Crown reinforcement for a radial tire

a technology of crown reinforcement and radial tires, which is applied in the direction of special tyres, wheels, vehicle components, etc., can solve the problems of crown reinforcement appearance and propagation cracks at said ends, greatly impaired durability of crown reinforcement, and inability to provide a completely satisfactory solution. , to achieve the effect of improving the resistance of the crown structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

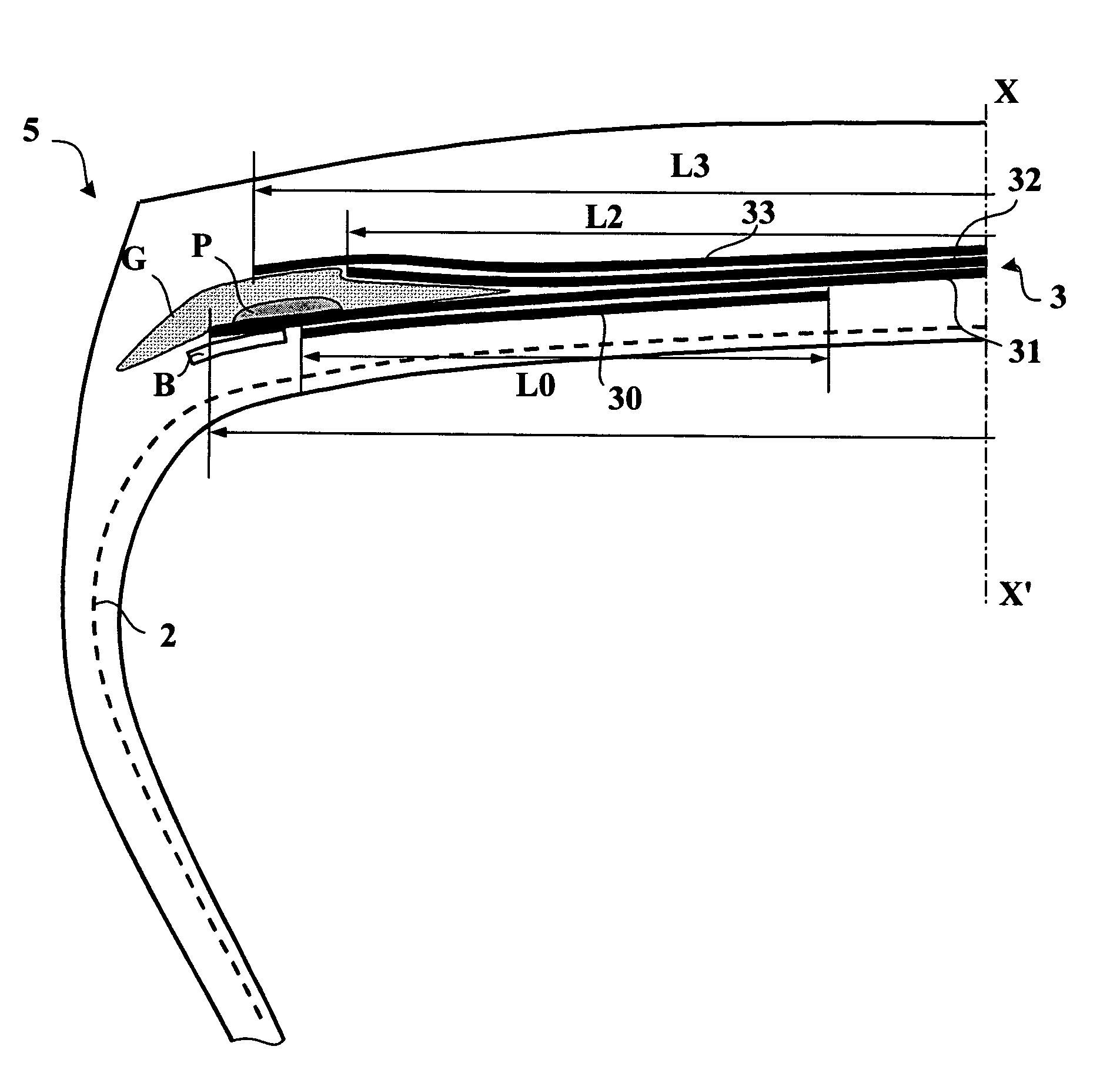

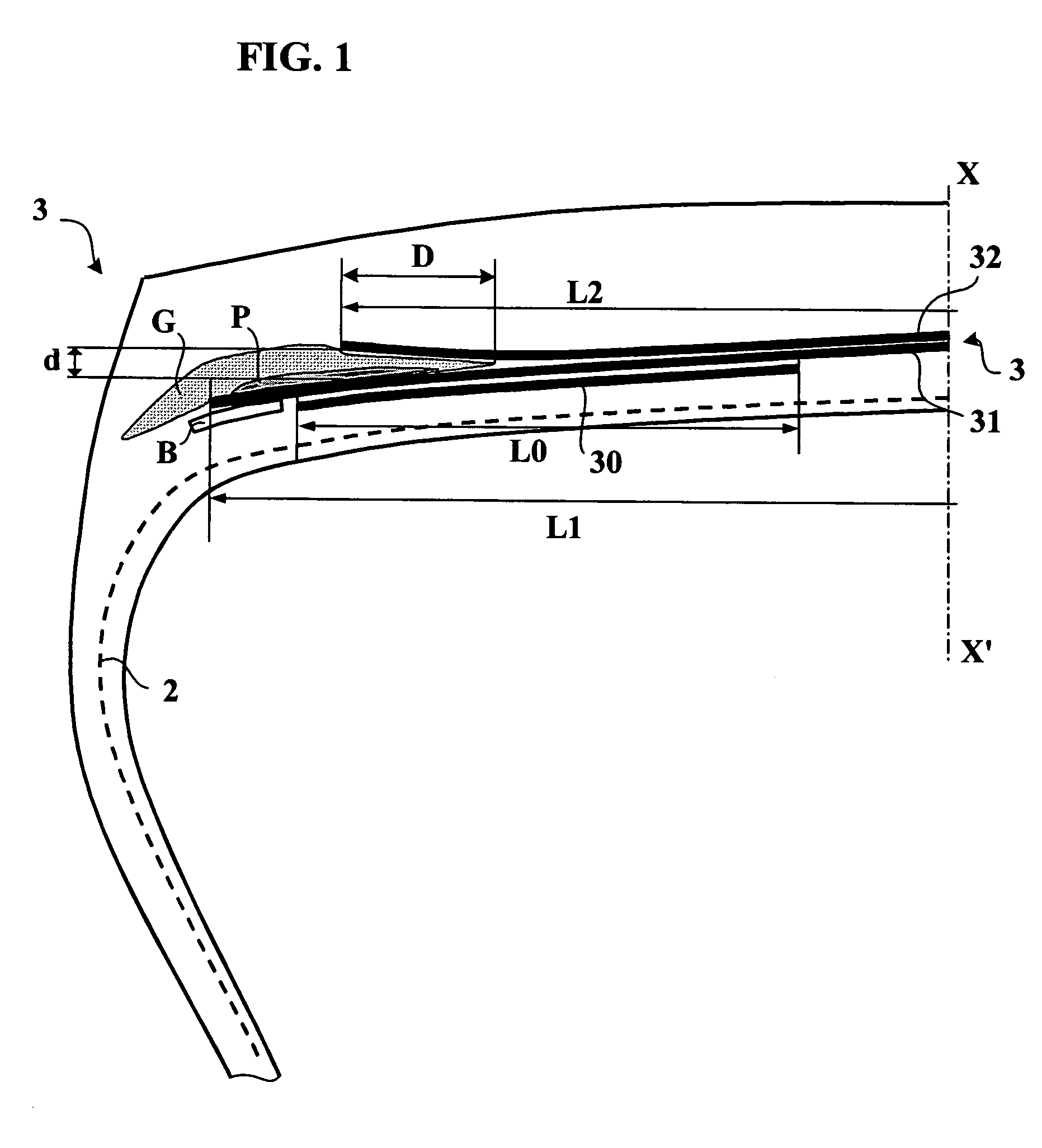

[0055]FIG. 1 shows a partial diagrammatic view in meridian section of a tire 1 of dimension 315 / 80.R.22.5 X. The tire 1 has a form ratio H / S substantially equal to 0.65, H being the height of the tire on its rim and S the maximum axial width of said tire mounted on its 9.00×22.5 operating rim and inflated to a recommended pressure of 9 bar.

