Fluid pressure control apparatus/process

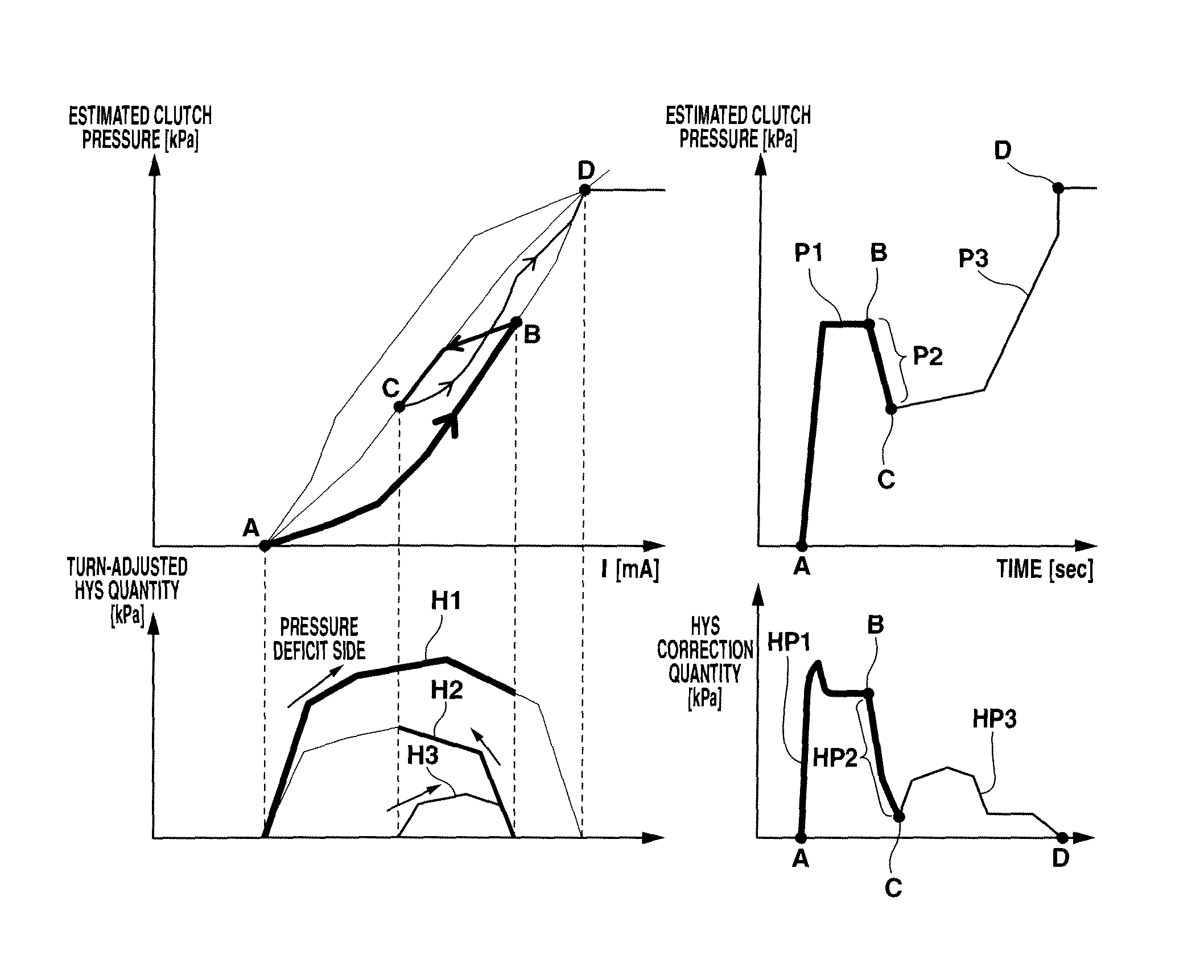

a technology of fluid pressure control and control apparatus, which is applied in fluid pressure control, process and machine control, etc., can solve the problems of inability to determine the quantity of hysteresis correction adequately, and achieve the effect of reducing or eliminating the hysteresis effect, improving the accuracy of pressure control, and reducing the hysteresis effect of a hysteresis characteristi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

