Hard capsule and method for producing same

a technology of hard capsules and capsules, which is applied in the field of hard capsules, can solve the problems of poor water solubility, low production efficiency, and high cost of hard capsules, and achieve the effects of reducing disintegration time, excellent stability, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

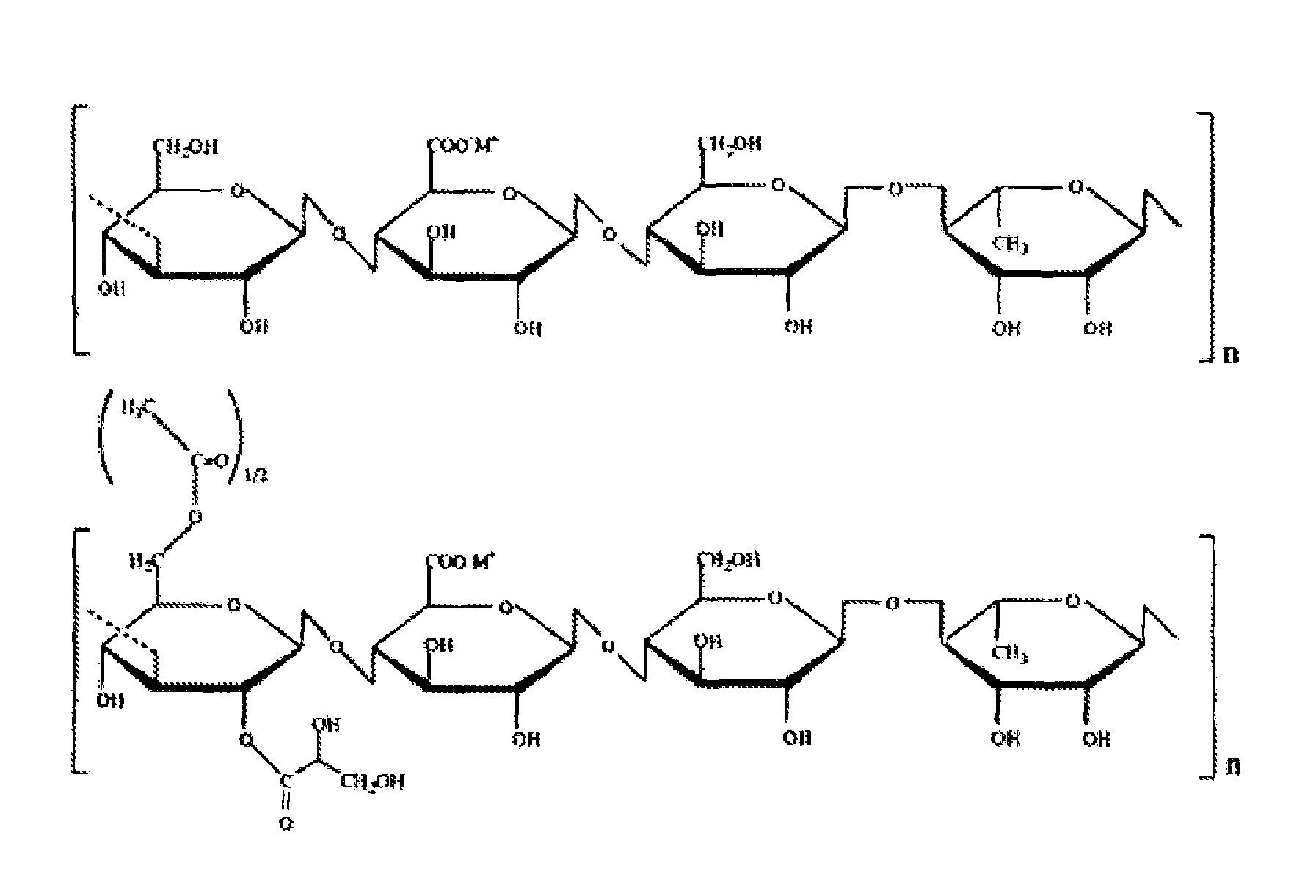

1. PVA Copolymer

[0150]122 g of PVA (type: EG-25; average polymerization degree: 1,700; saponification degree: 88%; produced by Nippon Synthetic Chemical Industry Co., Ltd.) and 648 g of ion exchange water were placed in a separable flask equipped with a cooling reflux condenser, a dropping funnel, a thermometer, a nitrogen inlet tube, and a stirrer. First, PVA was dispersed at an ordinary temperature, and then completely dissolved at 95° C. Subsequently, 3.8 g of acrylic acid and 26.6 g of methyl methacrylate were added thereto. After the flask was purged with nitrogen, the temperature was increased to 50° C. Thereafter, 8.5 g of tertiary butyl hydroperoxide and 8.5 g of sodium erythorbate were added thereto. The reaction was terminated after 4 hours, thereby obtaining a PVA copolymer aqueous solution. The obtained PVA copolymer aqueous solution was used in the following experiments.

[0151]The pH of the PVA copolymer aqueous solution was 4.0. The solution was further mixed with ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com