Roller drying assembly line for peppers

An assembly line and roller technology, applied in applications, food processing, food science, etc., can solve the problems of shriveled and bent millet peppers, affecting integrity, etc., and achieve the effect of preventing falling and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

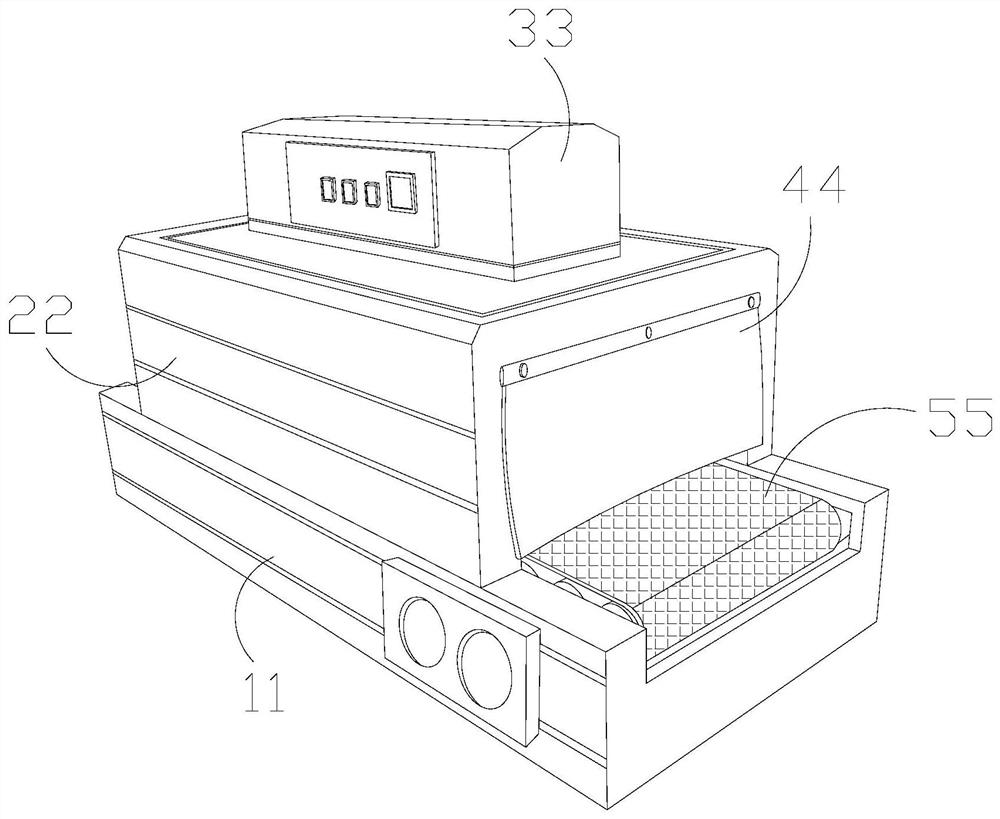

[0032] as attached figure 1 to attach Figure 6 Shown:

[0033] The present invention provides a drum drying assembly line for peppers, the structure of which includes a bottom control box 11, a drying box 22, a control box 33, a curtain 44, and a roller chain 55, and the roller chain 55 is installed in the bottom control box 11 for flexible connection. A drying box 22 is installed on the top of the bottom control box 11, a control box 33 is fixed on the top of the drying box 22, and the curtain 44 is fixed on the outer surface of the drying box 22.

