Fastener installation tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

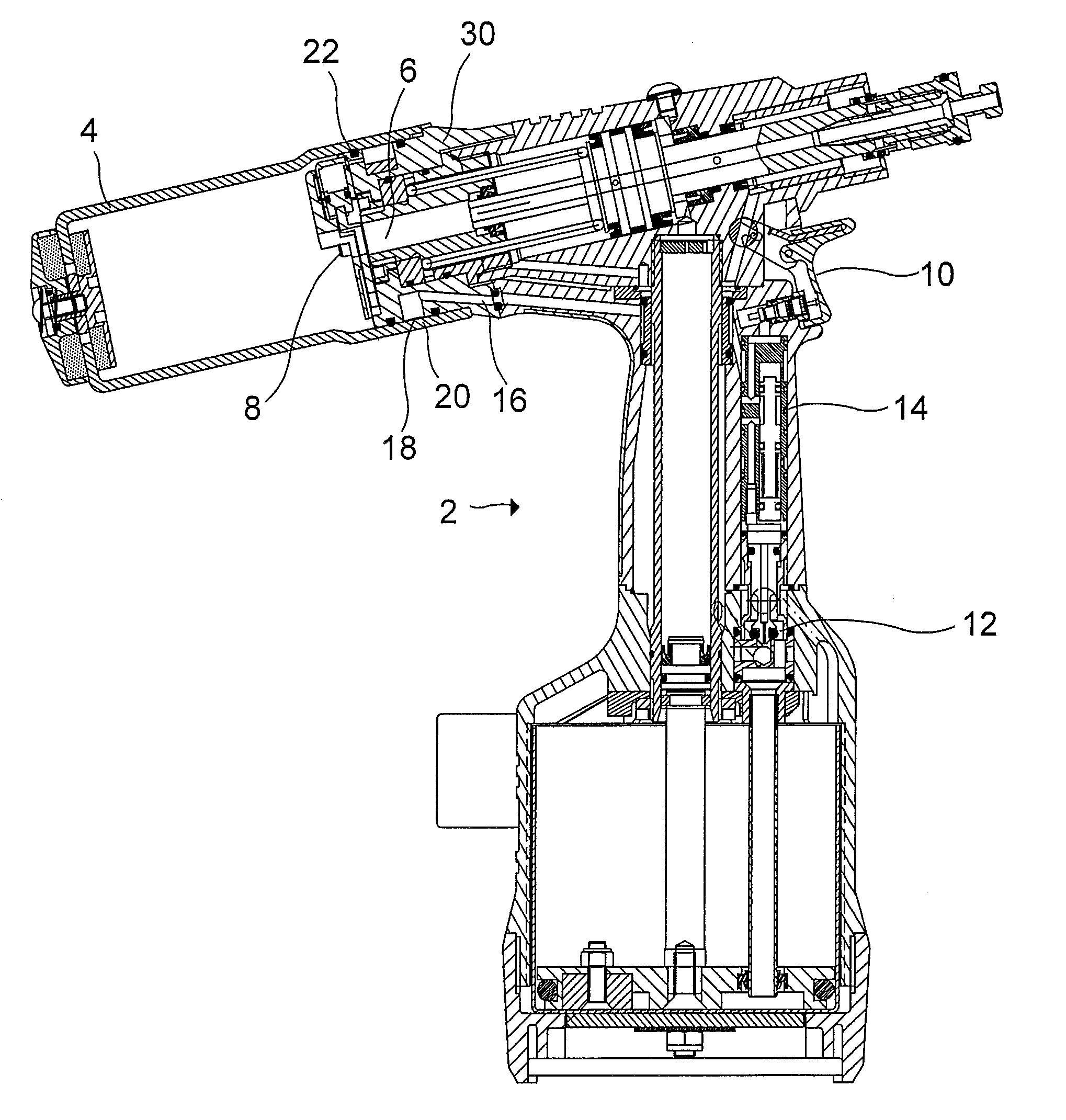

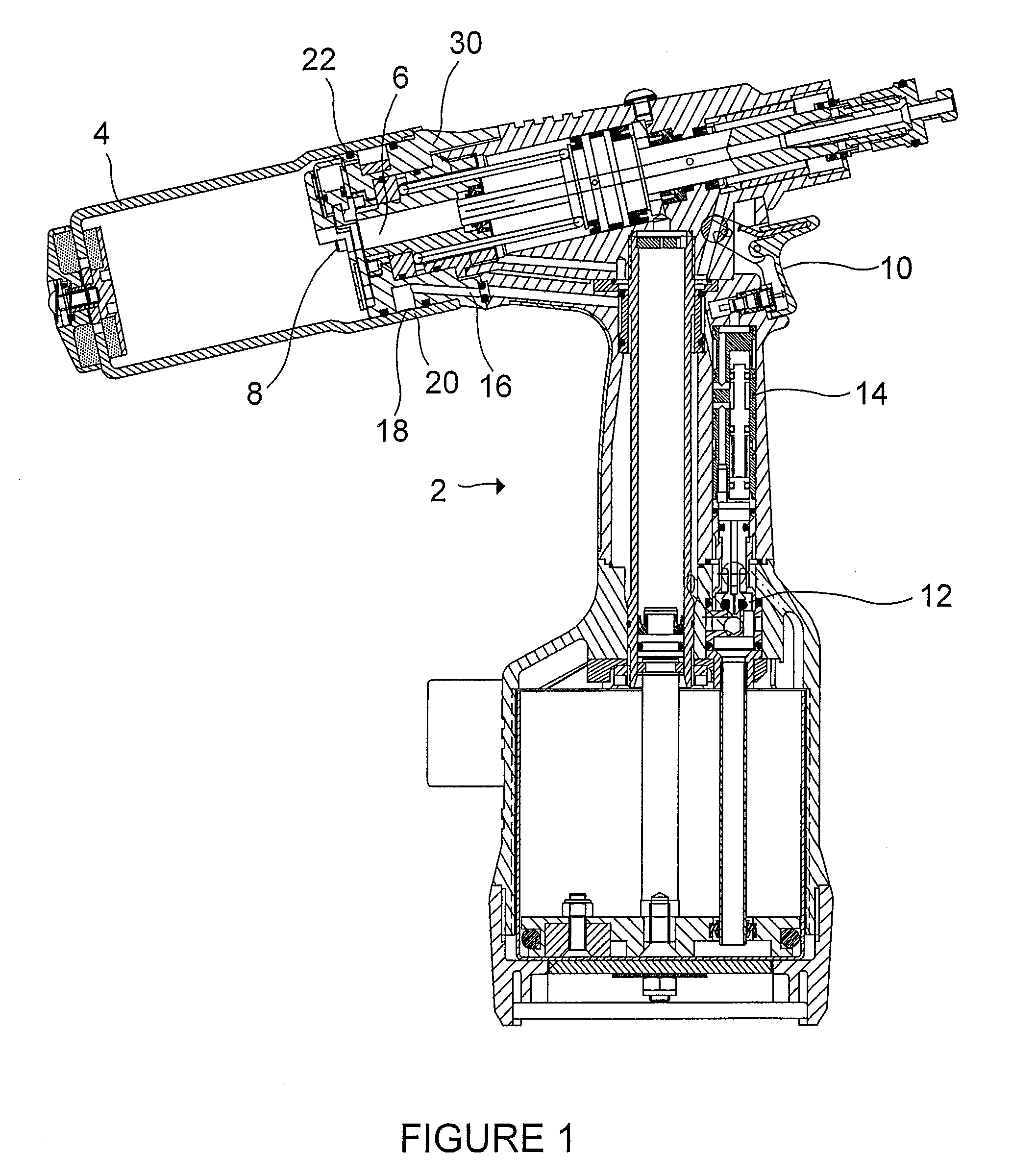

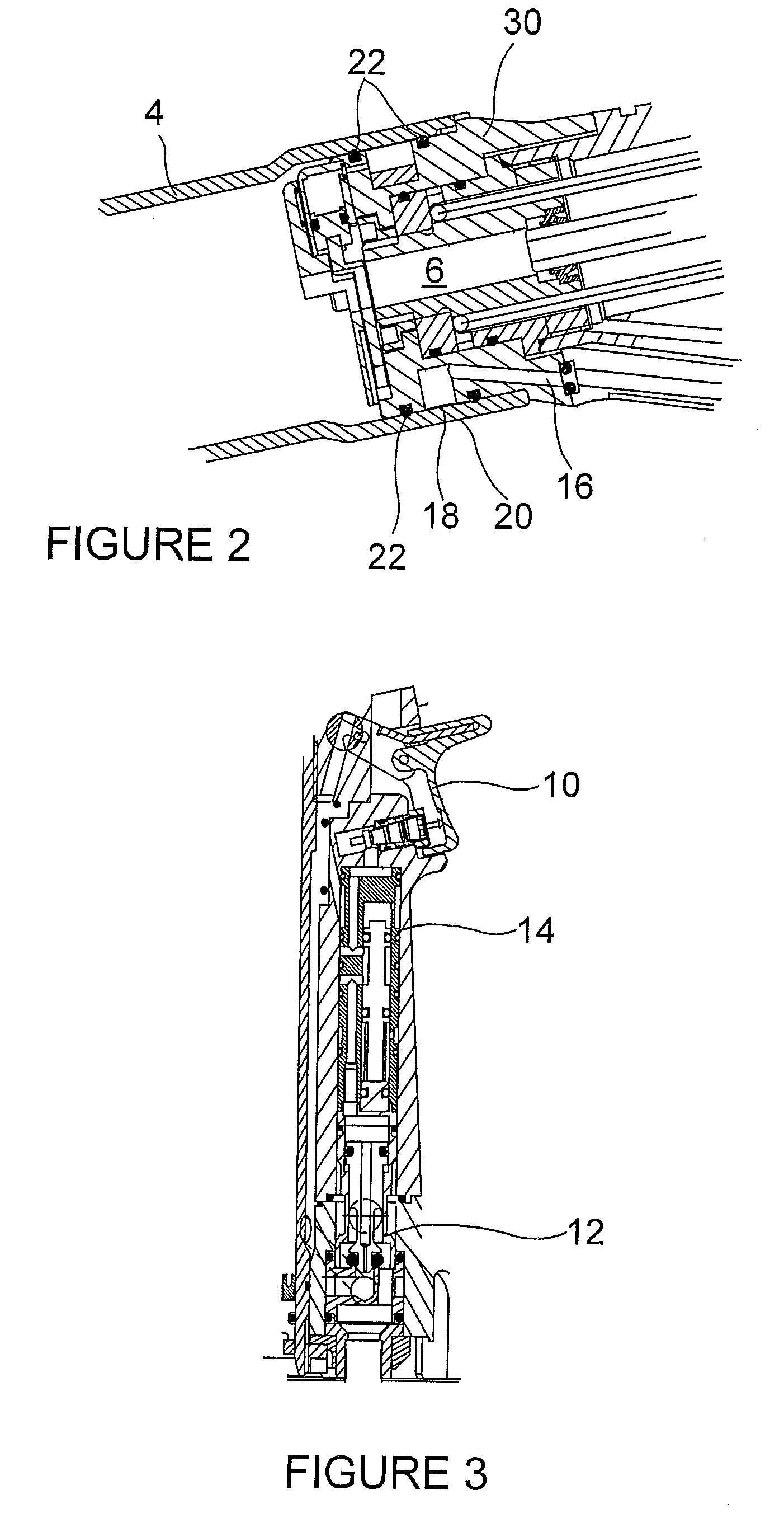

[0027]In the first embodiment, as illustrated in FIGS. 1 to 6, the disabling means is arranged to actuate in response to a loss of pressure signal. In the alternative embodiment of FIGS. 7 to 10, the disabling means is caused to actuate to prevent operation of the tool when a signal is received. The same numerals have been used as for the first embodiment where appropriate.

[0028]As illustrated in FIGS. 7 and 9, the tool 2 of this embodiment includes a sleeve 28 positioned between the adaptor 30 and the collector bottle 4. The sleeve 28 seals the