Feed systems and methods for rotary screen separators

a technology of rotary separator and feed system, which is applied in the direction of filtration separation, separation process, moving filter element filter, etc., can solve the problems of fine opening, inability to pass as much liquid material through the perforation, and undetectable high volume of solids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

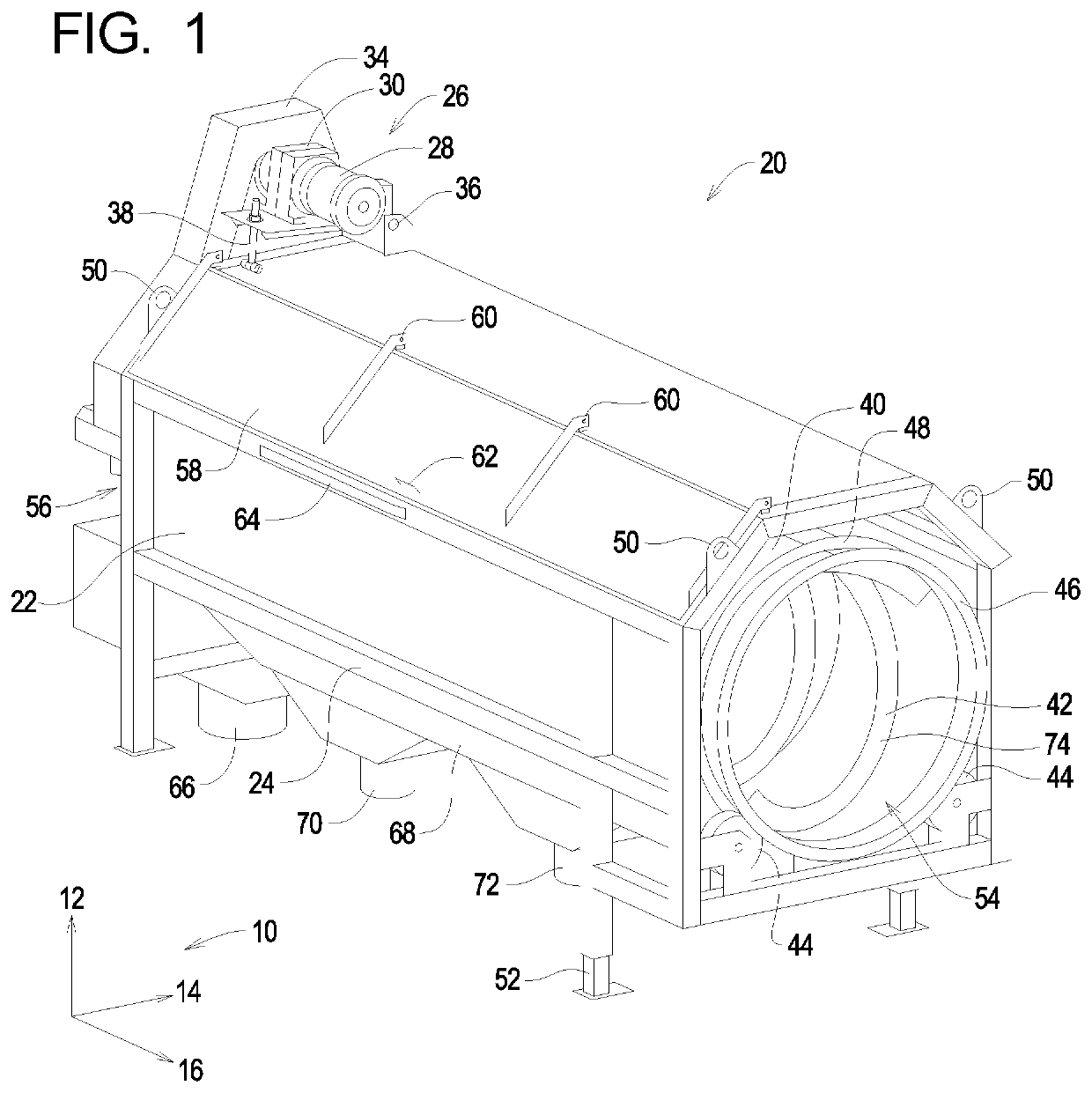

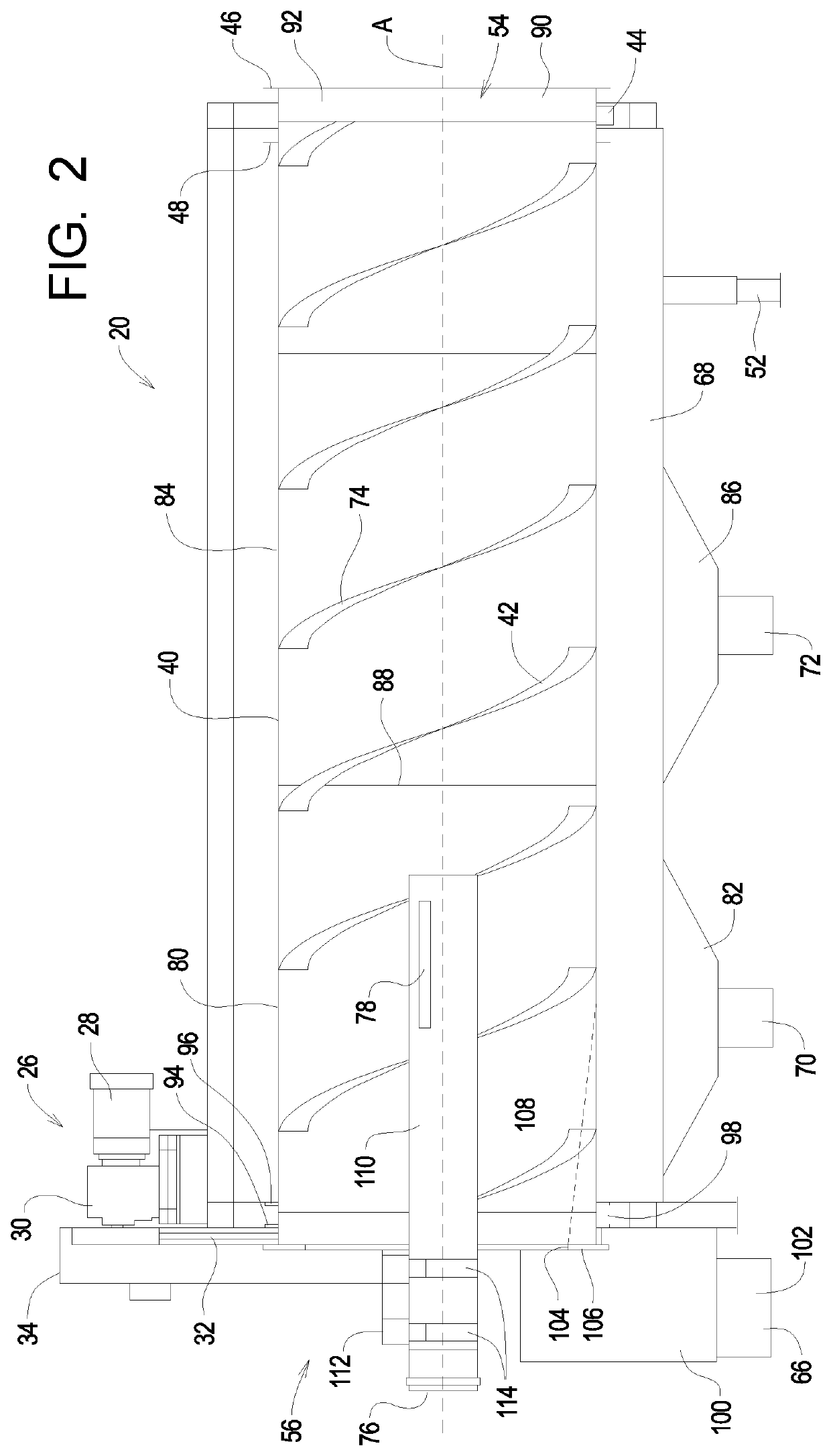

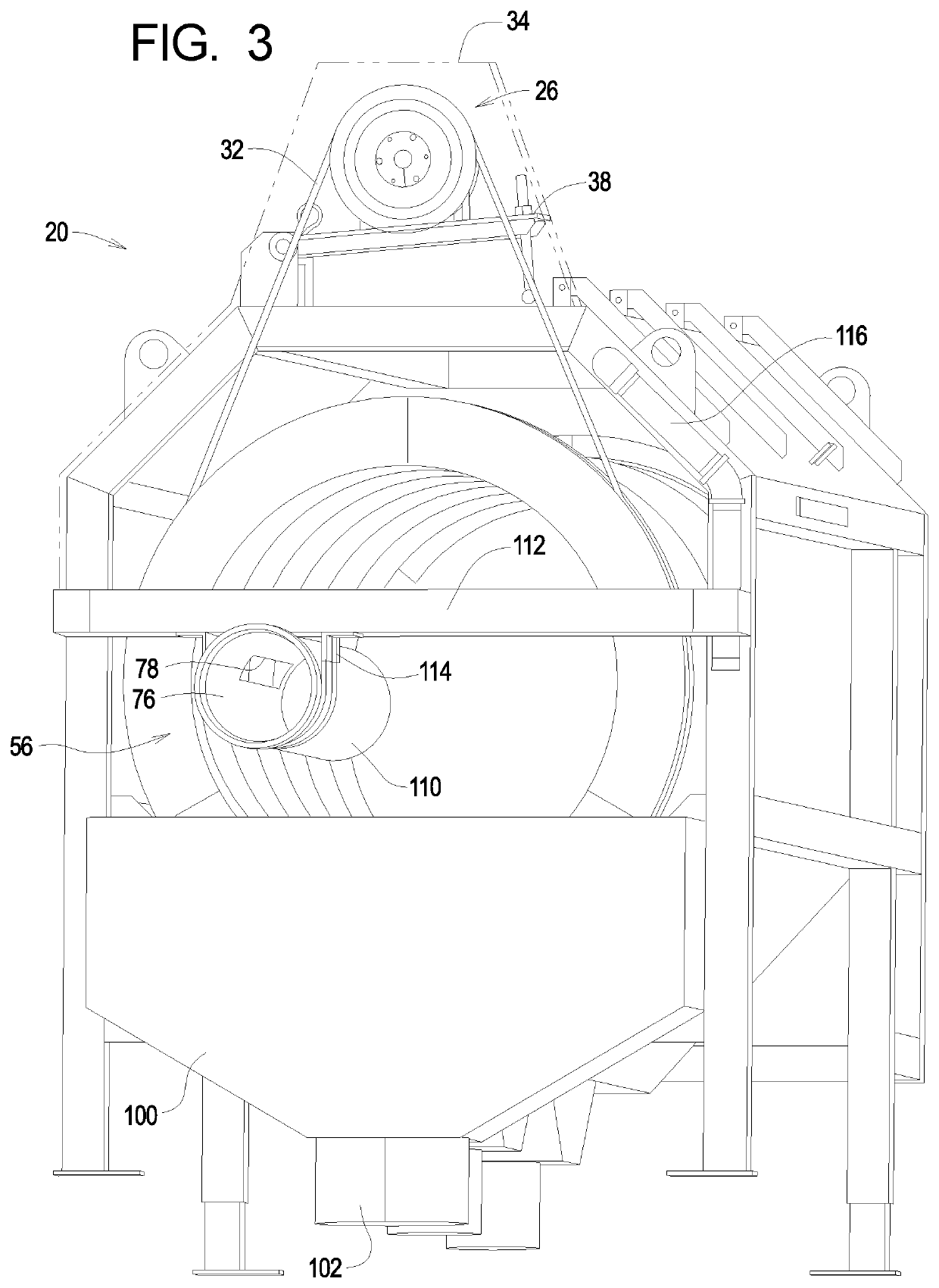

[0029]A rotary screen separator is disclosed herein which may generally comprise a frame and a rotating perforated screen supported by the frame. In one form, the rotating screen is horizontally aligned at a slight angle and often comprises an internal screw flight. The screw flight is operatively configured to reposition the media to be separated from the input end of the separator to the solids discharge end. As the material moves through the screen separator, liquid and fine particles are removed through the perforations in the screen.

[0030]The example hybrid rotary screen separator of the present invention comprises at least two separate regions each comprising a different screen size. In the example hybrid rotary screen separator disclosed herein, the perforations of the screen on the input end of the separator comprise a much finer hole size than the perforations toward the solid discharge end. These regions of fine screen and coarse screen may be separate structures which may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com