Low noise vibrating string transducer

a transducer and low noise technology, applied in the field of transducers, can solve the problems of lacombe not revealing the shielding of the circuit or cable, the noise of the circuit must be eliminated by most amplifiers, and the noise is substantial and highly undesirable, so as to achieve a wide tonal range, reduce the noise contained, and reduce the effect of common mode rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

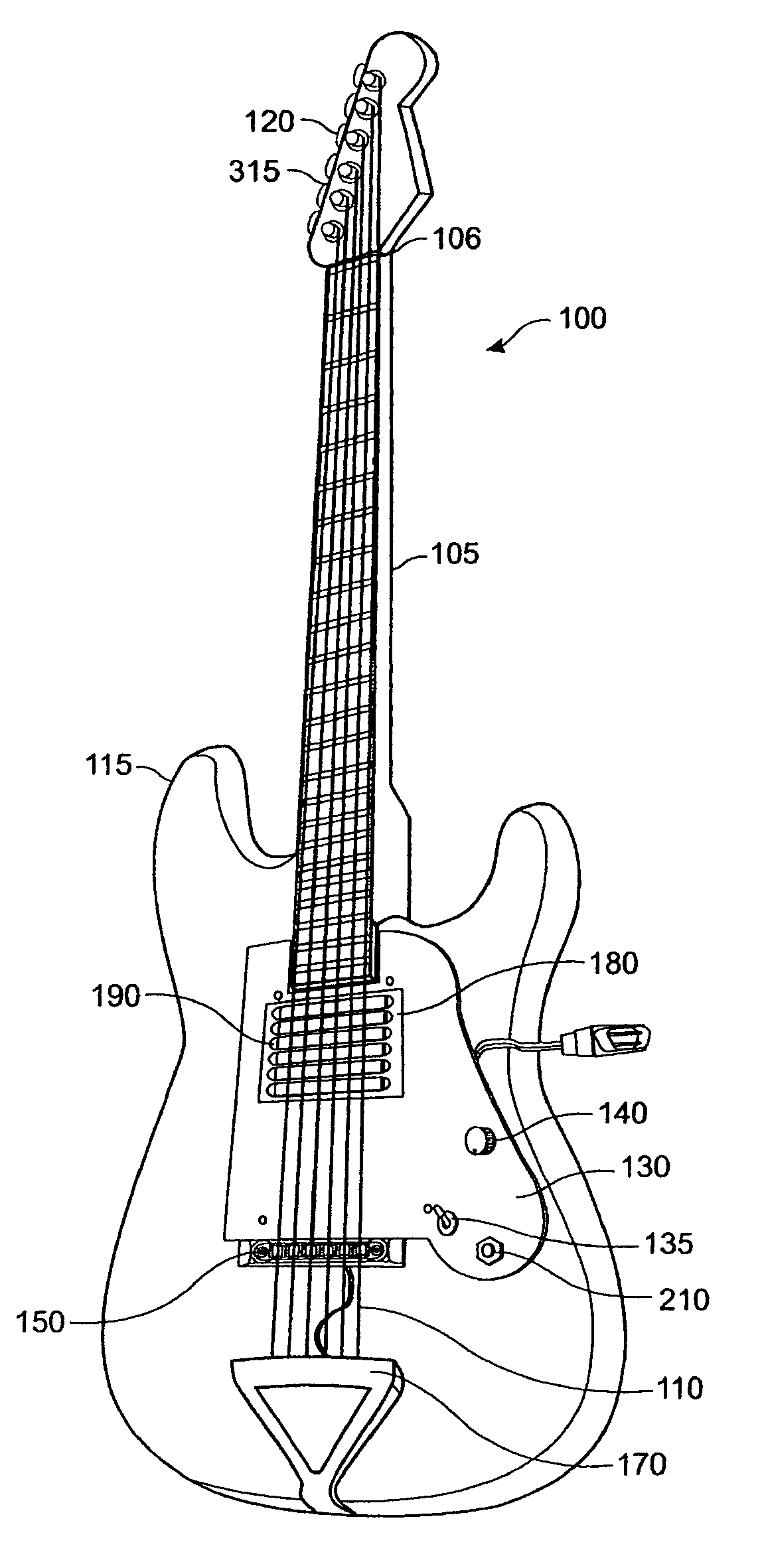

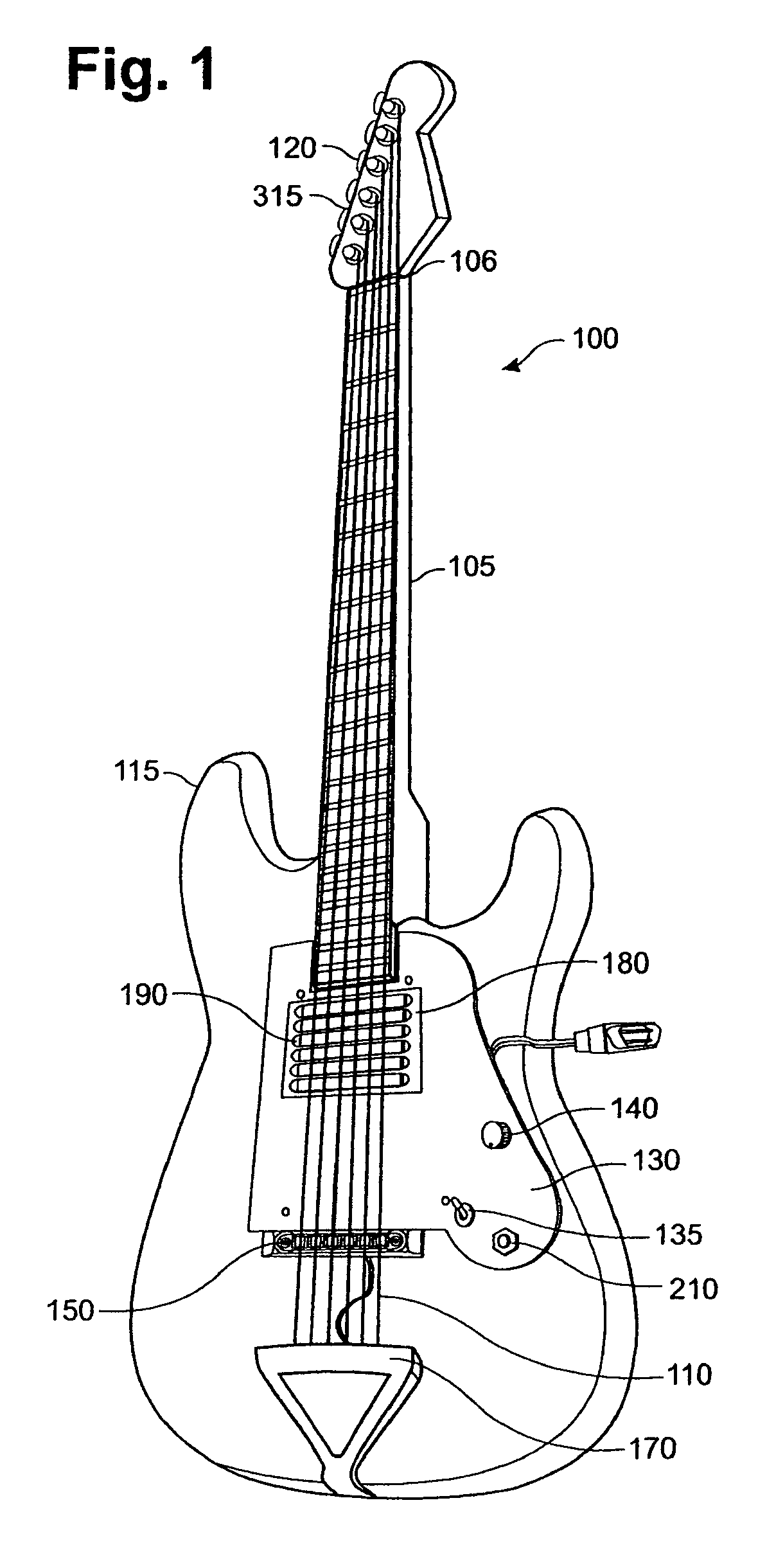

[0033]By way of one example of many to serve as background in understanding the present invention, FIG. 1 shows a standard electric guitar 100. The guitar 100 has six strings 110 that are connected from one end at the tuning head 120 to an opposite end of a sting securing mechanism 170 across a fret board 105 and a guitar body 115. The strings 110 are typical guitar strings made of metal and are wound tight at the tuning knobs 315 so that the stings 110 will be in tune when the strings are picked. The strings 110 rest upon a bridge 150. The bridge 150 is located slightly above the securing mechanism 170.

