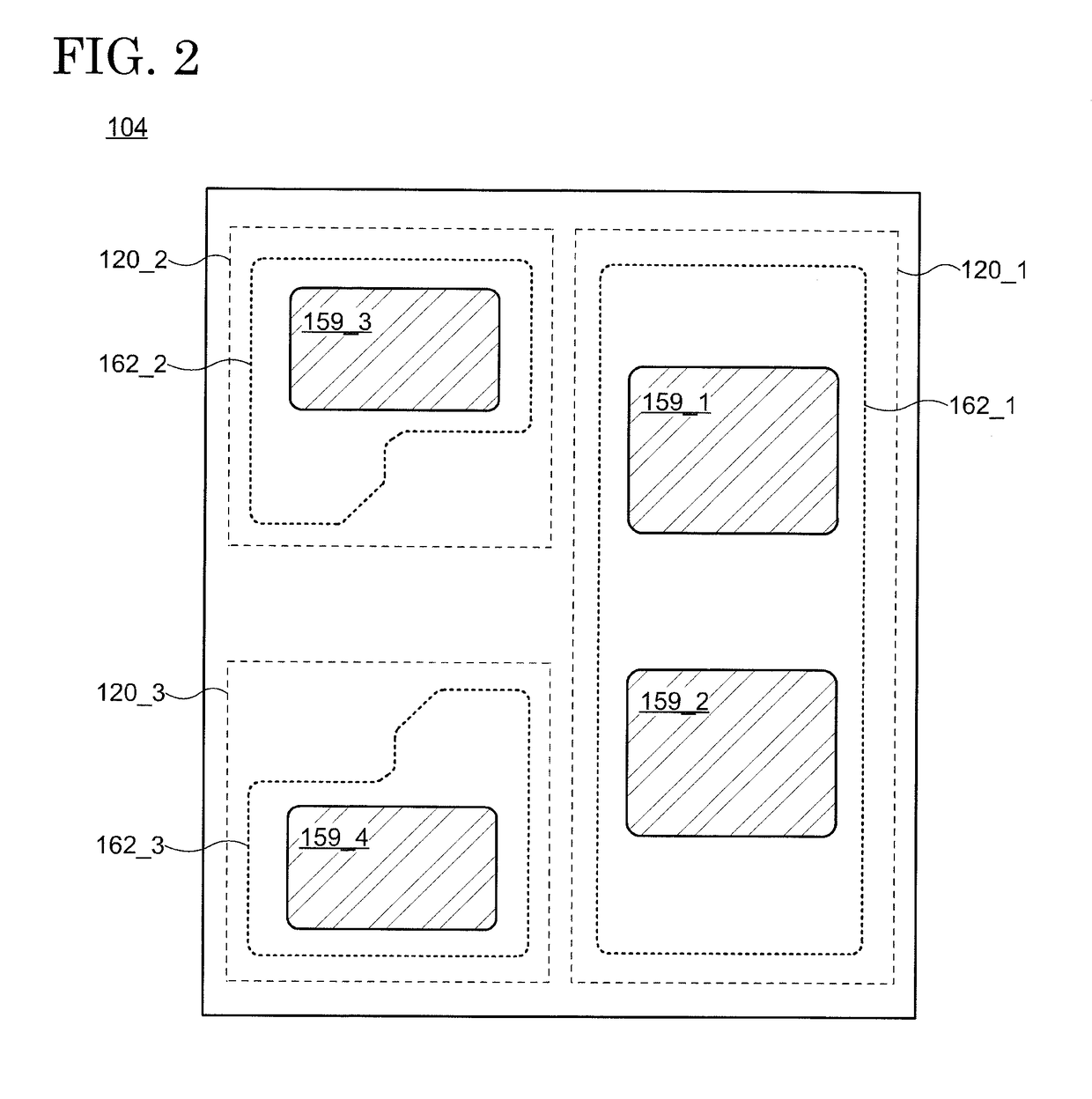

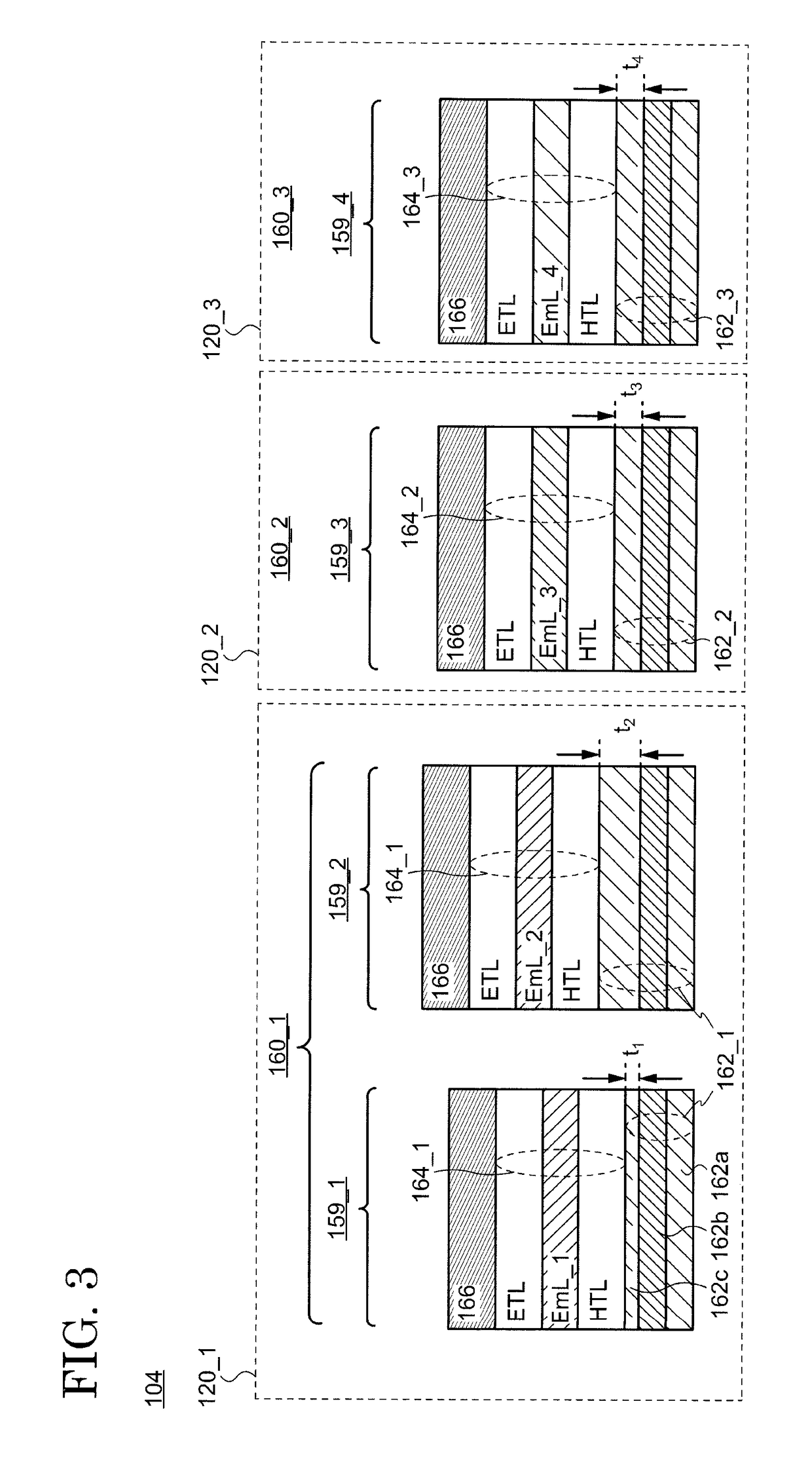

Light-emitting element and display device having the light-emitting element

InactiveUS20190006625A1Reduce the impactProperty variationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

Disclosed is a light-emitting element including a reflective electrode, a light-transmitting electrode over the reflective electrode, a partition wall over the light-transmitting electrode, the partition wall having a first opening and a second opening which overlap with the light-transmitting electrode, an electroluminescence layer over the first opening and the second opening, and an opposing electrode over the electroluminescence layer. A thickness of the light-transmitting electrode in a region overlapping with the first opening is smaller than a thickness of the light-transmitting electrode in a region overlapping with the second region.