aperture 18 through which compressed air would otherwise be vented. Between the tool 2 and sleeve 28 is a cavity 26.

[0029]When the collector bottle 4 is connected to the tool 2, a further, venting valve 24 is maintained in a closed state. When the venting valve 24 is closed, the positive pressure in the cavity 26 is allowed to vent to the atmosphere. In this state, a pressure signal is not sent to the disabling valve 14, and therefore the di...

Example

[0031]A third embodiment of the present invention is illustrated in FIGS. 11 and 12. The same numerals have been used as for the first embodiment where appropriate.

[0032]In the third embodiment, the disabling valve 14 is not present. The disabling means includes a chamber 32, which is provided in place of the valve 14 of the previous embodiments, and an internal valve 34, provided in the cavity 26, at the entrance to channel 16.

[0033]When the collector bottle 4 is connected to the tool 2, the venting valve 24 is maintained in a closed state. When the venting valve 24 is closed, the positive pressure in the cavity 26 is allowed to vent to the atmosphere. The internal valve 34 is maintained in a closed state, thereby preventing air escaping from the channel 16. In this state, no air is supplied to the chamber 32 via the channel 16. Air is fed to the chamber only by means of the main operating valve 12, and is prevented from escaping through cavity 26 by the internal valve 34. Thus air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com