Waste heat utilization device and operating method

a technology of waste heat and operating method, which is applied in the direction of steam engine plants, mechanical equipment, machines/engines, etc., can solve the problems of inability to drop the pressure in the working medium during cooling to ambient temperature, and achieve the effects of reducing equipment complexity, high pressure, and relatively easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

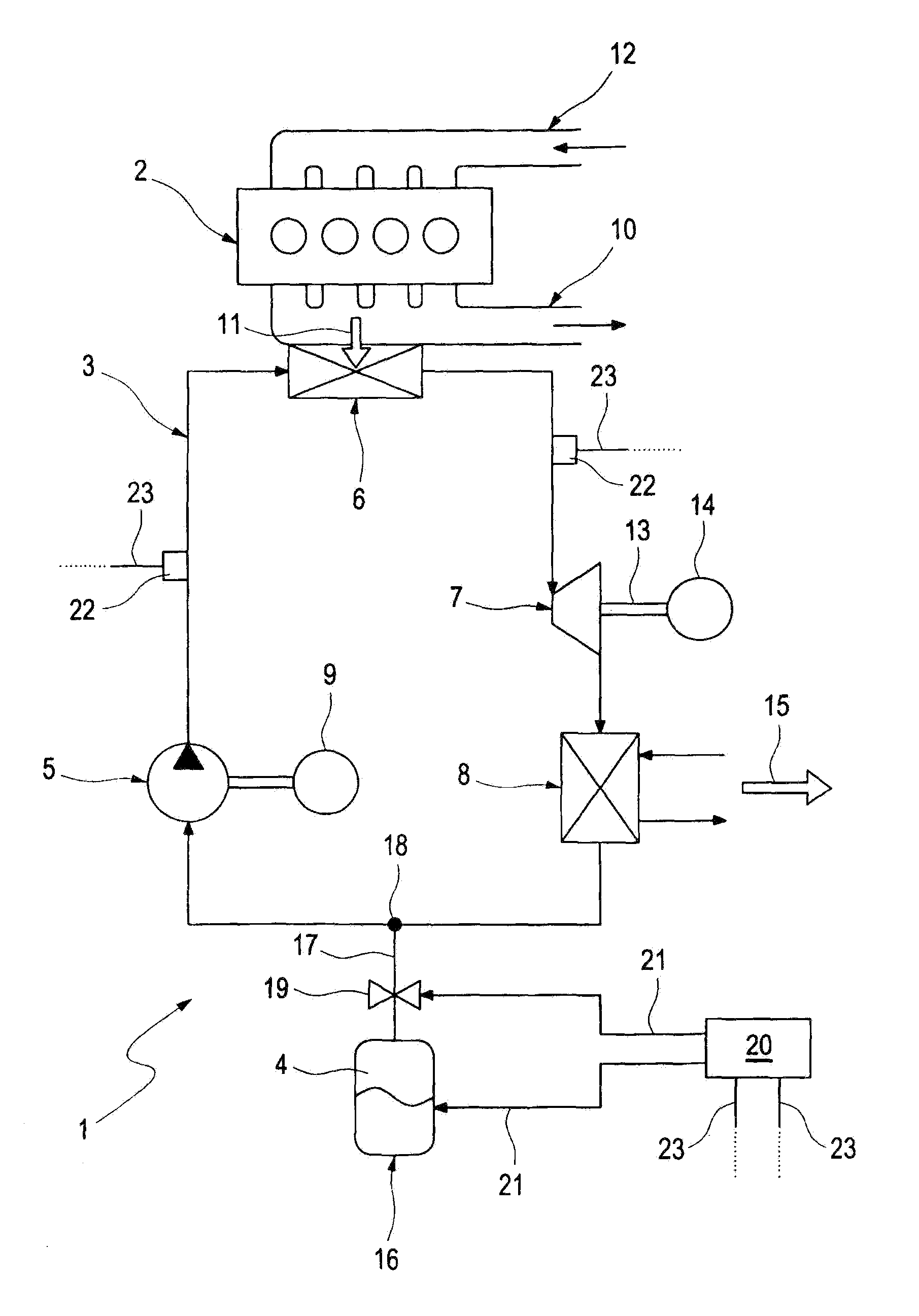

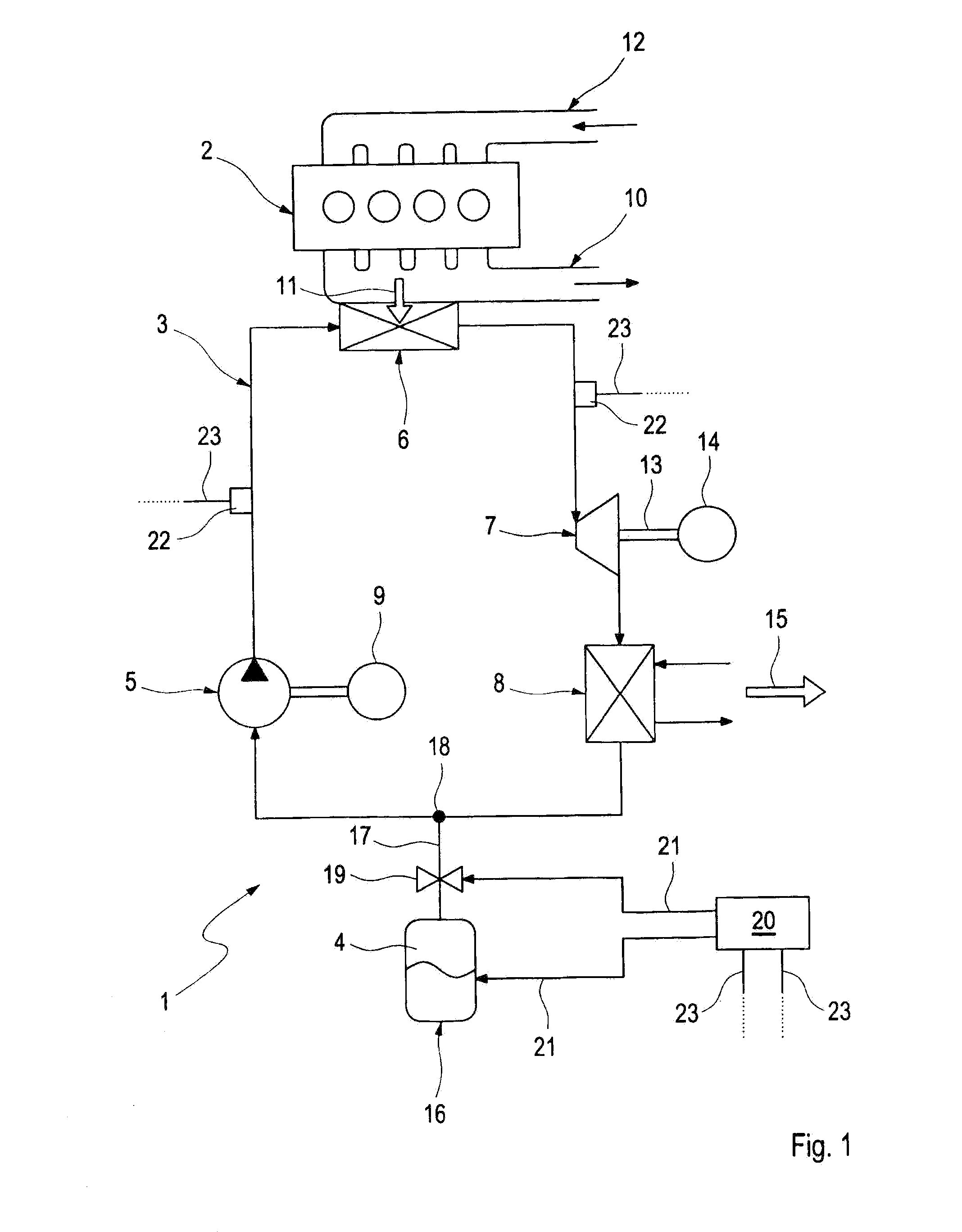

[0022]According to FIG. 1, a waste heat utilization device 1 which together with an internal combustion engine 2 may be situated in a motor vehicle includes a waste heat utilization circuit 3 in which a working medium 4 circulates. The waste heat utilization circuit 3 is preferably designed as a closed circuit. The waste heat utilization device 1 also includes a pumping device 5, an evaporator 6, an expansion machine 7, and a condenser 8.

[0023]The pumping device 5 is situated in the waste heat utilization circuit 3, and is used for pressurizing the working medium 4 to a high pressure. The pumping device 5 is advantageously designed as a volumetric pump, and for this purpose is drive-coupled to a drive motor 9. The evaporator 6 is situated in the waste heat utilization circuit 3, downstream from the conveying device 5, and is used for evaporating the pressurized working medium 4, for which purpose the evaporator 6 utilizes waste heat from the internal combustion engine 2. To this end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com