Owner:JAPAN DISPLAY INC

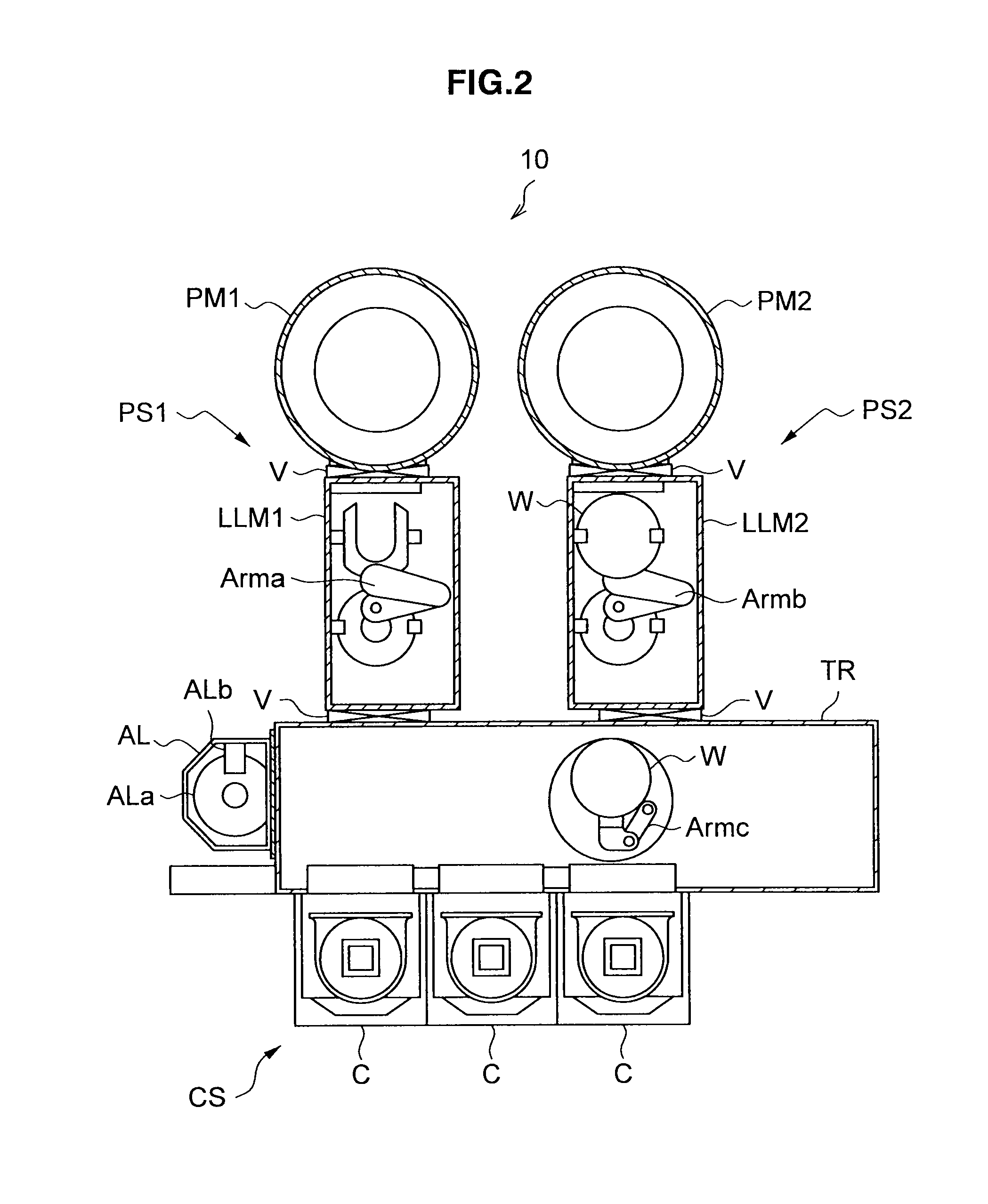

Device for controlling processing system, method for controlling processing system and computer-readable storage medium stored processing program

ActiveUS20090076647A1Production of product can be suppressedIncrease productionProgramme controlDigital data processing detailsMachine controlProcess module

A processing system includes process modules, load lock modules, an equipment controller, and a machine controller. The equipment controller controls transfer and processing of wafers in the processing system. A transfer destination determining portion determines the transfer destination of each wafer such that each wafer is sequentially transferred to a normally operating process module. When an abnormality occurs in a process module, an evacuation portion temporarily evacuates to a cassette stage the wafer determined is to be transferred to the abnormal process module and that has not yet been transferred to the abnormal process module. When a new transfer destination of the evacuated wafer is determined, if a process that is performed immediately before processing the evacuated wafer in the processing module as the new transfer destination satisfies a predetermined condition, a transfer inhibition portion inhibits the transfer of the evacuated wafer to the new transfer destination.

Owner:TOKYO ELECTRON LTD

Additive manufacturing apparatus and a flow device for use with such apparatus

ActiveUS10926327B2Improve entrapmentImprove transportAdditive manufacturing apparatusIncreasing energy efficiencyThermodynamicsManufactured apparatus

Owner:RENISHAW PLC

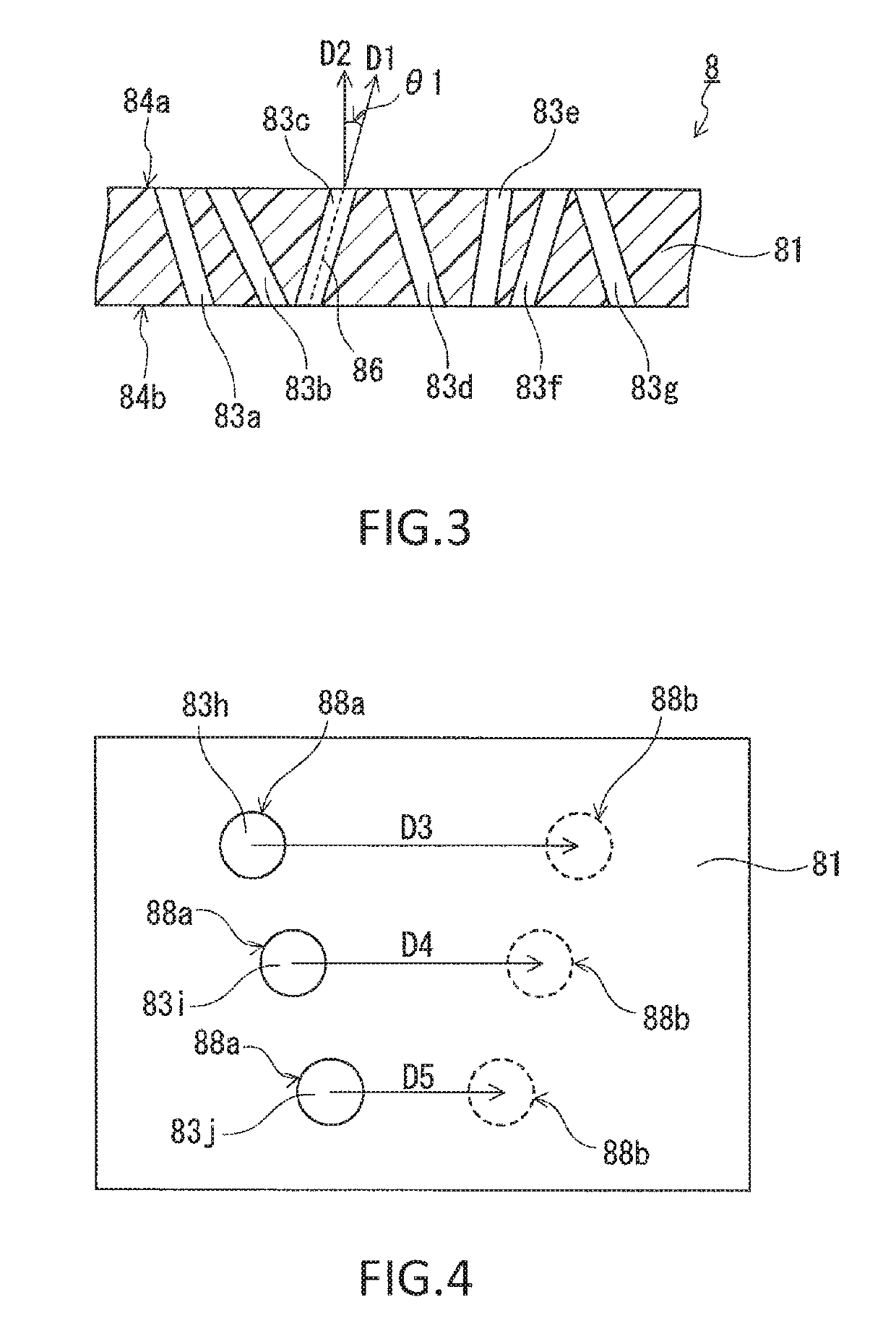

Acoustic resistor, acoustic resistor member including same, and audio device including same

ActiveUS10362387B2Little changeProperty variationHearing aid ventsEarpiece/earphone attachmentsElectrical resistance and conductanceEngineering

An acoustic resistor for use in an audio device includes a resin film having air permeability in a thickness direction of the resin film, and the resin film is a non-porous film having through holes formed to extend straight through the resin film in the thickness direction. This acoustic resistor is used in an audio device including: a transducing part that performs conversion between sound and an electrical signal and that includes an acoustic element; a housing enclosing the transducing part and having at least one opening; and a passage for gas that is present inside the housing and communicates with the opening and in which the acoustic element is placed. The acoustic resistor is placed between the opening and the acoustic element in the passage. The variation in properties of the acoustic resistor of the present disclosure can be made smaller than that of conventional acoustic resistors.

