Bilateral abrasive disc pad

a technology of abrasive discs and abrasives, which is applied in the direction of flexible wheel parts, metal-working equipment, manufacturing tools, etc., can solve the problems of affecting the efficiency of the multi-stage grinding or polishing operation, and affecting the efficiency of the multi-stage grinding operation. , to achieve the effect of reducing runout and unwanted vibration, avoiding thread strippage, and easy unscrewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The invention will now be described with reference to the accompanying drawings. However, the invention is not limited to the particular illustrated embodiments. To the contrary, the invention is limited only by the accompanying claims and their equivalents.

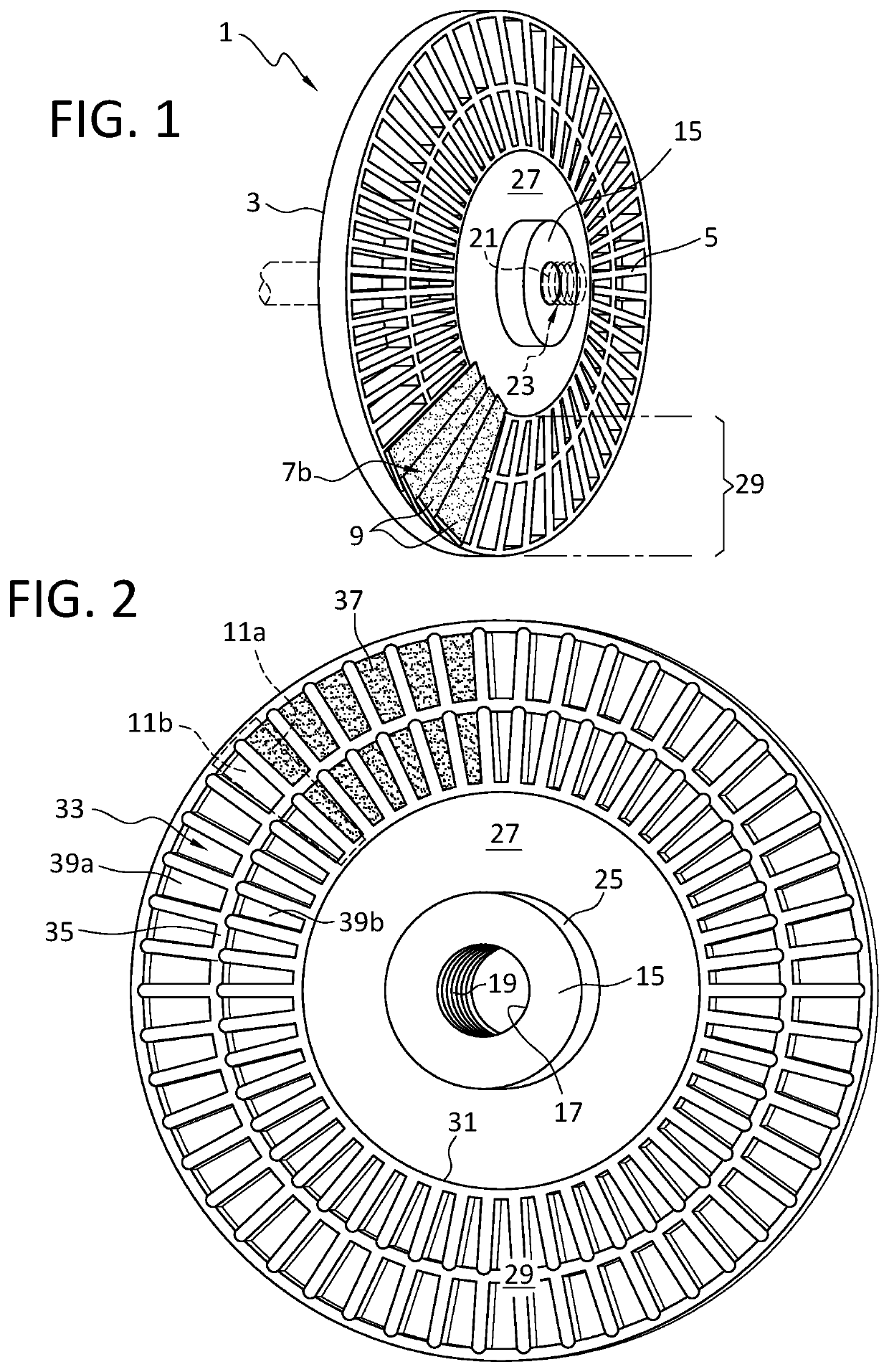

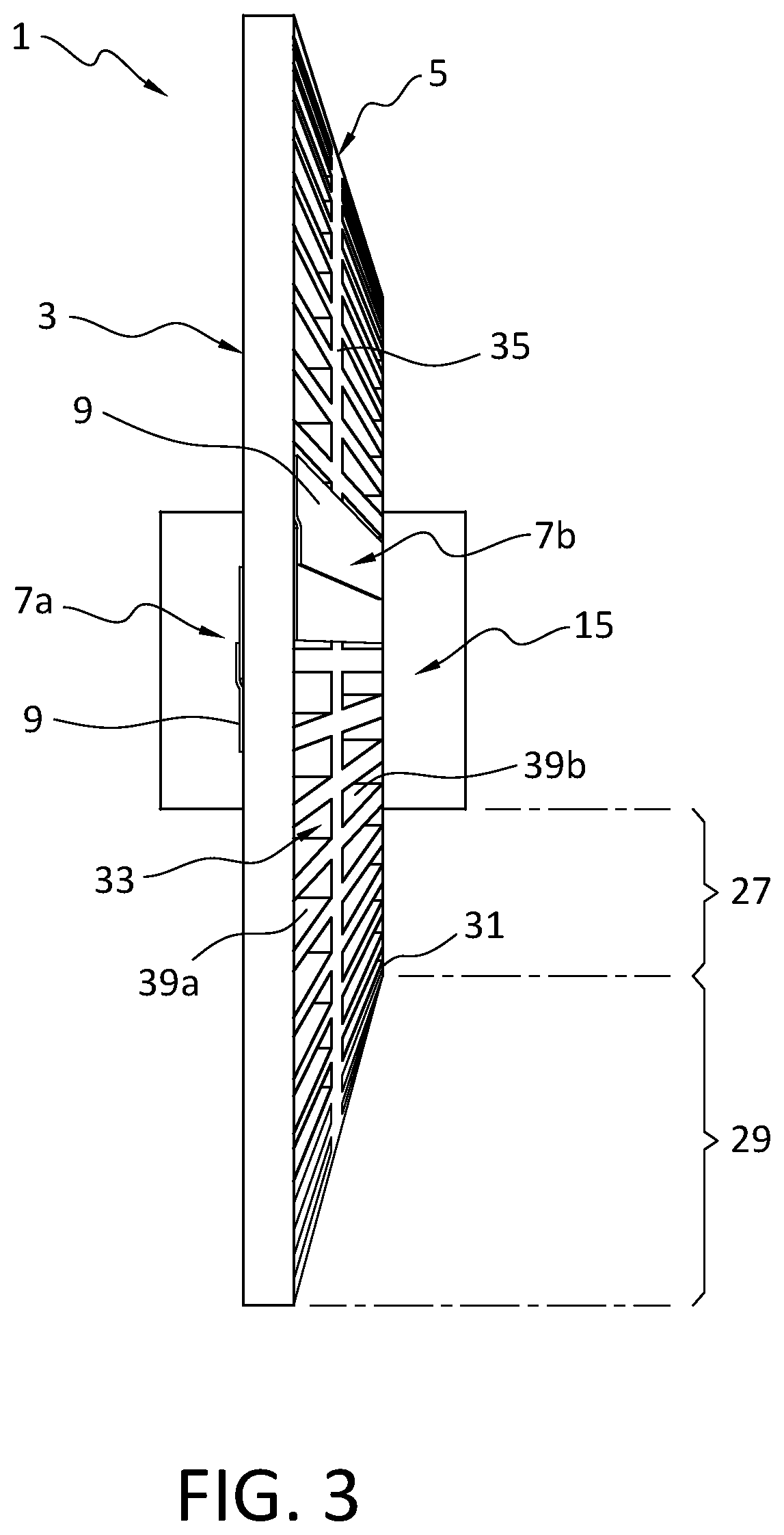

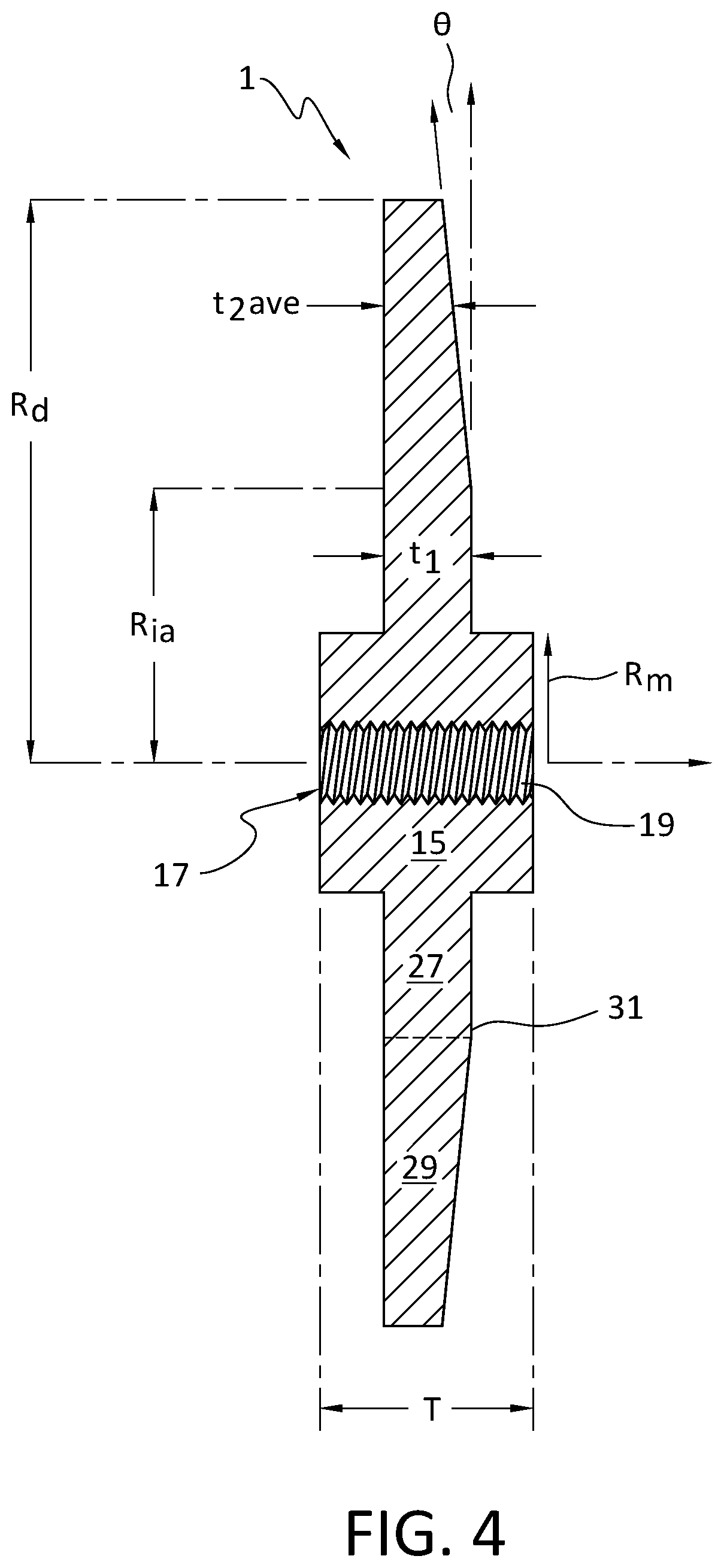

[0016]With reference to FIGS. 1-3, the double-sided abrasive pad 1 of the invention includes a flat side 3, a convex side 5, and two sets 7a, 7b of overlapping, fan-shaped adhesive flaps 9 mounted on the sides 3, 5 of the pad 1. Each of the flaps 9 has a bound side 11a affixed to the pad 1, and a free or loose side 11b that overlaps the bound side 11a of an adjacent flap 9. A cylindrically-shaped mounting section 15 forms the center section of the pad 1. The mounting section 15 has a mounting hole 17 concentrically positioned around the axis of rotation of the disc 1. The inner surface of the mounting hole 17 includes a screw thread 19 that is engageable with a complementary screw 21 thread of a driven shaft 23 of a grinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com