Hydraulic control for powershift transmission

a technology of hydraulic control circuit and transmission line, applied in mechanical equipment, transportation and packaging, gearboxes, etc., can solve the problems of reduced operating performance, insufficient transmission gear ratio for launching, and little design flexibility for accommodating, so as to reduce the cost of the control system and achieve greater independence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

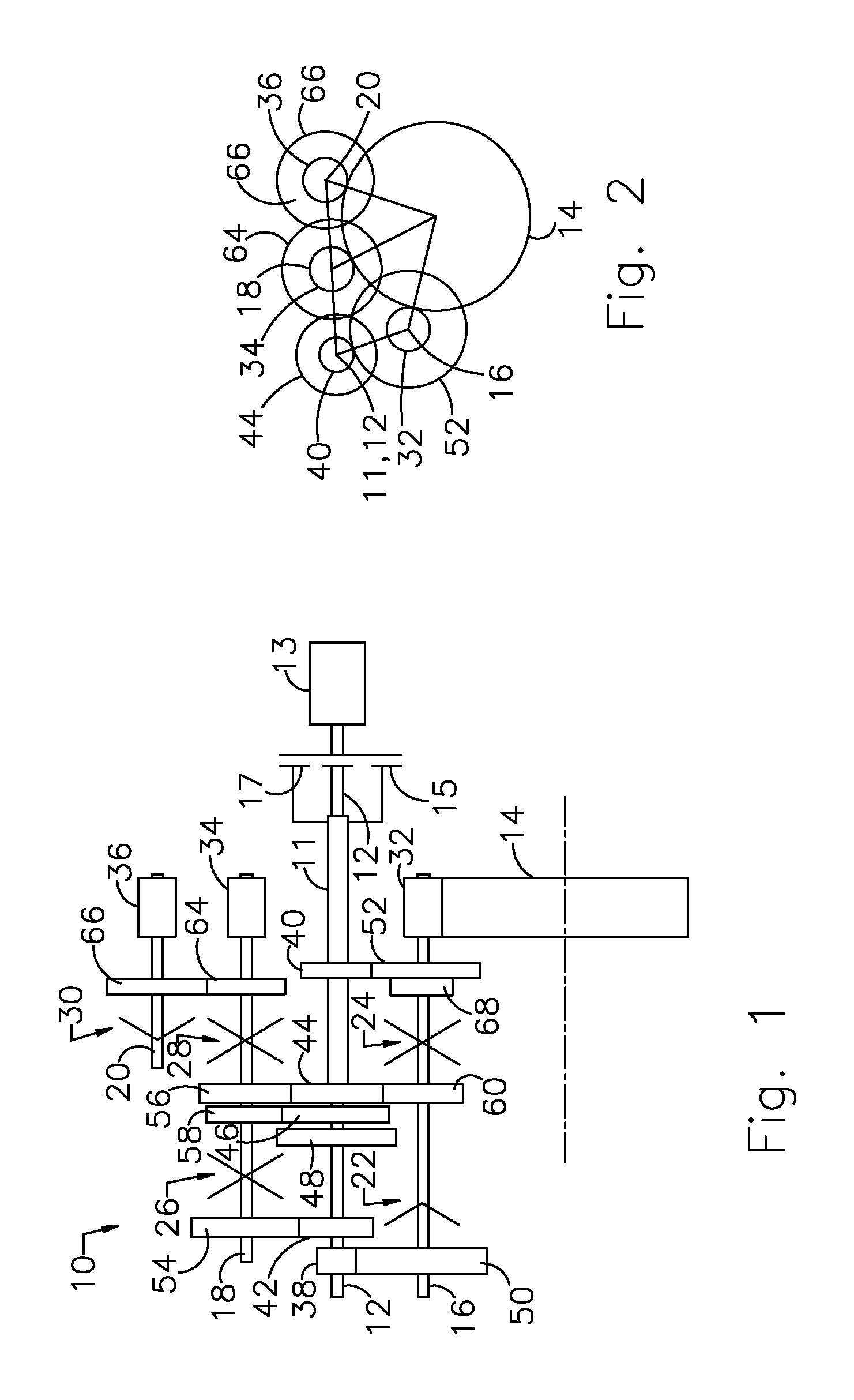

[0020]Referring now to FIG. 1, a powershift transmission 10 includes first and second coaxial input shafts 11, 12, an output gear 14 driveably connected to the vehicle wheels (not shown); first, second and third layshafts 16, 18, 20, respectively; a 1-neutral synchronizer 22; a 6-2 synchronizer 24; a 3-5 synchronizer 26; a 4-R synchronizer 28; and a L synchronizer 30. Outer shaft 11 is driveably connected to an engine 13 through an input clutch 15. Inner shaft 12 is driveably connected to the engine through an input clutch 17.

[0021]Each layshaft 16, 18, 20 includes an output pinion 32, 34, 36, secured to the respective layshaft. Each synchronizer is secured to the layshaft on which it is supported and includes a selector sleeve having a neutral position from which it is moved axially along the shaft to secure a gear to the shaft. Input clutches 15, 17 include sets of clutch plates, which alternately engage and disengage mutually.

[0022]Secured to input shaft 12 are input pinions 38, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com