Electric motor with minimized cogging and related method of determining stator pole geometry

a technology of electric motors and cogging, applied in the direction of dynamo-electric machines, magnetic circuit shapes/forms/construction, supports/enclosements/casings, etc., can solve the problems of reducing output torque, the effect of completely minimizing cogging torque, and reducing manufacturing costs, so as to reduce manufacturing costs and design labor hours. , the effect of easy efficient steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

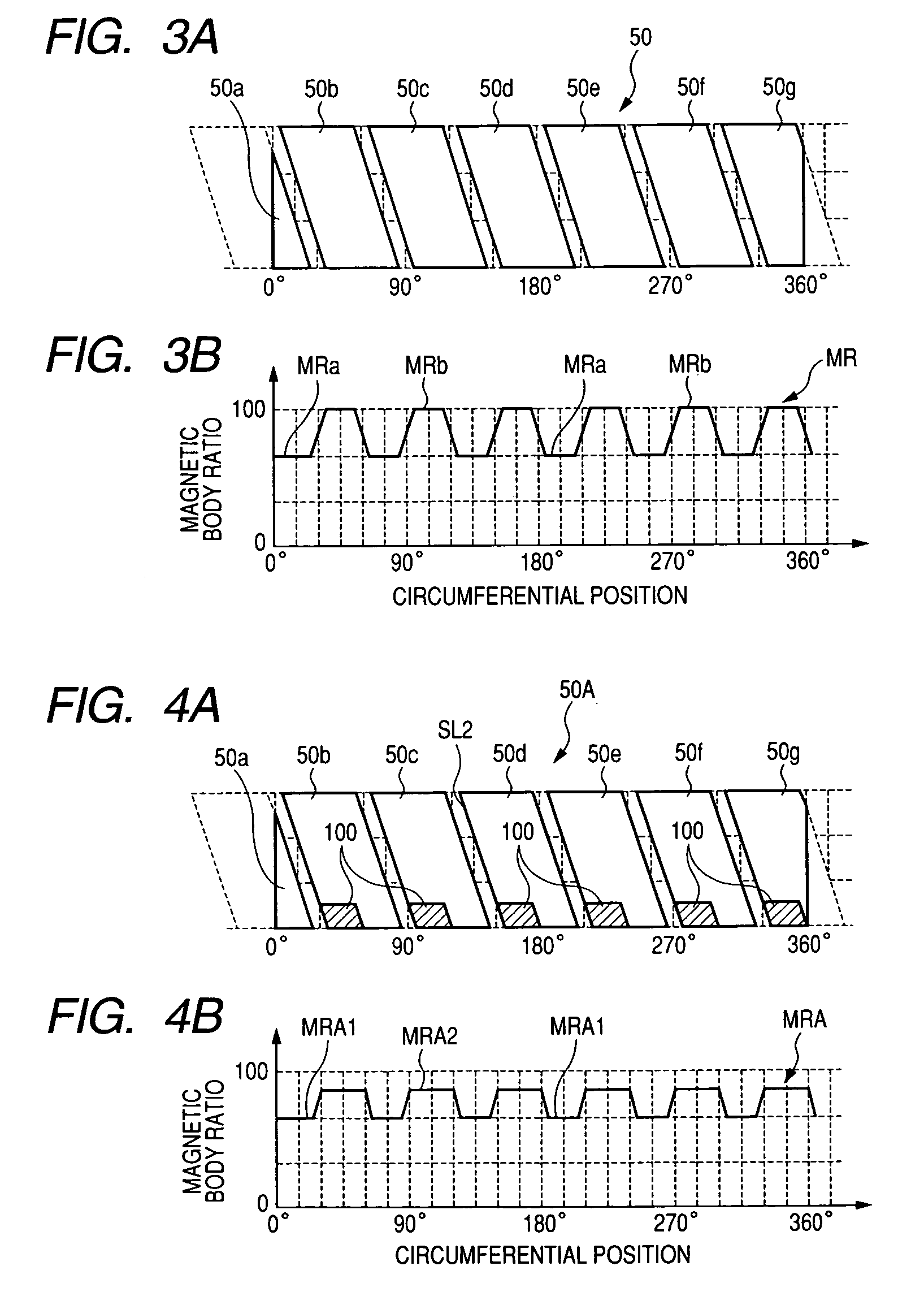

[0098]FIGS. 4A and 4B are views showing an electric motor of a first embodiment according to the present invention. With the electric motor of the present embodiment, a stator 50A fundamentally has the same structure as the stator 50 shown in FIG. 3A except for stator poles 50b to 50g having one axial ends provided with magnetic reluctance equalizing elements including non-magnetic body segments 100, respectively, in a high-ratio magnetic body distribution area. With the stator 50A having the high-ratio magnetic body distribution area additionally incorporating the non-magnetic body segments 100 as shown in FIG. 4A, the stator 50A has low-ratio magnetic body distribution areas MRA1 and high-ratio magnetic body distribution areas MRA2 that vary in a minimized range MRA along the circumferential periphery of the stator 50A. Since the low-ratio magnetic body distribution areas MRA1 and the high-ratio magnetic body distribution areas MRA2 have less variation in the magnetic body distrib...

second embodiment

