High-heeled shoe sole structure and high-heeled shoe including same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0091]FIG. 10 illustrates a high-heeled shoe for explaining the present invention, and FIG. 11 illustrates an exploded view of main portions of the high-heeled shoe of FIG. 10.

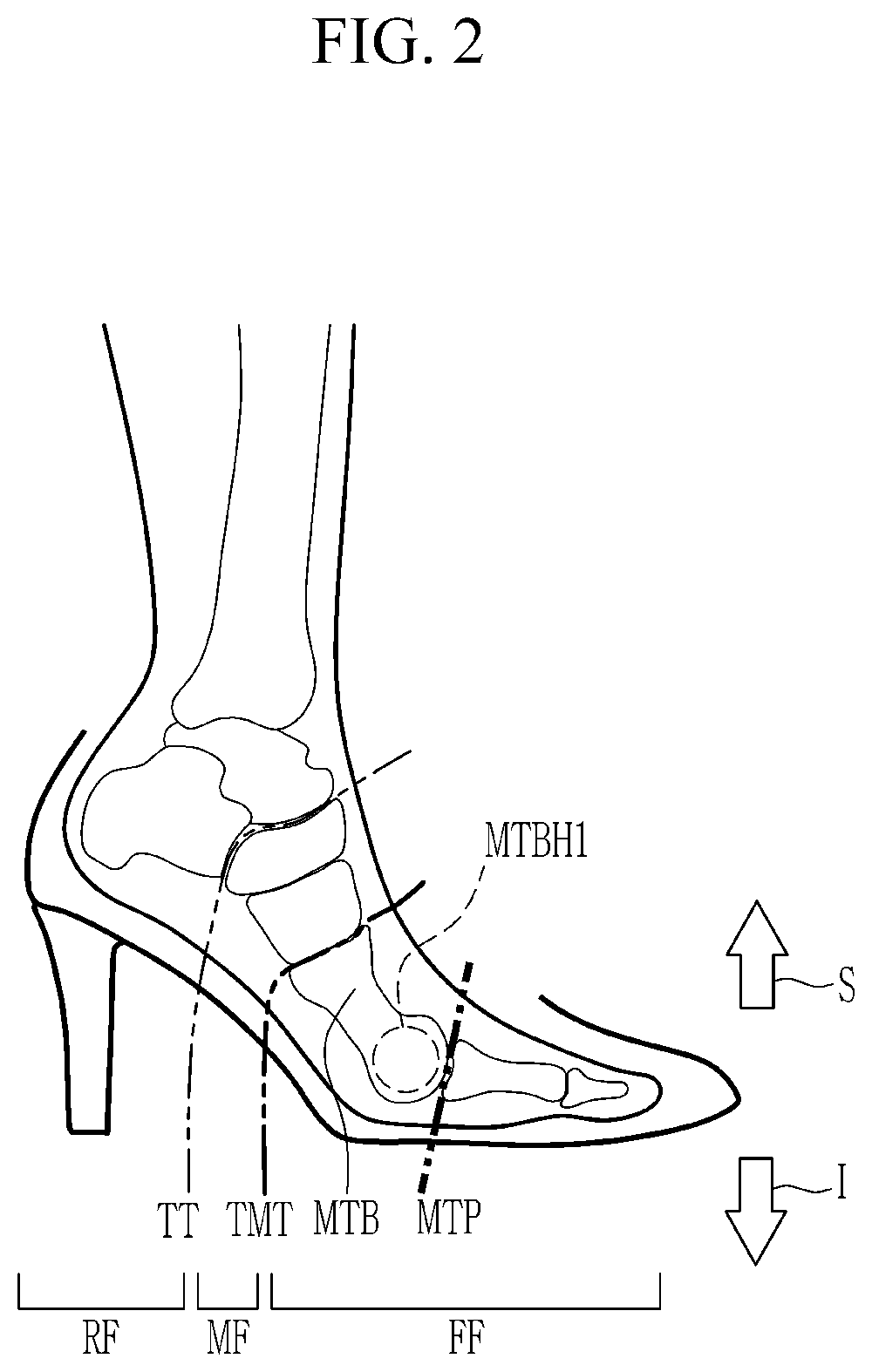

[0092]The high-heeled shoe of the first embodiment of the present invention includes a foot fixing portion 1, an insole 3, a sole structure 5, an outsole 7, and a heel 9.

[0093]The foot fixing portion 1 is a portion that may wrap the foot, forms a shape of the shoe, and is made of leather, etc. In addition, the insole 3 is a portion that is in direct contact with the sole of the foot. The sole structure 5 may support a load of a pedestrian, and simultaneously, maintain a shape of the shoe. In addition, the insole 3 may be coupled to an upper side of the sole structure 5. The outsole 7 is coupled to a lower portion of the sole structure 5, and a front side thereof directly contacts the ground. The heel 9 is coupled to the sole structure 5 to support a load of the heel of the foot.

[0094]The sole structure 5 of th...

second embodiment

[0132]FIG. 18 is a drawing for explaining a second embodiment of the present invention. FIG. 19 is a cross-sectional view of the bending portion 13 of the sole structure 5 of FIG. 18 taken along the transverse center line. FIG. 20 is a cross-sectional view of the sole structure 5 of FIG. 18 taken along the longitudinal center line. FIG. 21 is a drawing of an example in which an auxiliary member Sb is attached in the second embodiment. Compared with the first embodiment of the present invention, a feature of the present invention that is different from the first embodiment will be mainly described, and a description of the same feature as that of the first embodiment follows that of the first embodiment.

