Pivotal device for scissors

a pivot device and scissors technology, applied in the field of pivot devices for scissors, can solve problems such as interference with the operation of scissors, and achieve the effect of reducing the risk of loosening of screws and/or nuts, and less likely to mov

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

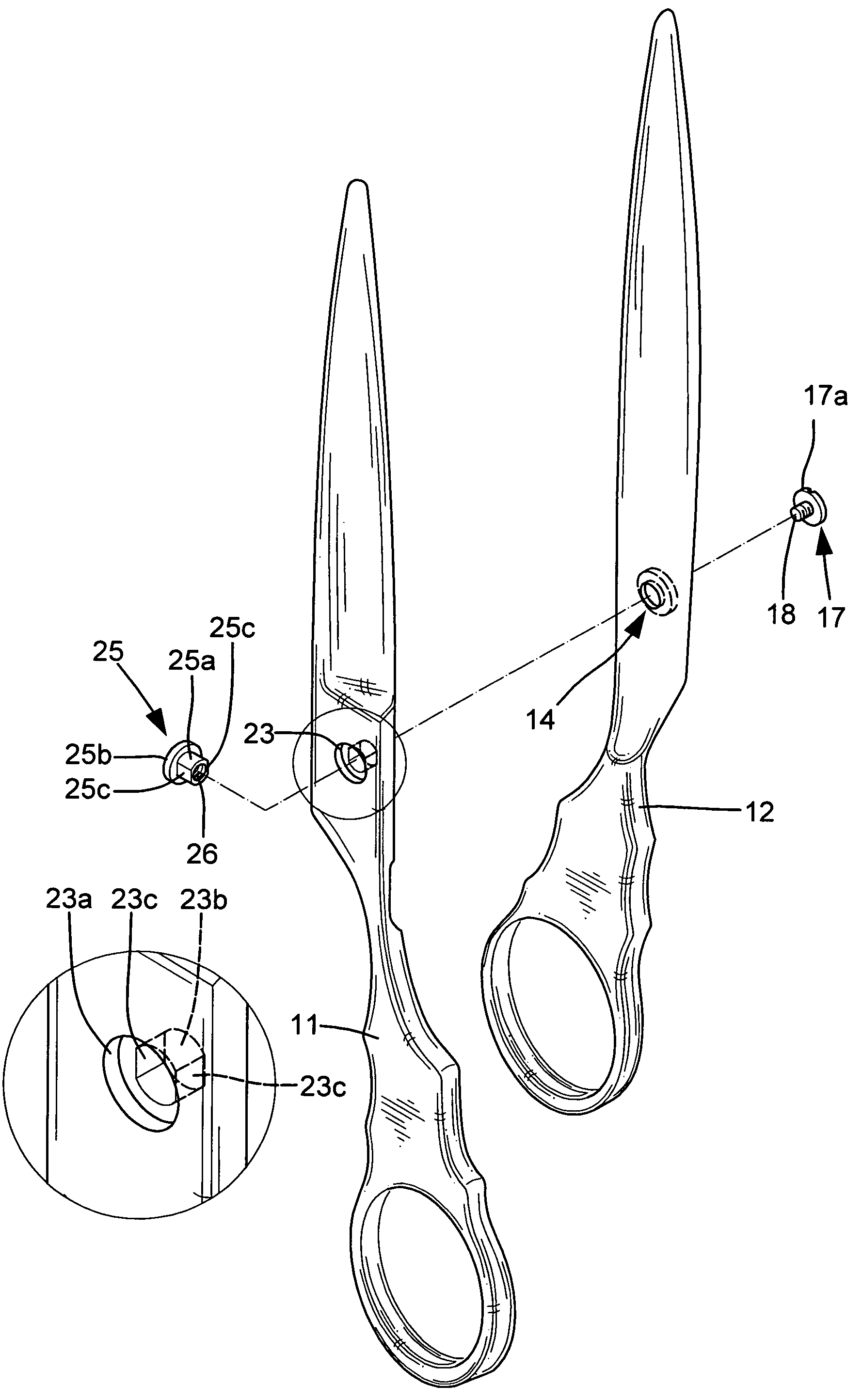

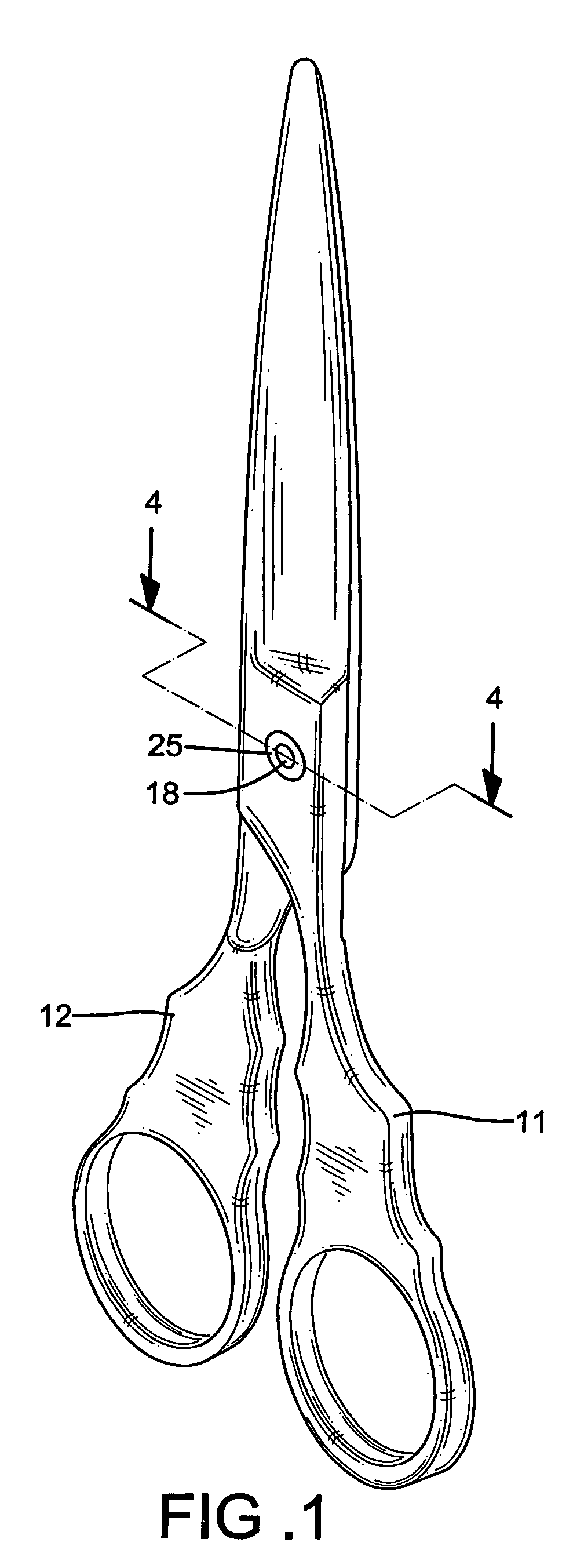

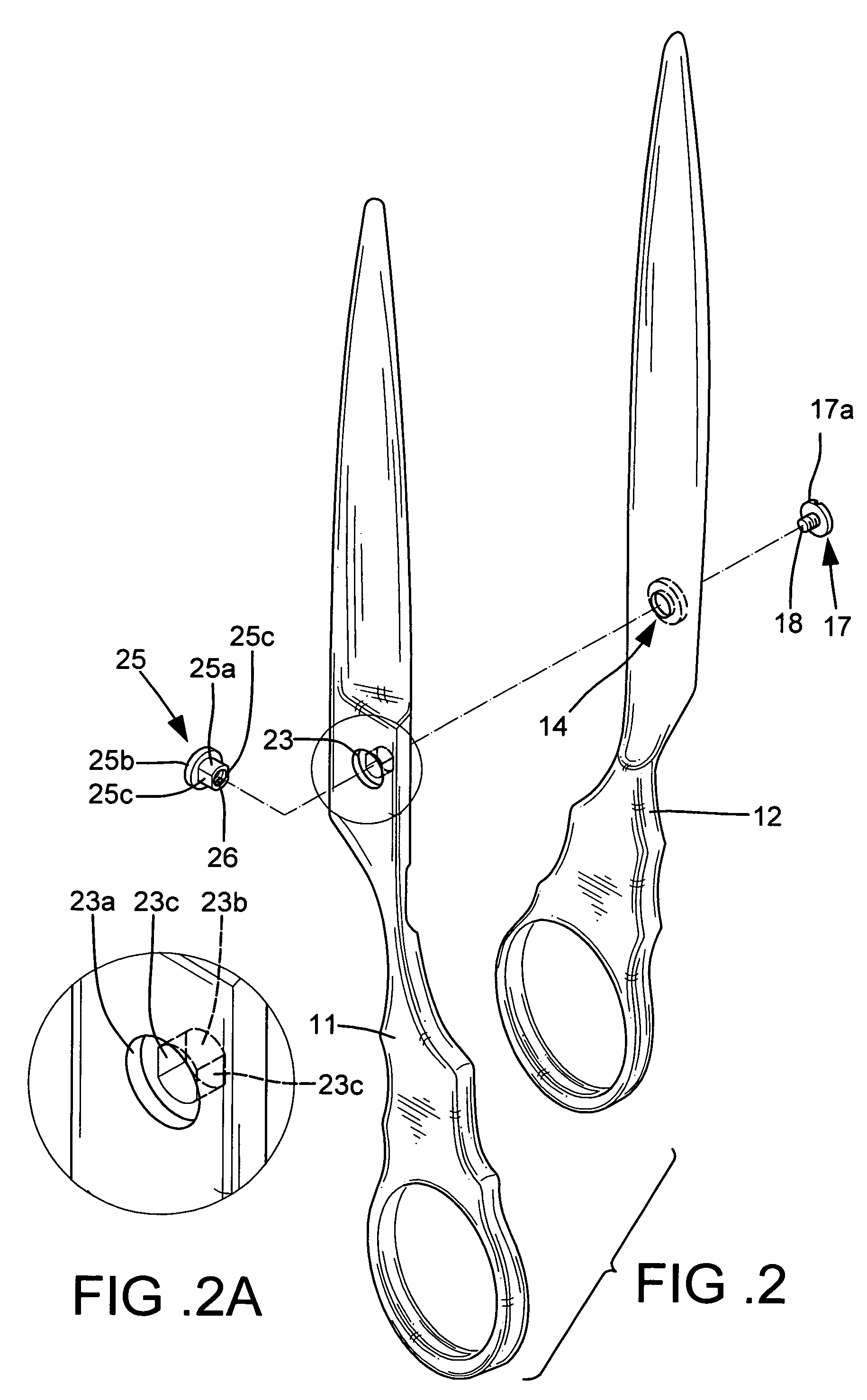

[0031]Referring to FIGS. 1 through 5, a pair of scissors in accordance with the present invention comprises a first scissor element 11, a second scissor element 12, and a pivotal device for pivotally engaging the first scissor element 11 with the second scissor element 12.

[0032]As illustrated in FIGS. 2, 2A, and 4, the first scissor element 11 includes a countersink 23 extending from a first side of the first scissor element 11 through a second side of the first scissor element 11. The countersink 23 of the first scissor element 11 has a larger section 23a facing away from the second scissor element 12 and a smaller section 23b facing the second scissor element 12. It is noted that the smaller section 23b is substantially circular and includes two flat portions 23c parallel to each other. In other words, the smaller section 23b is non-circular.

[0033]As illustrated in FIGS. 2 and 4, the second scissor element 12 includes a countersink 14 extending from a first side of the second scis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com