Owner:NITTO DENKO CORP

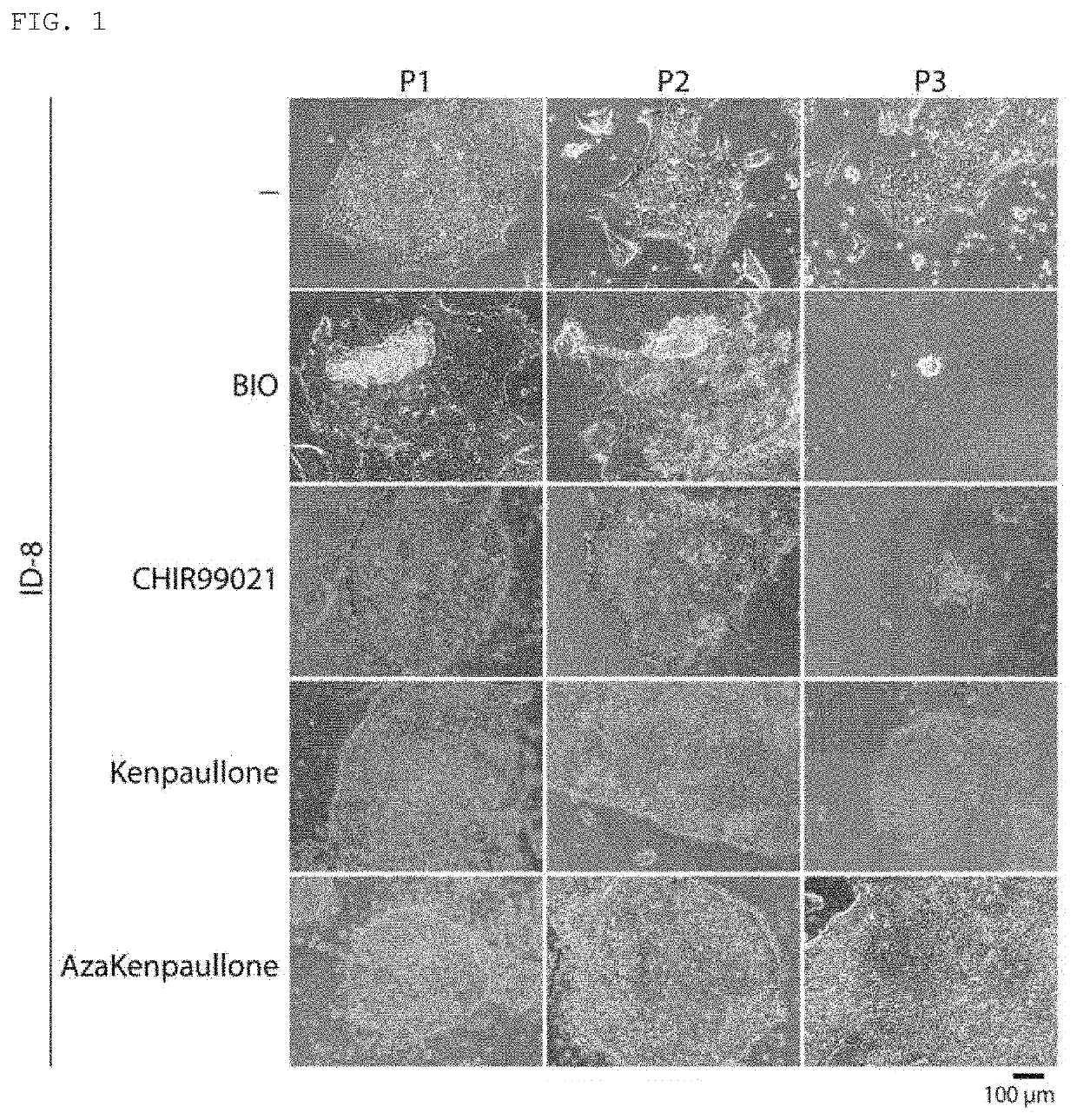

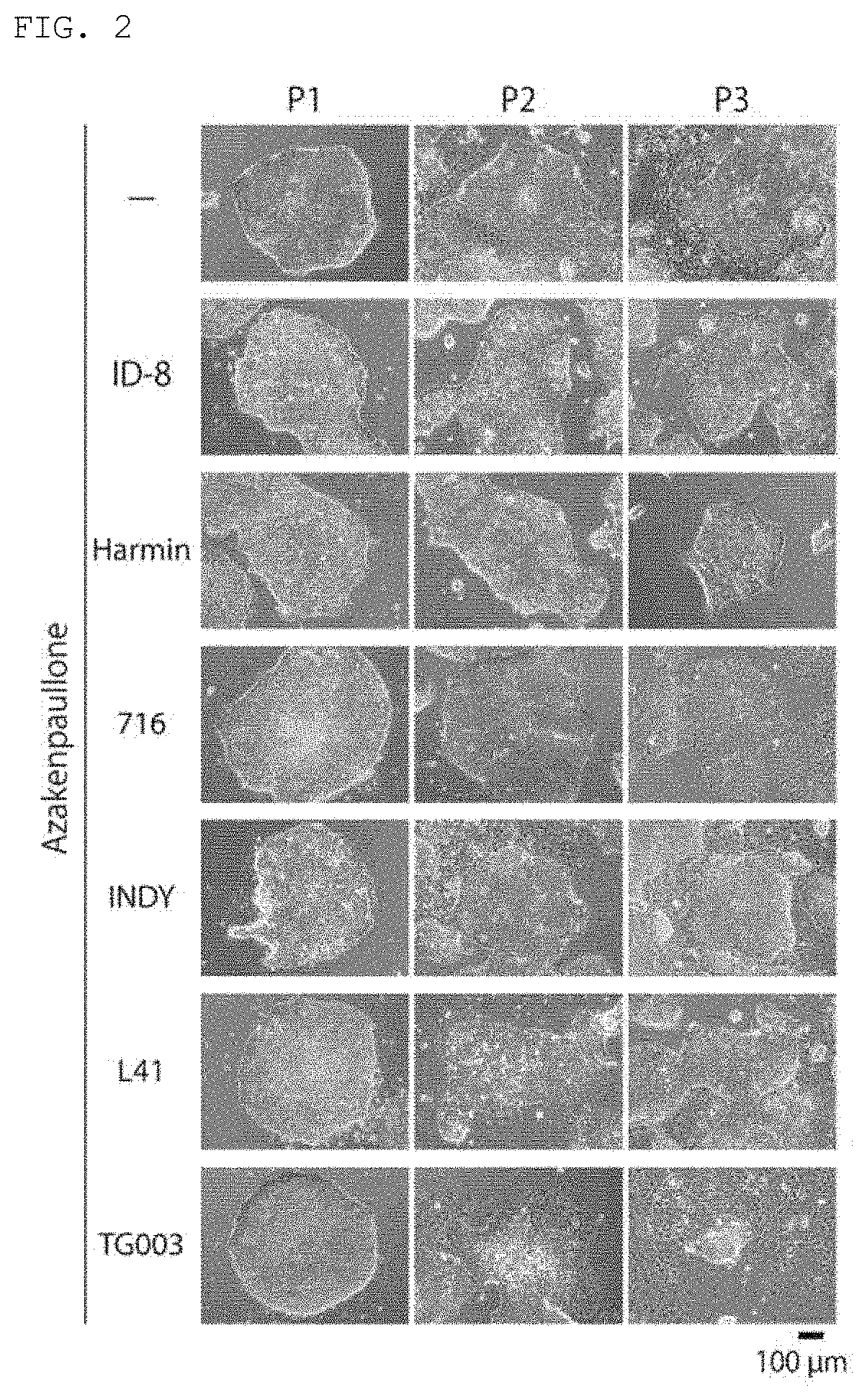

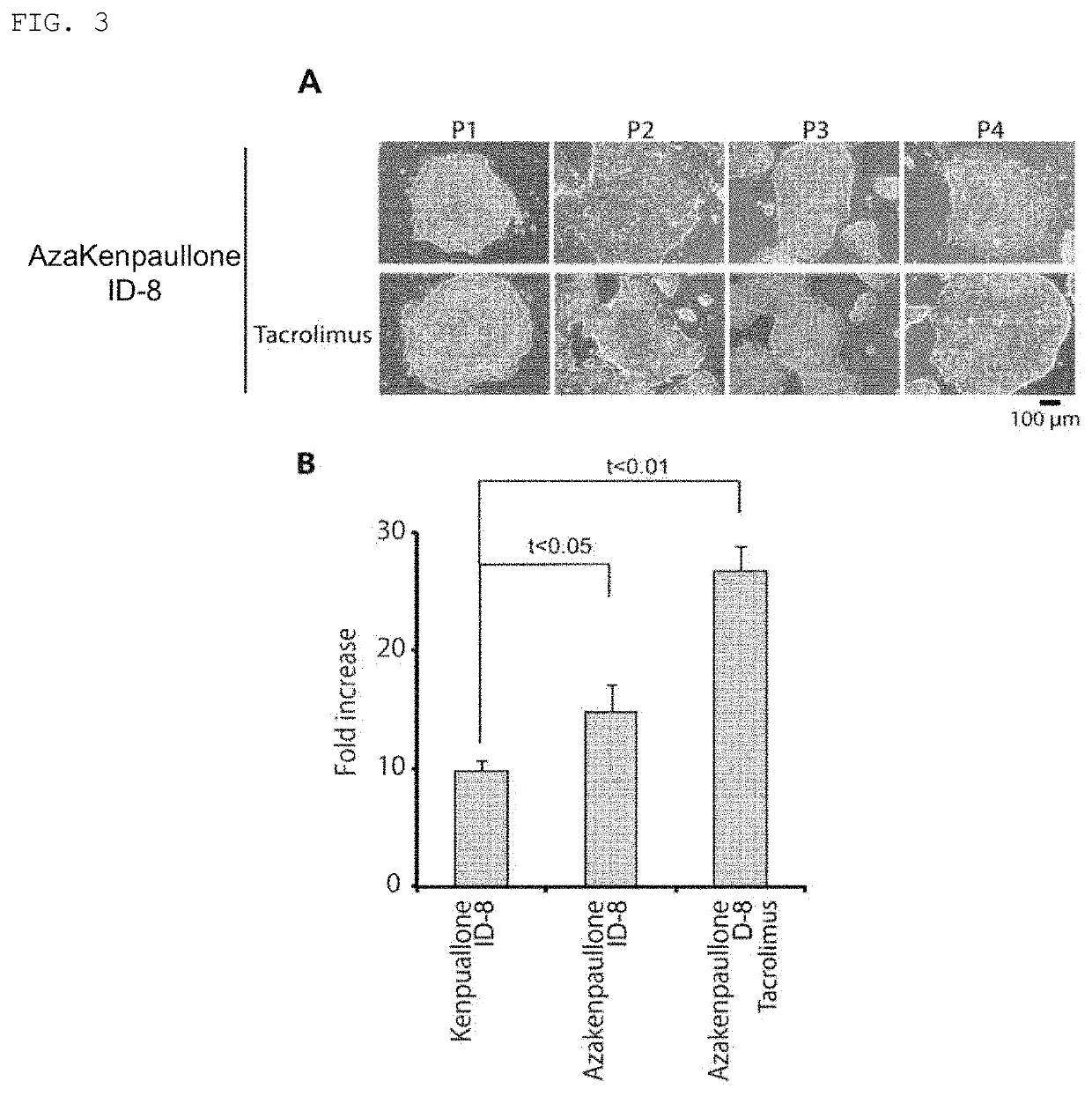

Culture medium for pluripotent stem cells

ActiveUS11015169B2Cheap preparationProperty variationGenetically modified cellsCulture processBiochemistryMultipotential stem cell

An object of the present invention is to provide a medium that comprises fewer protein components and enables the maintenance of pluripotent stem cells in an undifferentiated state. The culture medium for pluripotent stem cells comprises a GSK3β inhibitor (A) and a DYRK inhibitor (B).

Owner:KYOTO UNIV

Glass material manufacturing method and glass material manufacturing device

ActiveUS11319237B2Improve homogeneityProperty variationGlass furnace apparatusGlass reforming apparatusManufactured materialLaser beams

Provided is a method that can manufacture a glass material having excellent homogeneity by containerless levitation. With a block (12) of glass raw material held levitated above a forming surface (10a) of a forming die (10) by jetting gas through a gas jet hole (10b) opening on the forming surface (10a), the block (12) of glass raw material is heated and melted by irradiation with laser beam, thus obtaining a molten glass, and the molten glass is then cooled to obtain a glass material. Control gas is jetted to the block (12) of glass raw material along a direction different from a direction of jetting of the levitation gas for use in levitating the block (12) of glass raw material or the molten glass.

Owner:NIPPON ELECTRIC GLASS CO LTD

Nitride semiconductor device and method of manufacturing the same

ActiveUS7842962B2Low working voltageReduce variationSemiconductor/solid-state device manufacturingSemiconductor devicesContact layerContact resistance