[0099]FIGS. 5A and 5B are views showing an electric motor of a second embodiment according to the present invention. With the electric motor of the present embodiment, a stator 50B fundamentally has the same structure as the stator 50 shown in FIG. 3A except for stator poles 50b to 50g having one axial ends provided with magnetic reluctance equalizing elements including magnetic body segments 110, respectively, in an area laying at a low-ratio magnetic body distribution area. With the stator 50B having the low-ratio magnetic body distribution area additionally incorporating the magnetic body segments 110 as the magnetic reluctance equalizing elements as shown in FIG. 5A, the stator 50B has low-ratio magnetic body distribution areas MRB1 and high-ratio magnetic body distribution areas MRB2 that vary in a minimized range along the circumferential periphery of the stator 50B. Since the low-ratio magnetic body distribution areas MRB1 and the high-ratio magnetic body distribution areas M...

third embodiment

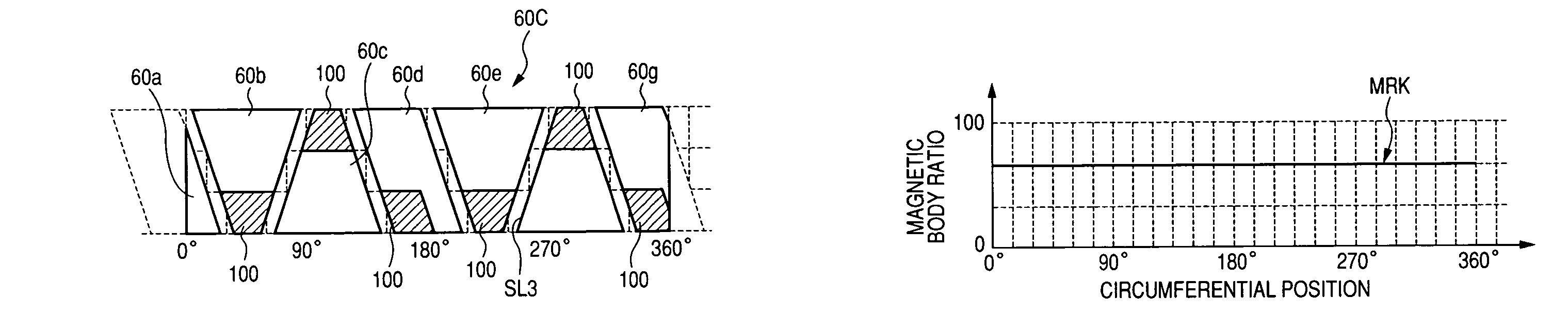

[0102]FIGS. 7A and 7B are views showing an electric motor of a third embodiment according to the present invention. With the electric motor of the present embodiment, a stator 60A fundamentally has the same structure as the stator 60 shown in FIG. 6A except for stator poles 60b to 60g having axial ends provided with magnetic reluctance equalizing elements including non-magnetic body segments 100, respectively, that are alternately disposed in opposing axial ends of the stator poles 60b to 60g in a high-ratio magnetic body distribution area. In particular, with the structure shown in FIG. 7A, the trapezoid-shaped stator magnet poles 60b, 60c, 60e, 60f have narrow ends incorporating the non-magnetic body segments 100, respectively. The stator poles 60d, 60g also incorporate the non-magnetic body segments 100, respectively. With such a stator 60A having the high-ratio magnetic body distribution areas additionally incorporating the non-magnetic body segments 100 as shown in FIG. 7A, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com