Method of injecting and reacting super-critical phase carbon dioxide without pressure loss

a super-critical phase carbon dioxide and reaction method technology, applied in the direction of supercritical condition processes, bulk chemical production, chemistry apparatus and processes, etc., can solve the problems of increasing the solubility of various materials, causing undesirable reactions, and unable to maintain the poin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

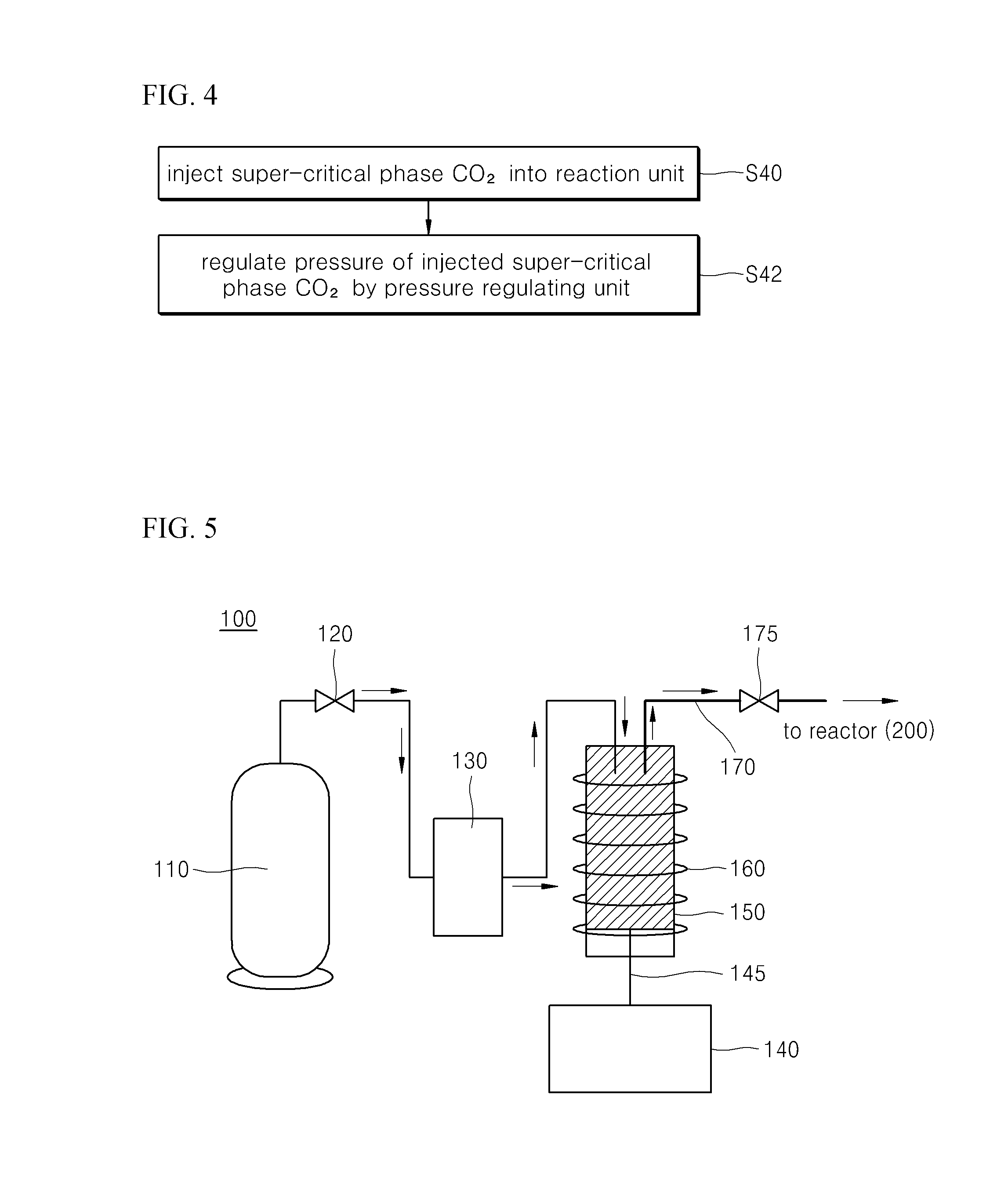

[0035]Hereinafter, a method of injecting and reacting super-critical phase CO2 without pressure loss according to an exemplary embodiment of the present invention will be described in detail with reference to accompanying drawings.