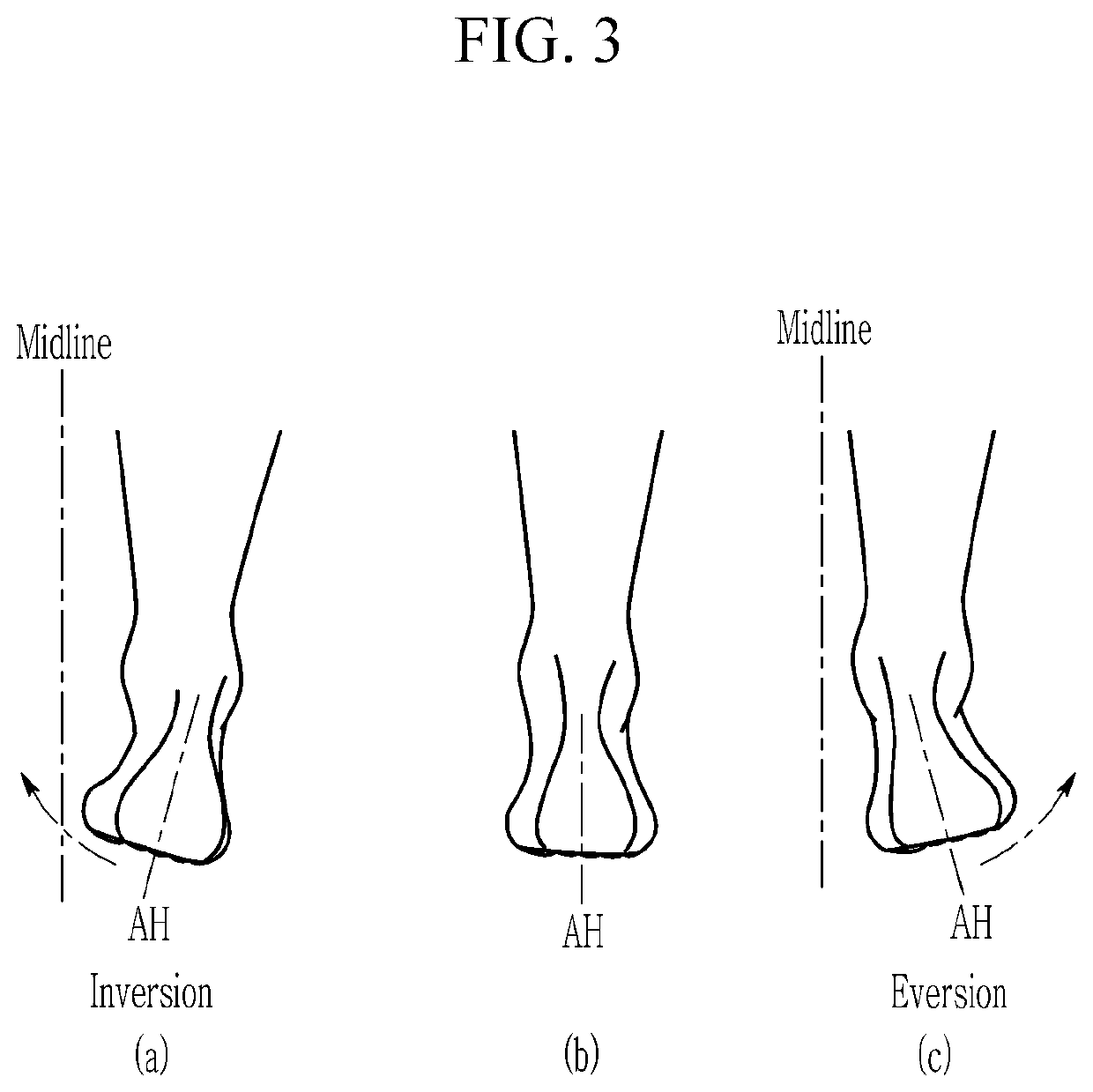

[0133]In the sole structure 5 of the second embodiment of the present invention, in order to further enhance the one-way flexibility of the bending portion 13 and in order that bending degrees of an inner portion 13h (medial side portion) and an outer portion 13i (lateral side portion...

fourth embodiment

[0138]FIG. 23 is a drawing for explaining a fourth embodiment of the present invention, showing the sole structure 5. Compared with the above-described embodiments, a feature of the present invention that is different from the above-described embodiments will be mainly described, and a description of the same feature as those of the above-described embodiments follows that of the above-described embodiments.

[0139]In the sole structure 5 of the fourth embodiment of the present invention, in order to further enhance the one-way flexibility of the bending portion 13 and in order that bending degrees of an inner portion (medial side portion) and an outer portion (lateral side portion) are different, at least one or more bending adjustment holes 13j and 13k may be provided in the bending portion 13.

[0140]As in the case of having the bending adjustment holes 13j and 13k of the fourth embodiment of the present invention and the bending adjustment groove 13g of the second embodiment, a very...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com