Constructional element

a construction element and element technology, applied in the field of construction elements, can solve the problems of a relatively large number of toys, and a difficult transportation and/or storage of constructional elements, and achieve the effects of reducing the environmental footprint of constructional elements, low density, and low mass or weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

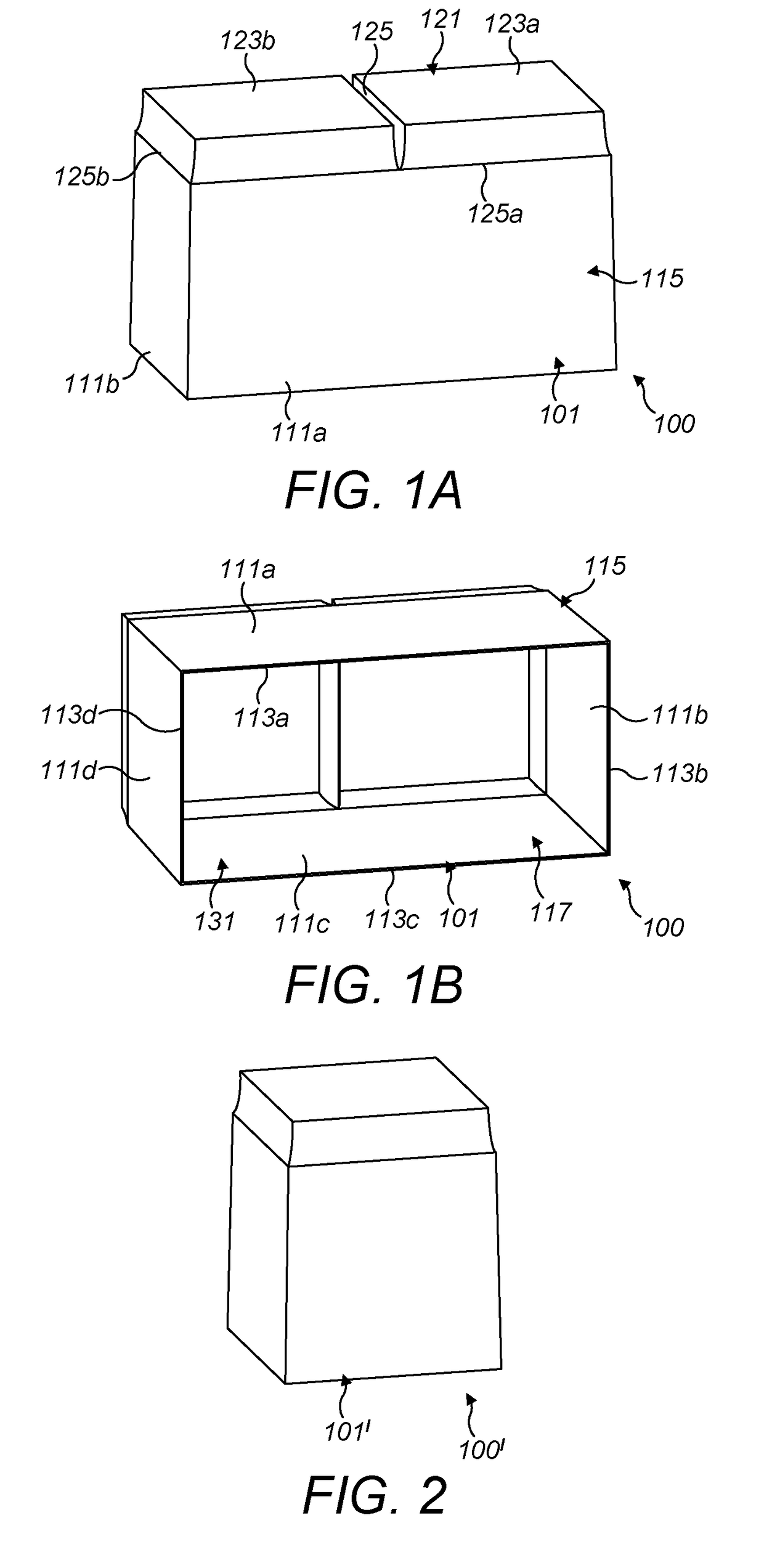

[0082]FIGS. 1A & 1B show a constructional element 100 according to an example embodiment. The constructional element 100 is moulded as one piece from paper pulp, having relatively smooth surfaces and a relatively uniform wall thickness in a range 0.5-5 mm. The constructional element 100 is hollow, generally cuboidal having five walls and has approximate dimensions 150 mm length by 75 mm width by 75 mm height. These dimensions are illustrative only and the size of embodiments of the present invention can vary greatly from this example.

[0083]The constructional element 100 comprises a first part 101. The first part 101 has four generally trapezoidal, planar first side walls 111a, 111b, 111c &111d, arranged mutually perpendicularly. Opposed first side walls (i.e. 111a &111c, 111b &111d) are similarly sized. The first side walls 111a, 111b, 111c &111d thus generally taper towards a rectangular first end wall 121. The free edges 113a, 113b, 113c &113d of the first side walls 111a, 111b, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com