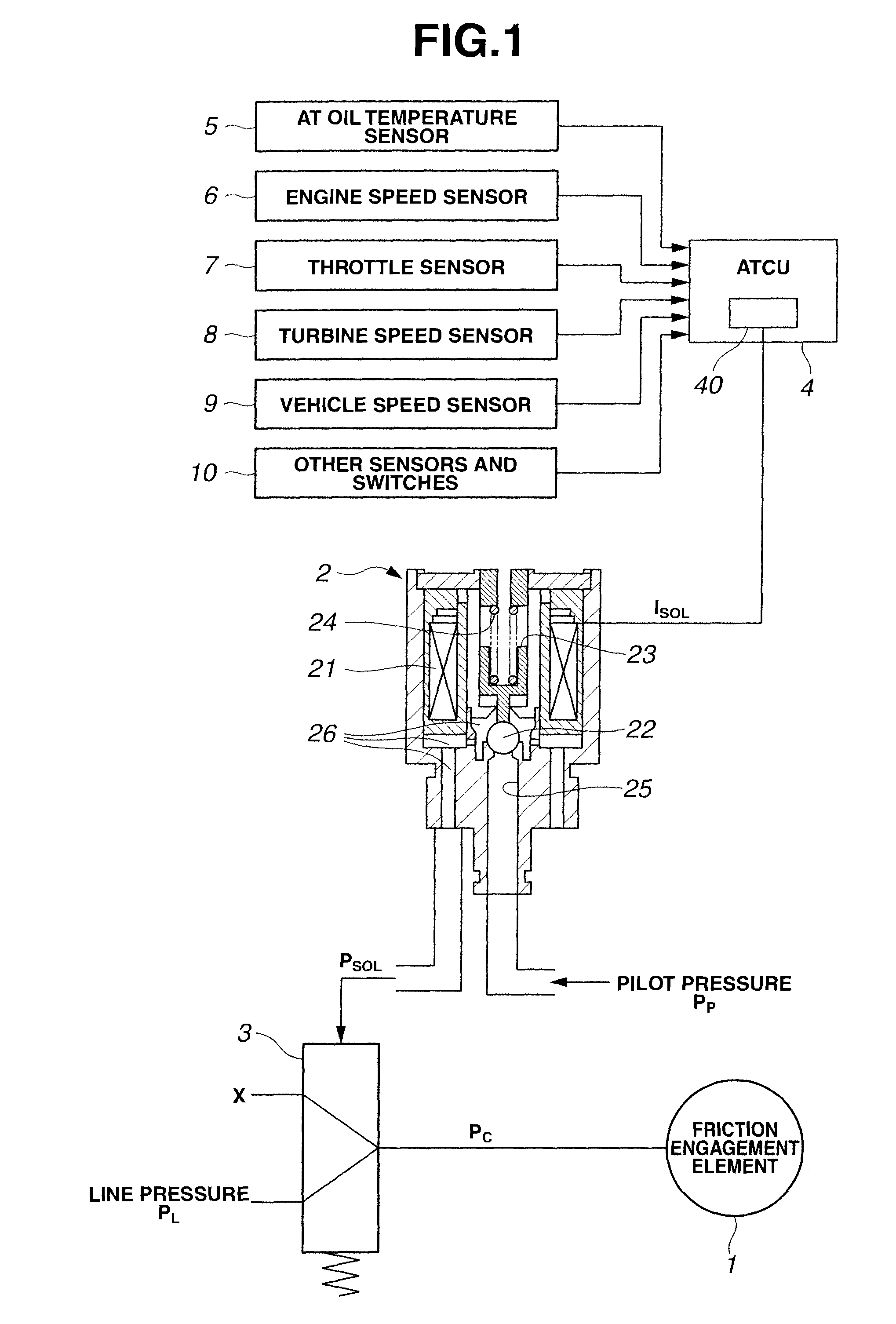

[0086]A fluid pressure control system according to a second embodiment is a control system for controlling the fluid pressure of a friction engagement element in an automatic transmission for a vehicle, and the control system of the second embodiment has the same construction as the fluid pressure control system of the first embodiment as shown in FIG. 1.

