Hollow core optical fibre

a hollow core and optical fibre technology, applied in the field of hollow core optical fibres, can solve the problems of low optical loss and the loss level achieved so far with hollow core fibres is not yet fully competitive with the performance available from solid core fibres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Aspects and features of certain examples and embodiments are discussed / described herein. Some aspects and features of certain examples and embodiments may be implemented conventionally and these are not discussed / described in detail in the interests of brevity. It will thus be appreciated that aspects and features of optical fibres discussed herein which are not described in detail may be implemented in accordance with any conventional techniques for implementing such aspects and features.

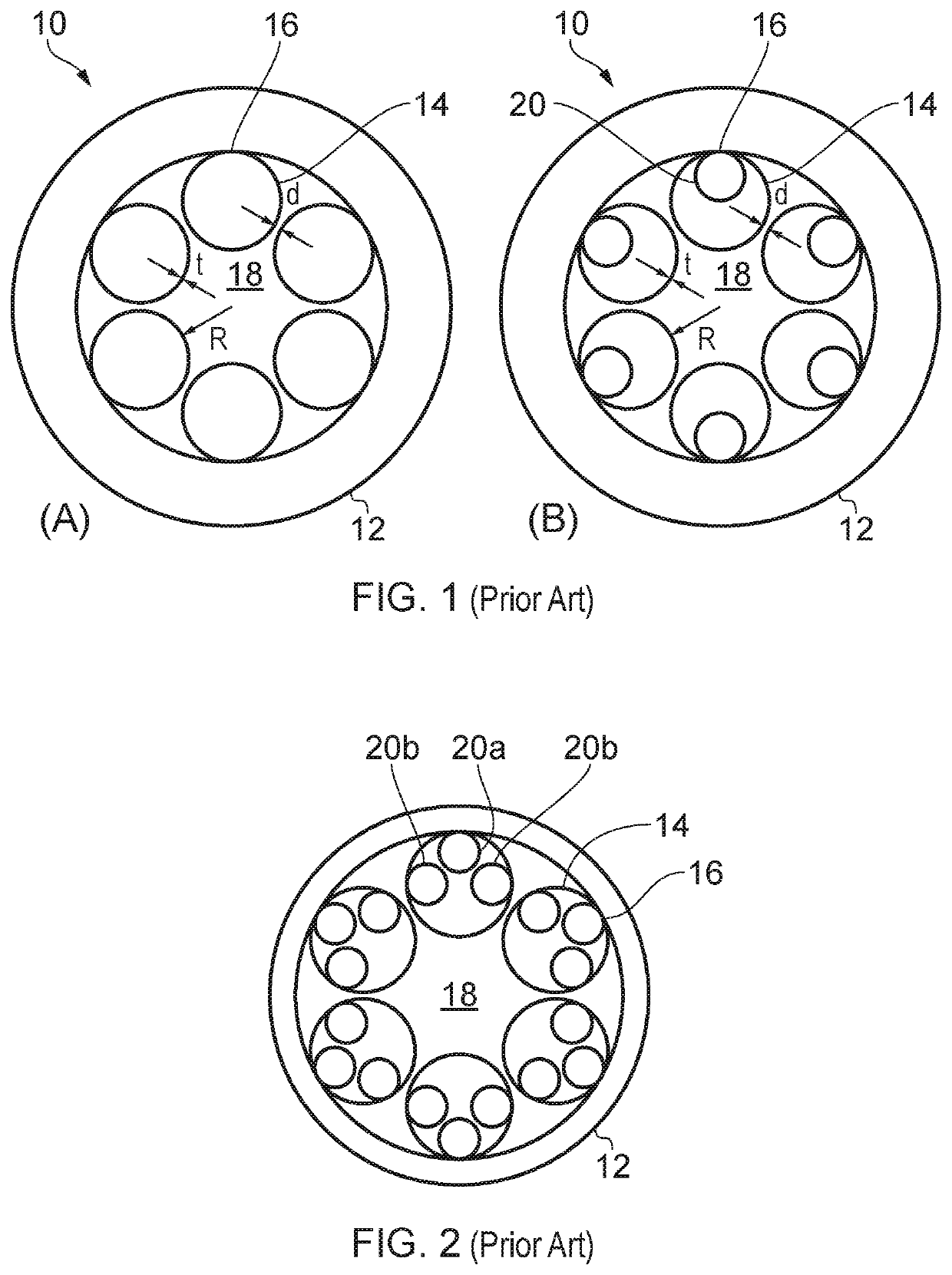

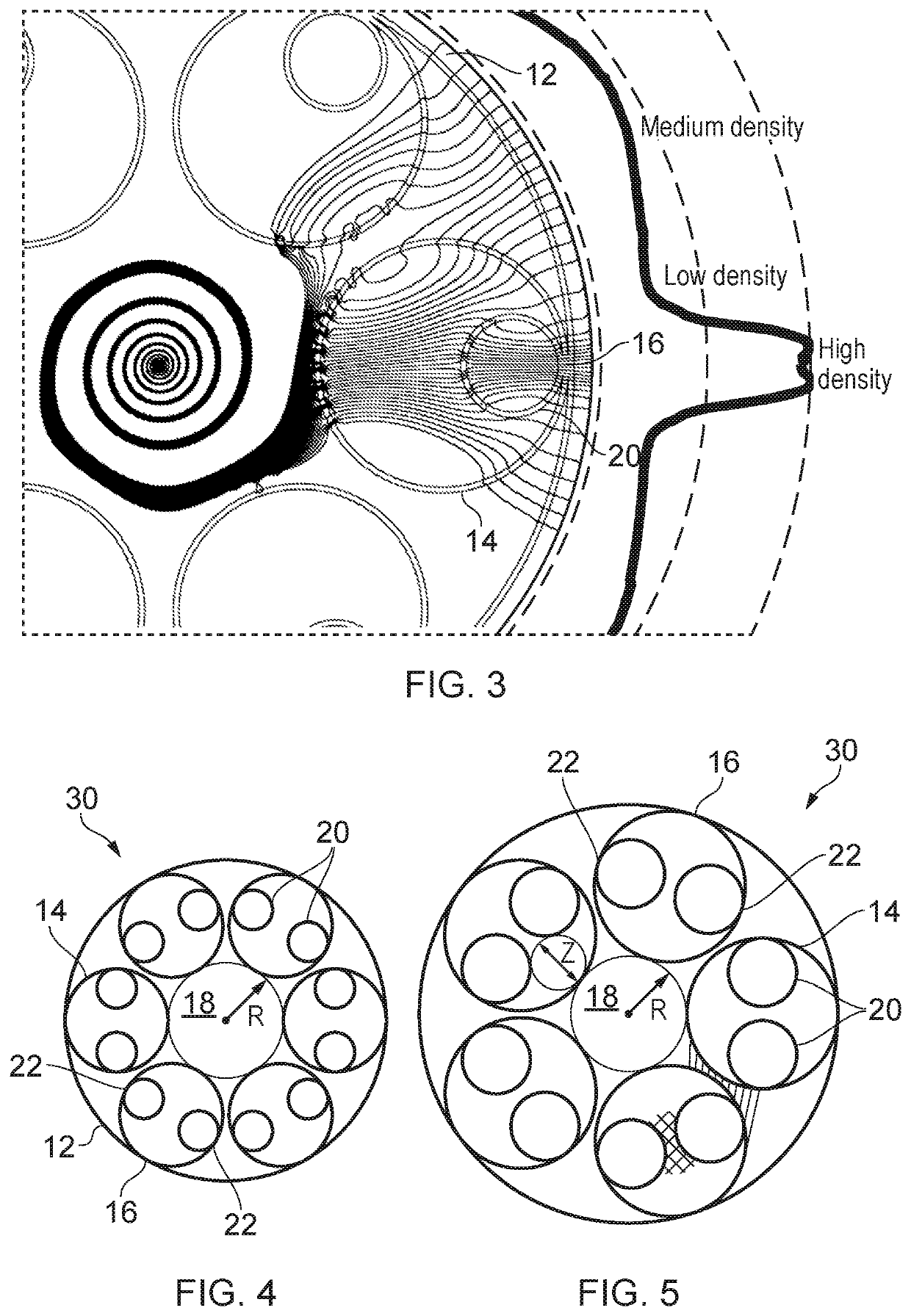

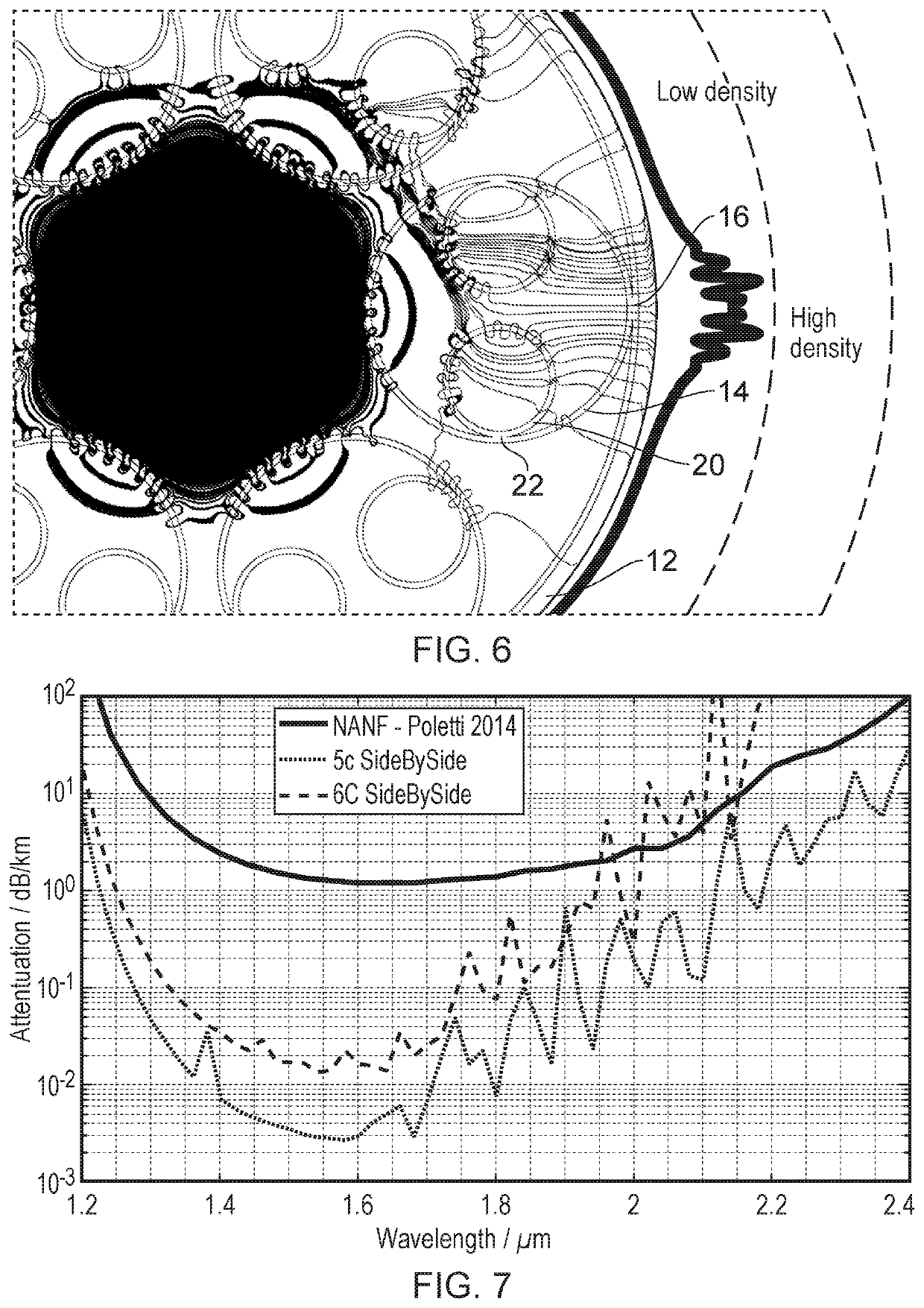

[0026]The type of hollow core optical fibre that can be described as antiresonant hollow core fibre (ARF) at its simplest comprises a tubular outer jacket, and number of cladding capillaries arranged in a ring inside the jacket, and secured or bonded to the inner surface of the jacket. A central void within the ring of capillaries forms a hollow core along which one or more optical modes can be guided by an antiresonant waveguiding effect.

[0027]FIG. 1(A) shows a transverse cross-sectional vie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com