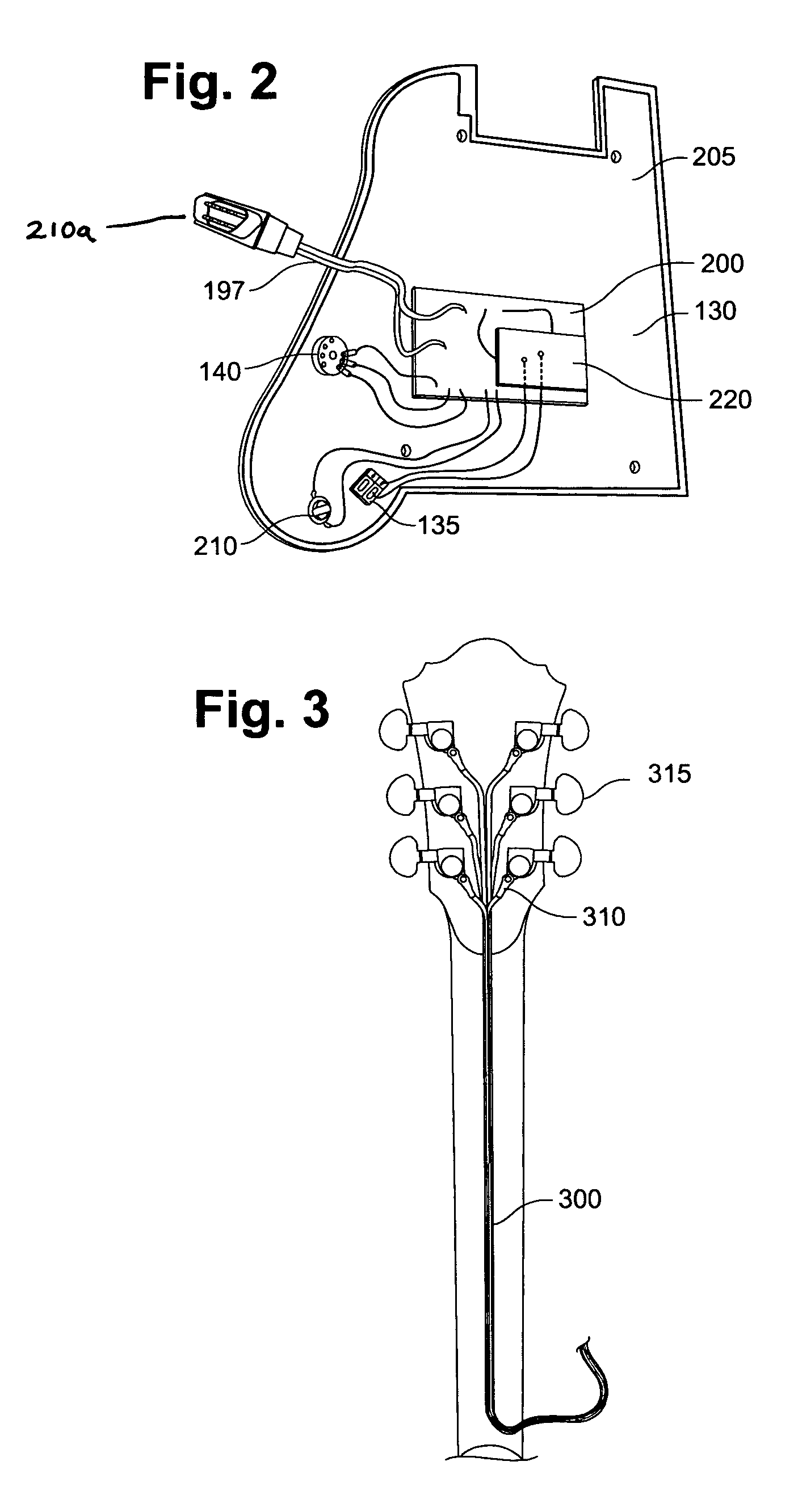

[0034]Directly under the strings 110 and below the fret board 105 sits the base plate 130. The base plate 130 is typically made from thin, rigid, abrasion resistant plastic designed to fit underneath the stings of most guitars without modification. Attached to the base plate are the volume knob 140, the power switch 135, and an output jack 210. A plastic magnet tray 180 is also shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com