Sole Structure for a Sports Shoe

a technology for sports shoes and soles, applied in the field of sports shoe sole structures, can solve the problems of energy loss, energy loss, and excessive bending of local shoes, and achieve the effect of improving the cushioning properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first alternative embodiment

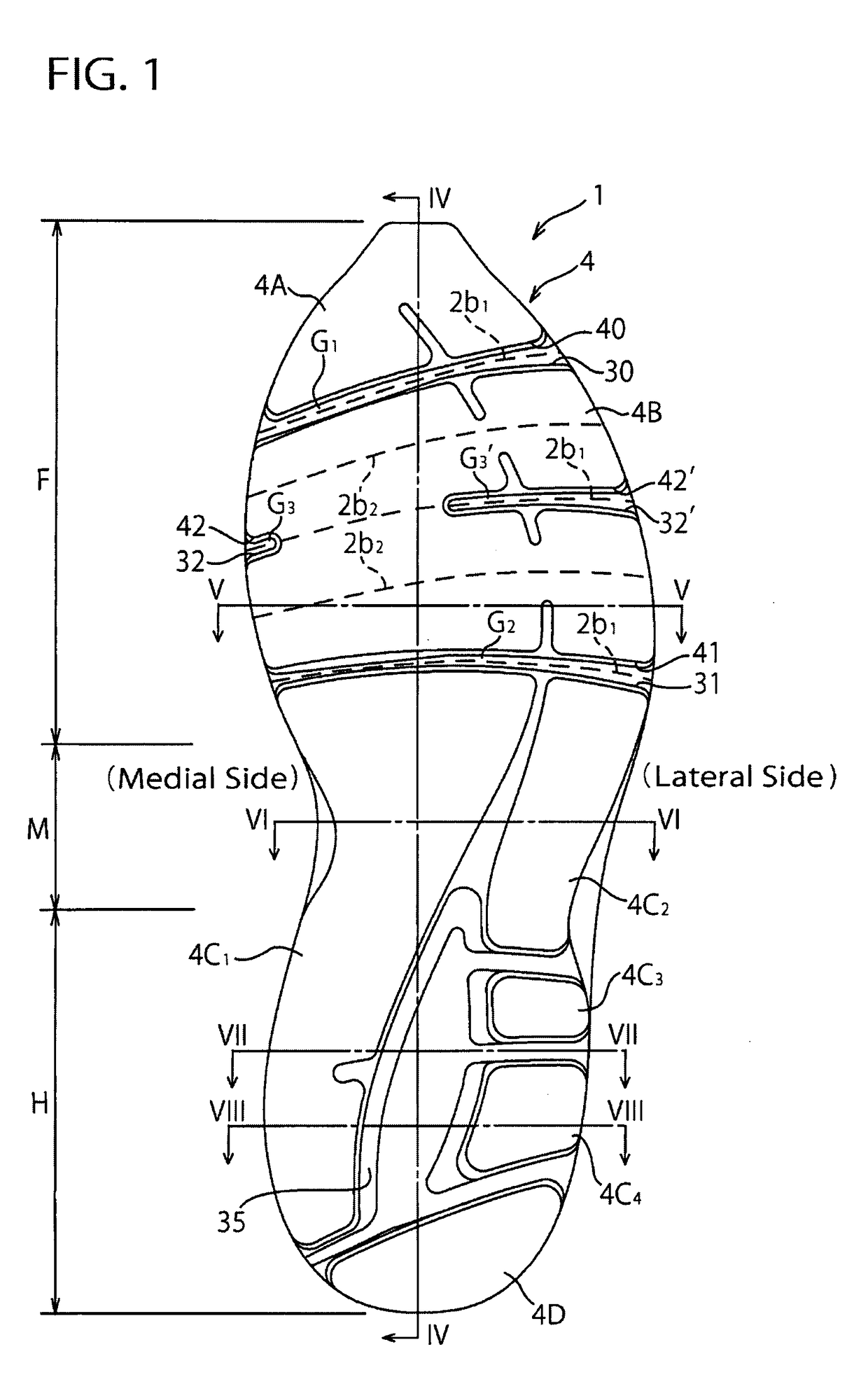

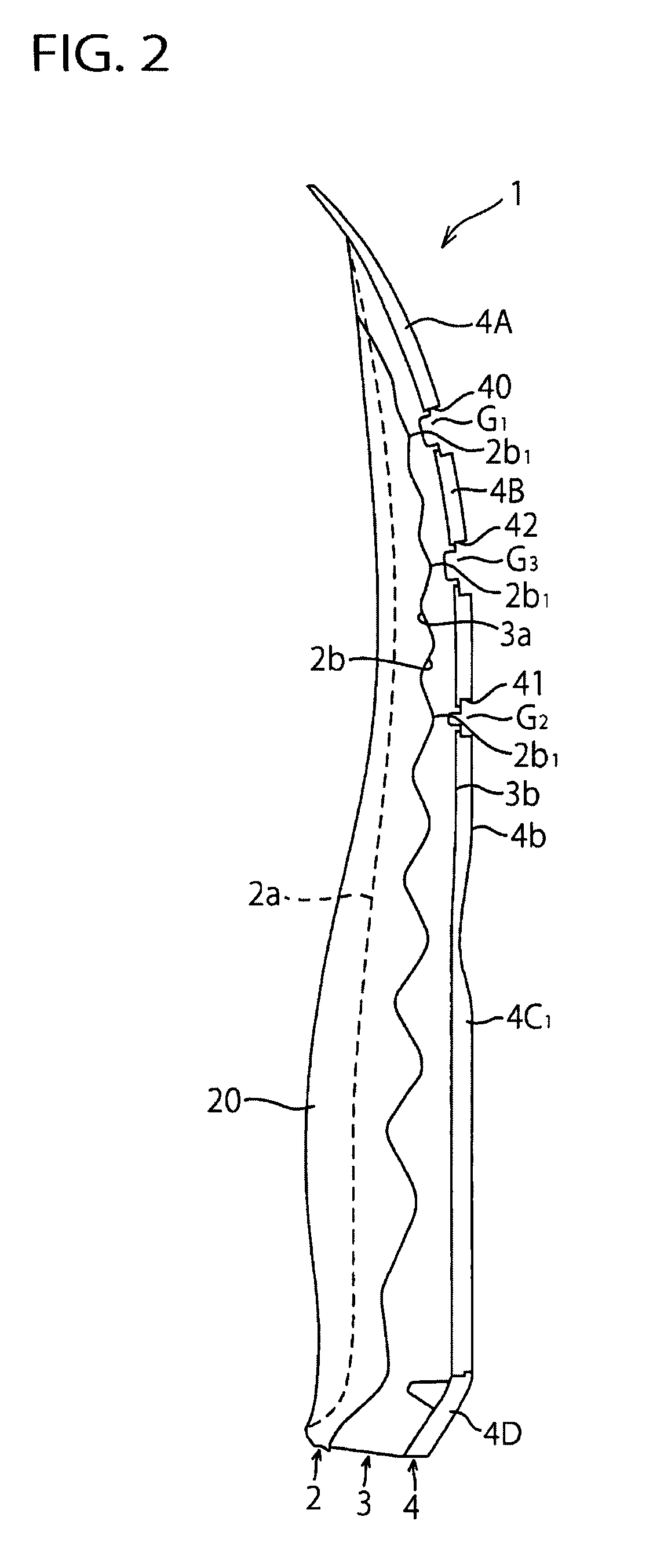

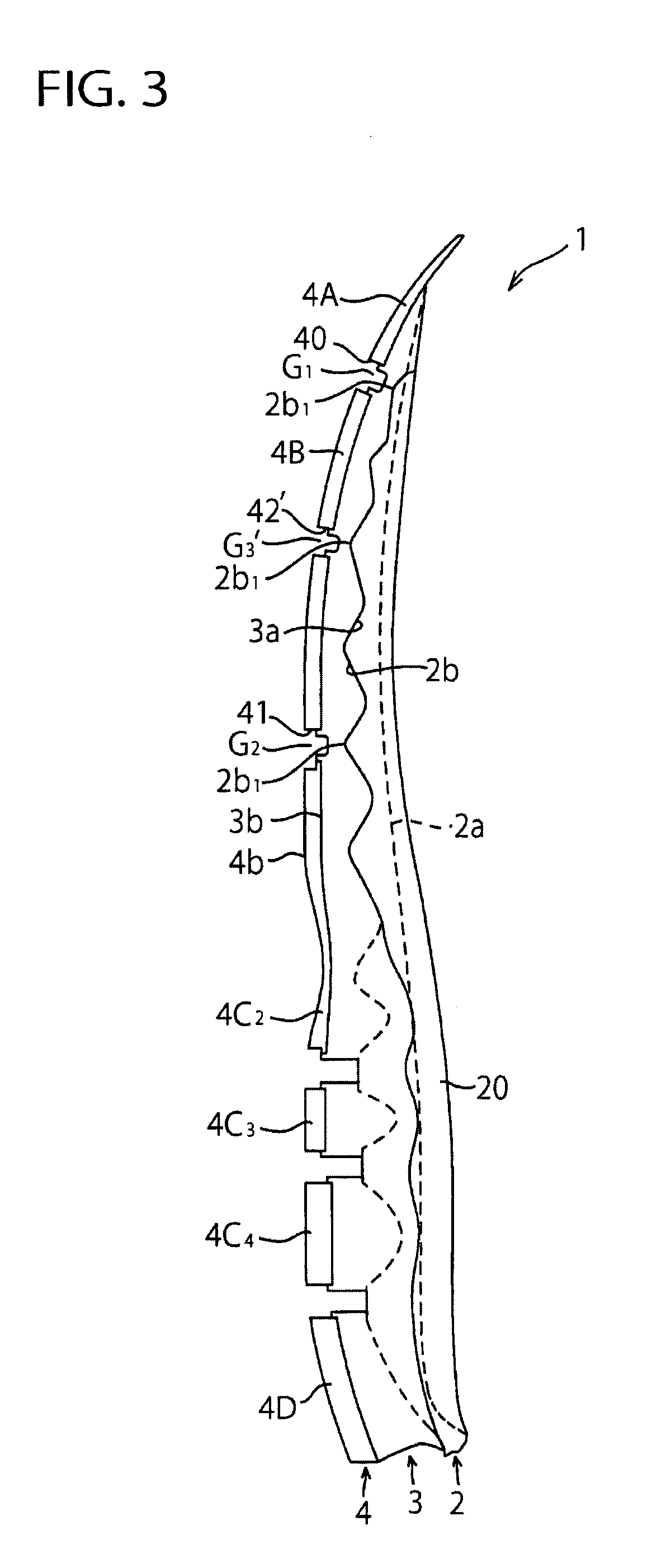

[0079]In the above-mentioned embodiment, an example was shown in which the sole bent grooves G1, G2, G3, G3′ provided at the forefoot region F of the sole structure 1 comprise the slits (or through grooves) 40, 41, 42, 42′ passing through the outsole 4 and the concave grooves (or blind grooves) 30, 31, 32, 32′ formed on the lower midsole 3, respectively but application of the present invention is not limited to such an example.

[0080]FIGS. 14 to 21 show a sole structure of a sports shoe according to a first alternative embodiment. In these drawings, like reference numbers indicate identical or functionally similar elements. Here, an indoor sports shoe is taken for an example of the sports shoe. As shown in