Cleaner head for a vacuum cleaner

a vacuum cleaner and cleaner head technology, applied in the direction of suction cleaners, cleaning equipment, suction nozzles, etc., can solve the problems of reducing pick-up performance, increasing the torque of the agitator, and the failure of the agitator, so as to reduce the size of the housing and the overall footprint of the cleaner head, and facilitate maintenance and/or replacement. , the effect of simple maintenance and/or replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

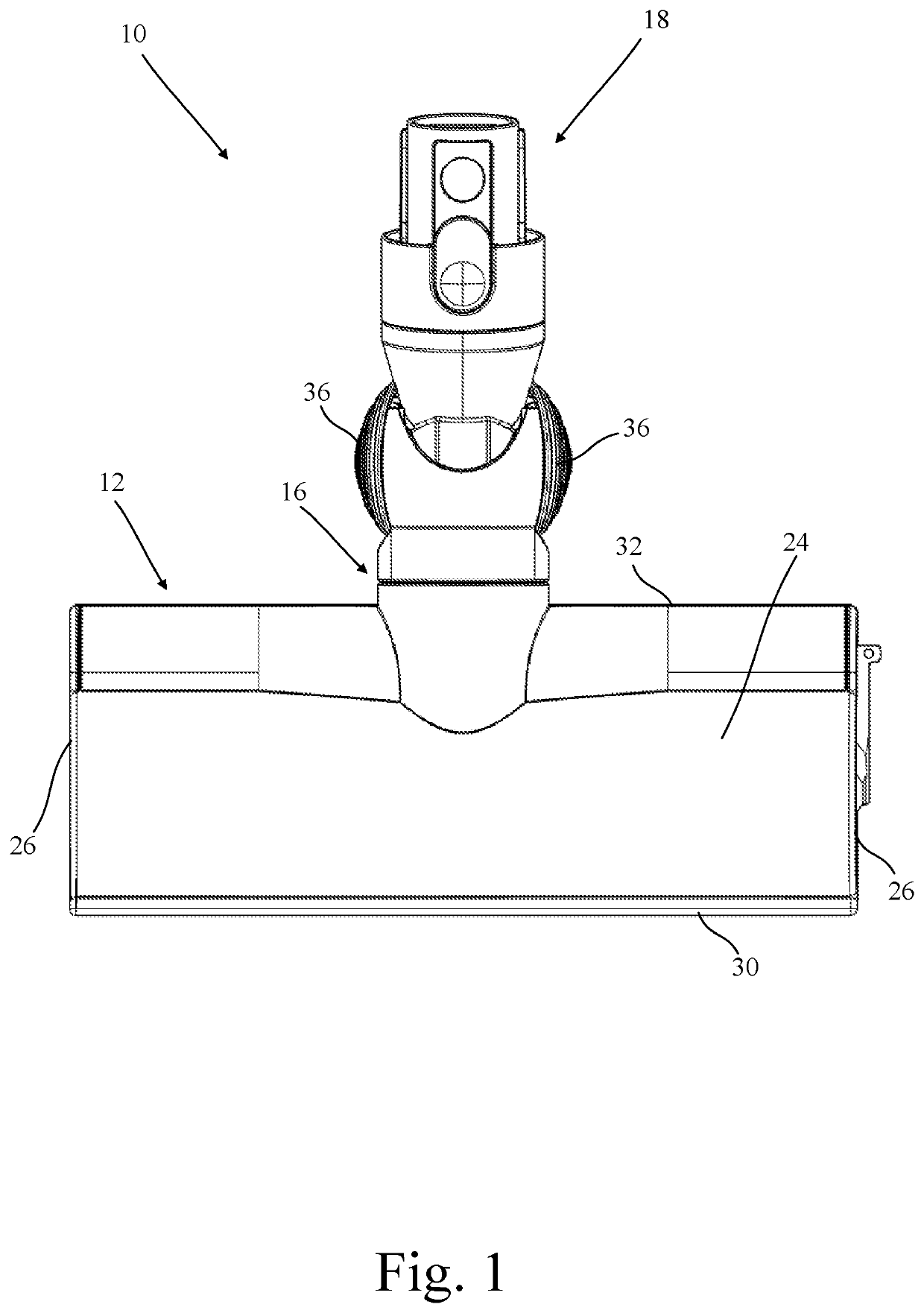

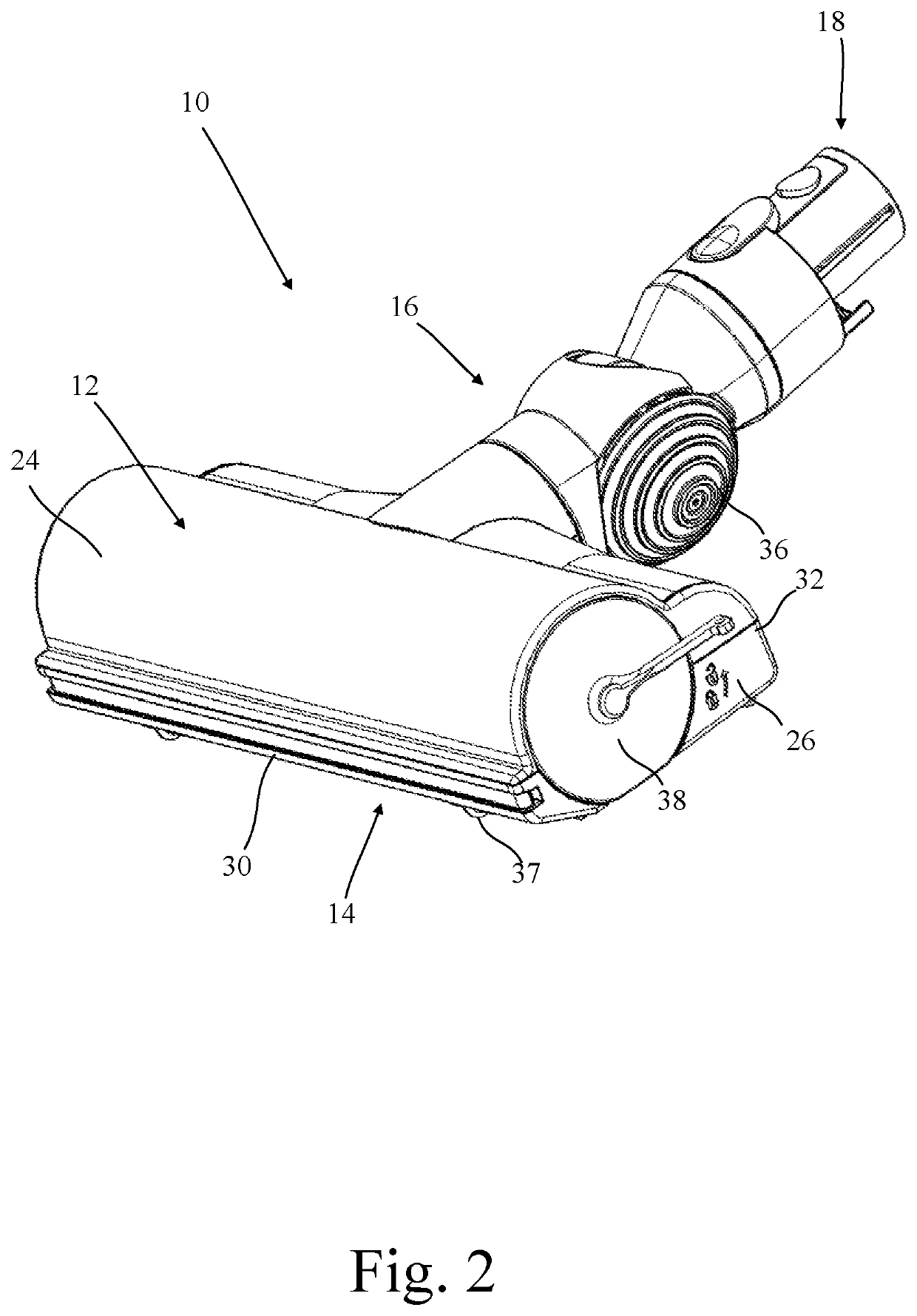

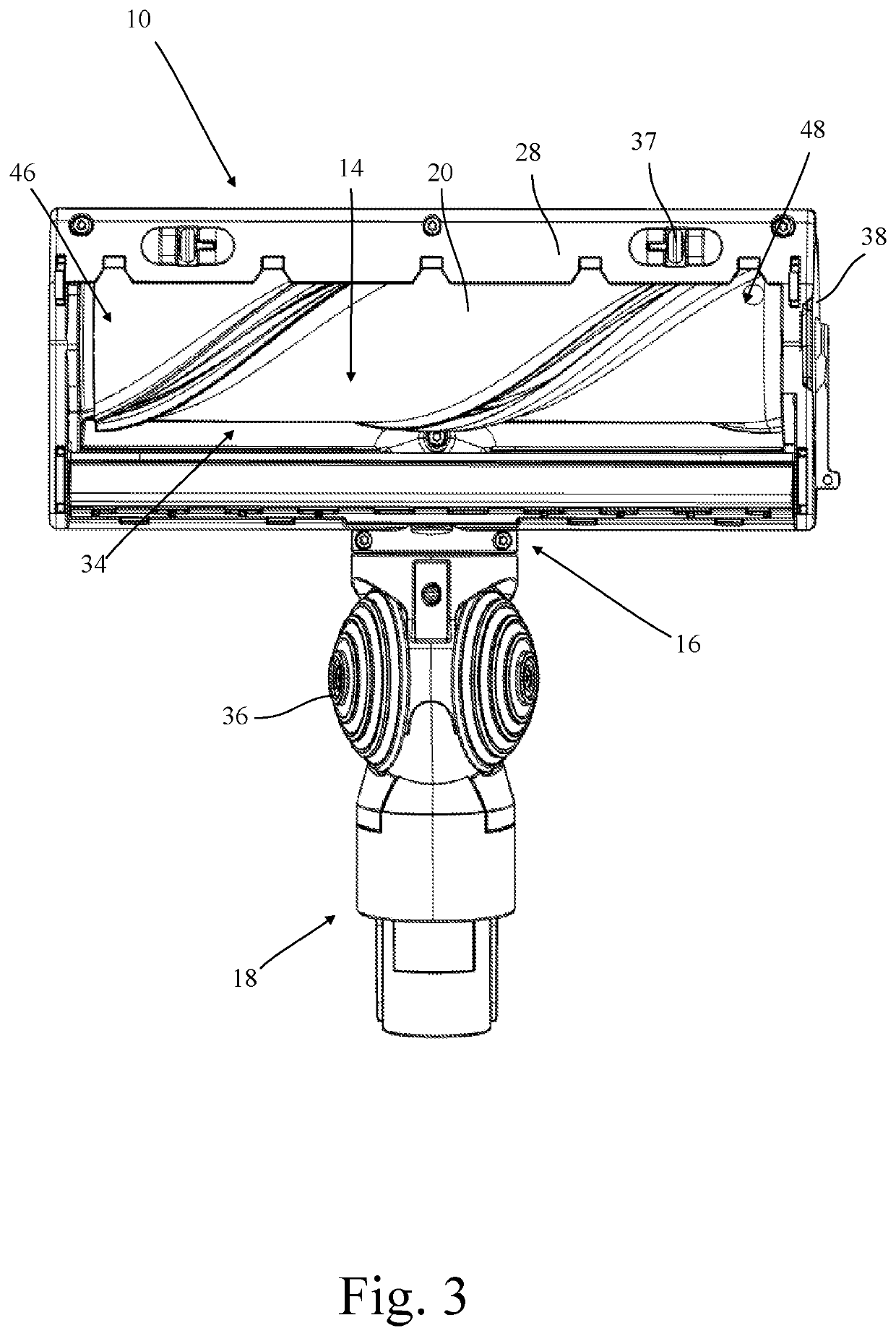

[0057]a cleaner head according to the present invention, generally designated 10, is shown in FIGS. 1-4.

[0058]The cleaner head 10 comprises a housing 12, a dirty air inlet 14, a dirty air outlet 16, a connection formation 18 extending from the dirty air outlet 16, an agitator in the form of a brush bar 20, a motor and drive unit 22, and a debris removal module 23.