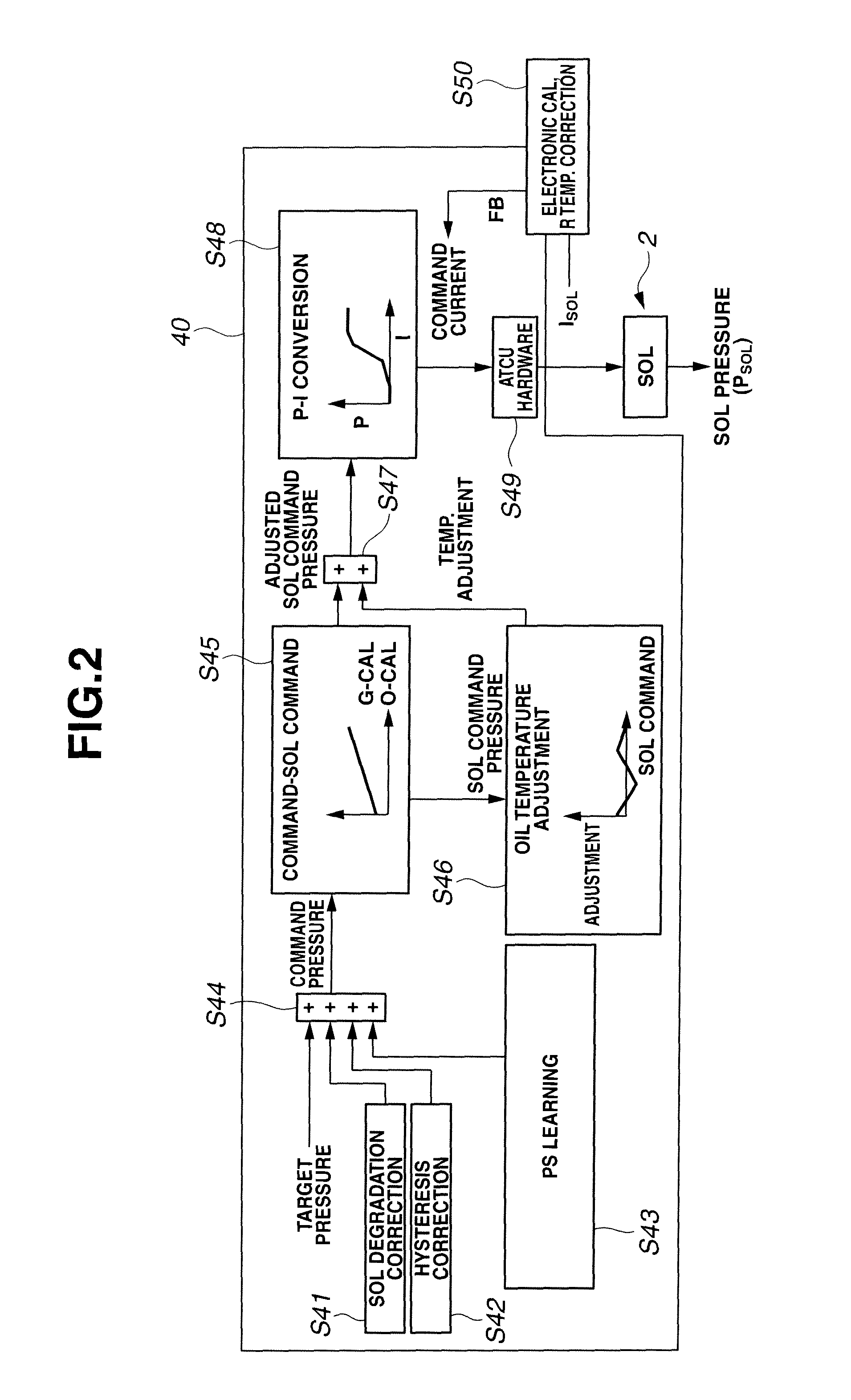

[0087]FIG. 11 is a control block diagram for illustrating the flow of the hysteresis pressure correction quantity calculating process in the clutch pressure correcting section 40 of automatic transmission control unit 4 according to the second embodiment. This hysteresis pressure correction quantity calculating process includes the following steps.

[0088]A step S500 is a differentiating step for determining a command current variation quantity of the command current as the correction input. In this example, the command current variation quantity is determined by a differentiating operation by differentiating the command current.

[0089...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com