Bucket for a bucket elevator

a bucket elevator and bucket technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of limited filling and discharge openings, and achieve the effect of improving ejection behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

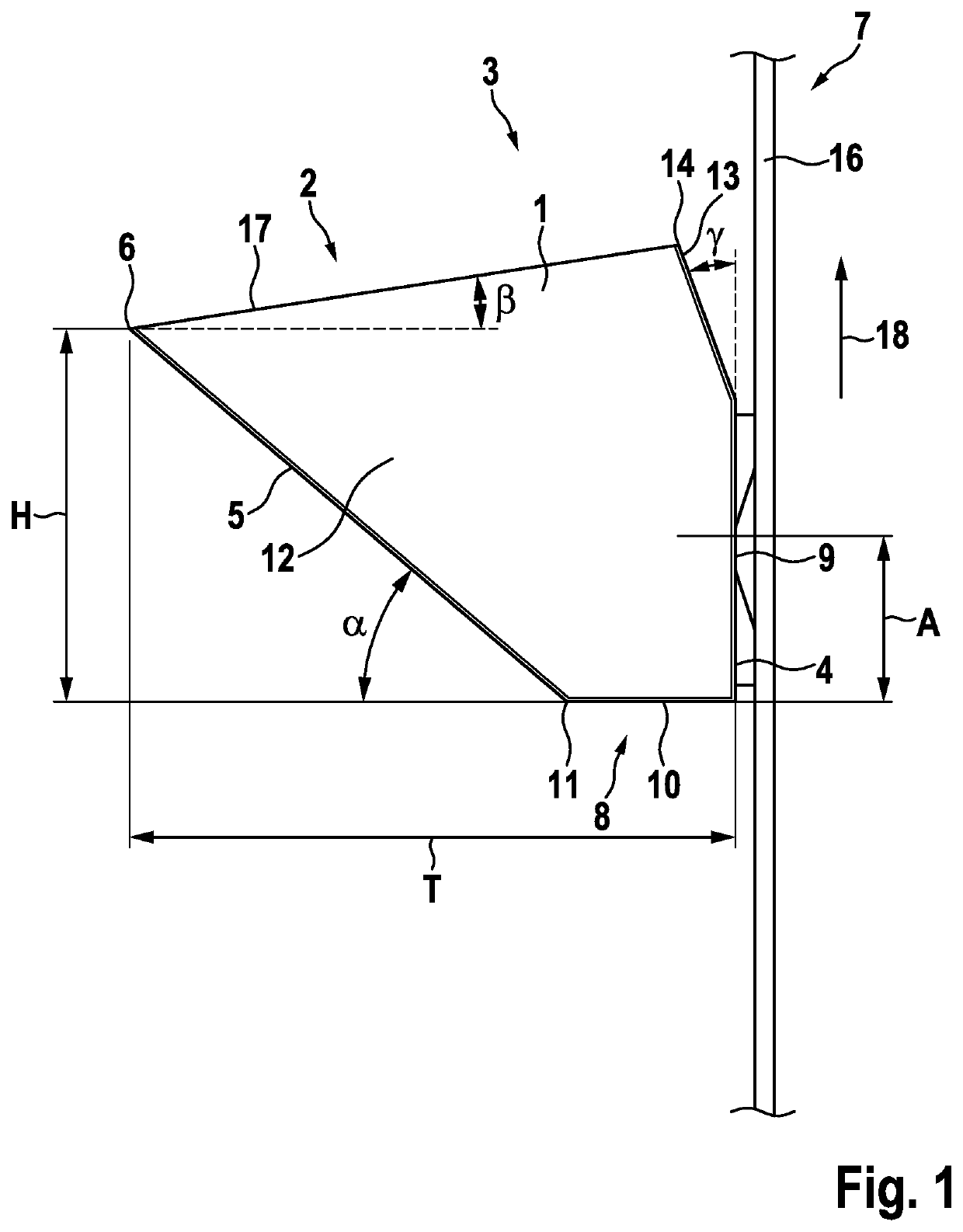

[0029]FIG. 1 shows a bucket 1 according to the invention, which has a bucket wall 3 with a front bucket wall 5, a rear wall 4, sidewalls 12 connecting the front bucket wall 5 and the rear wall 4, and a base 10. The bucket 1 is tethered to a belt 16 of a conveyor device via a tethering device 9, which has a vertically upwardly directed direction of movement 18. On its upper side, the bucket 1 has a filling and discharge opening 2, which is formed by an edge closing the bucket wall 3 towards the top. The edge has several sections. Here, the front edge 6 is associated with the front bucket wall 5 and forms the frontmost point of the bucket 1, which is thus furthest away from the conveyor device 7. Sidewalls12 each have sidewall upper edges 17, which laterally delimit the filling and discharge opening 2. The rear wall 4 has an upper edge 14 which limits the filling and discharge opening 2 at the rear. In the embodiment shown, the upper edge 14 forms the highest point of the bucket 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com