Pressure-flushing system for a toilet bowl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]It is obvious that individual embodiments of the invention are to be illustrative and are not restrictive for technical solutions. A person skilled in the art will be able to find or establish many equivalents to the specific embodiments of the invention using no more than routine experiments. Such equivalents also fall under the patent claims.

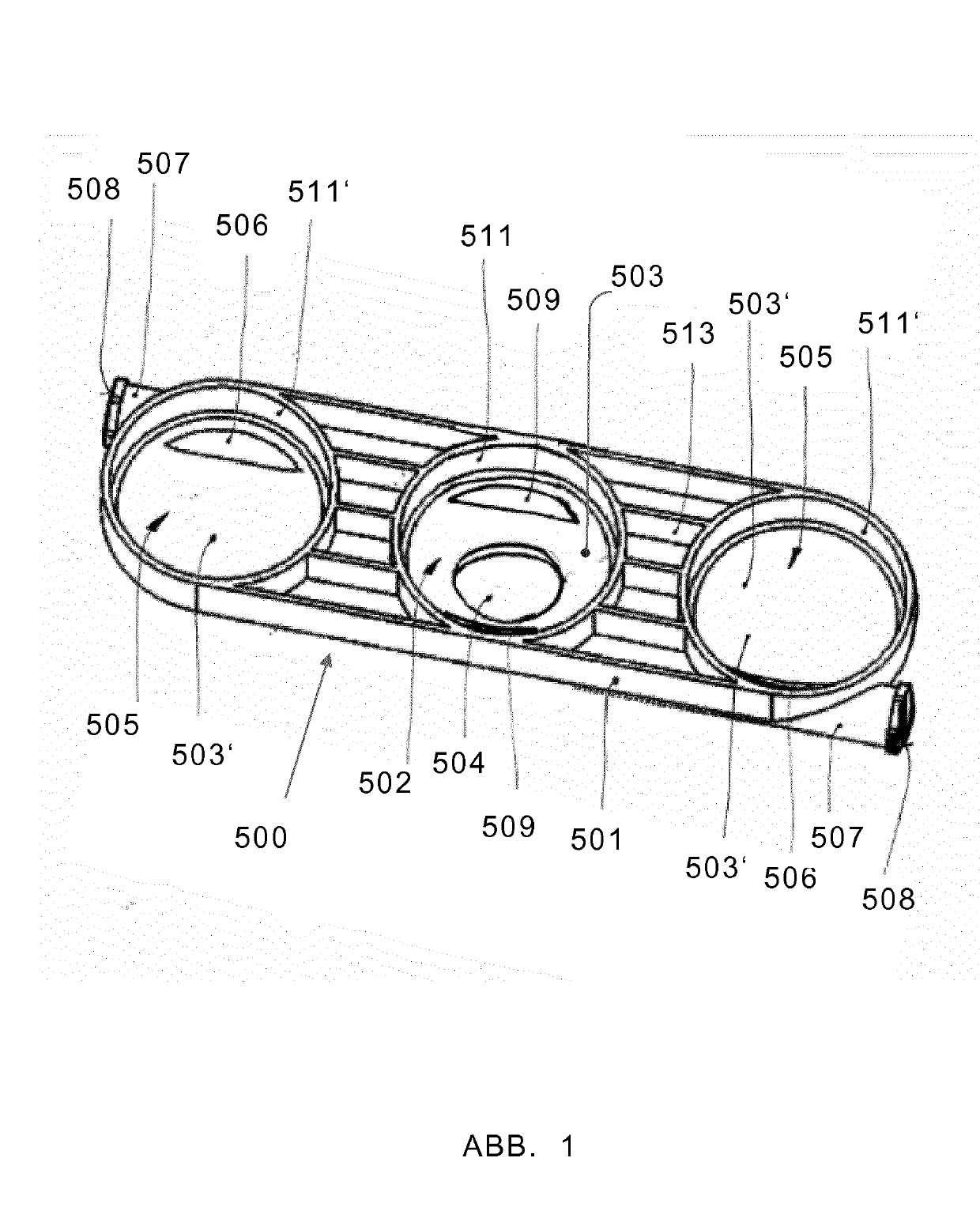

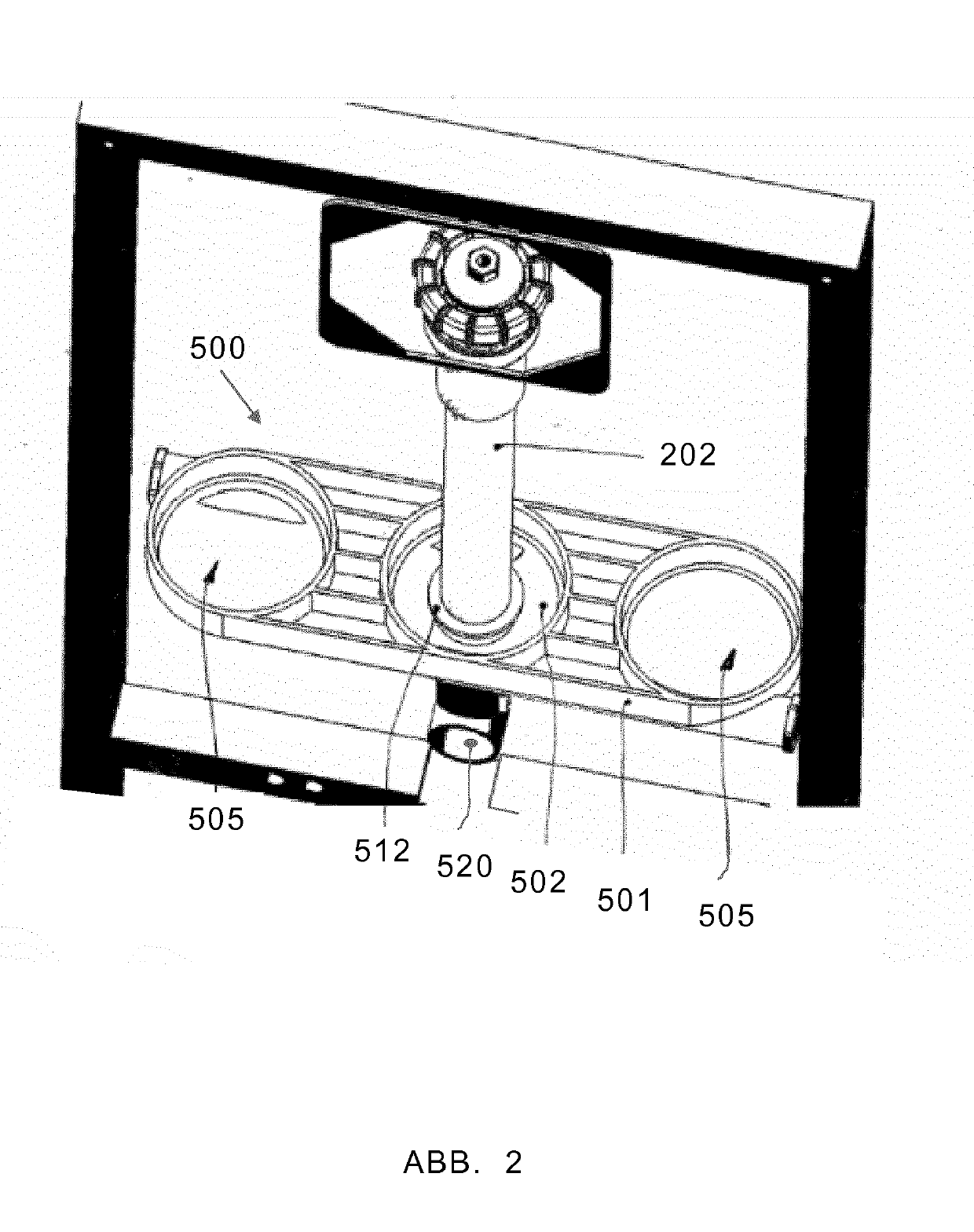

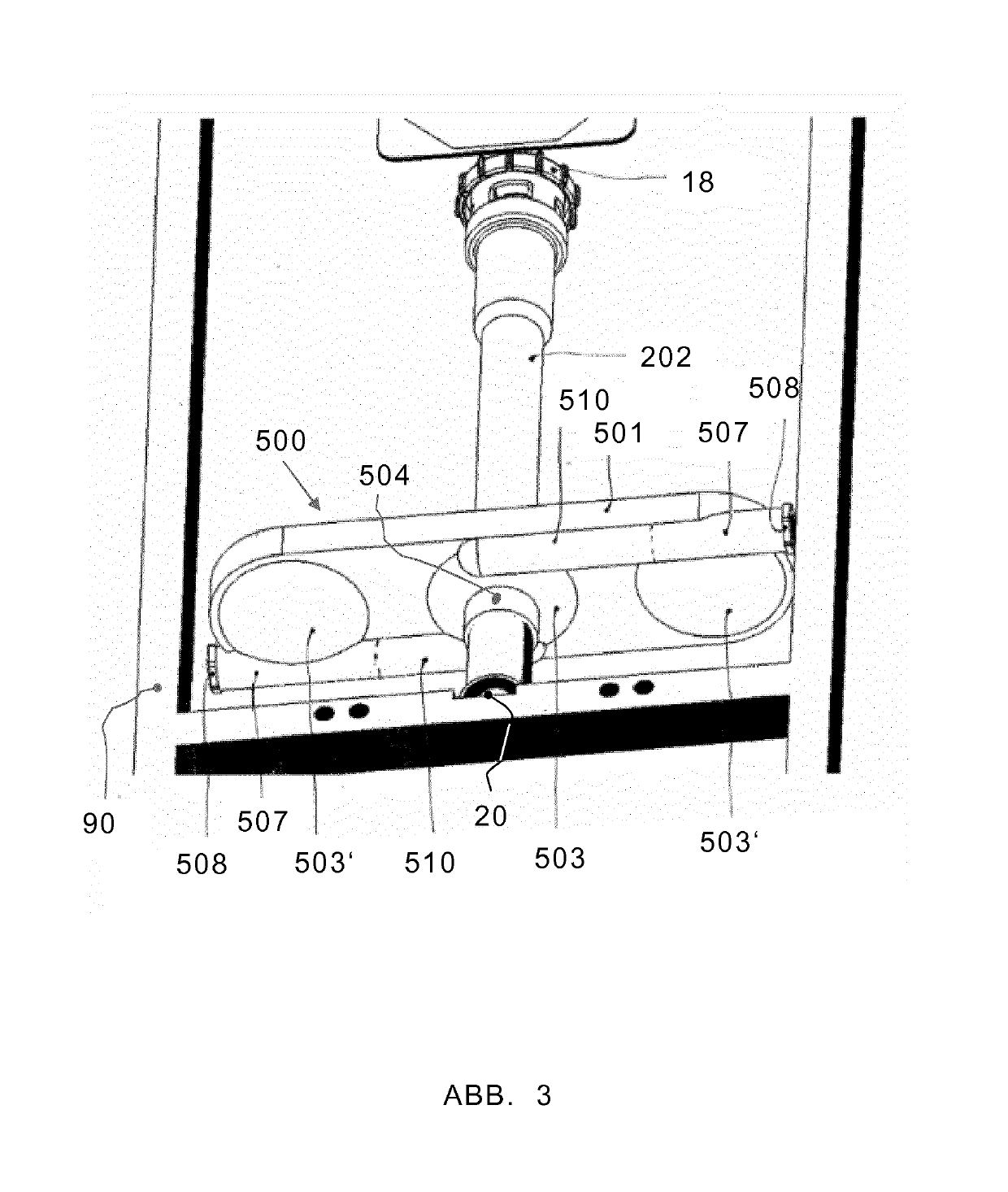

[0055]A specific embodiment of a cistern mounting 500 for a toilet water pressure flushing system 100 according to the invention using pressure wave flushing is shown in the example illustrated in FIGS. 1 to 3. The cistern mounting 500 for the toilet water pressure flushing system comprises a carrier plate 501 having a centrally arranged open outflow shell 502 accessible from above for accommodating an outflow module 200 (see FIG. 4), wherein the outflow shell 502 has an outflow opening 504 for the mounting of an outflow pipe 202 in its base 503 (FIG. 2). The carrier plate 501 furthermore has two open inflow shells 505 accessible from ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com