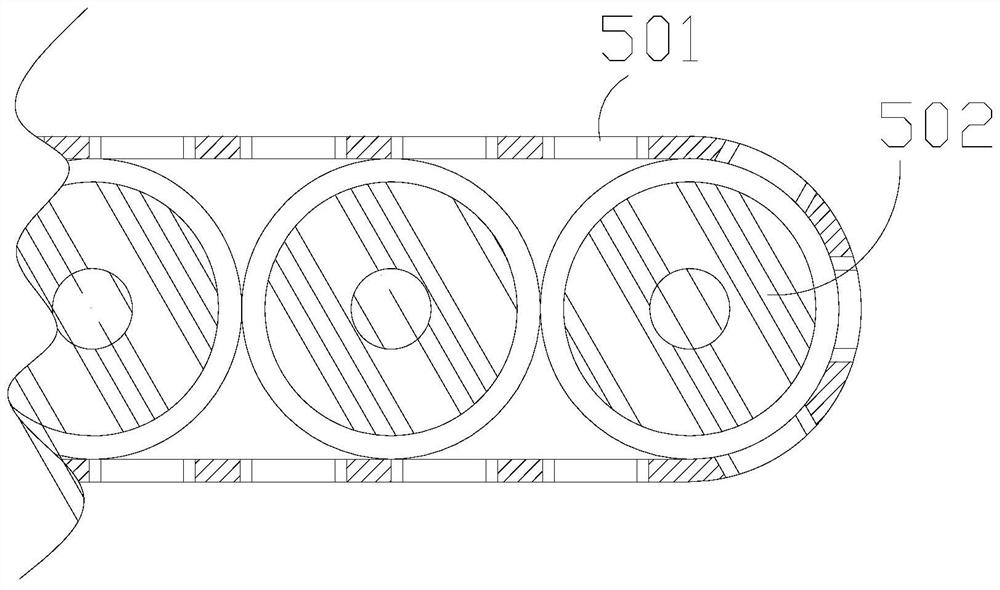

[0034] The roller chain 55 includes a hollow chain 501 and a drum 502 , and the hollow chain 501 moves against the outer surface of the drum 502 .

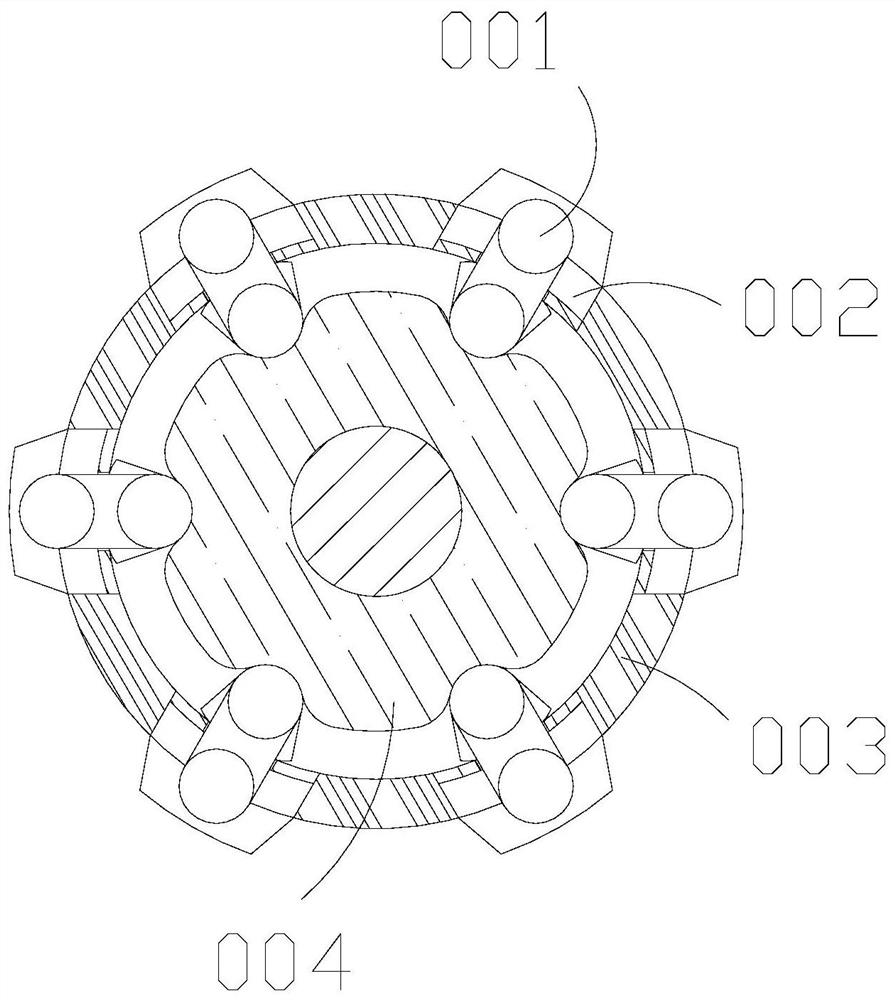

[0035] Wherein, the drum 502 includes a top block 001, a port 002, a shell 003, and an internal pressure core 004, the top block 001 is located inside the port 002, the port 002 and the shell 003 are an integrated structure, the top The inner ring end of the block 001 is in contac...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the hollow chain 501 includes a solid block k11 and a swing plate k12, the swing plate k12 is connected with the solid block k11, the swing plate k12 is a symmetrical structure, and the solid block k11 allows the whole chain to be connected together, so When the pendulum plate k12 is at rest, it will be in a flat state, and it will be opened when there is an external force to promote it.

[0044] Wherein, the pendulum plate k12 includes a notch 111, a main board 112, an insulating layer 113, and a swivel 114, the notch 111 runs through the inside of the main board 112, the insulating layer 113 is attached to the bottom of the main board 112, and the The swivel body 114 is embedded inside the main board 112, the notch 111 is a hollow structure, and the barrier layer 113 is made of smooth material, which can slide smoothly when foreign objects interfere. When the notch 111 is in a flat state as a whole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com