[0036]Prior to the description of the method of injecting and reacting super-critical phase CO2 without pressure loss according to an exemplary embodiment of the present invention, the structure of a basic apparatus for realizing the method will be described below.

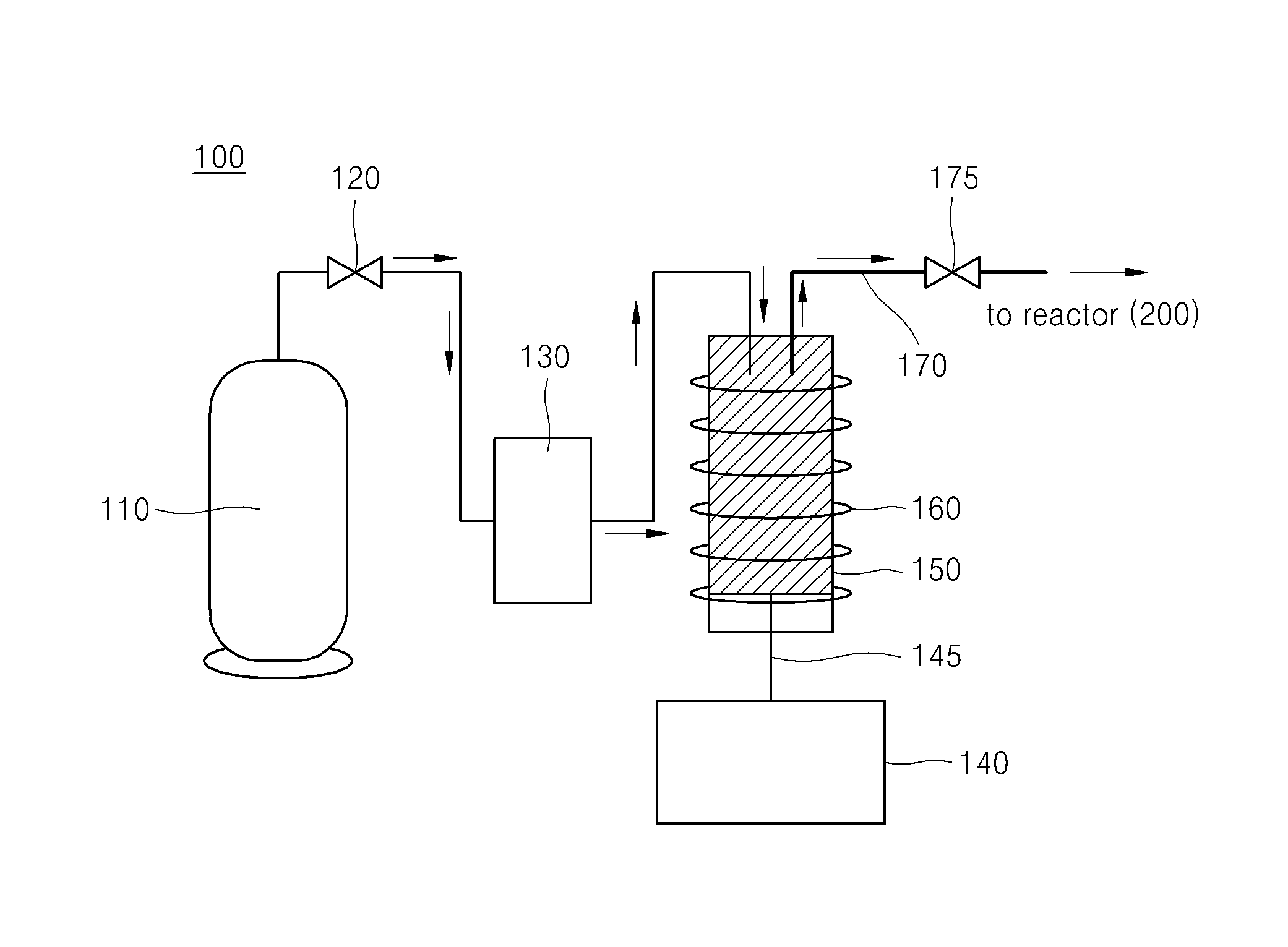

[0037]FIG. 1 is a block diagram schematically showing the structure of an apparatus for injecting and reacting super-critical phase CO2 without pressure loss according to an exemplary embodiment of the present invention.

[0038]As shown in FIG. 1, the apparatus for injecting and reacting the super-critical phase CO2 without pressure loss may include an injection unit 100, a reaction unit 200, and a pressure regulating unit 300.

[0039]Those skilled in the art should recognize that the structure of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap