Louver assembly

a technology of louver and assembly, which is applied in the direction of lighting and heating apparatus, heating types, ventilation systems, etc., can solve the problems of affecting the performance of louver assemblies, affecting the drainage of rainwater, and affecting the design of louver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

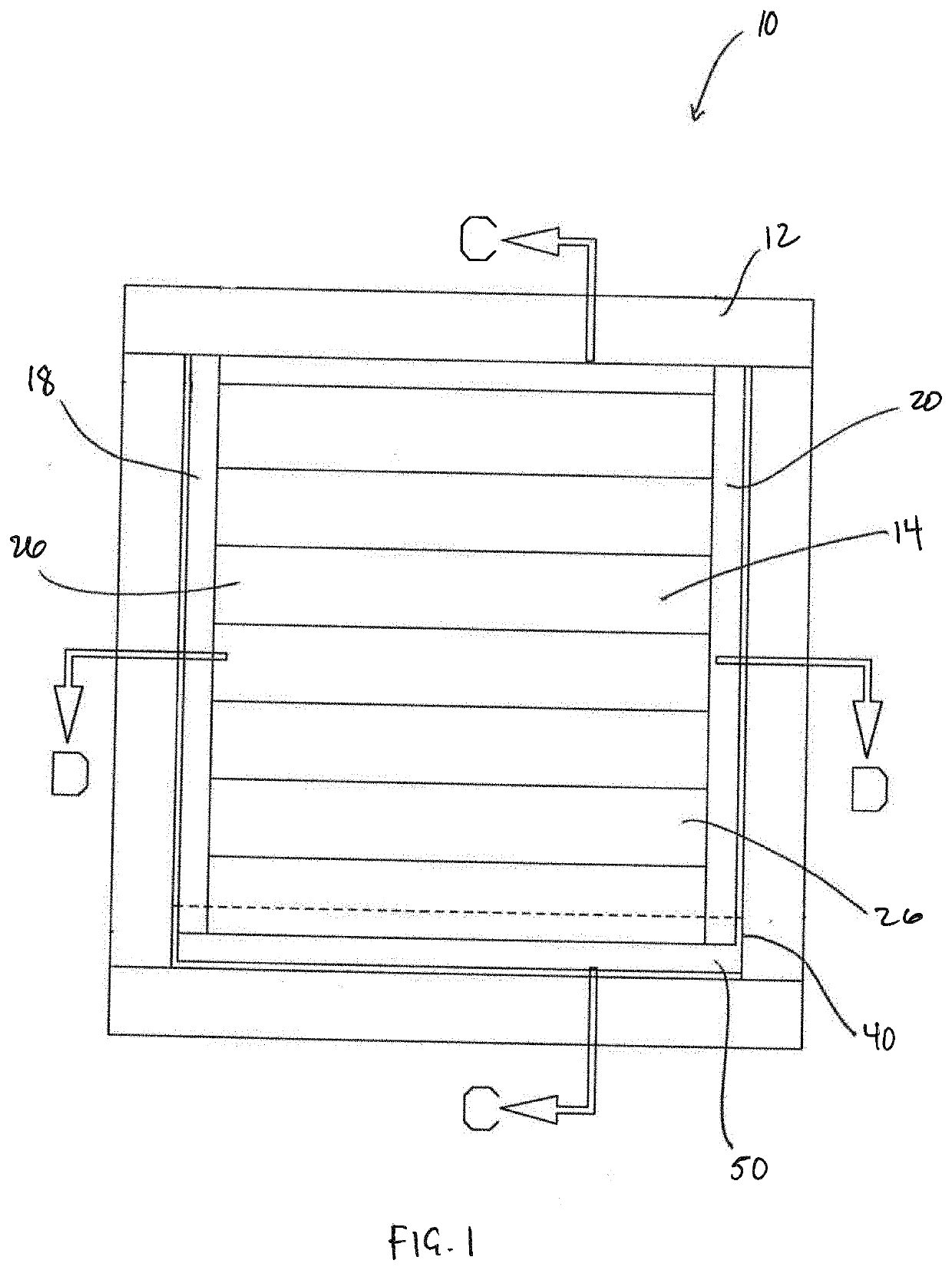

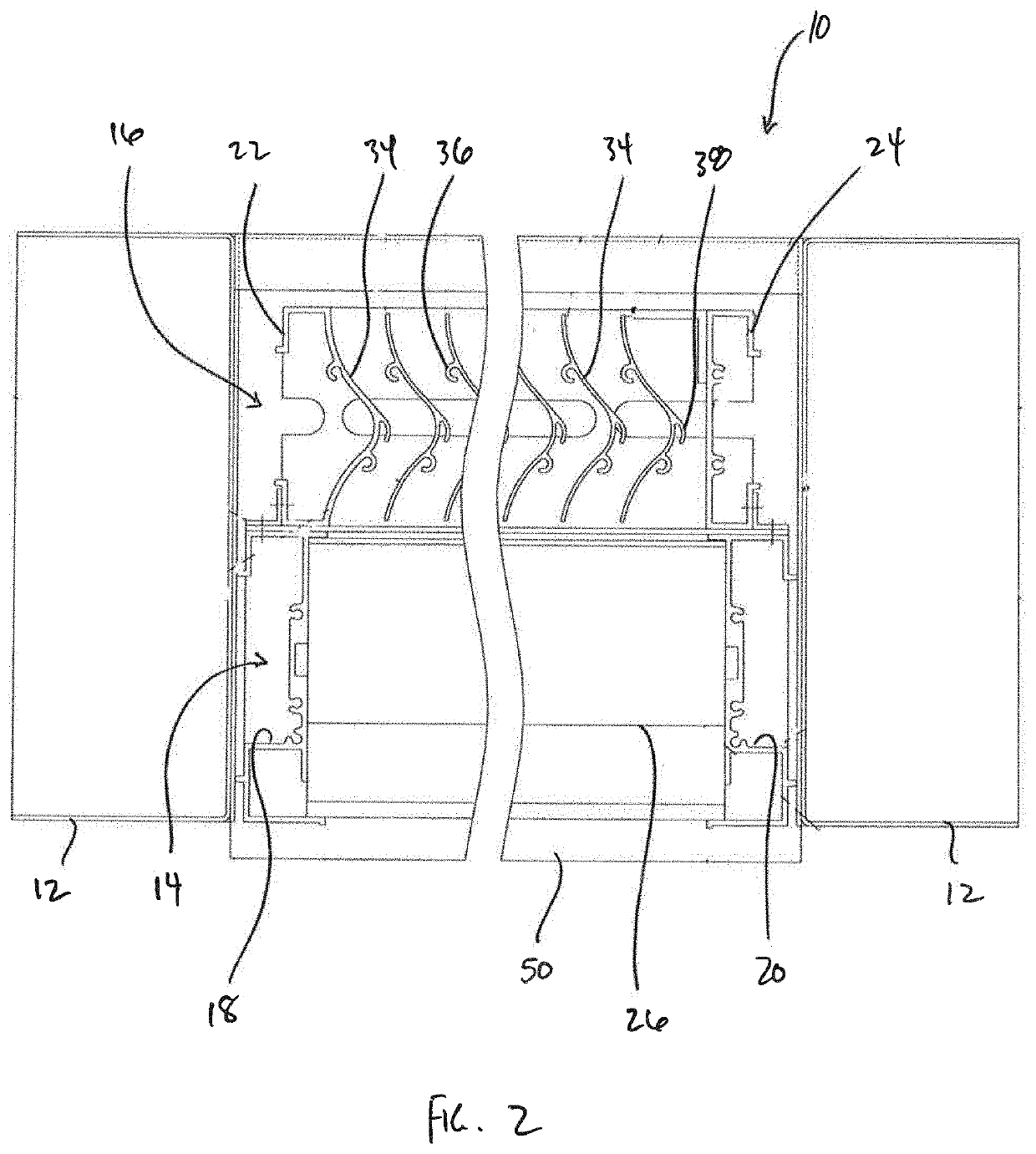

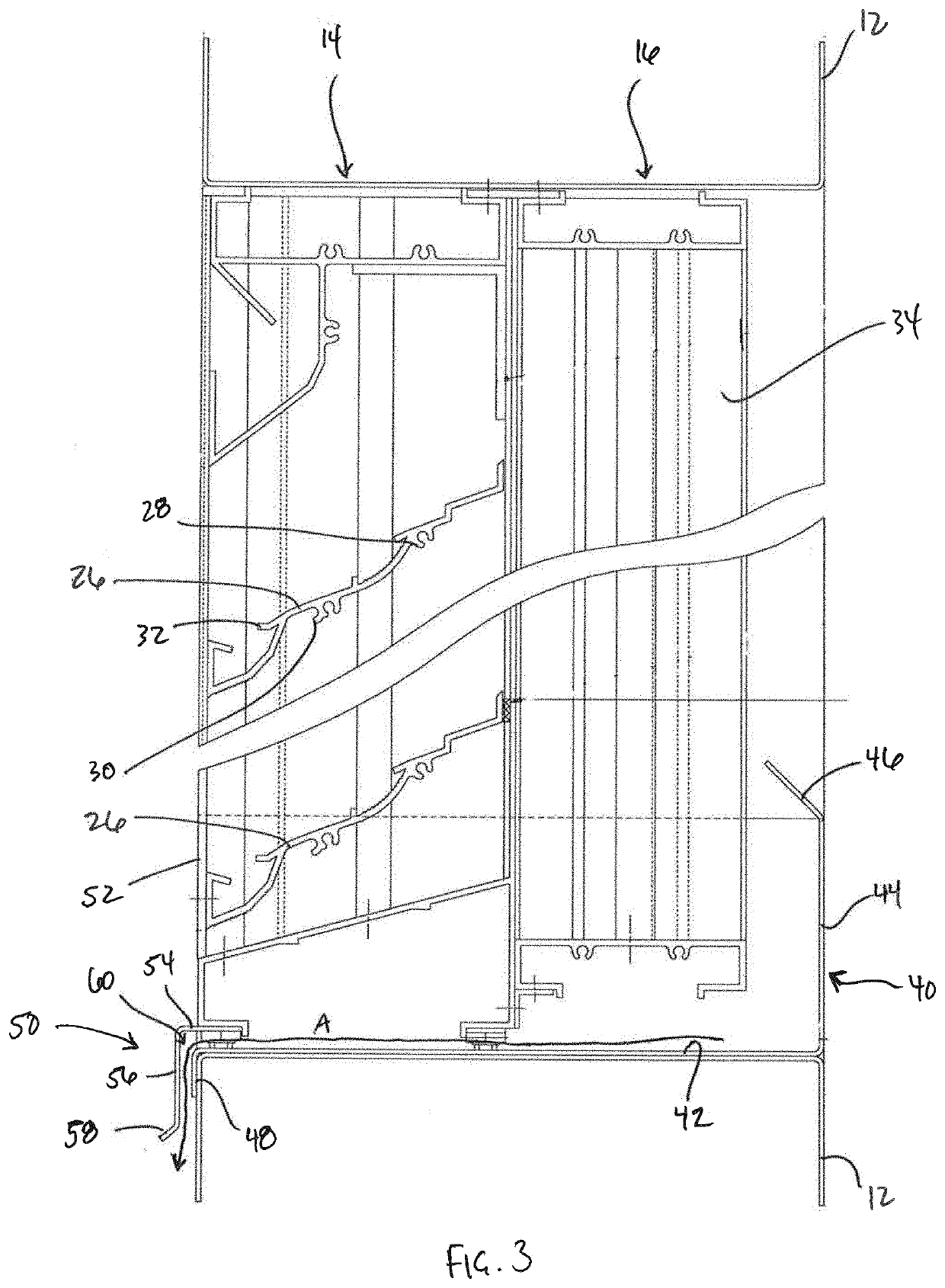

[0020]With reference to FIGS. 1-3, a louver assembly 10 according to an embodiment of the invention is illustrated. The lover assembly 10 is designed to be inserted within an opening in a wall of a building to permit outside air to flow therethrough into the building while removing water particles from the air to prevent excess moisture from entering the building. While the louver assembly 10 is disclosed herein as being disposed within an opening in a wall of a building or other structure, it will be readily appreciated, however, that the louver assembly 10 may be integrated into any known ventilation system, including those systems having stand-alone components, without departing from the broader aspects of the present invention.

[0021]As illustrated in FIGS. 1-3, the louver assembly 10 includes a generally rectangular outer frame 12 formed from generally U-shaped sleeves (including, for example, top, bottom, left and right sleeves). The sleeves, and thus the frame 12, may be forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com