[0059]The housing 12 has an upper wall 24, opposing side walls 26, a sole plate 28, a front wall 30, and a rear wall 32. Together the walls 24,26,28,30,32 define a substantially hollow internal chamber 34. An aperture formed in the sole plate 28 defines the dirty air inlet 14, whilst an aperture formed in the rear wall 30 defines the dirty air outlet 16. The connection formation 18 is generally tubular in form, and extends from the dirty air outlet 16 to enable the cleaner head 10 to be connected to a vacuum cleaner main body, either directly, or, for example, via an appropriate wand. The connection formation 18 has a first...

second embodiment

[0083]a cleaner head according to the first aspect of the present invention, generally designated 200, is shown in FIG. 17.

[0084]The second embodiment of the cleaner head 200 is substantially the same as the first embodiment of the cleaner head 10, and differs only in that the debris removal module 23 comprises an additional pair of debris removal members 202, 204, an additional connecting arm 206, an additional counterweight 208, and an additional spring (not shown), as seen in FIGS. 18 and 19. The additional components are structurally and functionally identical to the corresponding components of the first embodiment of the cleaner head 10, and differ only in that they are mounted on opposite sides of the cylindrical intermediate portion 68 and the pair of opposing arms 70 of the base 54.

[0085]Thus in the second embodiment there are two pairs of debris removal members 56,58,202,204 which are diametrically opposed upon the base 54, defining first 86 and second 210 debris collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com