FIGS. 14 to 21, in this first alternative embodiment, there are provided sole bent grooves G1, G2, G3 at the forefoot region F of the sole structure 1, which are formed of concave grooves (or blind grooves) 45, 46, 47 respectively formed on the ground contact surface of the outsole...

second alternative embodiment

[0086]In the above-mentioned embodiment and the first alternative embodiment, an example was shown in which the ridge lines 2b1 of the wavy shapes of the lower surface 2b of the upper midsole 2 extend across the entire width of the sole (that is, from the medial side end to the lateral side end), but application of the present invention is not limited to such an example.

[0087]FIGS. 22 to 25 show a sole structure of a sports shoe according to a second alternative embodiment. Here, a running shoe is taken for an example of the sports shoe. In these drawings, like reference numbers indicate identical or functionally similar elements.

[0088]As shown in FIGS. 22 to 25, in this second alternative embodiment, at the longitudinally and laterally central part of the upper midsole 2 in the forefoot region F of the sole structure 1, there is formed a concavity 28 that opens to the side of the lower surface 2b. In this example, the concavity 28 is a generally rectangular shaped blind hole that i...

third alternative embodiment

[0107]FIG. 26 shows a third alternative embodiment of the present invention and it corresponds to FIG. 2 of the above-mentioned embodiment. In FIG. 26, like reference numbers indicates identical or functionally similar elements to those in FIG. 2. In the above-mentioned embodiment, an example was shown in which the hardness of the upper midsole 2 is higher than the hardness of the lower midsole 3, but in this third alternative embodiment, contrary to such an example, the hardness of the lower midsole 3 is higher than the hardness of the upper midsole 2.

[0108]Specifically, the hardness of the lower midsole 3 is set to, for example 60±4 C in the Asker C scale and the hardness of the upper midsole 2 is set to, for example 50±4 C in the Asker C scale. A difference between the hardness of the upper midsole 2 and the hardness of the lower midsole 3 is preferably approximately 5 C.

[0109]Also, in this third alternative embodiment, a phase of the wavy shapes of the upper and lower midsoles 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com