Environment-friendly white board coating wastewater recovery treatment method

A waste water recovery and treatment method technology, which is applied in waste paint treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of easy blockage of filter screen and inability to deal with electric flocs in time, so as to avoid Blockage, improve fishing effect, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the production process of coated whiteboard paper, a large amount of waste water will be generated. If the waste water is not treated, it will cause great harm to the environment. At present, for the treatment of waste water, electroflocculation is generally used to remove the waste water. After metal ions and other complexes are removed, secondary biochemical treatment of wastewater is carried out, and if a large amount of flocs produced during flocculation are not collected and filtered, metal ions will be wasted and the effect of subsequent biochemical treatment will be affected.

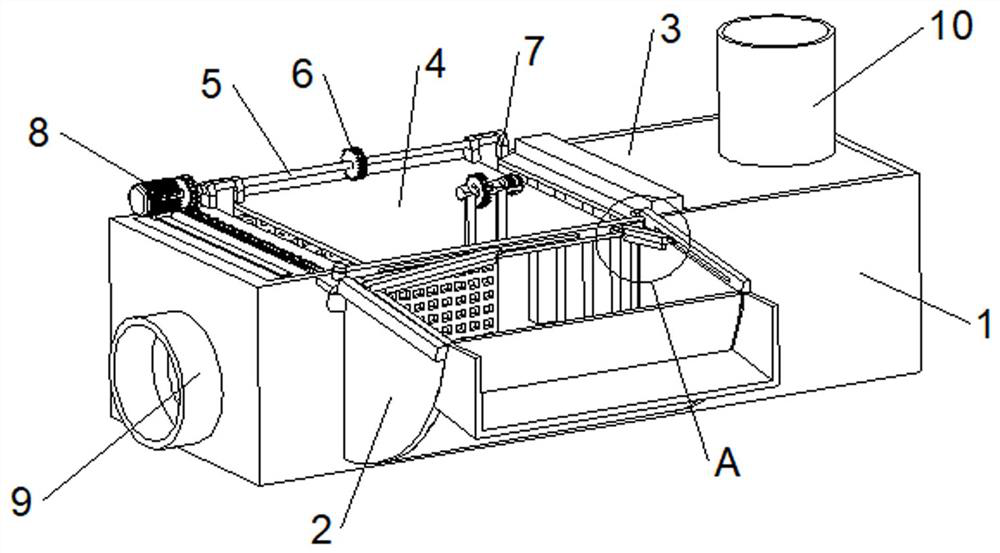

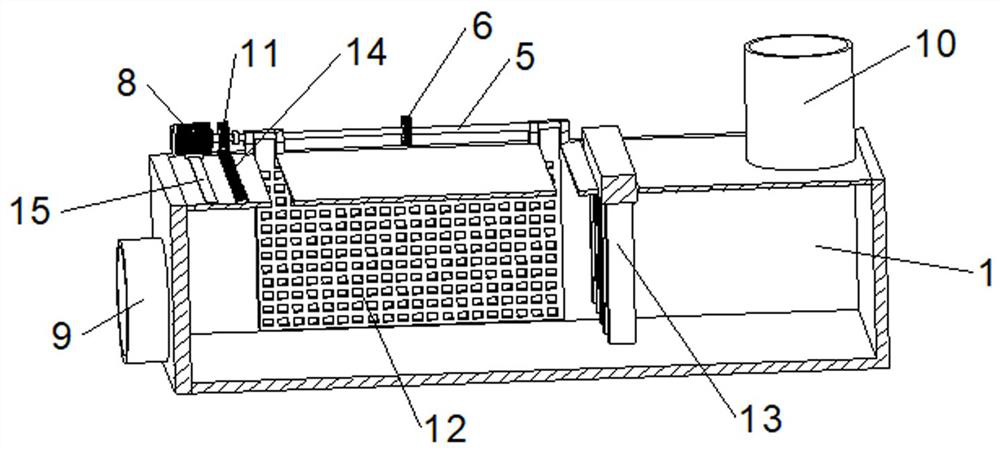

[0038] see figure 1 - Figure 4 As shown, the waste water produced by the production of coated whiteboard paper is collected by the collection device and introduced into the connected waste water treatment mechanism, the waste water treatment mechanism is communicated with the collection device through the water inlet 10, and the waste water enters the wastewater treatment mechanism thr...

Embodiment 2

[0041] Coated whiteboard paper wastewater contains a large amount of metal ions, and there is a large waste in direct disposal. Therefore, the recovery of the flocs produced by electroflocculation can realize the reuse of metal ions, and at the same time, the recovery of the flocs can also reduce the amount of water on the fishing net 12 . Residual flocs ensure the fishing effect of the fishing net 12 .

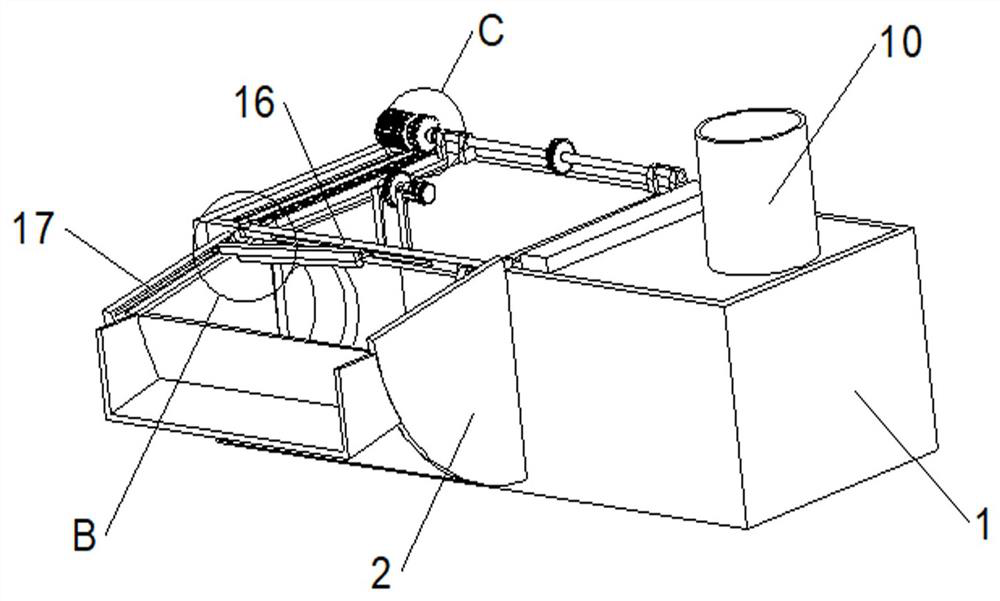

[0042] see Figure 5 - Figure 8 As shown, the cleaning mechanism above the upper floating tank 2 includes a main cleaning rod 16, a first side mounting bar 17, a first secondary cleaning rod 18, a second secondary cleaning rod 20 and a second side mounting bar 21. The first side mounting bar 17 and the second side mounting bar 21 are symmetrically installed on both sides of the upper floating box 2, the first side mounting bar 17 and the second side mounting bar 21 are both inclined and arranged in contact with the side wall of the upper floating box 2, and the first side m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com