Powertrain including input disconnect and accessory drive system for an electrically variable transmission

a technology of input disconnect and accessory drive system, which is applied in the direction of electric propulsion mounting, transportation and packaging, gearing, etc., can solve the problems of lack of mechanical point, steep grade and inability to sustain high-average cruising speed at desired high efficiency, and even small apus and even large energy storage device cannot accommodate high-average power vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

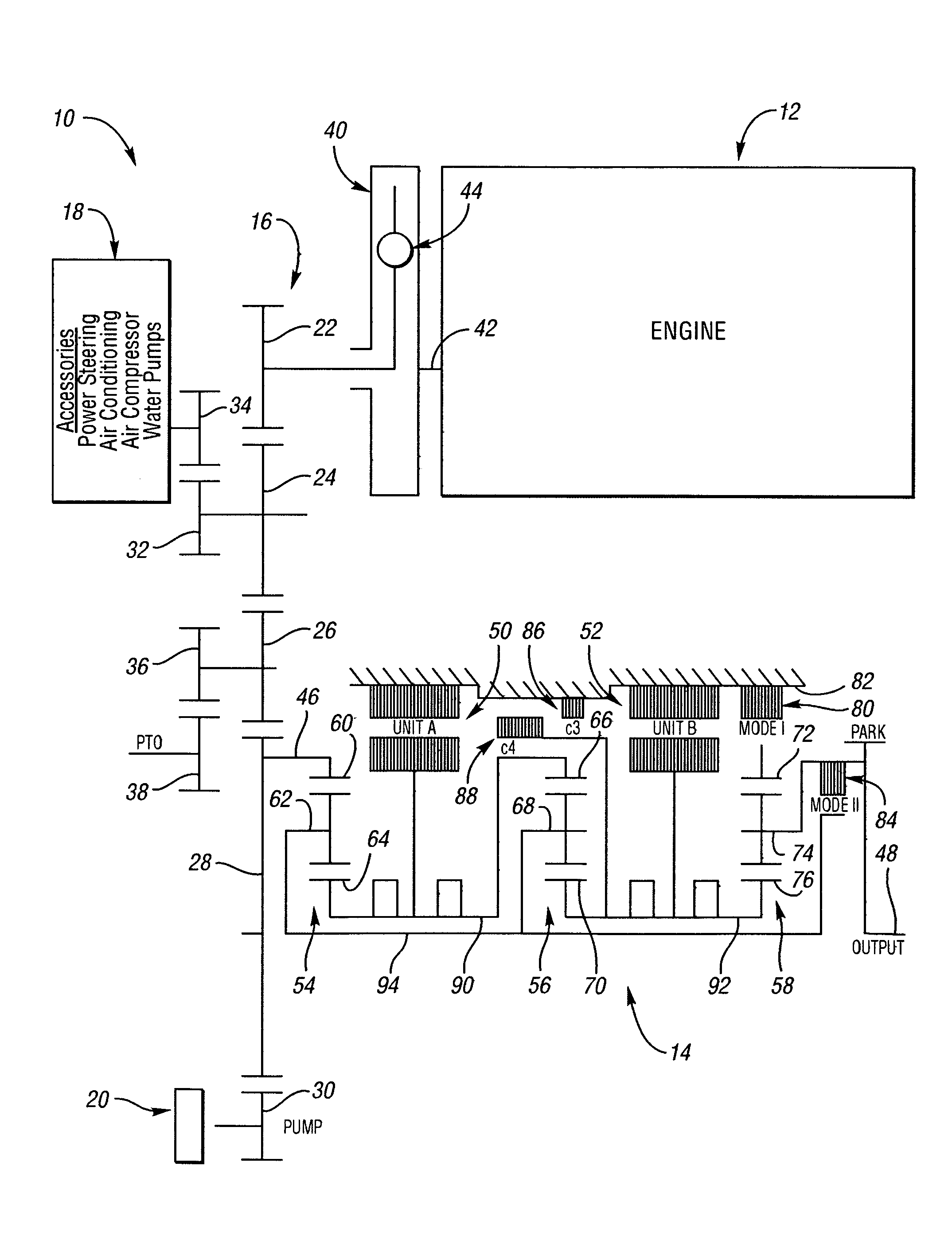

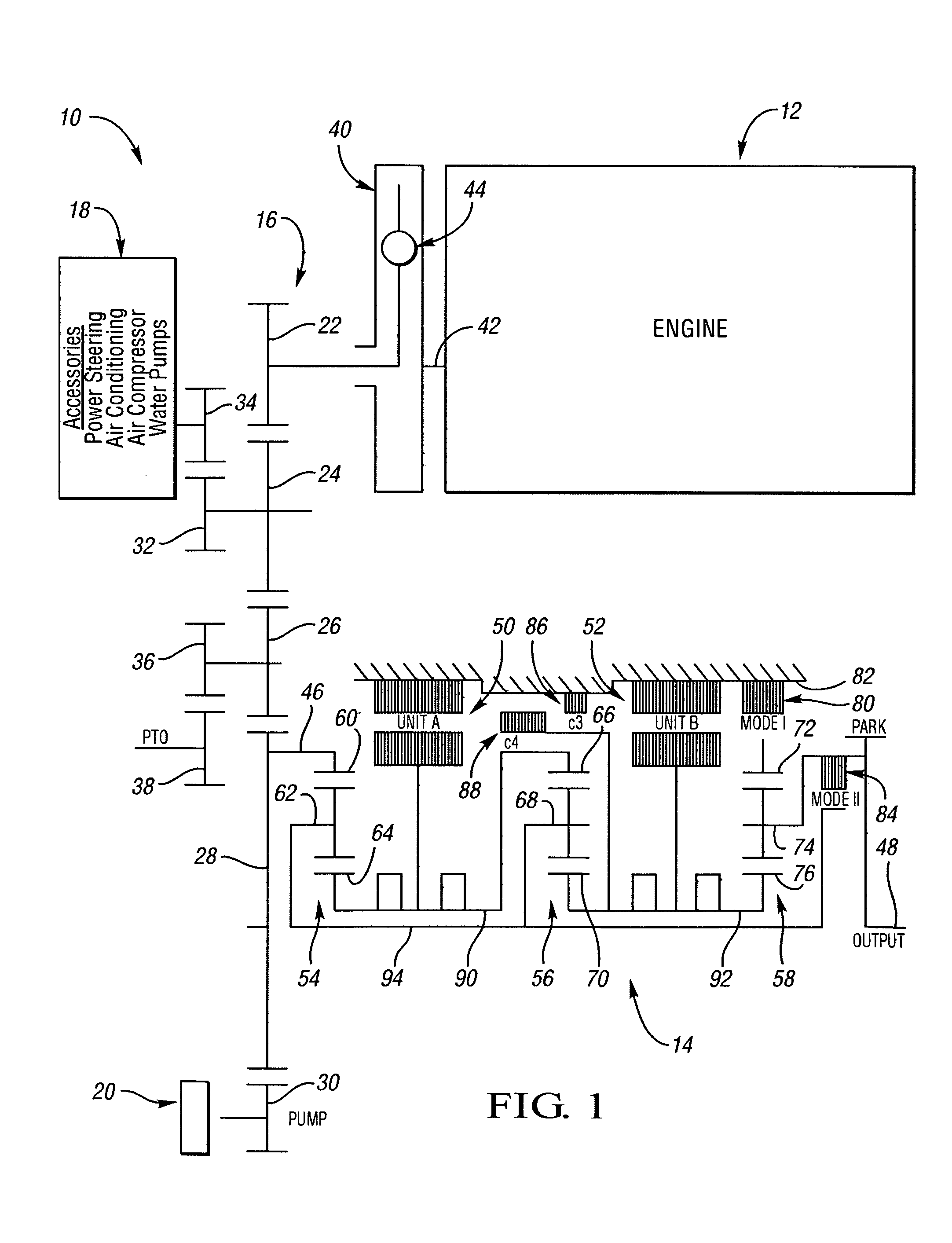

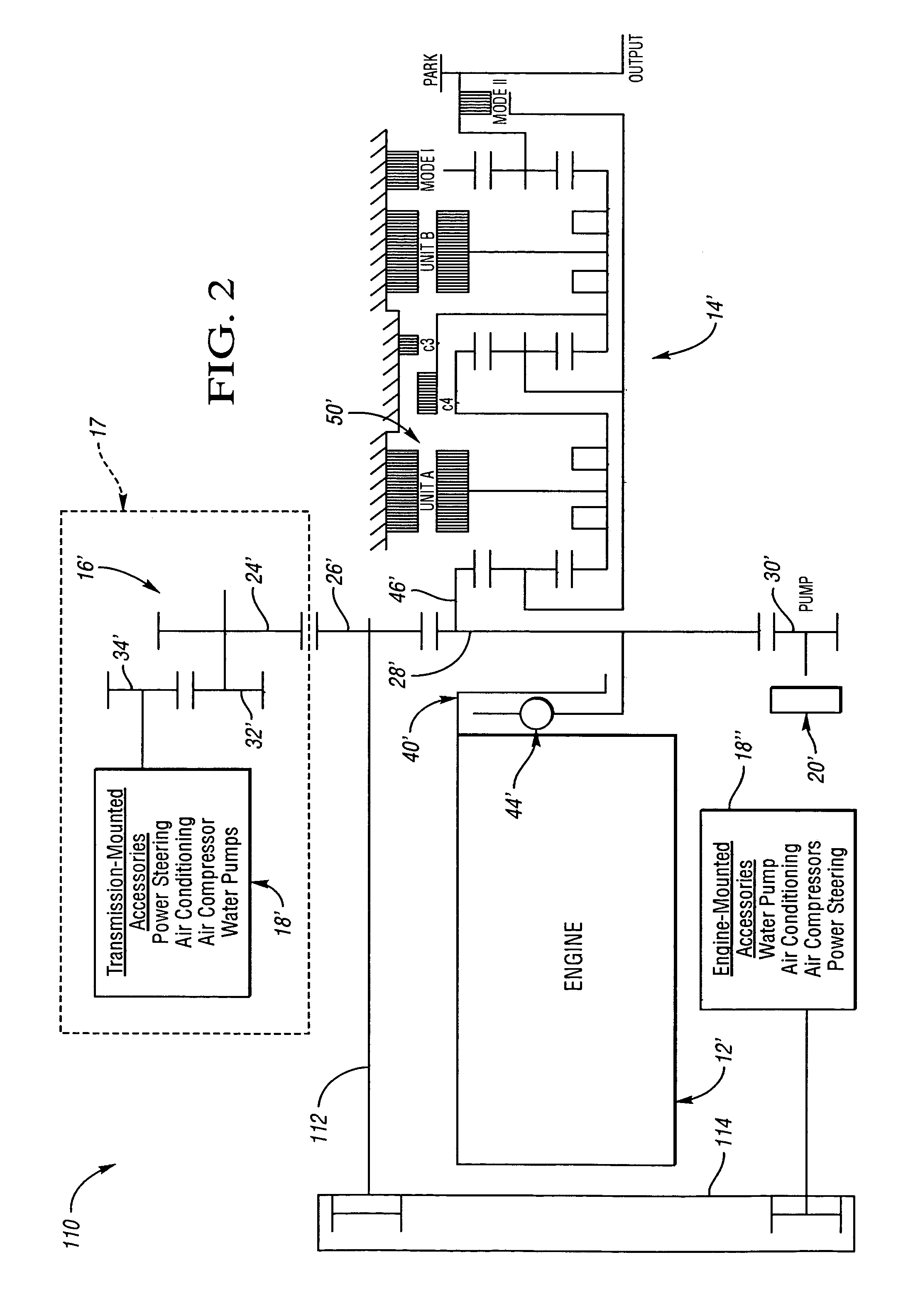

[0029]Referring to FIG. 1, a powertrain 10 is shown in accordance with a first embodiment of the invention. In this embodiment, an engine 12 and hybrid electrical transmission 14 are arranged in parallel to improve packaging length. In a rear bus application, this parallel arrangement provides additional space for passenger seating.

[0030]The hybrid electromechanical transmission 14 enables the vehicle to be driven in electric mode when the engine is not running. This mode may be selected to reduce idle fuel usage, reduce emissions, allow passenger drop off inside a building, provide noise reduction, etc. In such applications, driving accessories such as the air pump, water pump, power steering system, air conditioner, etc. may still be required, even with the engine off. Accordingly, the powertrain 10 provides a plurality of intermeshed accessory drive gears 16 which may be driven by the engine 12 or by the motor / generators of the transmission 14 to drive accessories 18, which may i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com