Owner:MITSUBISHI ELECTRIC CORP

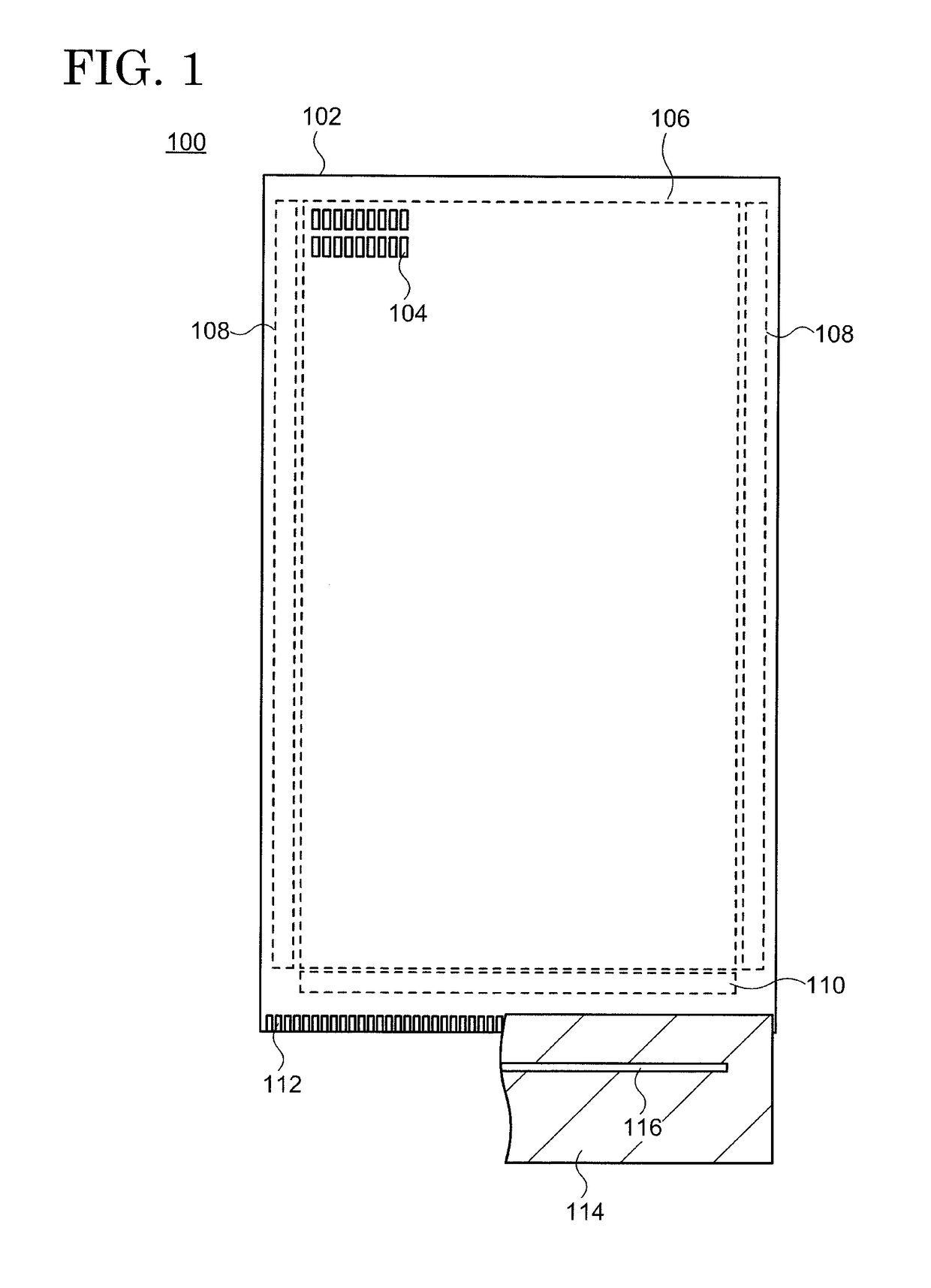

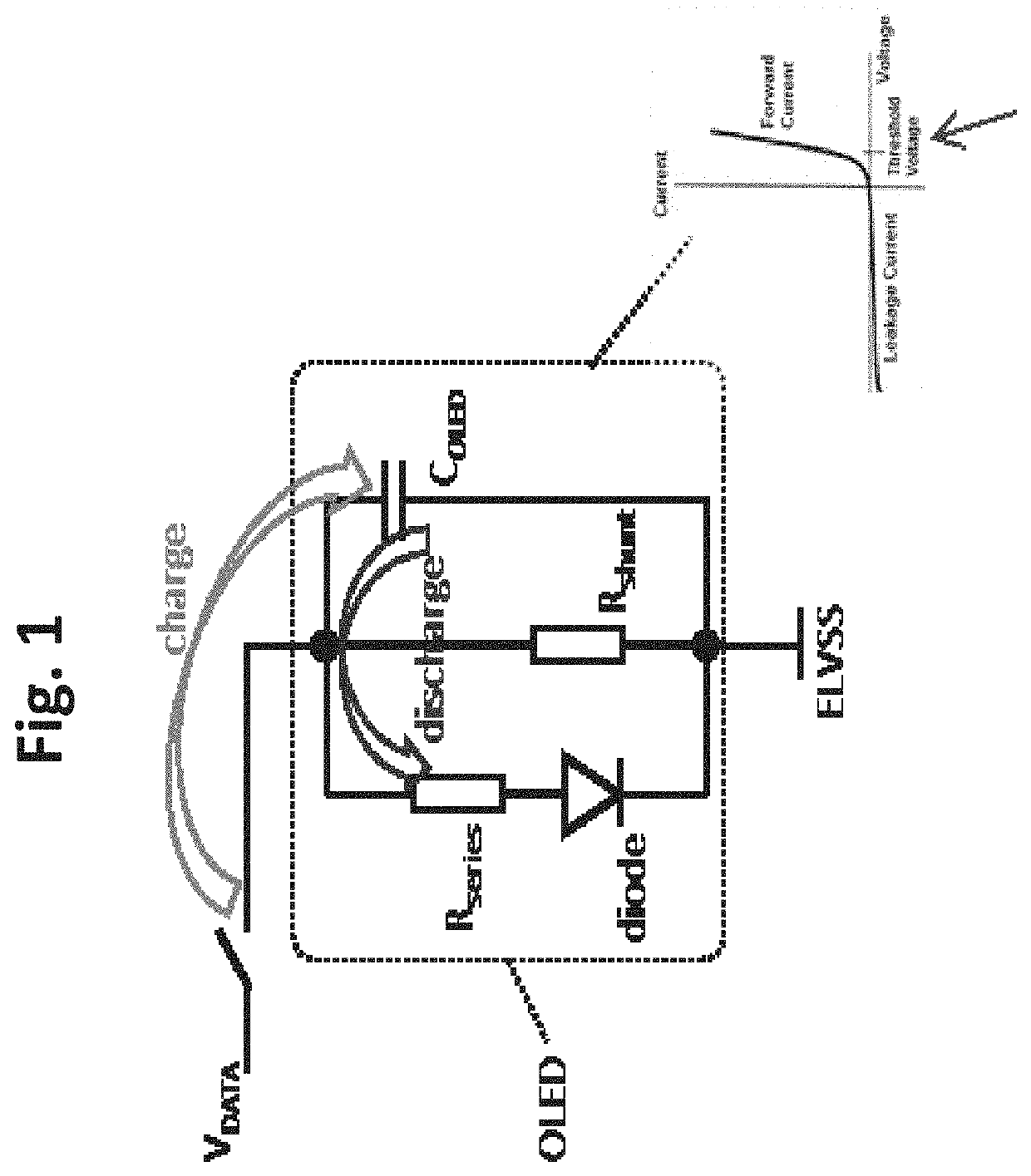

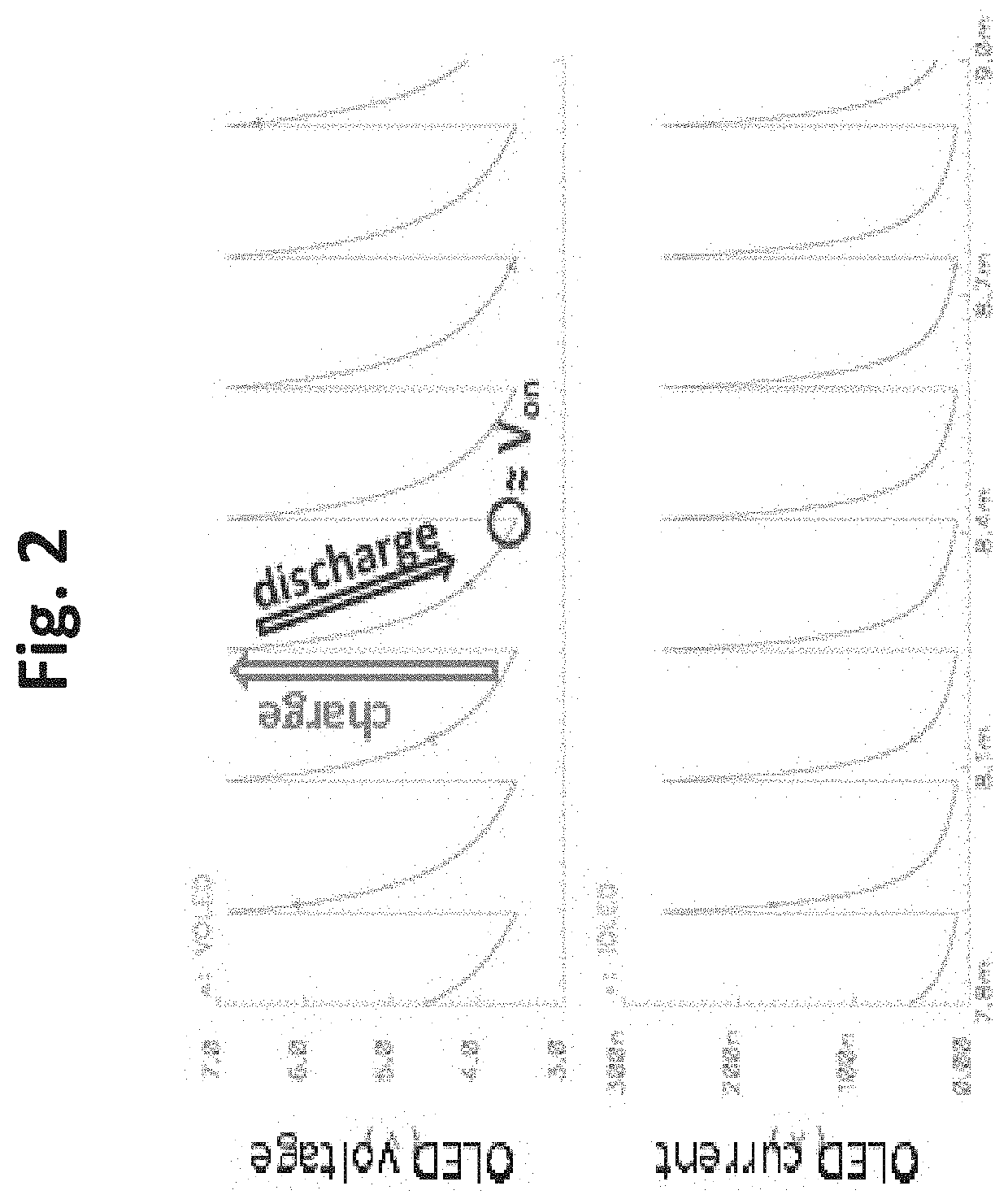

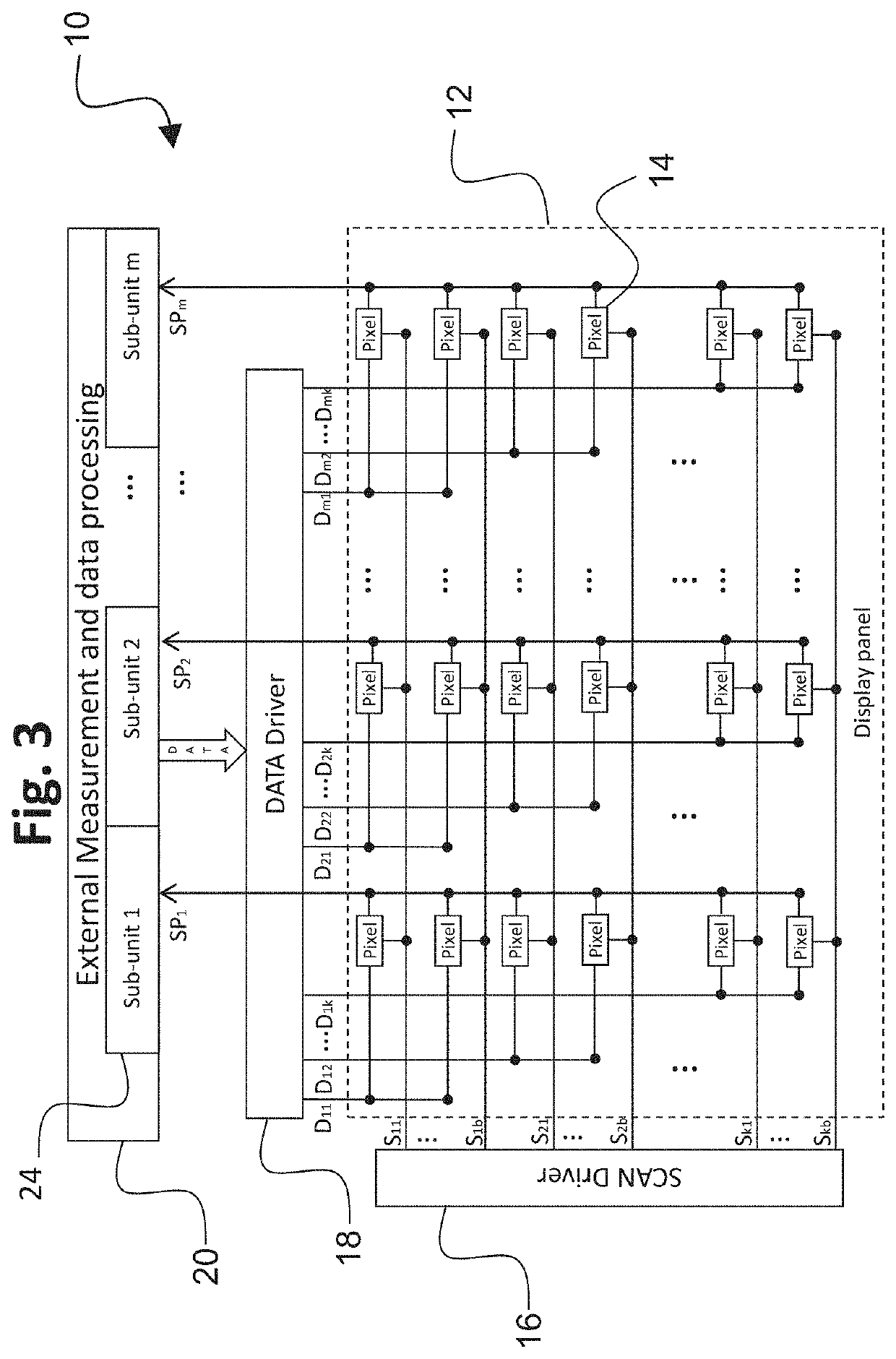

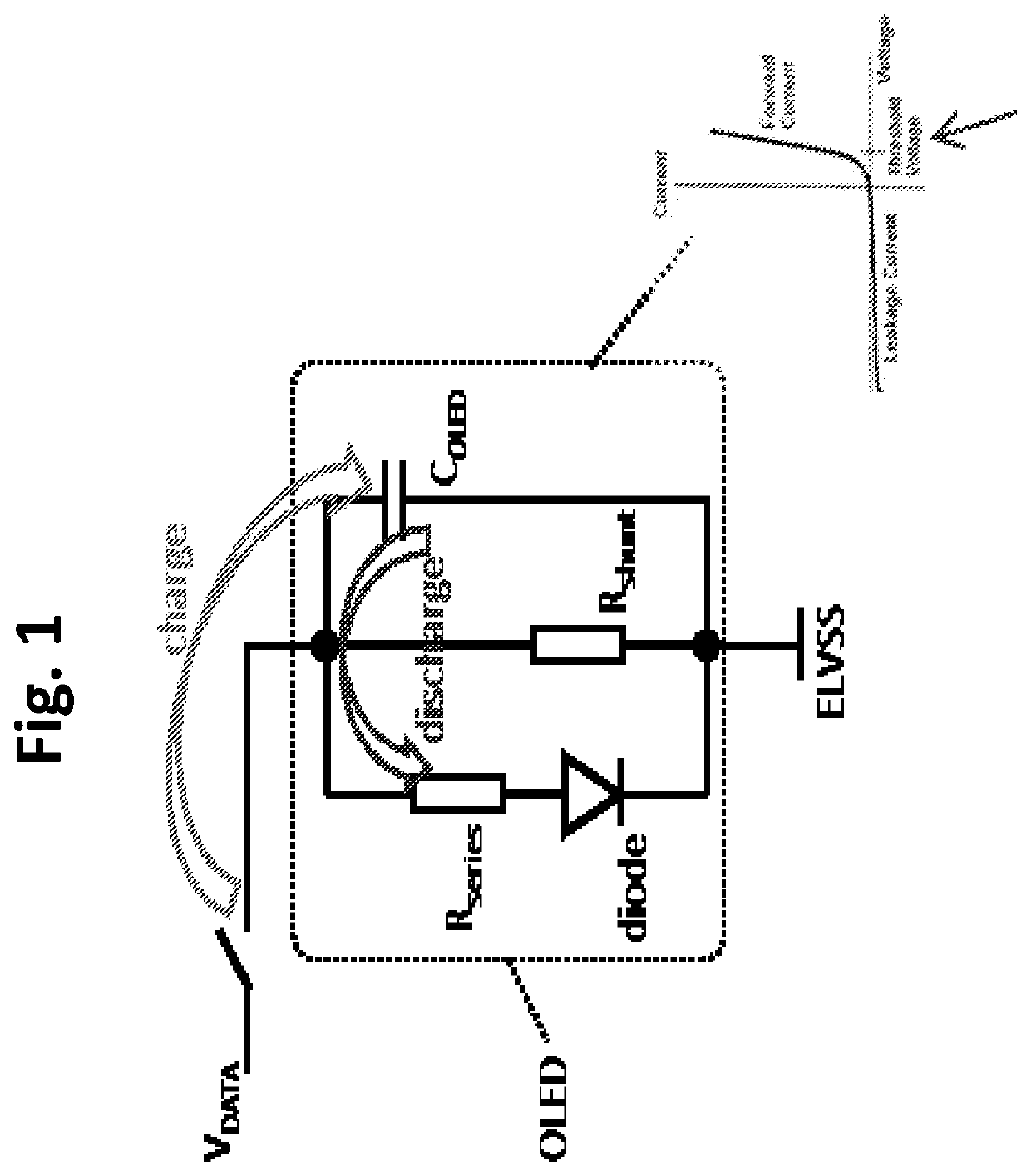

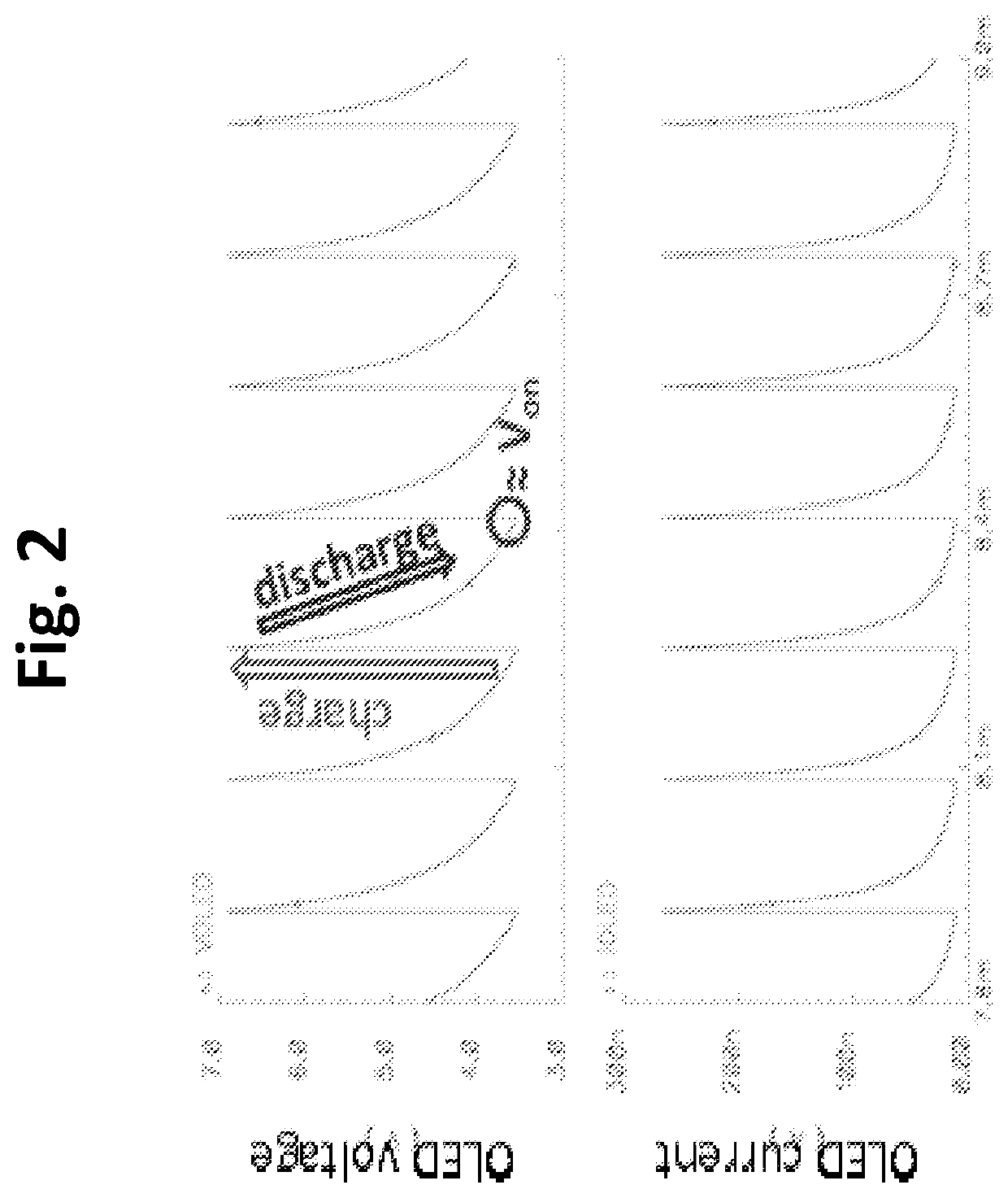

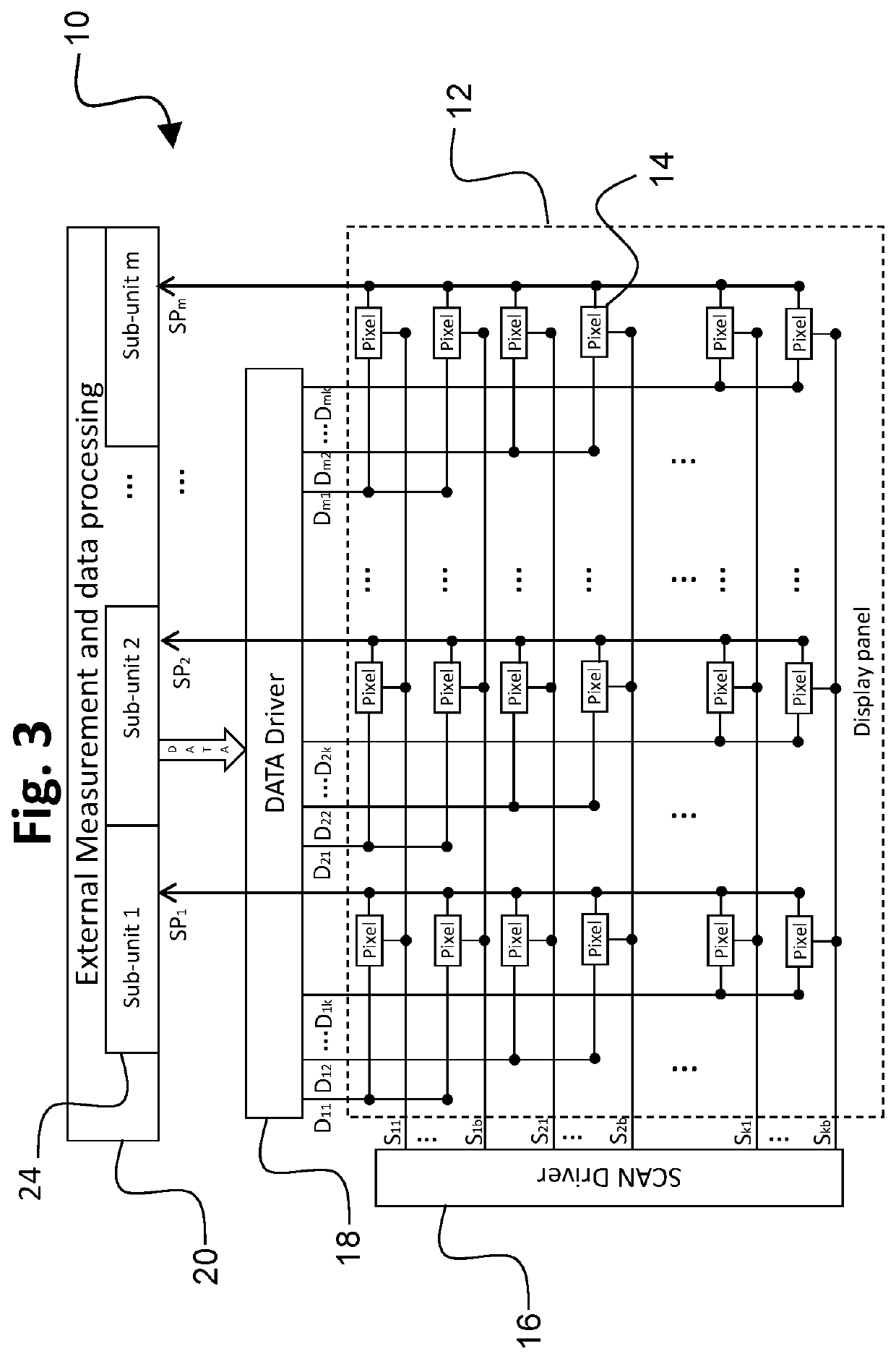

Pixel circuit using direct charging and that performs light-emitting device compensation

ActiveUS20200349889A1Eliminate needProperty variationStatic indicating devicesComputer hardwareHemt circuits

A display system includes a display panel comprising a plurality of pixel circuits, and a measurement and data processing unit that is external to the display panel. Each pixel circuit includes a light-emitting device having a first terminal connected to a first voltage supply and a second terminal opposite from the first terminal; a first transistor connected between a data voltage supply line from the measurement and data processing unit and the second terminal of the light emitting device; and a second transistor connected between the second terminal of the light-emitting device and a sample line to the measurement and data processing unit. The measurement and data processing unit samples a