Shift lever assembly with electronic detection of modes of transmission

a technology of electronic detection and shift lever, which is applied in the direction of gearing elements, control devices, vehicle components, etc., can solve the problems of increasing the risk of mistakes in detecting the position of the shift lever, and achieve the effect of improving the accuracy of the detection of the position, and accurate and reliable manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

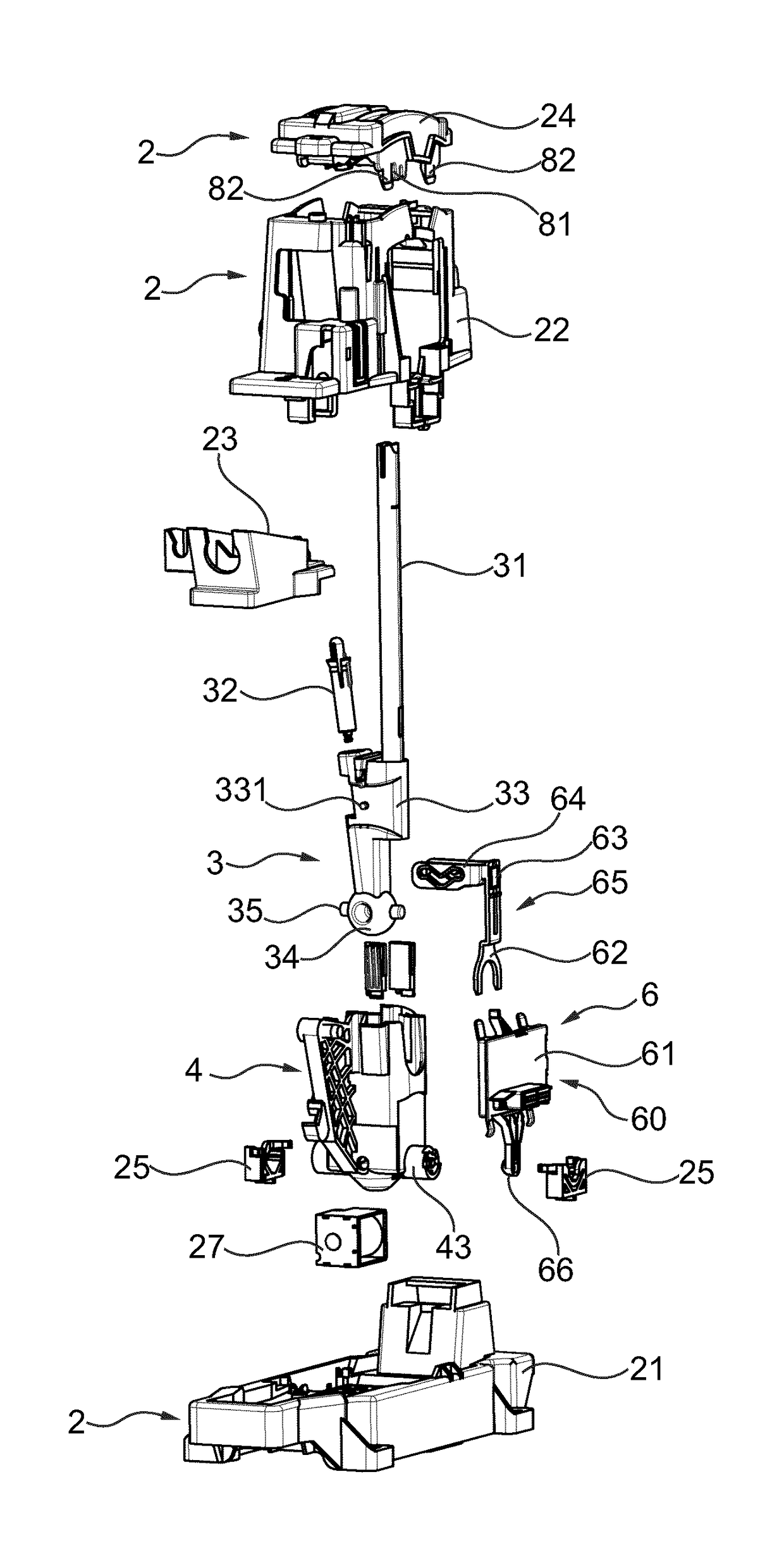

