Horizontally positionable vertical wine press

a vertical and wine press technology, applied in the field of wine presses, can solve the problems of press pan overflow, additional waste, and reduced extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

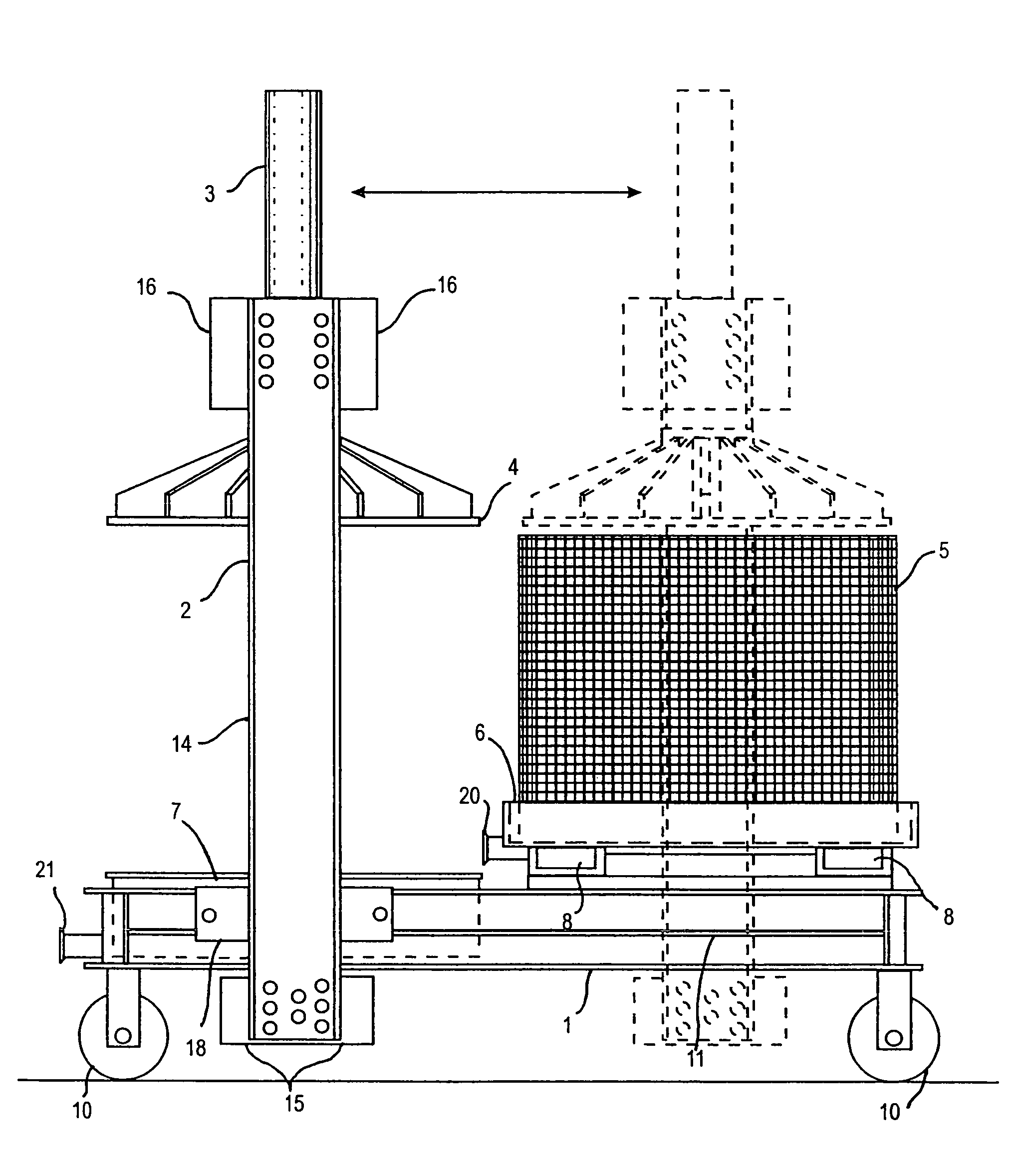

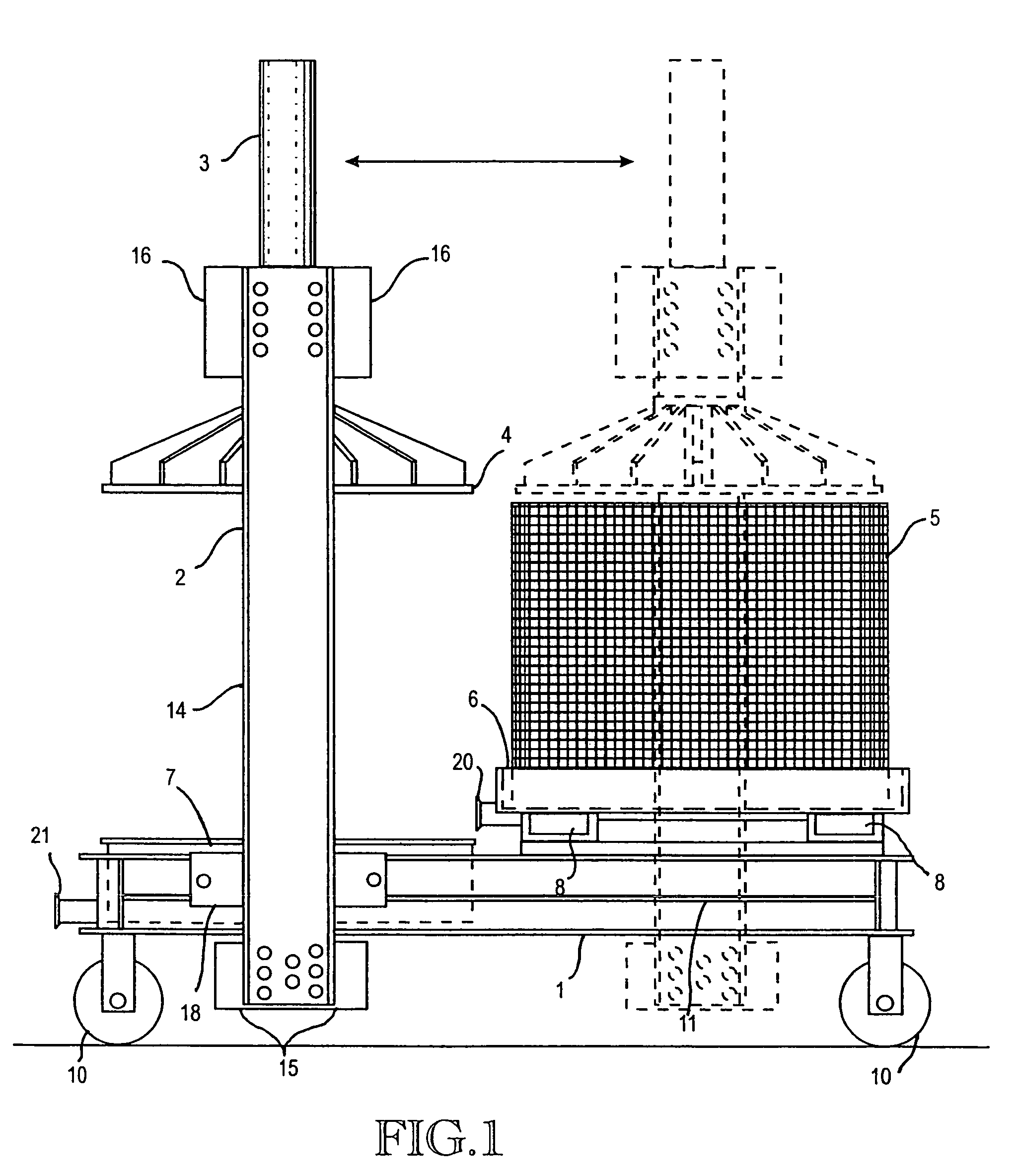

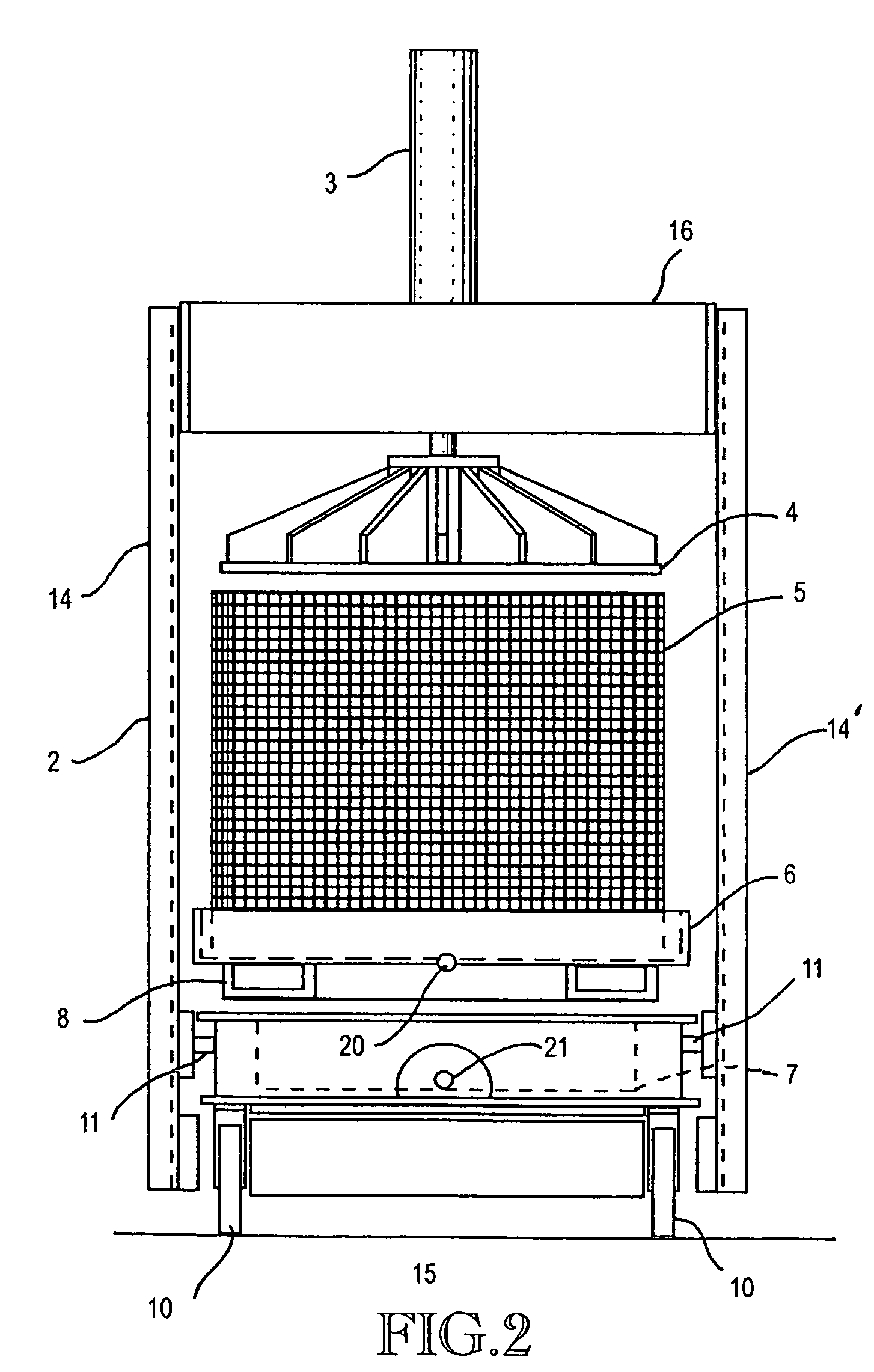

[0038]Referring to FIGS. 1, 2 and 3, a preferred embodiment of a wine press of the present invention consists of a rectangular horizontal frame 1, a vertical rolling frame 2 that holds a hydraulic or pneumatic ram 3, a circular press plate 4, a perforated circular press basket 5 and press pan 6, and a reservoir tub 7. The press pan 6 holding the perforated basket 5 is attached to a framework 8 having pockets, as might be fabricated of box steel members, that allows the arms of a forklift to be inserted securely in order to pick the press pan up. As shown in FIG. 3, the location of the press basket 5 rests within the press pan 6 that is contained within the horizontal frame 1. A press cycle is initiated with the filling of the press basket 5 with the material to be pressed. While the press basket 5 is being filled, the vertical frame 2 remains in a first position at the end of the horizontal frame 1 opposite the end where the press basket 5 is located. This allows for interference-fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com