Luminance level control device

a technology of level control and luminance, which is applied in the direction of color television details, television systems, instruments, etc., can solve the problems of visual recognition of unnatural changes in luminance, and achieve the effects of reducing power consumption, increasing video luminance, and increasing video luminan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0082](1) First Embodiment

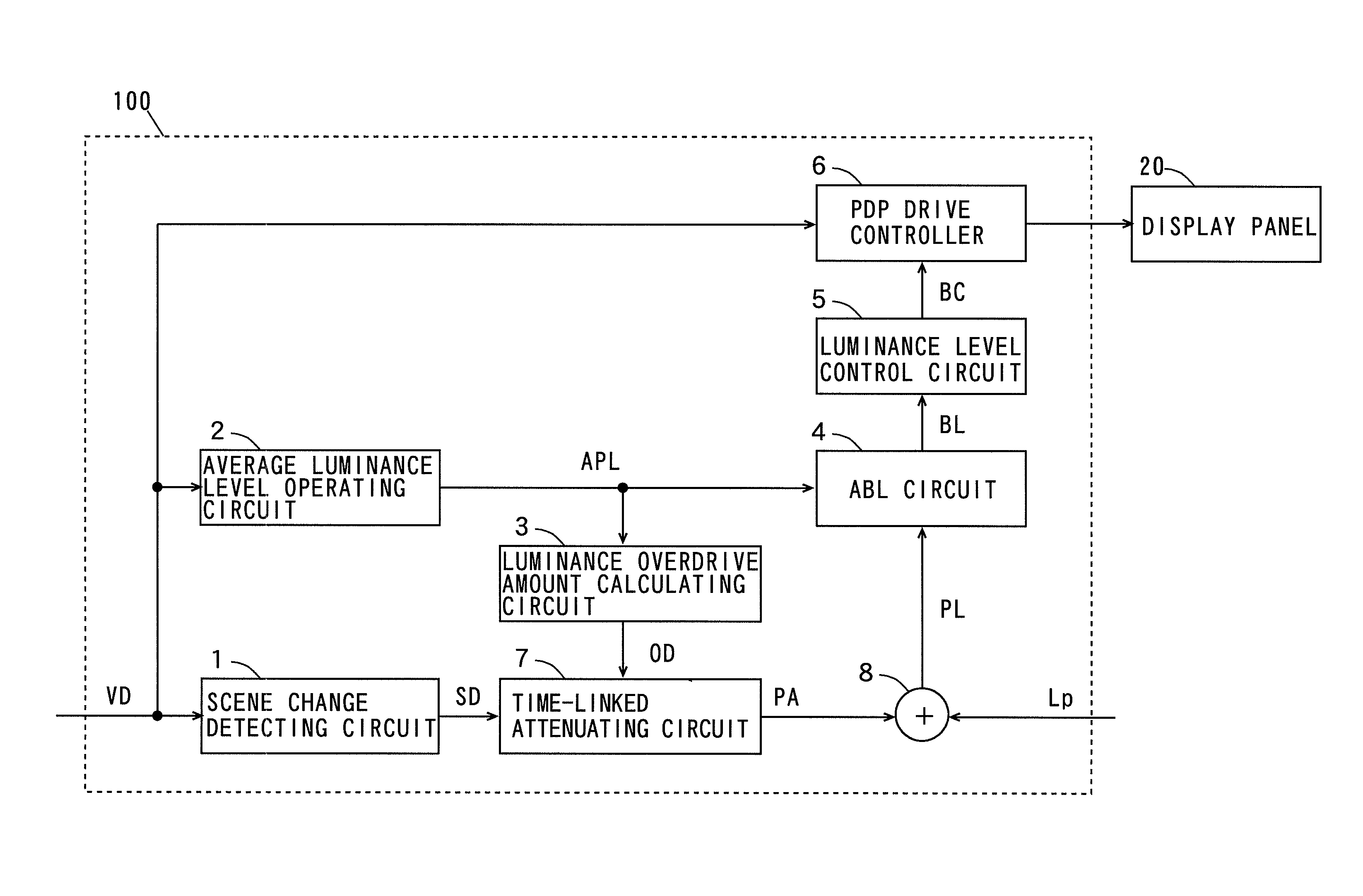

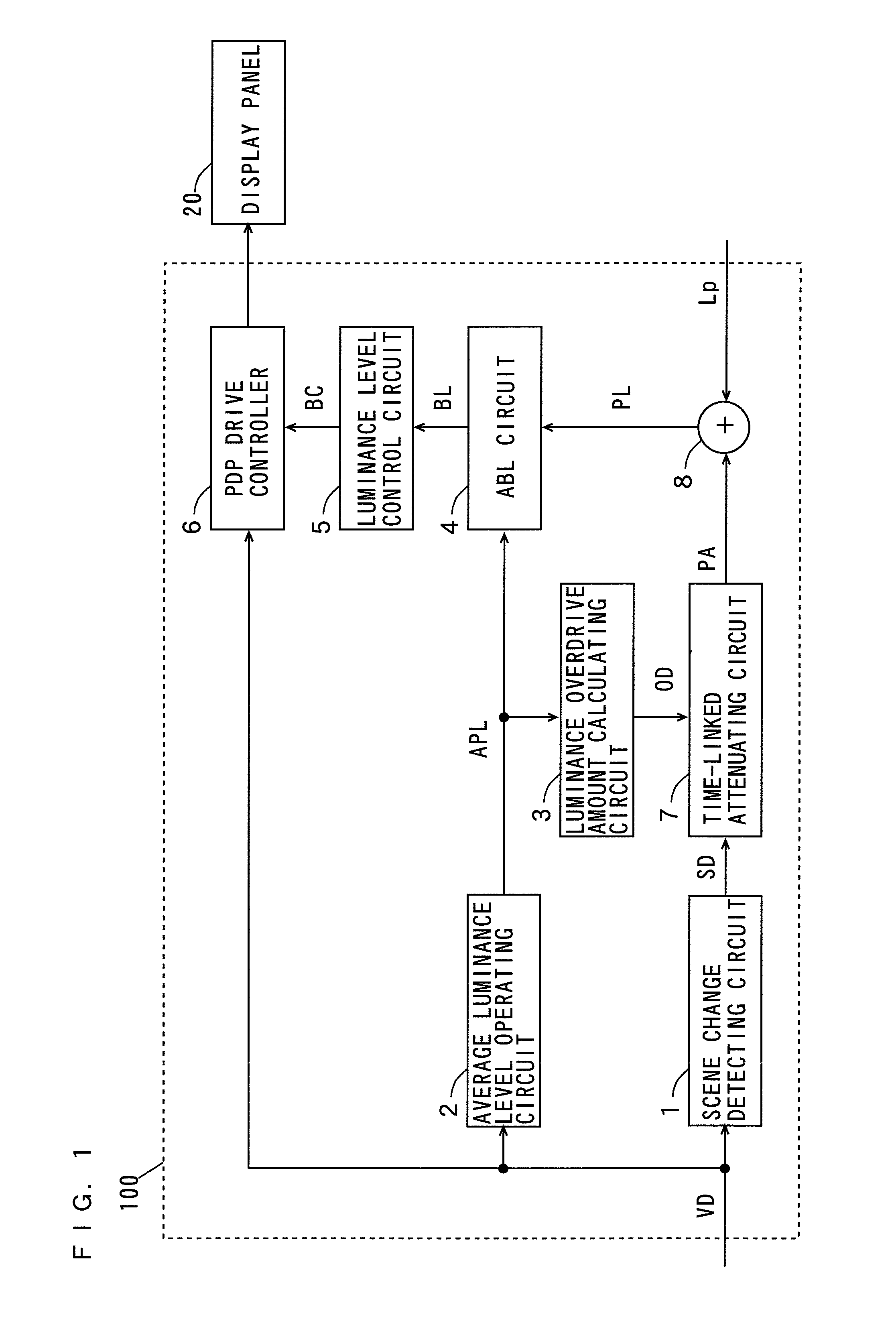

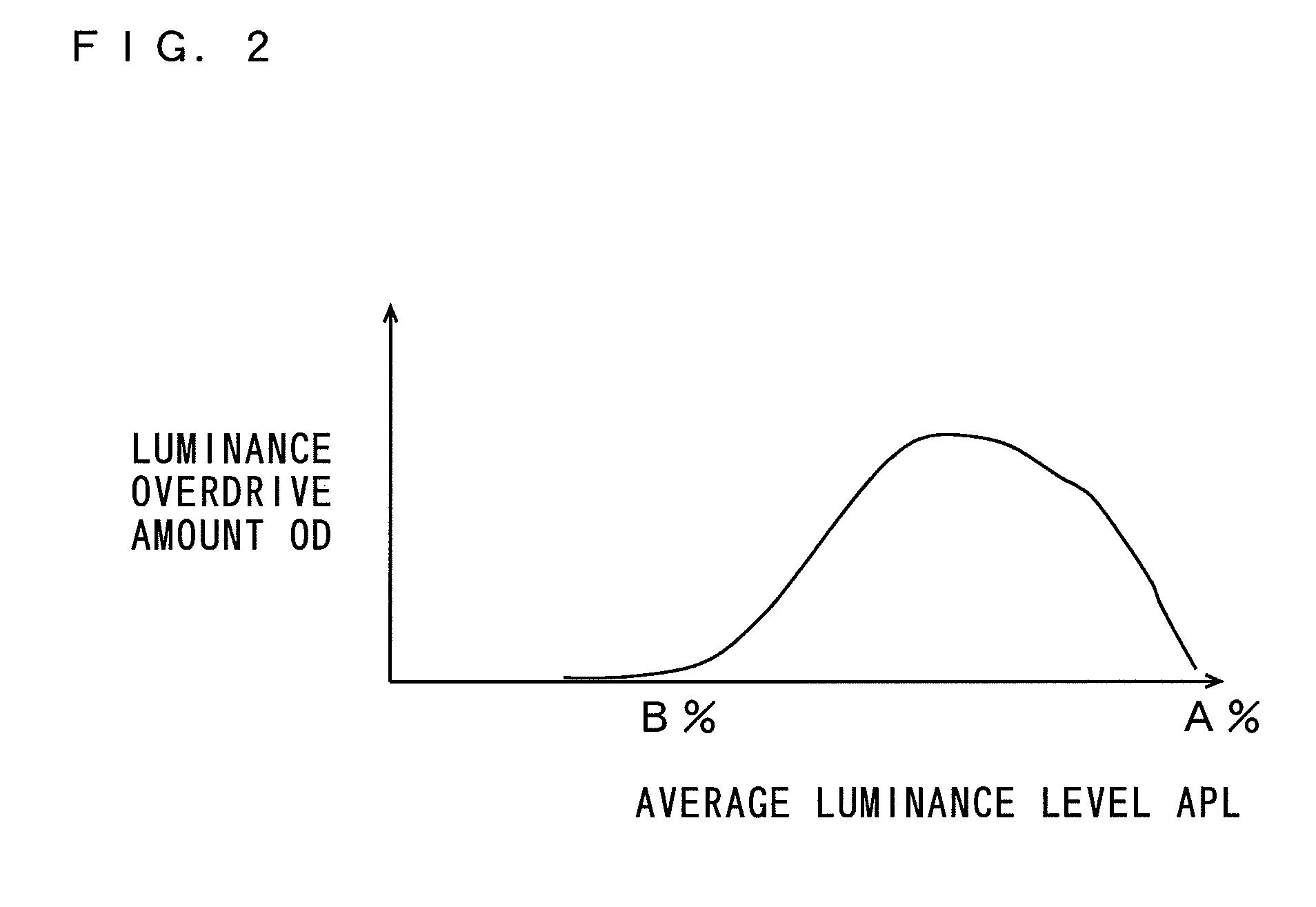

[0083]FIG. 1 is a block diagram showing the configuration of a luminance level control device according to a first embodiment of the present invention.

[0084]The luminance level control device 100 shown in FIG. 1 includes a scene change detecting circuit 1, an average luminance level operating circuit 2, a luminance overdrive amount calculating circuit 3, an automatically brightness limiting (hereinafter referred to as ABL) circuit 4, a luminance level control circuit 5, a plasma display panel (hereinafter referred to as PDP) drive controller 6, a time-linked attenuating circuit 7 and an adder 8. The luminance level control device 100 and a display panel 20 constitute a display device. In the present embodiment, the display panel 20 is a PDP.