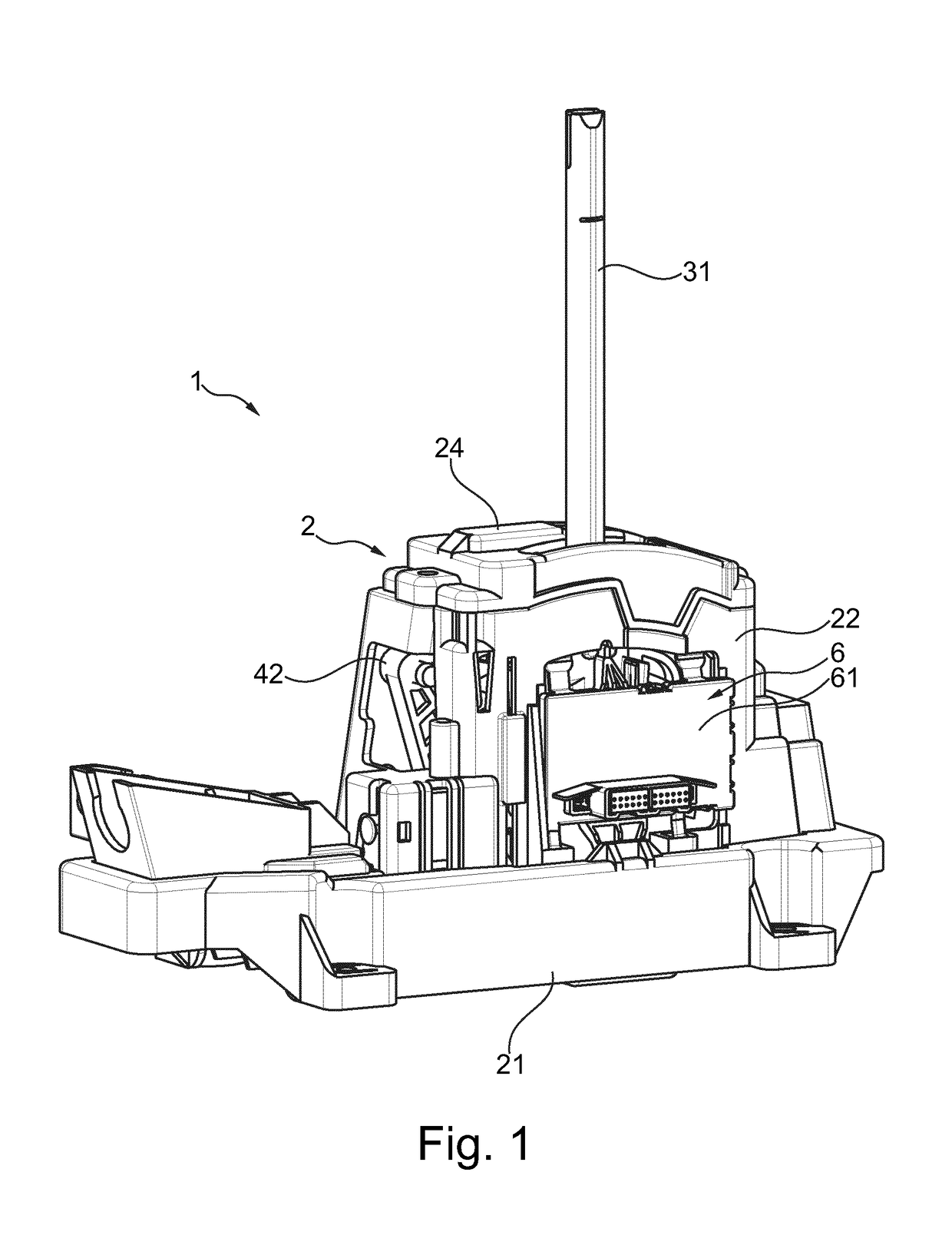

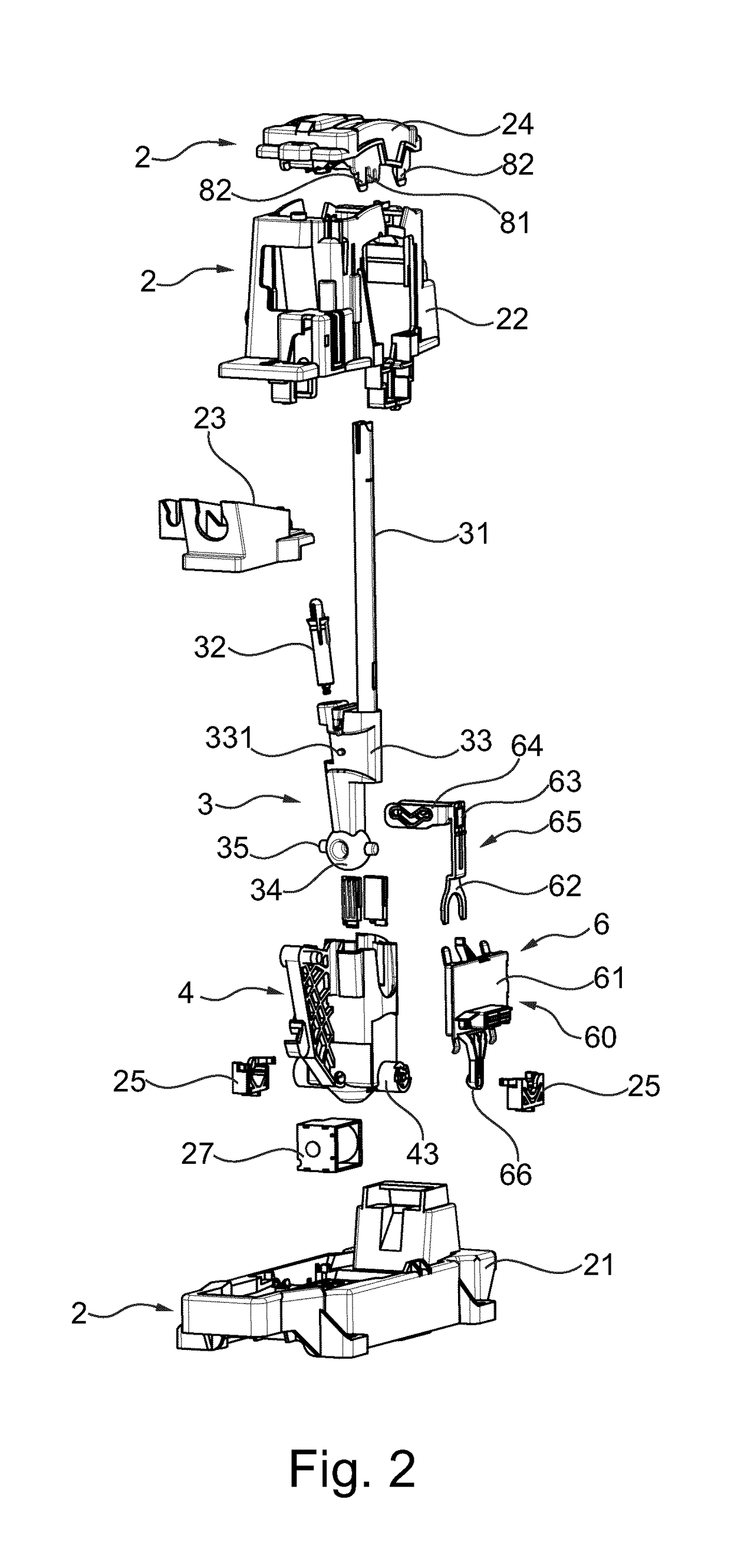

[0029]FIGS. 1 and 2 disclose a preferred embodiment of a shift lever assembly 1 with a housing 2, a shift lever unit 3, cable unit 4 and sensor assembly 6 that when mounted form an assembled shift lever assembly 1 as shown by FIG. 1. The shift lever unit 3 comprises a shift lever 31 and detent plunger 32 that are mounted in an overmold 33 extending towards a ball 34 of a ball joint with pegs 35. Said shift lever unit 3 is mounted in the cable unit 4 so that the ball 34 rests at a seat of the cable unit 4 and is arranged to pivot about a first axis α (see FIG. 6b). The shift lever 31 is arranged to pivot between a number of positions in a first gate, each position corresponding to a mode of transmission. Furthermore, the cable unit 4 is held by a base 21 of the housing 2 by means of receiving portions 25 that allow the cable unit 4 to pivot. Also provided is the sensor assembly 6 having a first member carrier 65, connected to the shift lever 31, and a carrier body 60 that is displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com