Image sensor and method for fabricating the same

a technology of image sensor and manufacturing method, which is applied in the field of image sensor, can solve the problem of rare improvement of image sensor efficiency, and achieve the effect of preventing the brightness and resolution of captured images from being reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

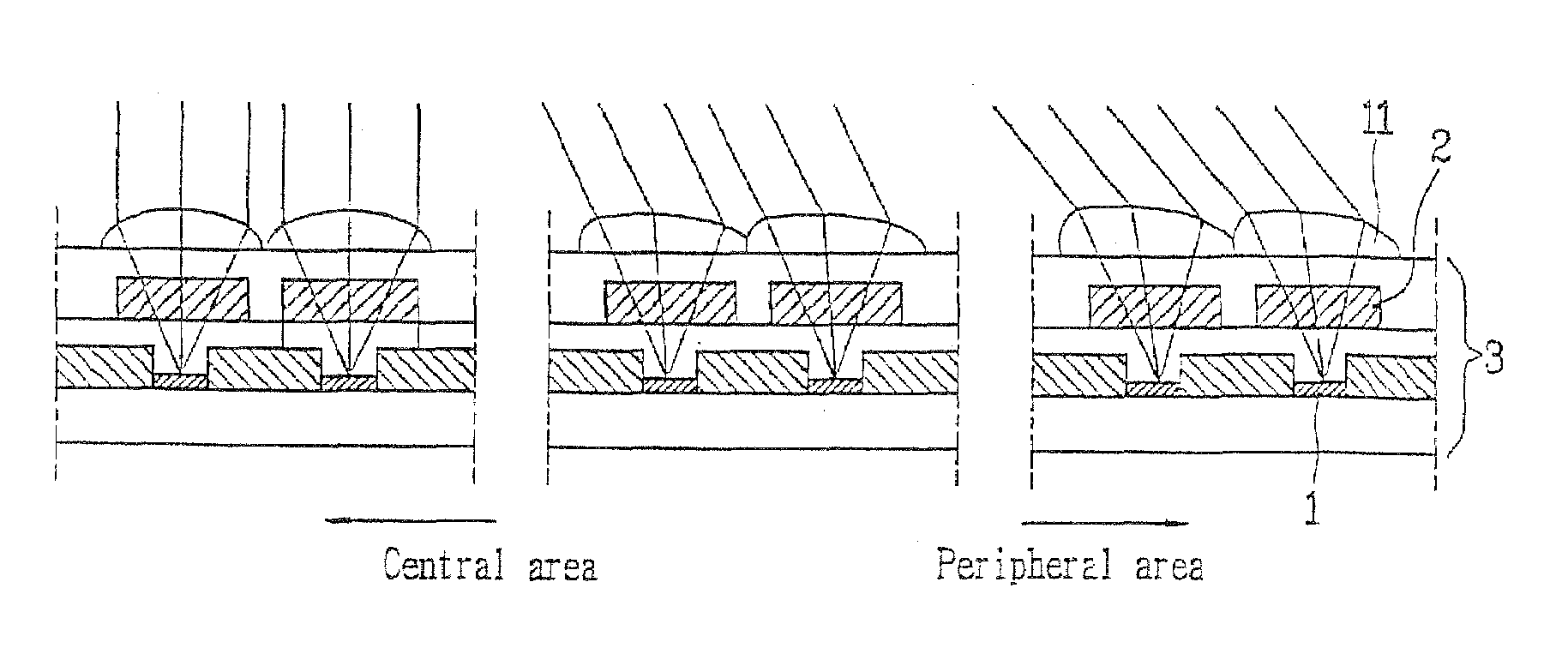

[0076]An image sensor and a method for fabricating the same in accordance with preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0077]FIG. 8 is a concept view showing that a prism 10 can vary an optical path of light.

[0078]As illustrated in FIG. 8, the micro prism 10 converts the optical path of light to be parallel to an optical axis in order to prevent reduction of optical efficiency due to light slantingly incident on peripheral pixels of an image sensor.

[0079]The relations between an inclination angle of light incident on the surface of the prism 10, an angle of refracted light and a gradient value of an incident surface of the prism 10 will now be explained with reference to FIG. 9.

[0080]FIG. 9 illustrates the refraction law of light, especially light passing through the prism 8 of FIG. 8.

[0081]FIG. 9 shows a refraction path of light when light is incident on an interface between different media having a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com