measured voltage at the second terminal of the light-emitting device through the sample line and outputs a data voltage to the light-emitting device based on the measured voltage to compensate variations in properties of the light-emitting device.

Owner:SHARP KK

Glass material manufacturing method and glass material manufacturing device

ActiveUS20190202726A1Improve homogeneityProperty variationGlass furnace apparatusGlass reforming apparatusLevitationIrradiation

Provided is a method that can manufacture a glass material having excellent homogeneity by containerless levitation. With a block (12) of glass raw material held levitated above a forming surface (10a) of a forming die (10) by jetting gas through a gas jet hole (10b) opening on the forming surface (10a), the block (12) of glass raw material is heated and melted by irradiation with laser beam, thus obtaining a molten glass, and the molten glass is then cooled to obtain a glass material. Control gas is jetted to the block (12) of glass raw material along a direction different from a direction of jetting of the levitation gas for use in levitating the block (12) of glass raw material or the molten glass.

Owner:NIPPON ELECTRIC GLASS CO LTD

Contact spring

ActiveUS20050051415A1Lessen contact obstacleReduce variationContact surface shape/structureMowersPush-buttonEngineering

There is provided a contact spring in a small-sized push-button switch capable of lessening contact obstacle between contacts caused by fine dust, and reducing variation in load characteristics even if heat is applied thereto or the switch is repetitively operated. The contact spring in the switch for allowing a movable contact provided at an inner side of a movable contact spring to contact or break off the contact with an opposed fixed contact so as to render the movable contact and the fixed contact to be in one of an electrically on or off state, wherein multiple movable contacts are formed by protruding a material of the movable contact spring by a thickness of not more than two thirds of a thickness of the movable contact spring on a circumference about a central portion of the movable contact spring and positioned at an equal central angle relative to the center of the movable contact spring in a direction from an outside to an inner side of the movable contact spring by means of half-cut working while forming a peripheral edge of a protruded contact surface in a sharp blade-shape.

