Wrapping head for wrapping loads, particularly palletized loads, and method of operation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

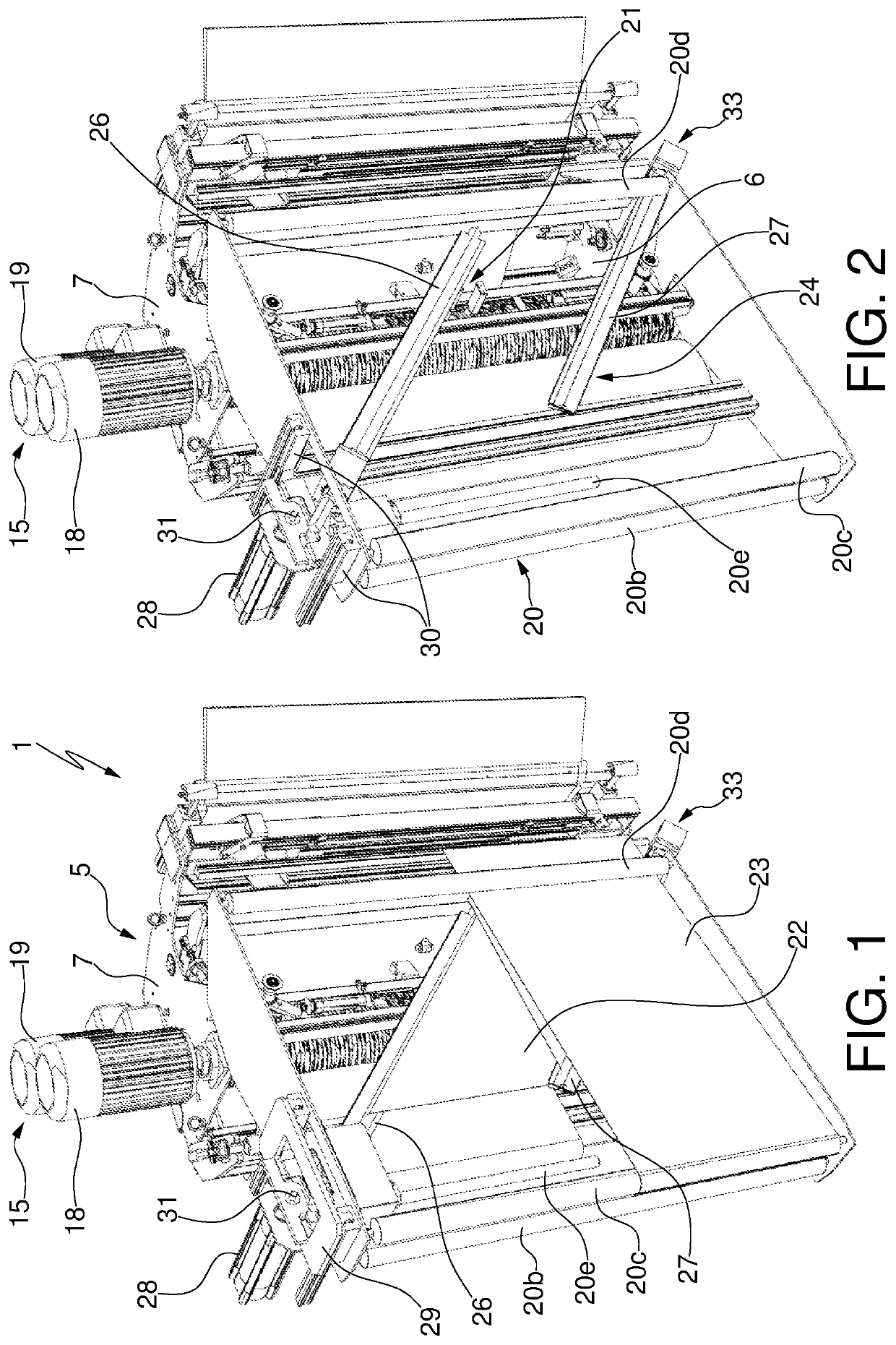

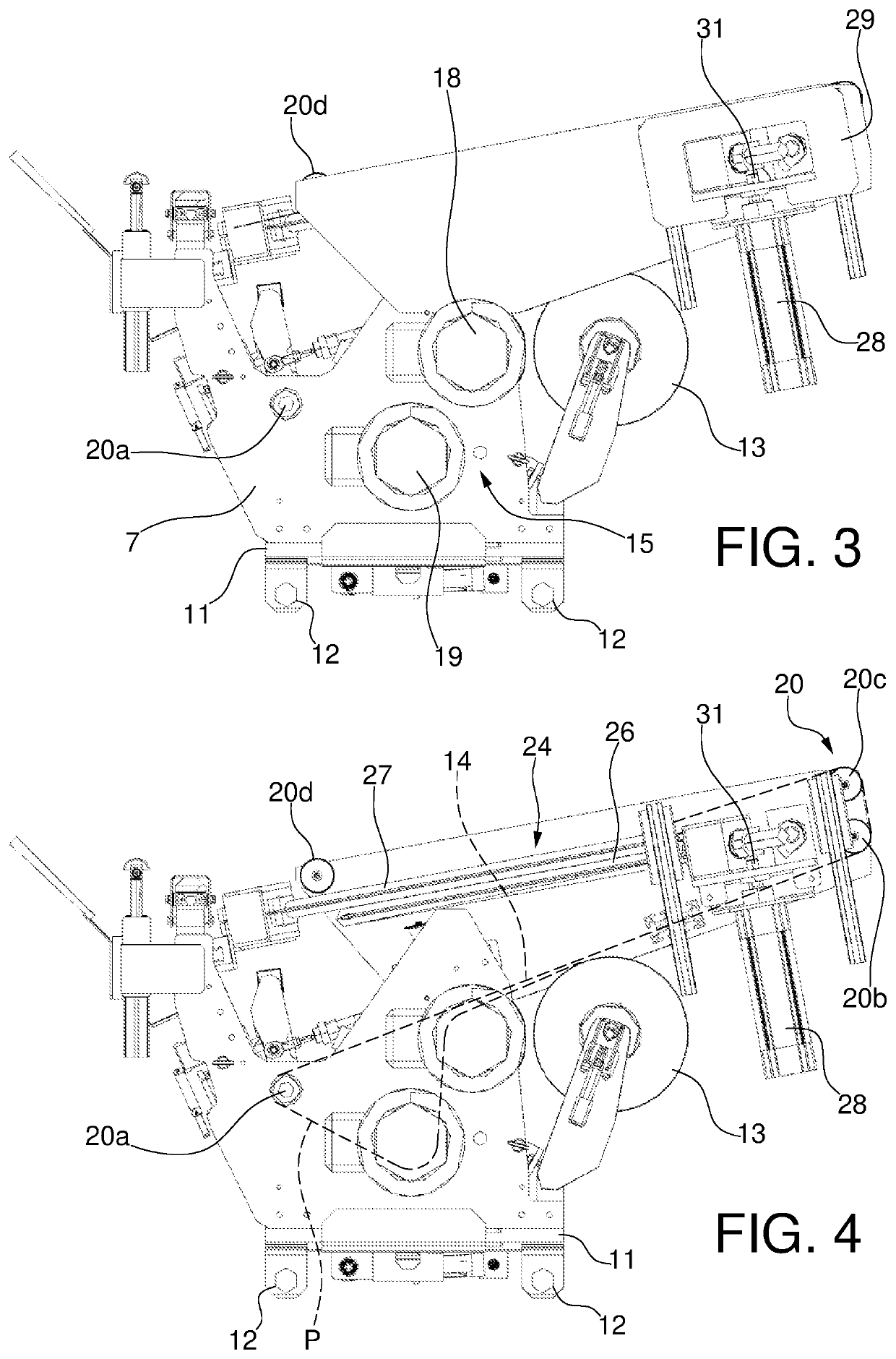

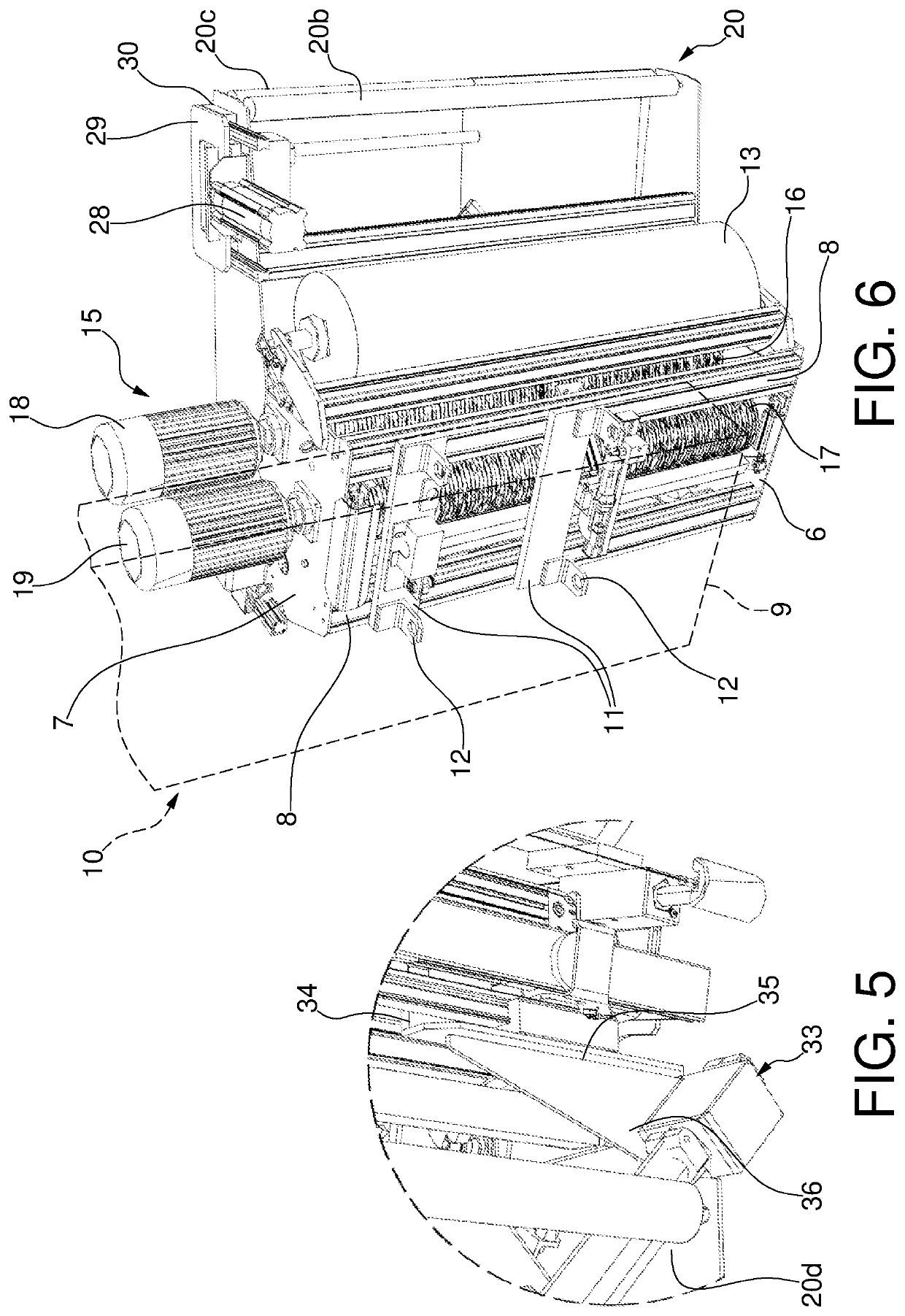

[0055]With reference to the FIG. 1, reference number 1 overall indicates a head for wrapping loads, more particularly palletized loads, according to the present invention.

[0056]In the following description, by way of a non-limiting example, reference will be made to a head 1 included in a wrapping station 2 (FIG. 7) in which the load 3, in particular a palletized load, is driven to rotate around a vertical or substantially vertical axis, on a suitable rotatable support platform 4, and the wrapping head 1 is fixed with respect to the load 3, and only executes vertical or substantially vertical movements.

[0057]However, the present invention can also be applied to a wrapping station 2 in which the load 3 is locally stationary, while the wrapping head 1 is supported, and driven, to rotate around the aforesaid stationary load 3.

[0058]The wrapping head 1 comprises a support framework 5.

[0059]The support framework 5 comprises a first plate 6, lower during use, and a second plate 7, upper d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com