Transponder carrier for a tire

a technology for transponders and tires, applied in the direction of instruments, burglar alarm mechanical actuation, other domestic objects, etc., can solve the problems of transponder malfunction, tire flexure, and effort to achieve a transponder carrier for rubber articles such as tires that can withstand forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

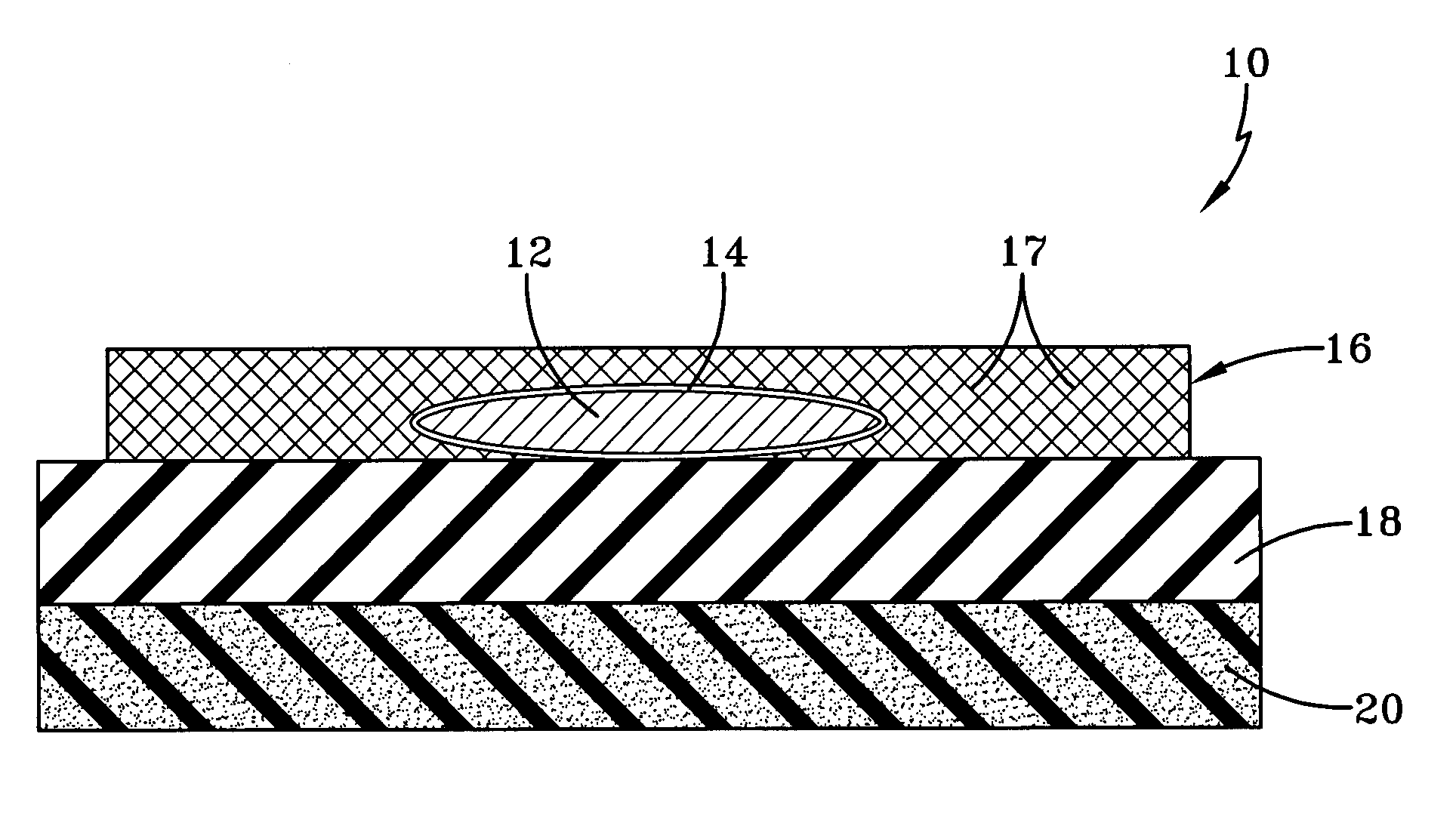

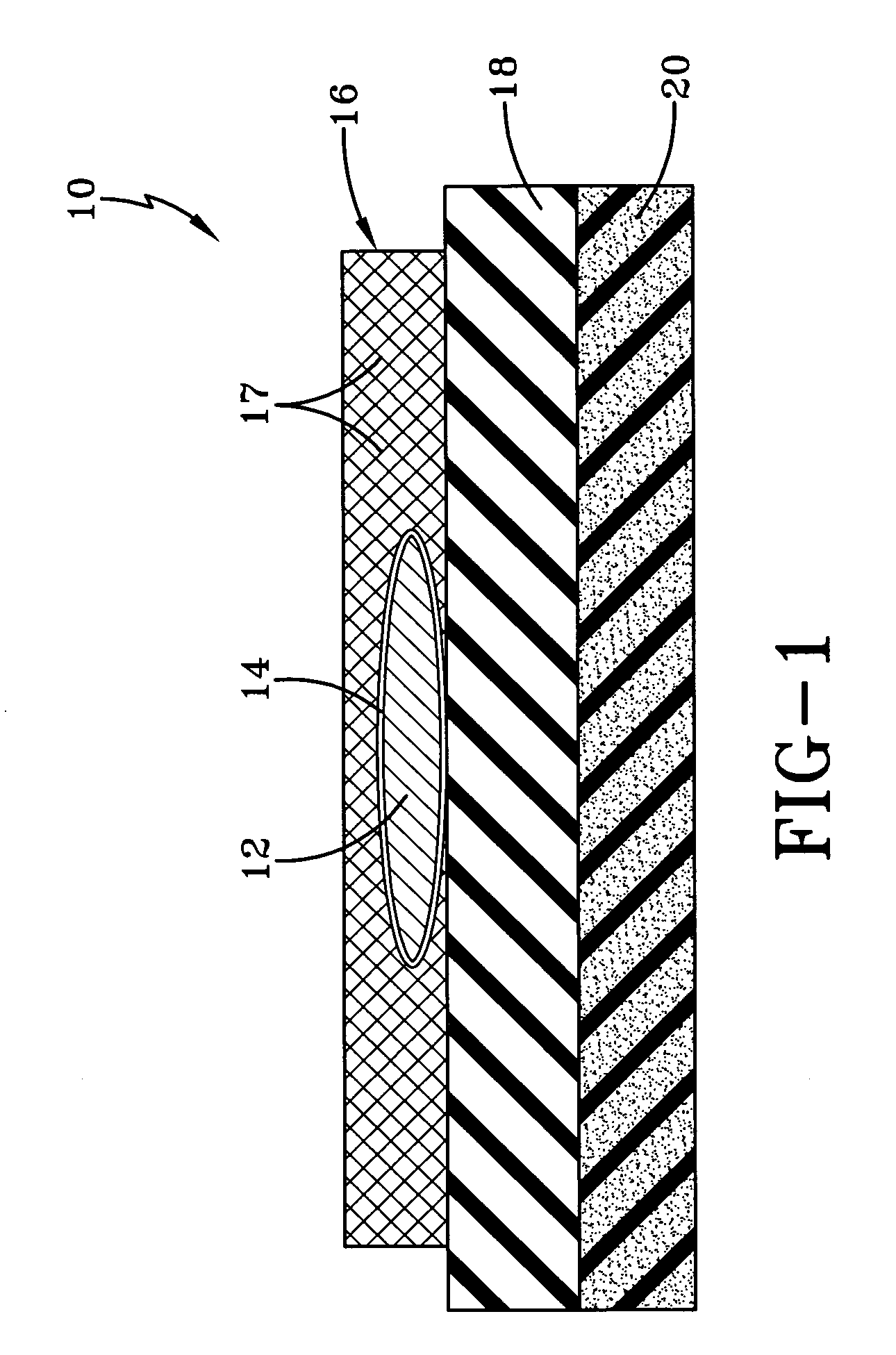

[0015]FIG. 1 shows in schematic representation a transponder carrier device 10. The transponder 12 is represented generically and, according to the invention, may be any electronics device that is intended to function at an embedded location within a host article. Of particular application is the incorporation of an RFID device or tag within the rubber composite material of a tire for the purpose of identifying the tire. The device 10 may also include a sensor component for monitoring a tire condition such as pressure, and communicating the pressure reading to an external reader (not shown). The transponder device 10 is typically rigid in construction. The transponder device 10 is coated with a coating 14 of adhesive of a type commercially available in the industry. A reinforcement cap 16 covers the transponder 12 and a base layer 18 and boding layer 20 underlies the transponder 12 and cap 16.

[0016]The completed carrier 10 may be referred to alternatively as a “patch”. The patch 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com