Owner:FUJI ELECTRONICS IND

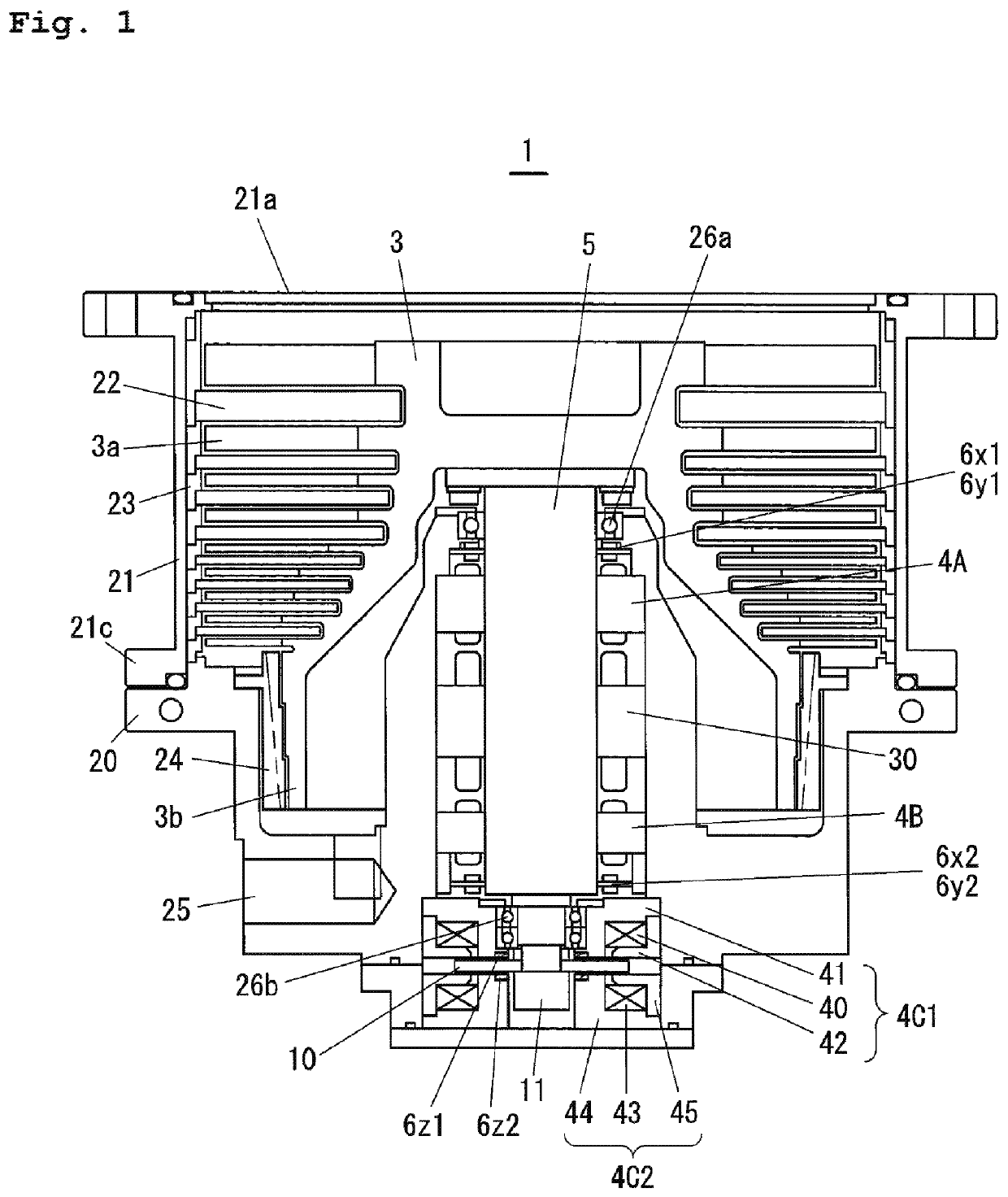

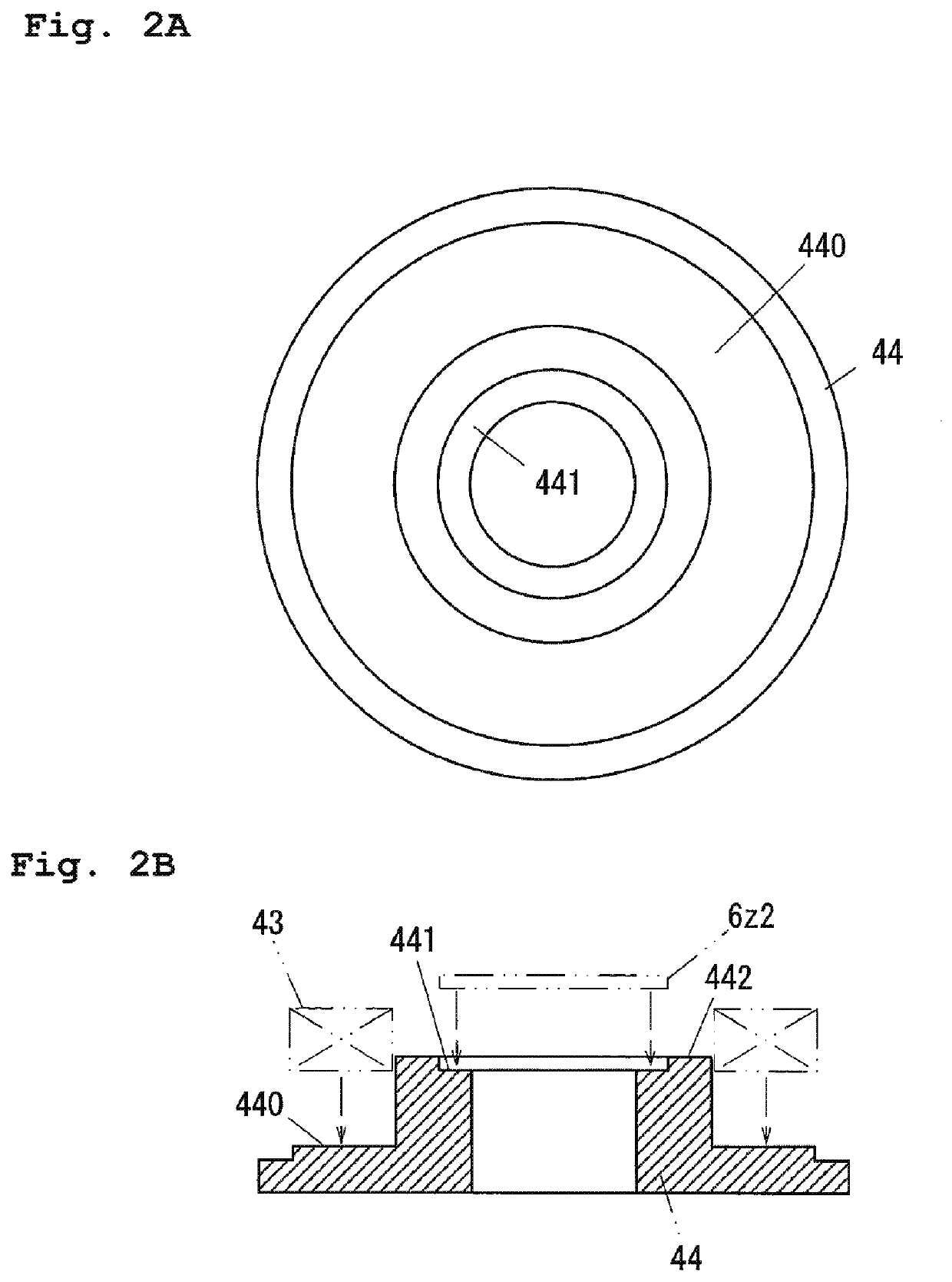

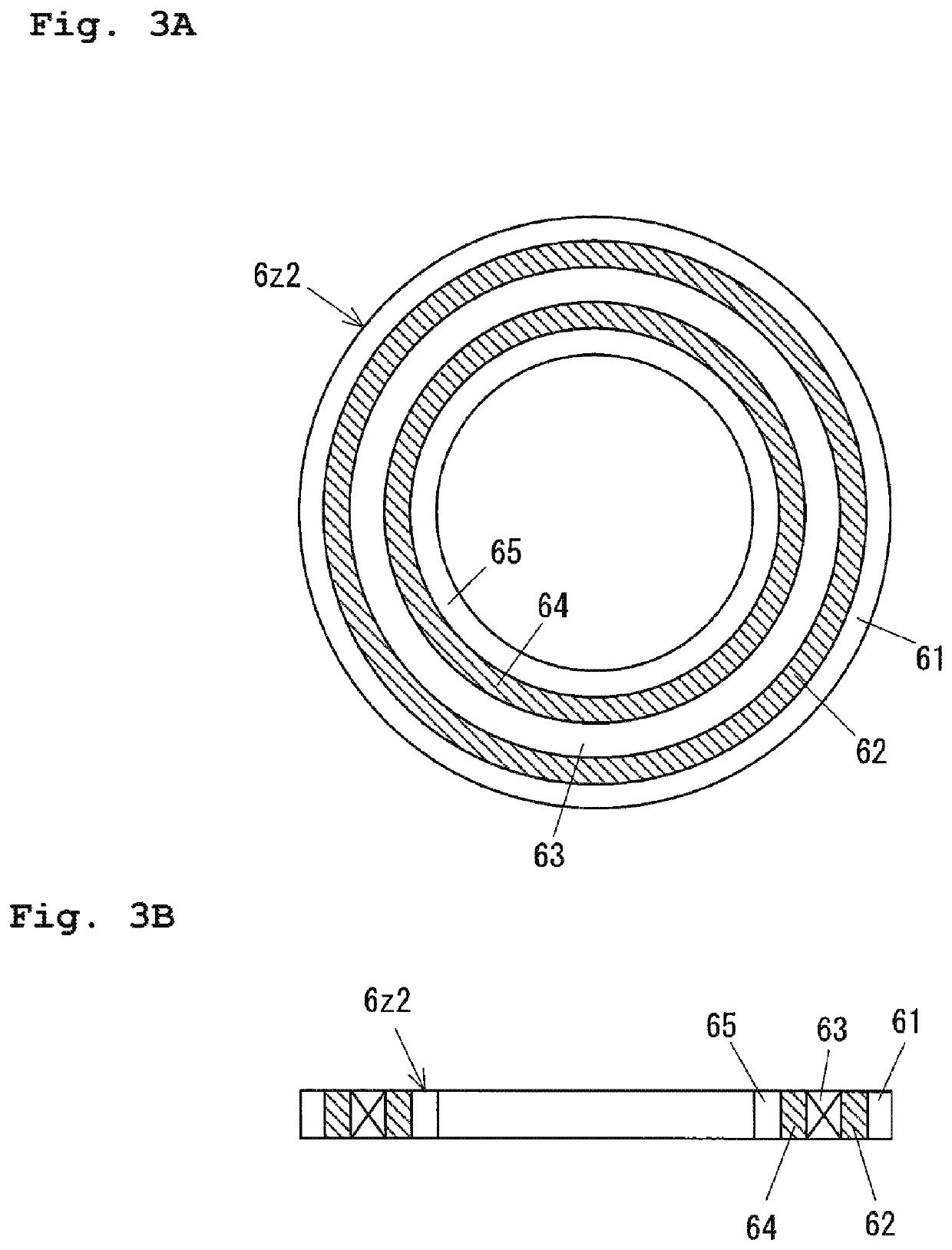

Magnetic bearing device and vacuum pump

ActiveUS10683893B2Reduce variationProperty variationShaftsMagnetic bearingsAxial displacementMagnetic bearing

A magnetic bearing device comprises a radial magnetic bearing configured to magnetically levitate and support a rotor shaft in a radial direction; an axial magnetic bearing configured to magnetically levitate and support, in an axial direction, a rotor disc rotatable together with the rotor shaft; and an axial displacement sensor disposed on a surface of an electromagnet core of the axial magnetic bearing facing the rotor disc and configured to detect axial displacement of the rotor disc.

Owner:SHIMADZU CORP

Pixel circuit using direct charging and that performs light-emitting device compensation

ActiveUS10762843B2Eliminate needProperty variationCathode-ray tube indicatorsComputer hardwareHemt circuits

A display system includes a display panel comprising a plurality of pixel circuits, and a measurement and data processing unit that is external to the display panel. Each pixel circuit includes a light-emitting device having a first terminal connected to a first voltage supply and a second terminal opposite from the first terminal; a first transistor connected between a data voltage supply line from the measurement and data processing unit and the second terminal of the light emitting device; and a second transistor connected between the second terminal of the light-emitting device and a sample line to the measurement and data processing unit. The measurement and data processing unit samples a measured voltage at the second terminal of the light-emitting device through the sample line and outputs a data voltage to the light-emitting device based on the measured voltage to compensate variations in properties of the light-emitting device.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com