[0085]A video signal VD representing video to be displayed is input to the scene change detecting circuit 1. The scene change detecting circuit 1 detects a scene change (switching of scenes) of the video based on changes...

second embodiment

[0124](2) Second Embodiment

[0125]FIG. 5 is a block diagram showing the configuration of a luminance level control device according to a second embodiment of the present invention.

[0126]The luminance level control device 100 shown in FIG. 5 is different from the luminance level control device 100 shown in FIG. 1 in that the scene change detecting circuit 1 detects the scene change based on the average luminance level APL output from the average luminance level operating circuit 2. Since the configuration and operation of other parts of the luminance level control device 100 of FIG. 5 is the same as the configuration and operation of the corresponding parts of the luminance level control device 100 of FIG. 1, the same portions are denoted by the same reference numerals and hence, the detailed description thereof is omitted.

[0127]The scene change detecting circuit 1 detects the scene change using the following method, for example. When a difference between the average luminance level o...

third embodiment

[0129](3) Third Embodiment

[0130]FIG. 6 is a block diagram showing the configuration of a luminance level control device according to a third embodiment of the present invention.

[0131]The luminance level control device 100 shown in FIG. 6 is different from the luminance level control device 100 shown in FIG. 1 in that a scene change number operating circuit 9 is further provided. Since the configuration and operation of other parts of the luminance level control device 100 of FIG. 6 is the same as the configuration and operation of the corresponding parts of the luminance level control device 100 of FIG. 1, the same portions are denoted by the same reference numerals and hence, the detailed description thereof is omitted.

[0132]The scene change detection signal SD output from the scene change detecting circuit 1 and the luminance overdrive amount OD output from the luminance overdrive amount calculating circuit 3 are supplied to the scene change number operating circuit 9.

[0133]The sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com