Pipe joint

a technology for pipes and joints, applied in the field of pipes, can solve problems such as complicated work, and achieve the effect of increasing the safety and endurance of the joint body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]One embodiment of the present invention is described with reference to the drawings.

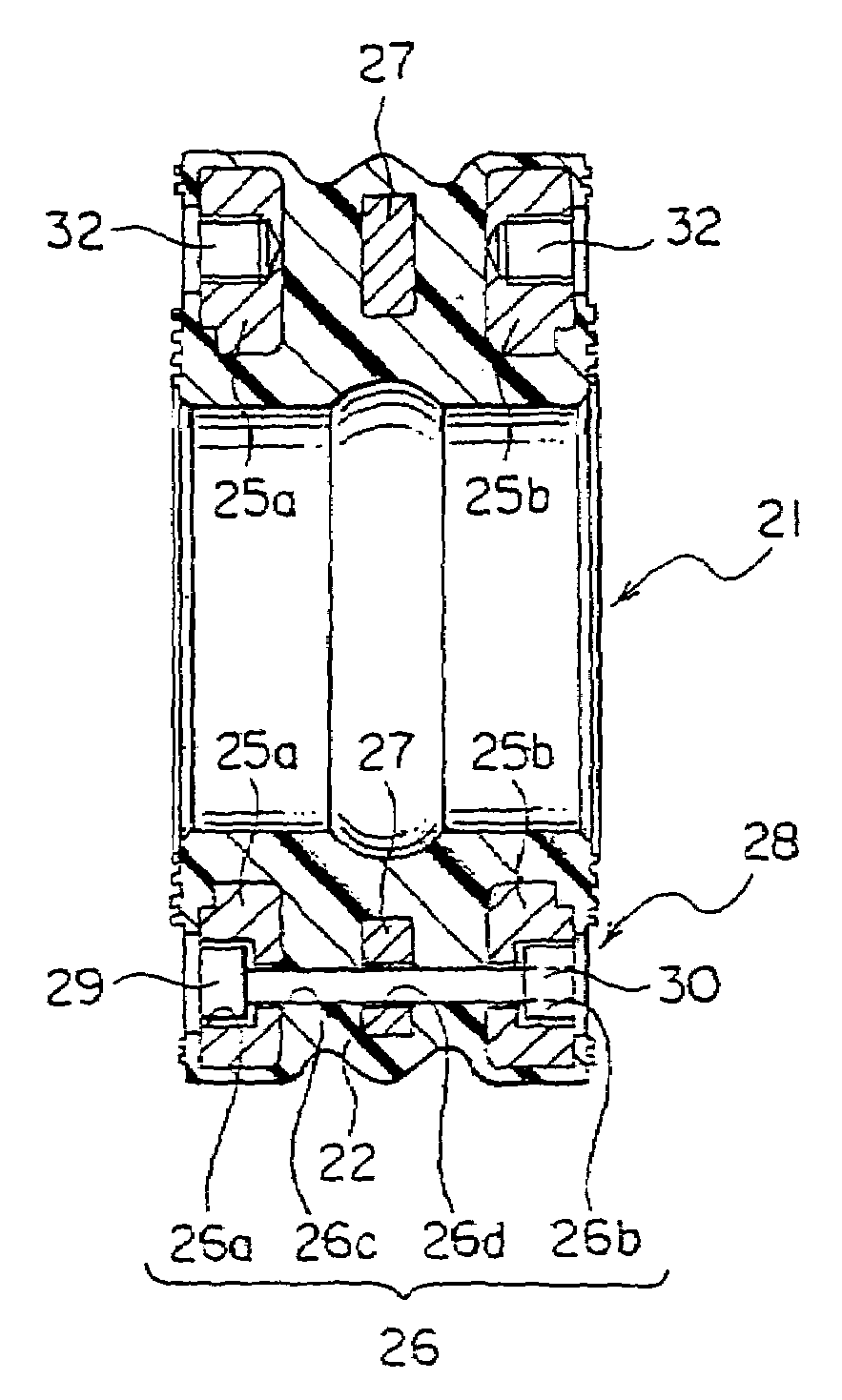

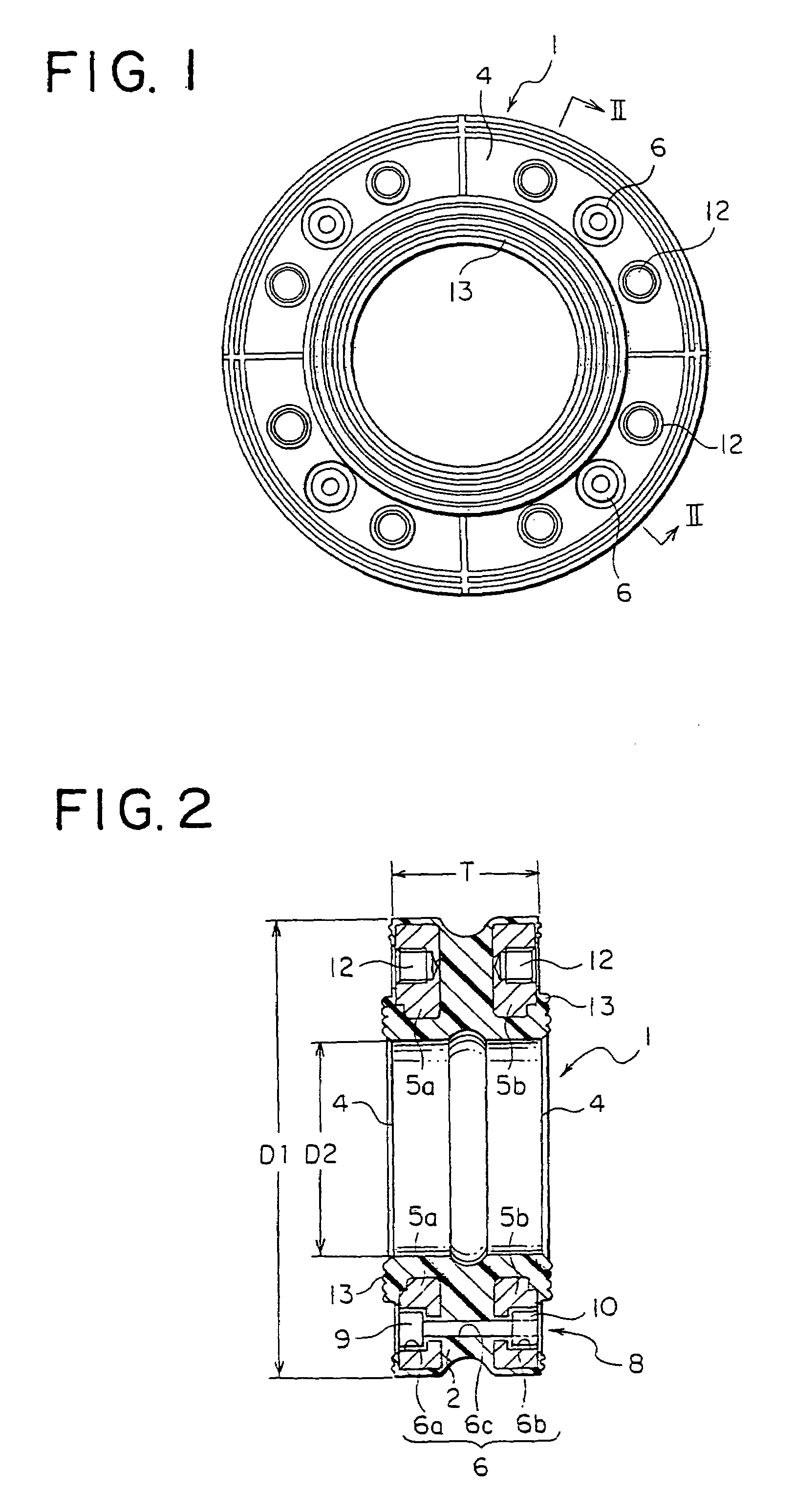

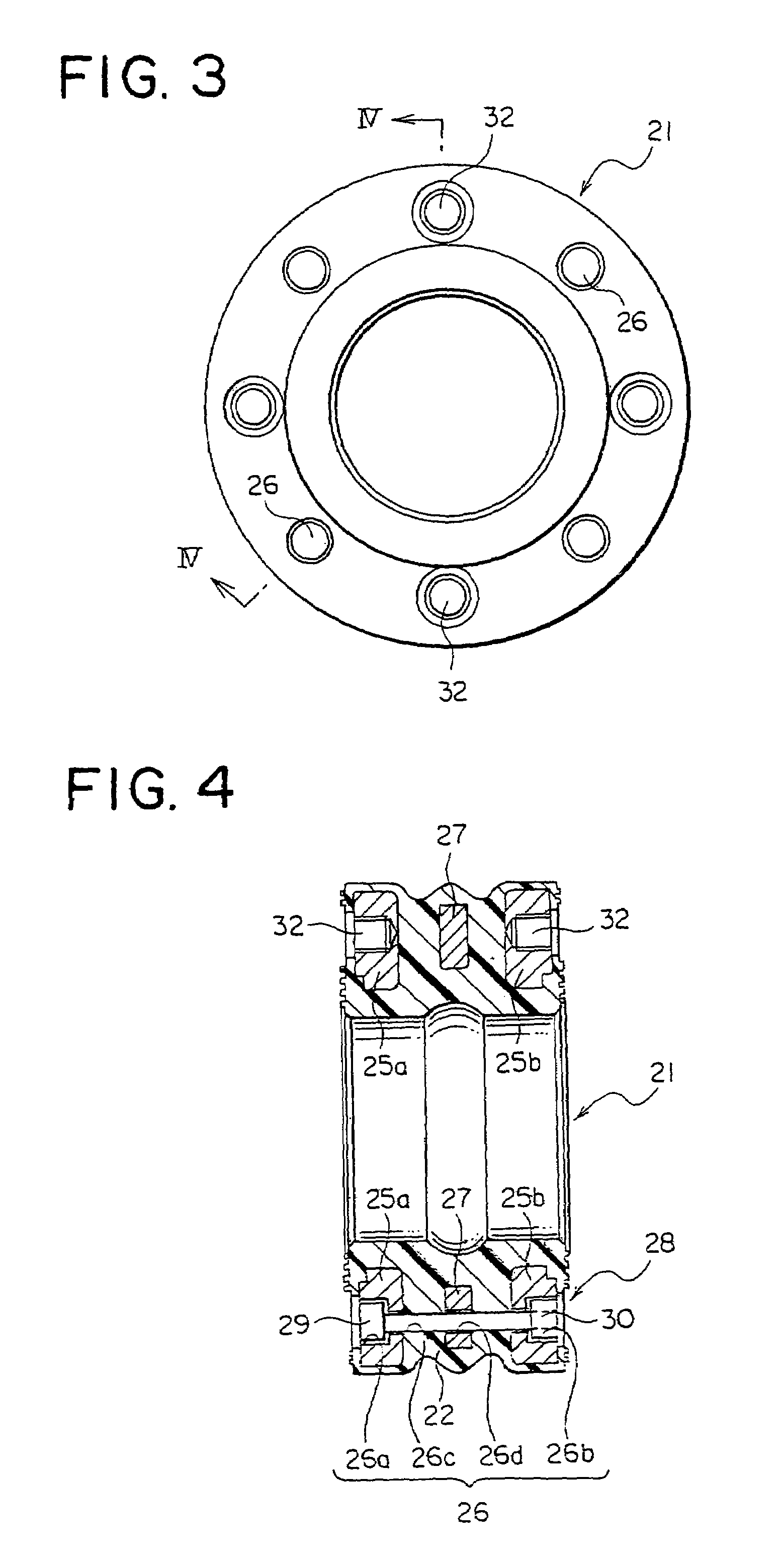

[0014]In FIGS. 1 and 2, the reference numeral 1 indicates a pipe joint comprising a hollow cylindrical joint body 2. The joint body 2 is made of thick elastic material having a capacity to resist pressure. At both ends inside the joint body 2 are embedded metallic circular flanges 5a, 5b each having the same shape. In the direction of the circumference of the flanges 5a, 5b and the joint body 2 are provided a plurality of through holes 6 communicating axially at prescribed intervals. In the flanges 5a, 5b, the through holes 6 are formed to be shoulder holes 6a, 6b, 6a being larger than 6b, while in the joint body 2, the through hole 6 is formed to be a shoulder hole 6c having the same diameter as that of the shoulder hole 6b. In the through hole 6 is inserted a bolt-nut 8 as a connecting appliance. Namely, the bolt-nut 8 specifically comprises a through bolt 9 and a nut 10, the head of the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com