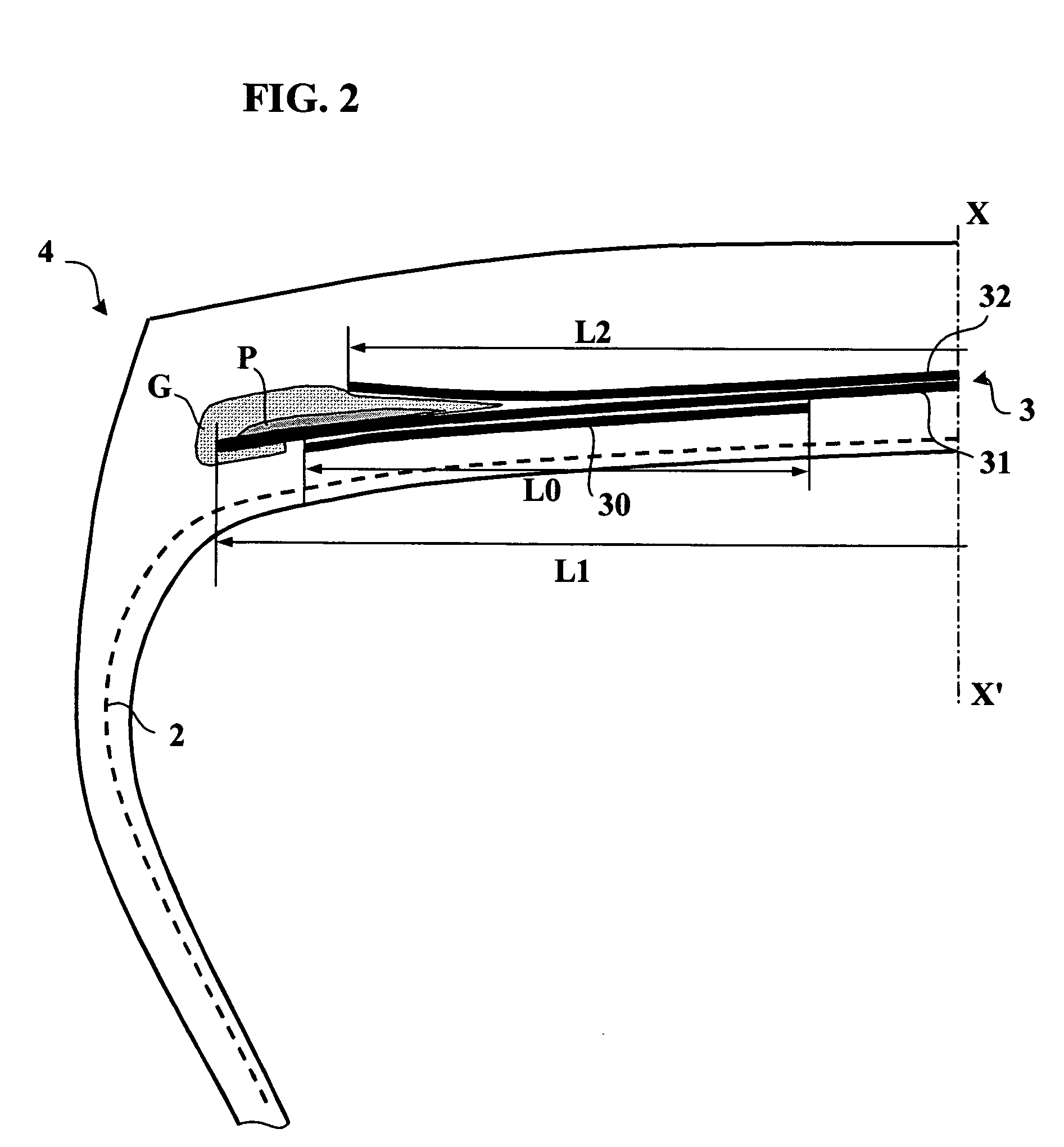

[0056]FIGS. 1 to 3 show only a half-view of the tires which are extended symmetrically relative to the axis XX′, which represents the circumferential median plane, or equatorial plane, of a tire.

[0057]The tire 1 comprises a radial carcass reinforcement composed of a single ply 2 of inextensible metal cables, that is to say, cables which have an elongation of at most 0.2% under a tensile force equal to 10% of the breaking load. Said carcass reinforcement is anchored within each bead; said beads are not shown in FIGS. 1 to 3. It is surmounted, radially to the outside, by a crown reinforcement 3 comprising radially from the inside to the outside:[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com